Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Even gas distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

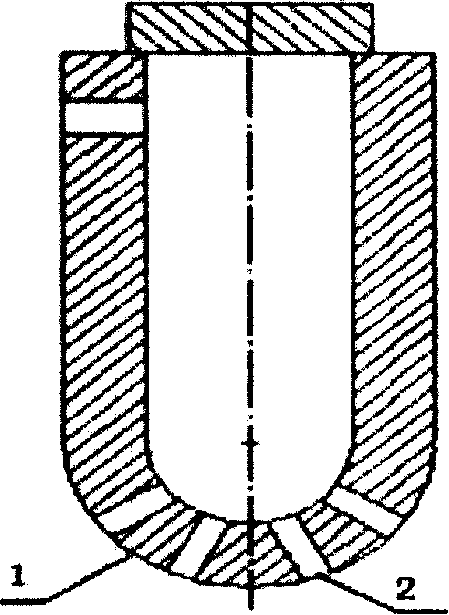

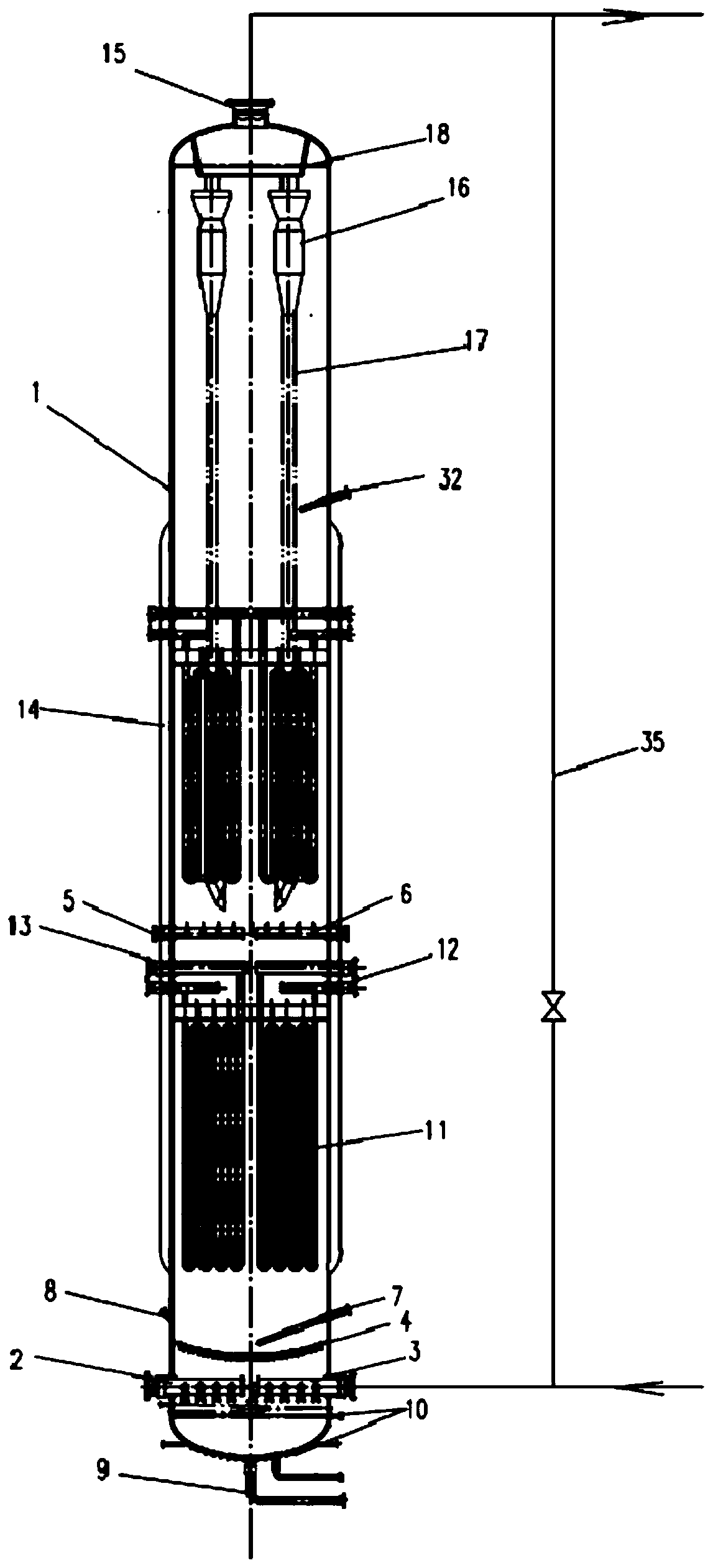

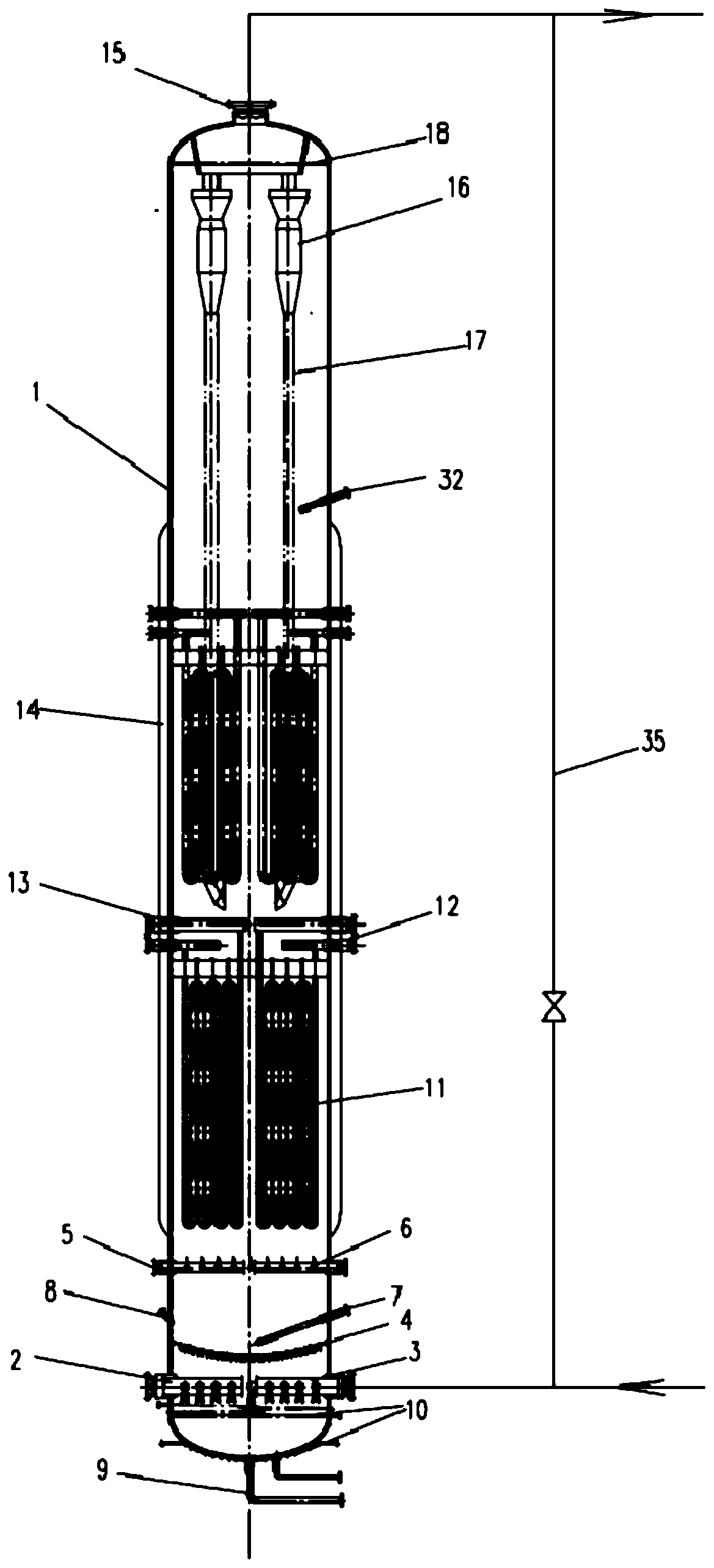

