Method for modifying soy protein concentrate

A technology for concentrated soybean protein and soybean protein concentrate, which is applied in the fields of protein food processing, protein food ingredients, food science, etc., can solve problems such as the modification process of concentrated soybean protein that has not yet been seen, and achieve good taste, passivate enzyme activity, fast and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

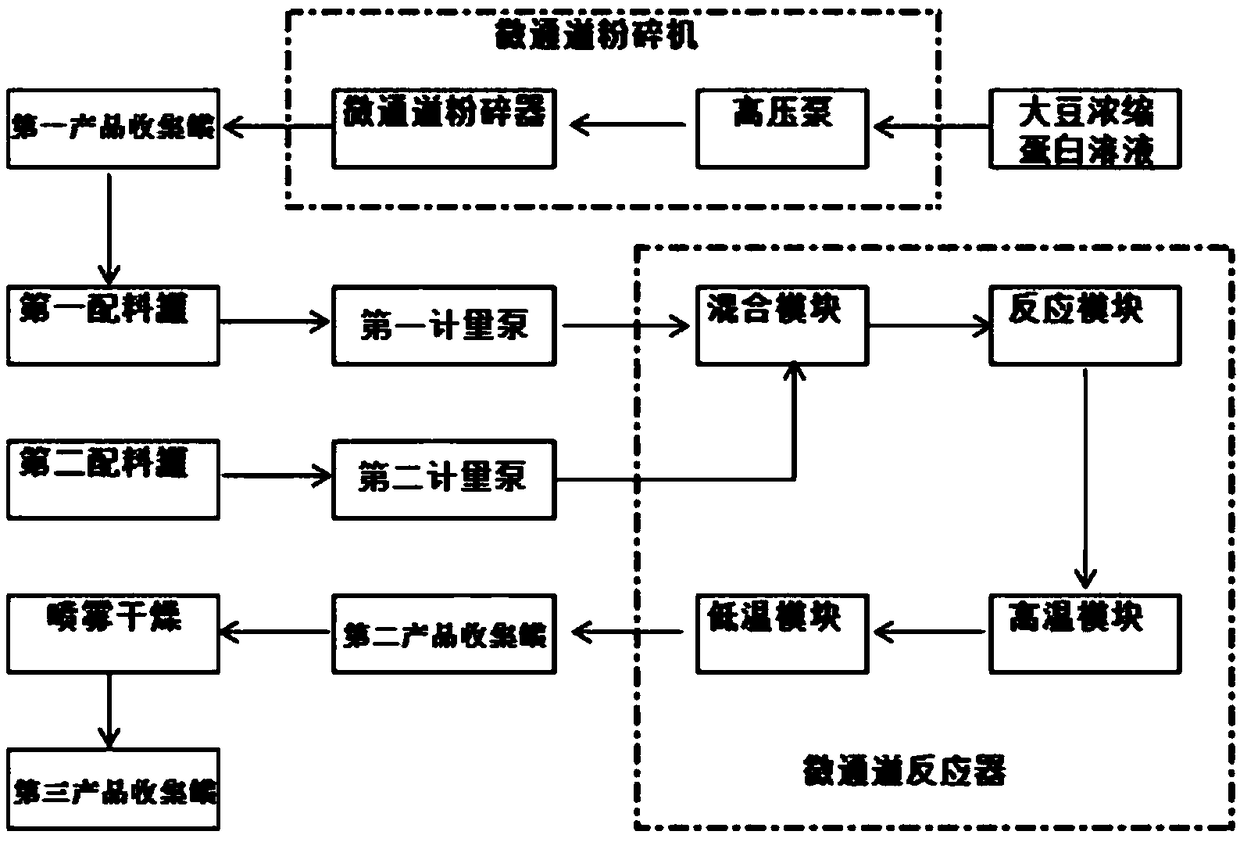

[0035] Example 1: Preparation of soybean protein concentrate by ultrafine pulverization in microchannel pulverizer and enzymatic hydrolysis in microchannel reactor

[0036] (1) Device:

[0037] 1) Conventional universal pulverizer

[0038] 2) According to Example 1 of patent CN201710044089.5, a microchannel pulverizer is produced, which includes a microchannel pulverizer and a high-pressure pump.