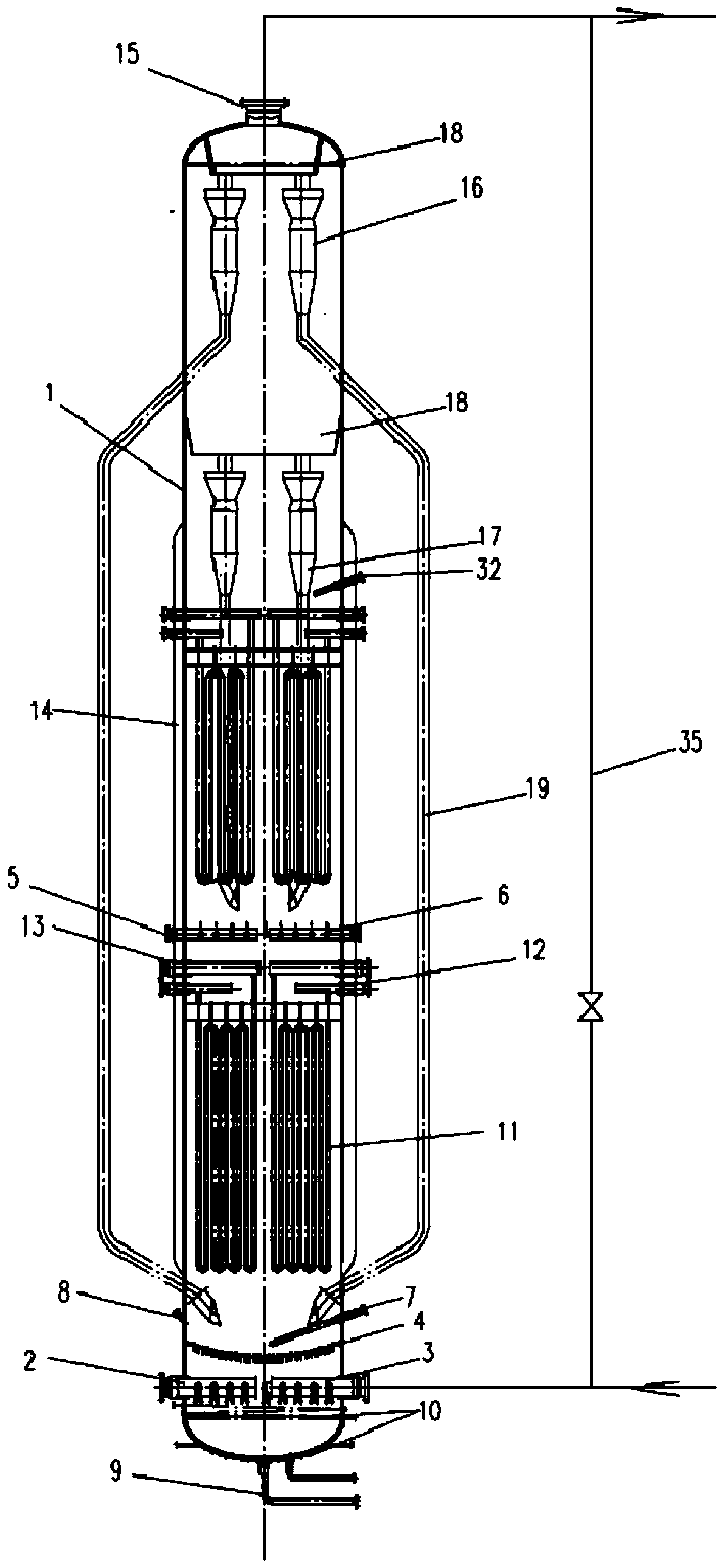

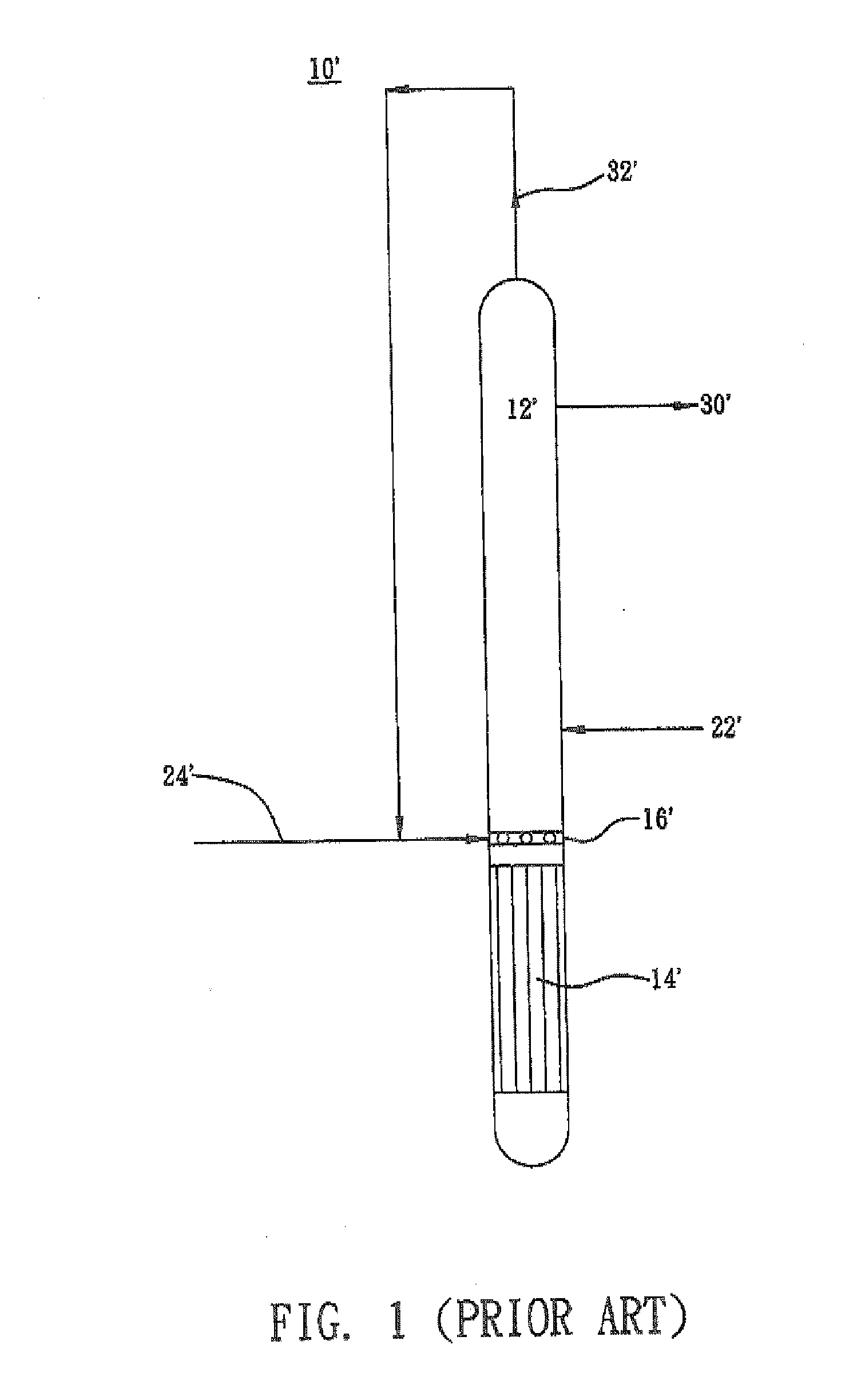

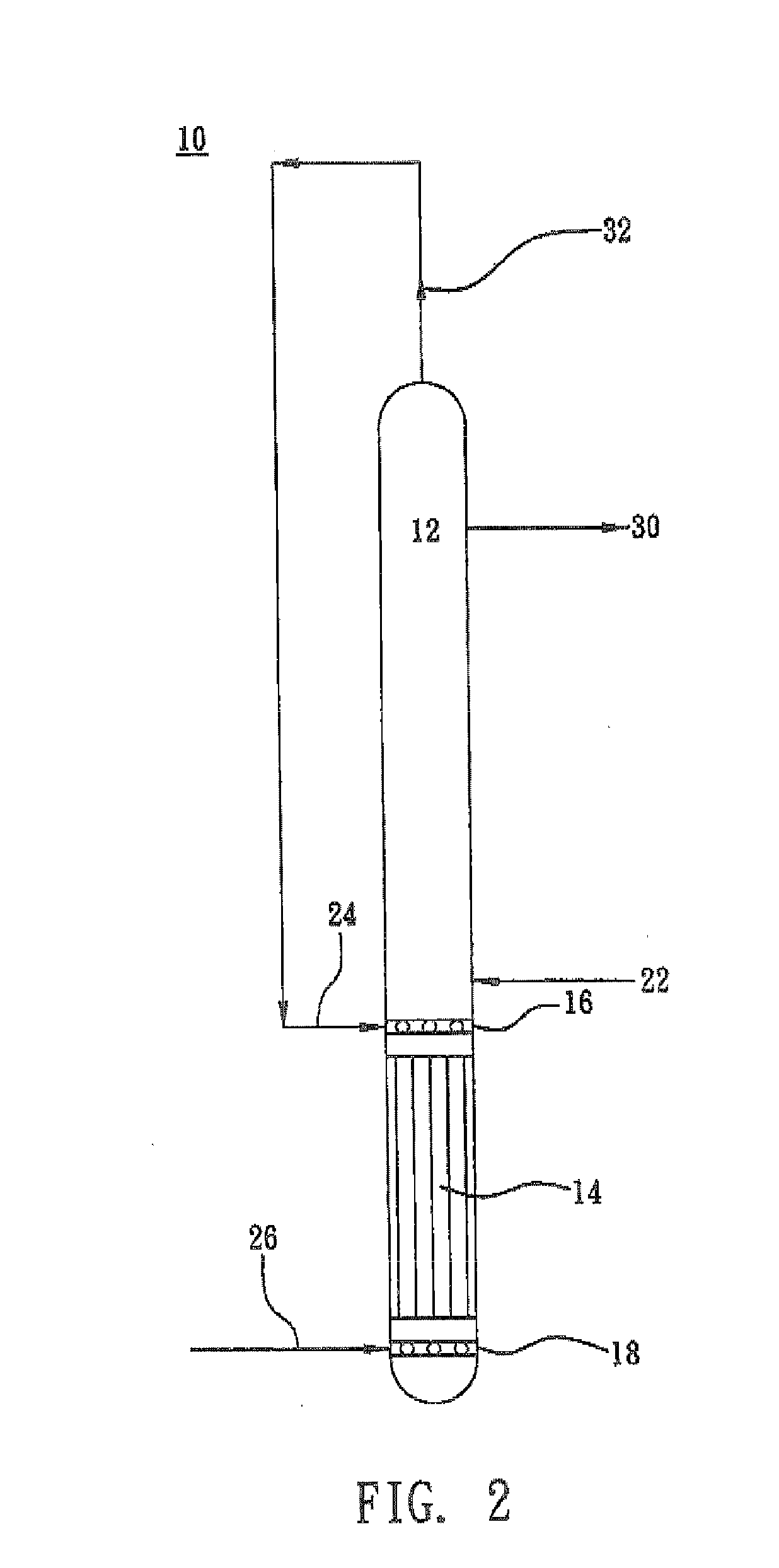

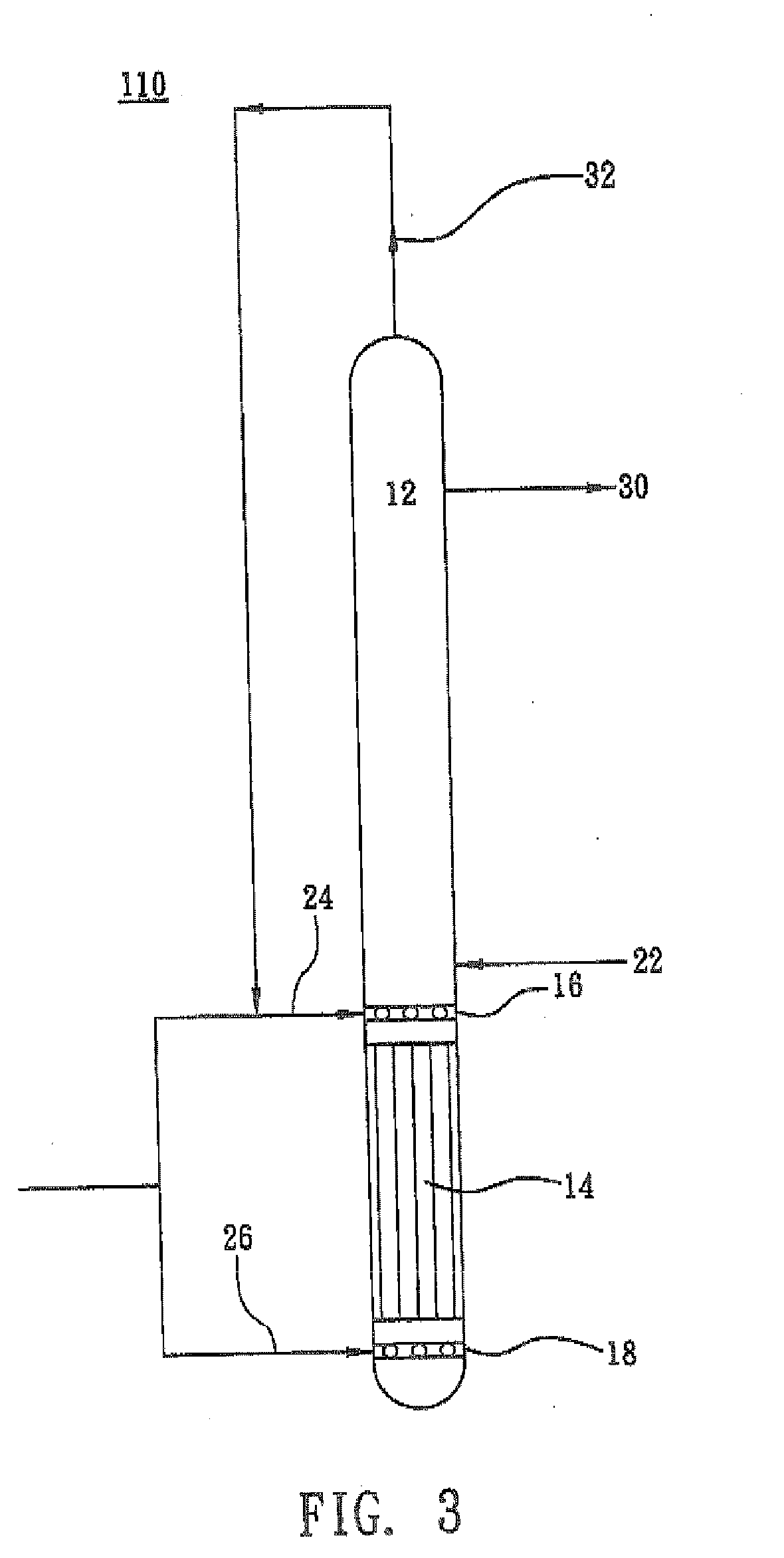

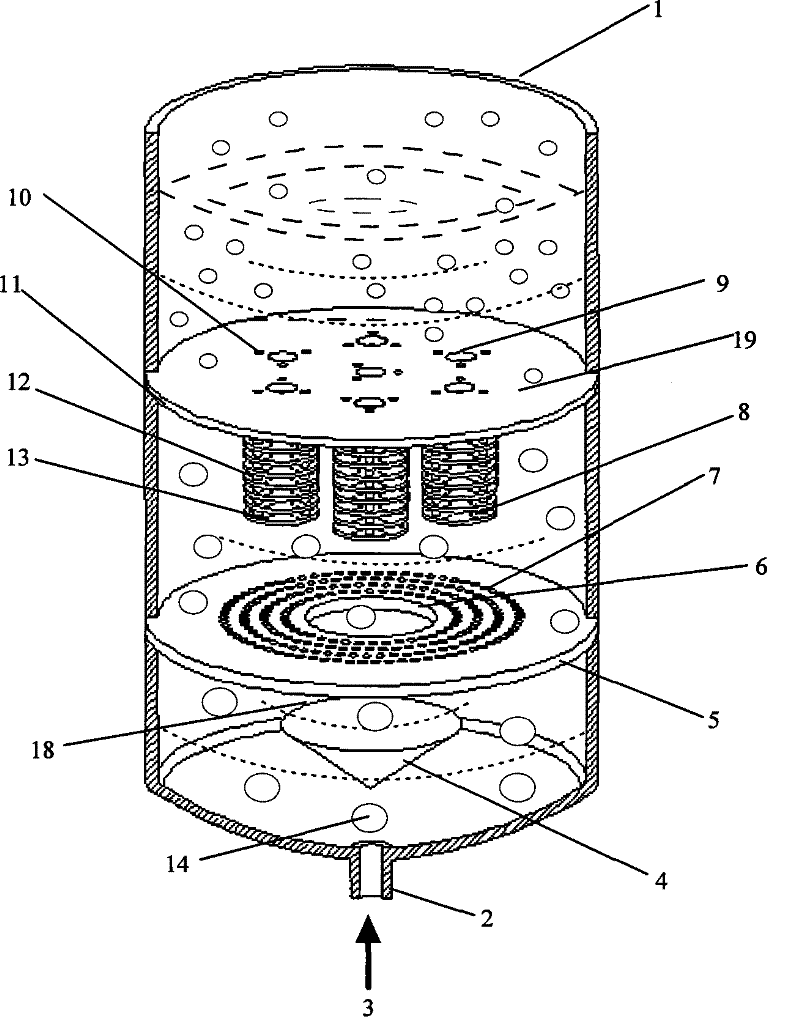

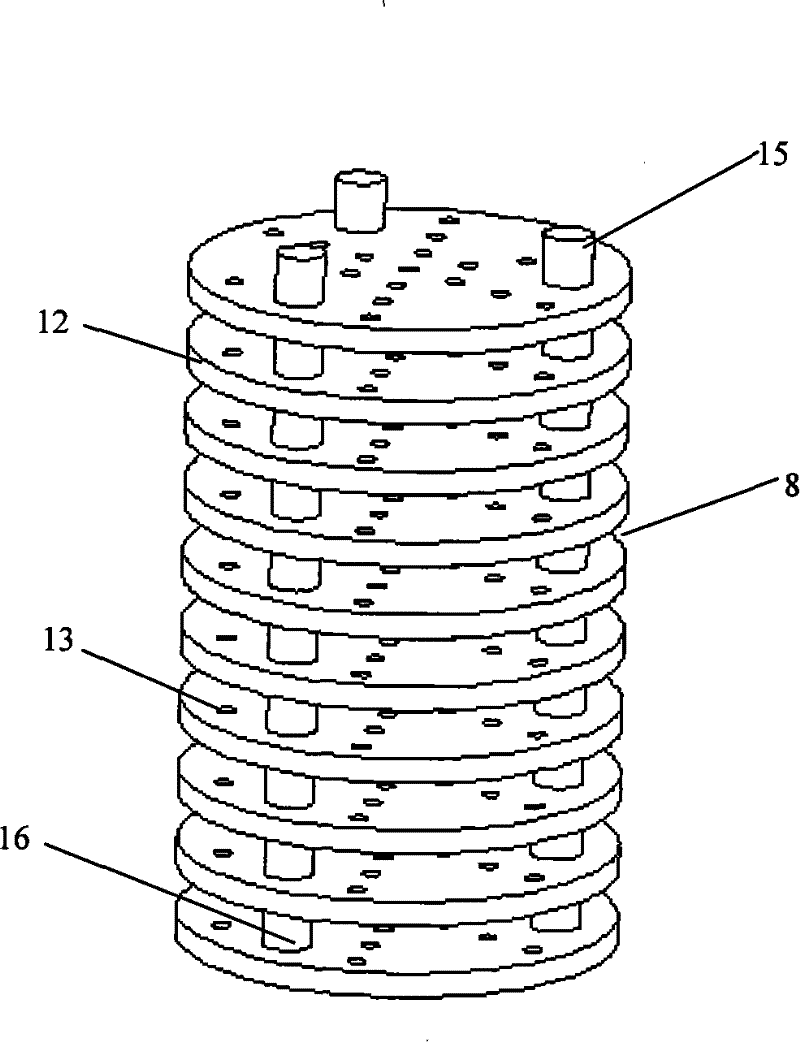