[0039] 3) The microchannel reactor device adopts a high-pressure microchannel reactor, including a mixing module, a reaction module, a high temperature module and a low temperature module. The length of the microchannel is determined according to the flow rate and the reaction residence time. The diameter is 0.3mm, and the heat exchange medium is heat transfer oil.

[0040] (2) Preparation of Enzymolysis Soybean Protein Concentrate:

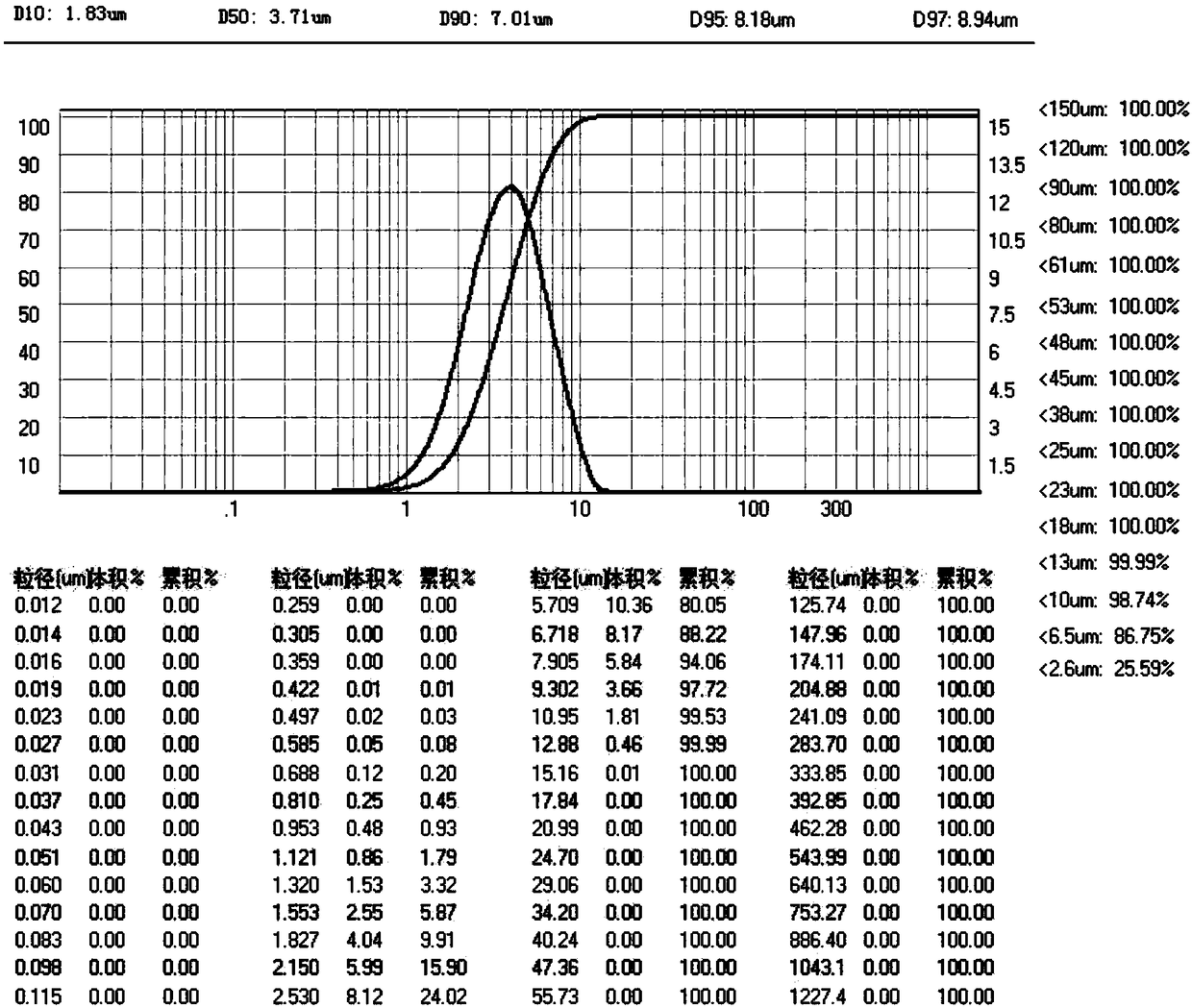

[0041] A-Preparation of ultrafine pulverized soybean protein concentrate:

[0042] 2kg soybean protein concentrate (protein content 70%) was pulve...

Embodiment 2

[0053] Embodiment 2: a comparative example corresponding to Embodiment 1.