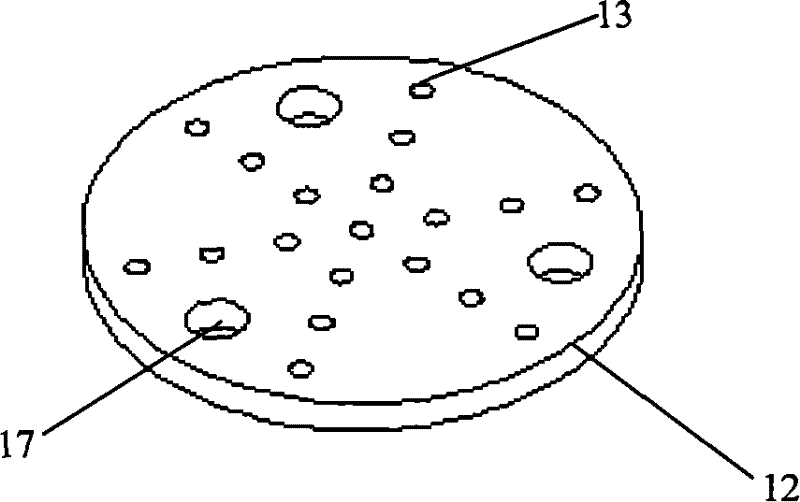

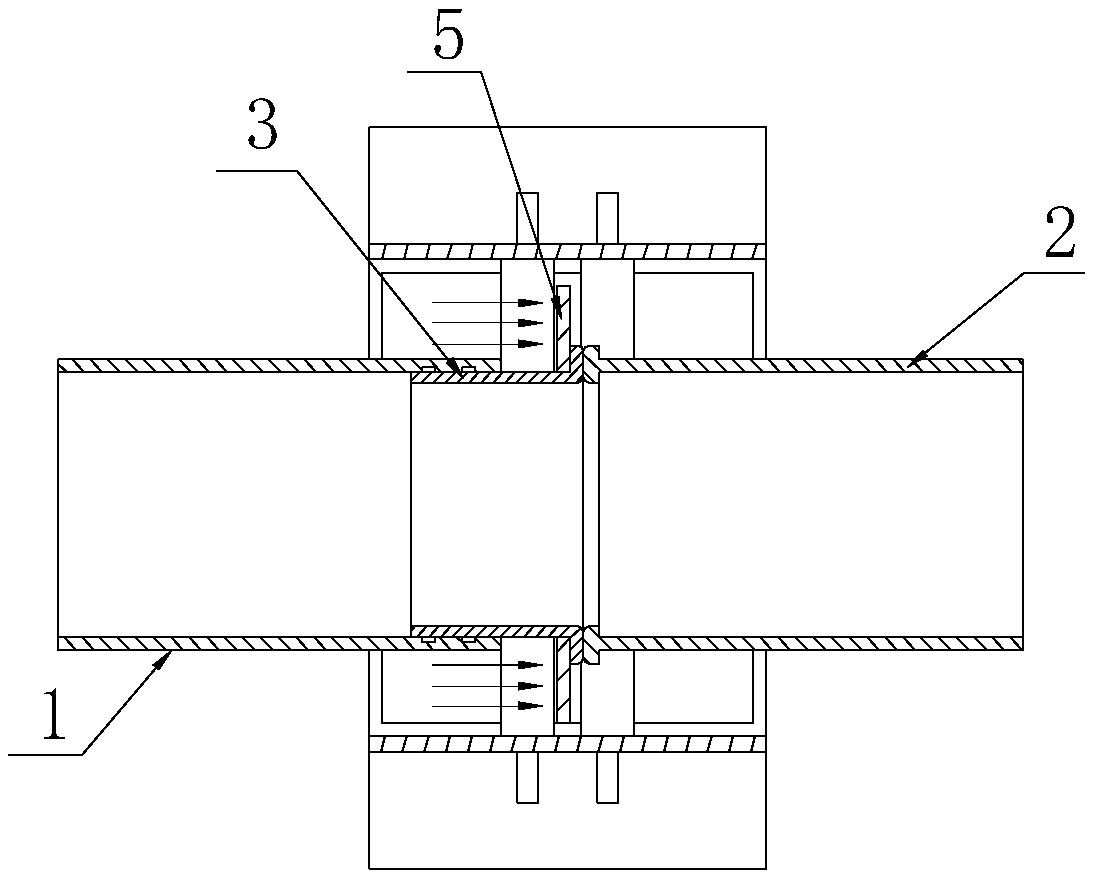

Up-flow reactor and application thereof

ActiveCN101632911AEvenly distributedSimple structureHydrocarbon oils refiningChemical/physical processesWaxShortest distance

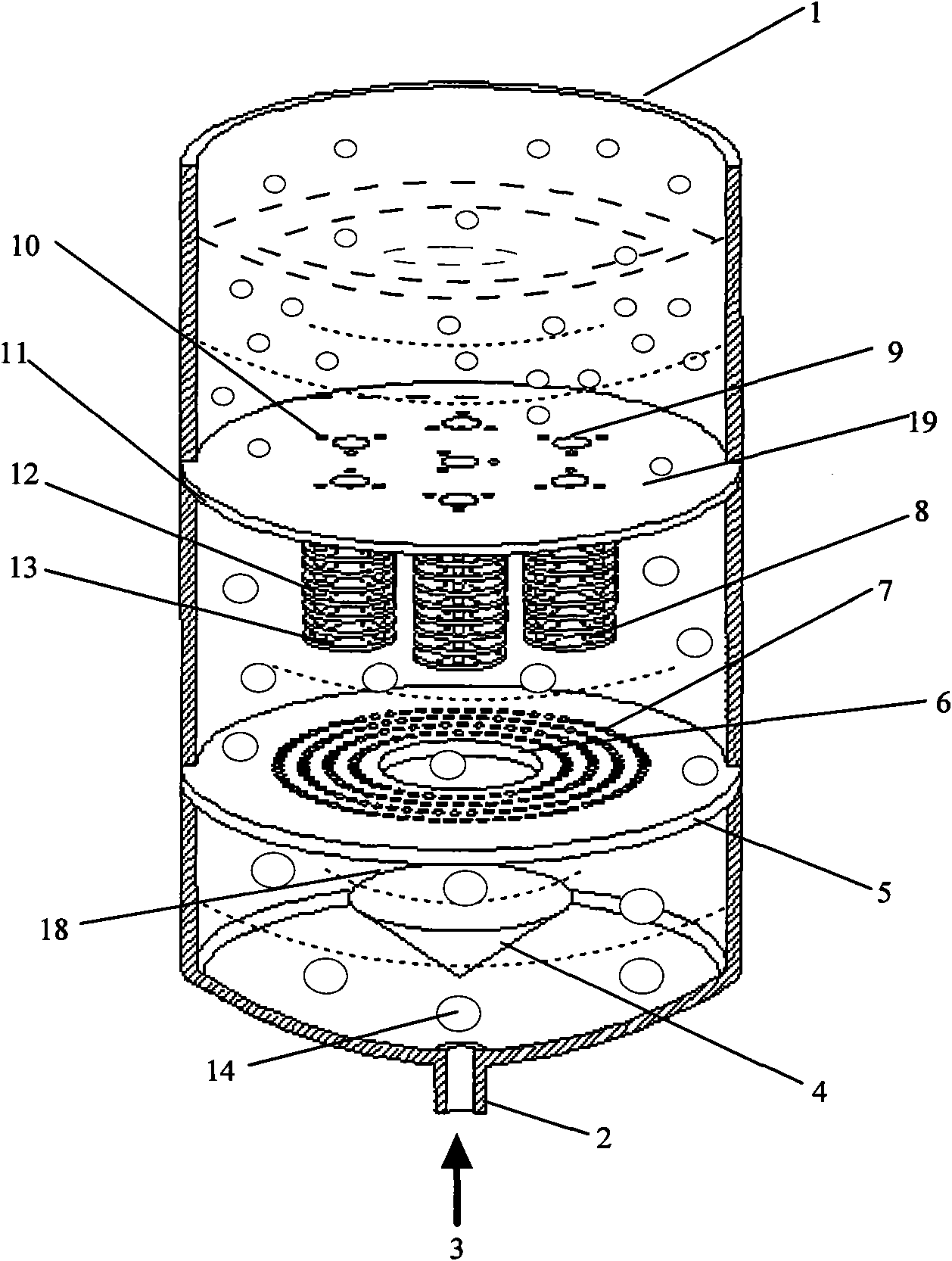

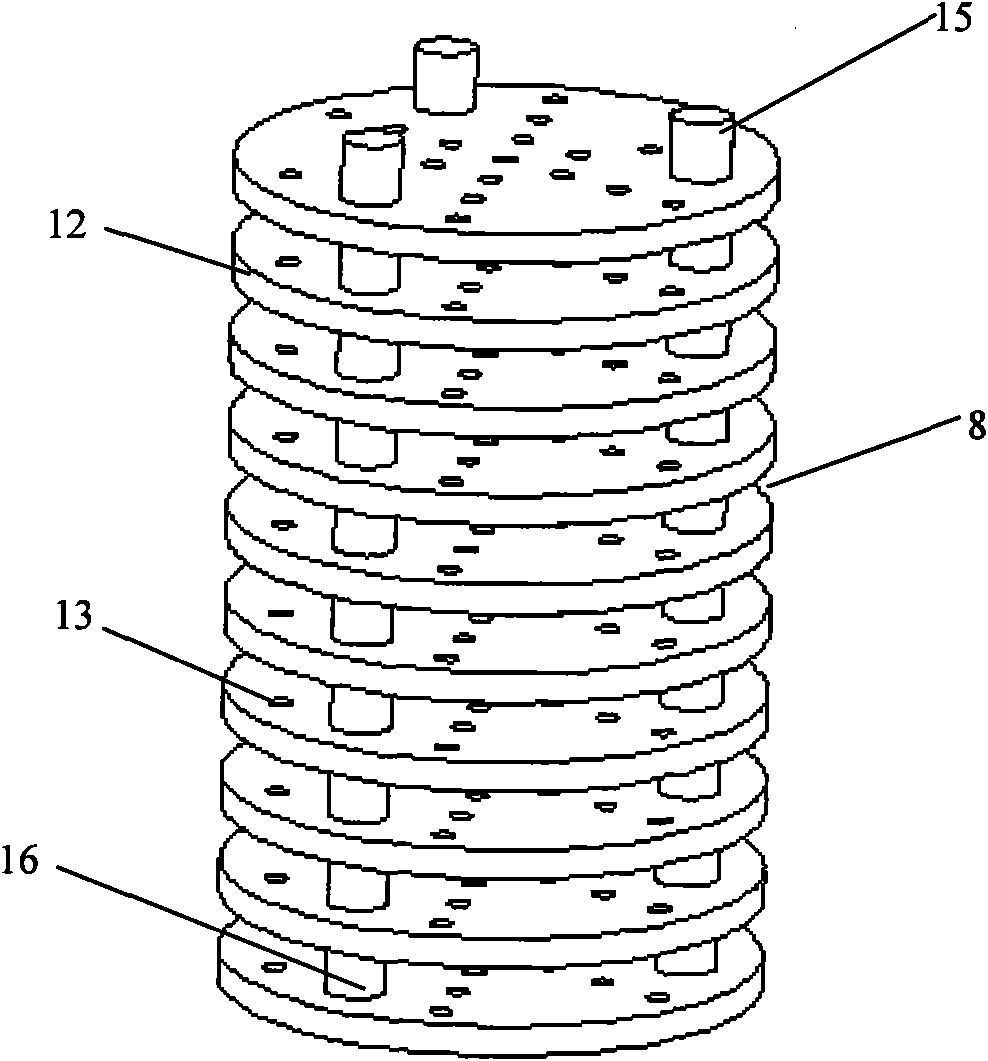

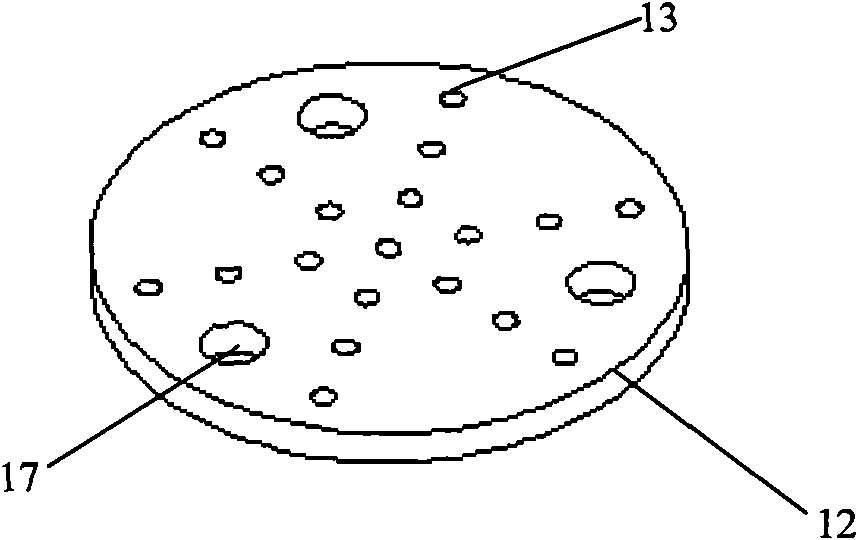

The invention discloses an up-flow reactor, which comprises an initial distributor positioned at the bottom of the reactor and an intermediate distributor above the initial distributor. The initial distributor consists of a conical traverse baffle and a sieve plate positioned above the conical traverse baffle; and the intermediate distributor consists of an open pore sieve plate and