[0054] (1) Device:

[0055] 1) Conventional universal pulverizer.

[0056] 2) 20L glass kettle type jacketed reaction kettle, mechanical stirring, heat transfer medium is heat transfer oil.

[0057] (2) Preparation of Enzymolysis Soybean Protein Concentrate:

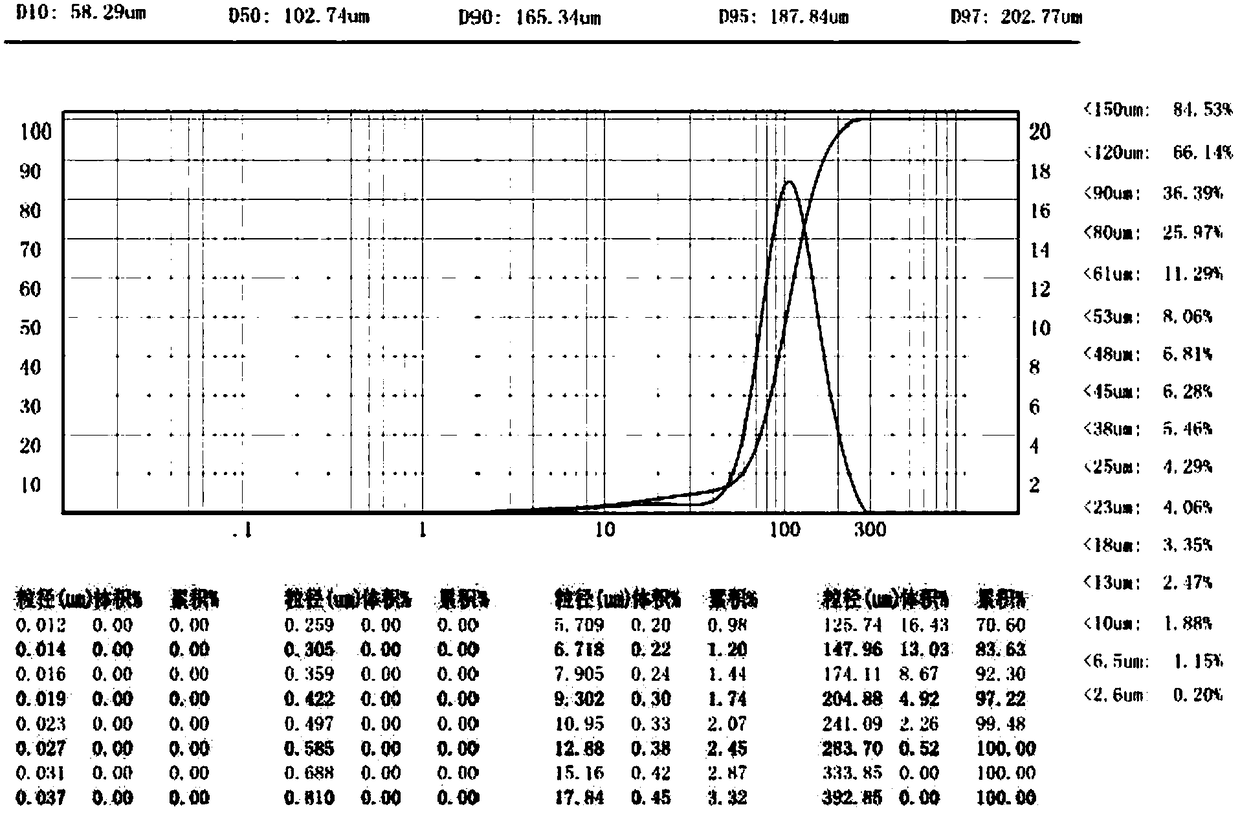

[0058] A- Conventional crushed soy protein concentrate preparation:

[0059] 2kg soybean protein concentrate (70% protein content) was pulverized for 30min with a conventional universal pulverizer (rotating speed 6000rpm), and the particle size D90 of the obtained pulverized soybean protein concentrate was 165.34um. 165.34um) was added with 8kg of water, and the pH value was adjusted to 7 under the condition of full stirring.

[0060] B-enzymatic hydrolysis reaction:

[0061] Pour the above-mentioned concentrated soybean protein slurry into a 20L glass kettle-type jacketed reactor, start the mechanical stirring, the stirring speed is 70rpm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com