a sieve plate string structure. The up-flow reactor provided by the invention can realize even distribution of gas in the reactor in short distance so as to improve the utilization rate of a catalyst and increase the space of a catalyst bed layer in the reactor. The up-flow reactor of the invention is particularly applied to a hydrogenation process of heavy oil (comprising wax oil, residual oil, coal liquefied oil and the like).

Owner:CHINA PETROLEUM & CHEM CORP +1

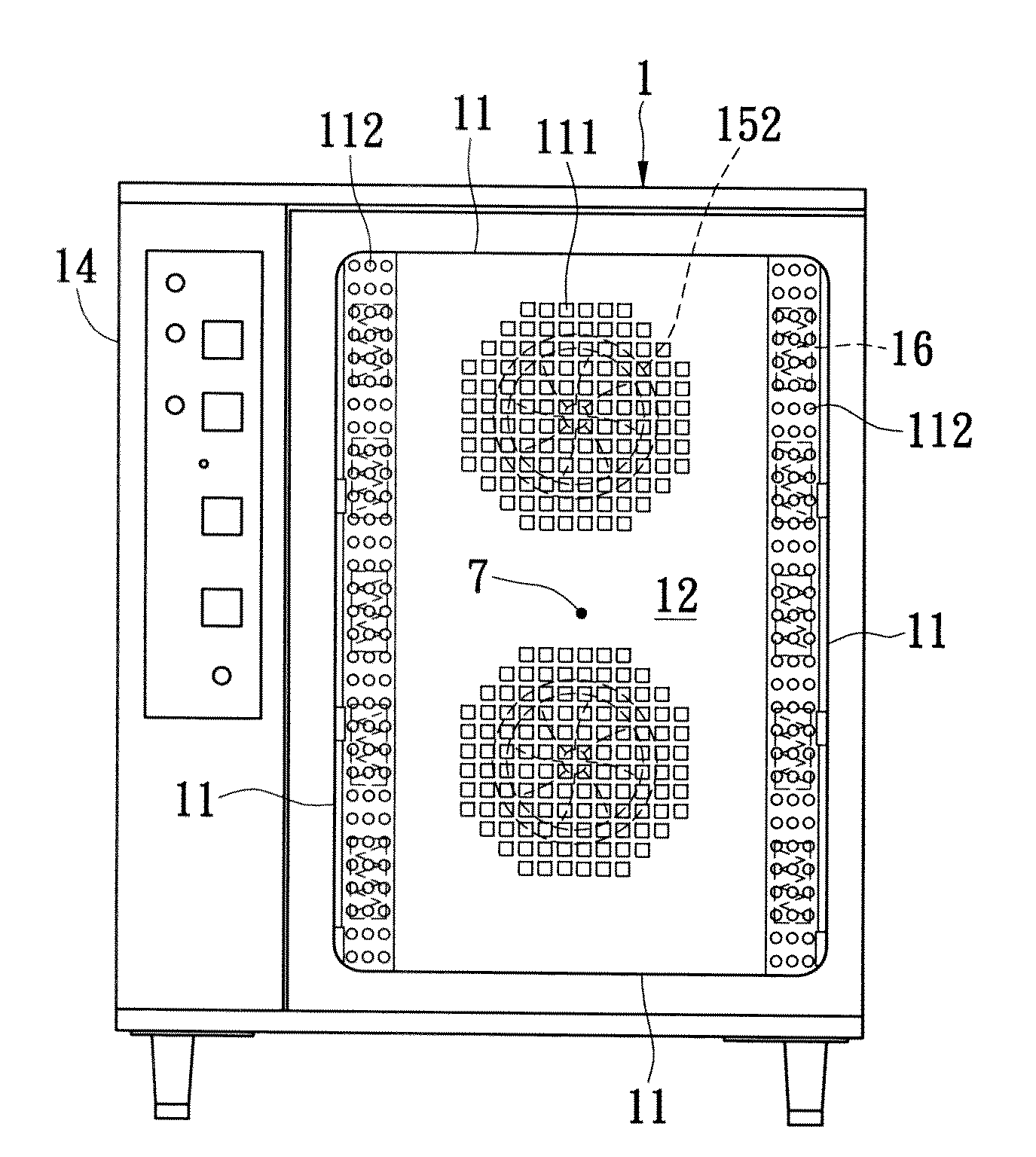

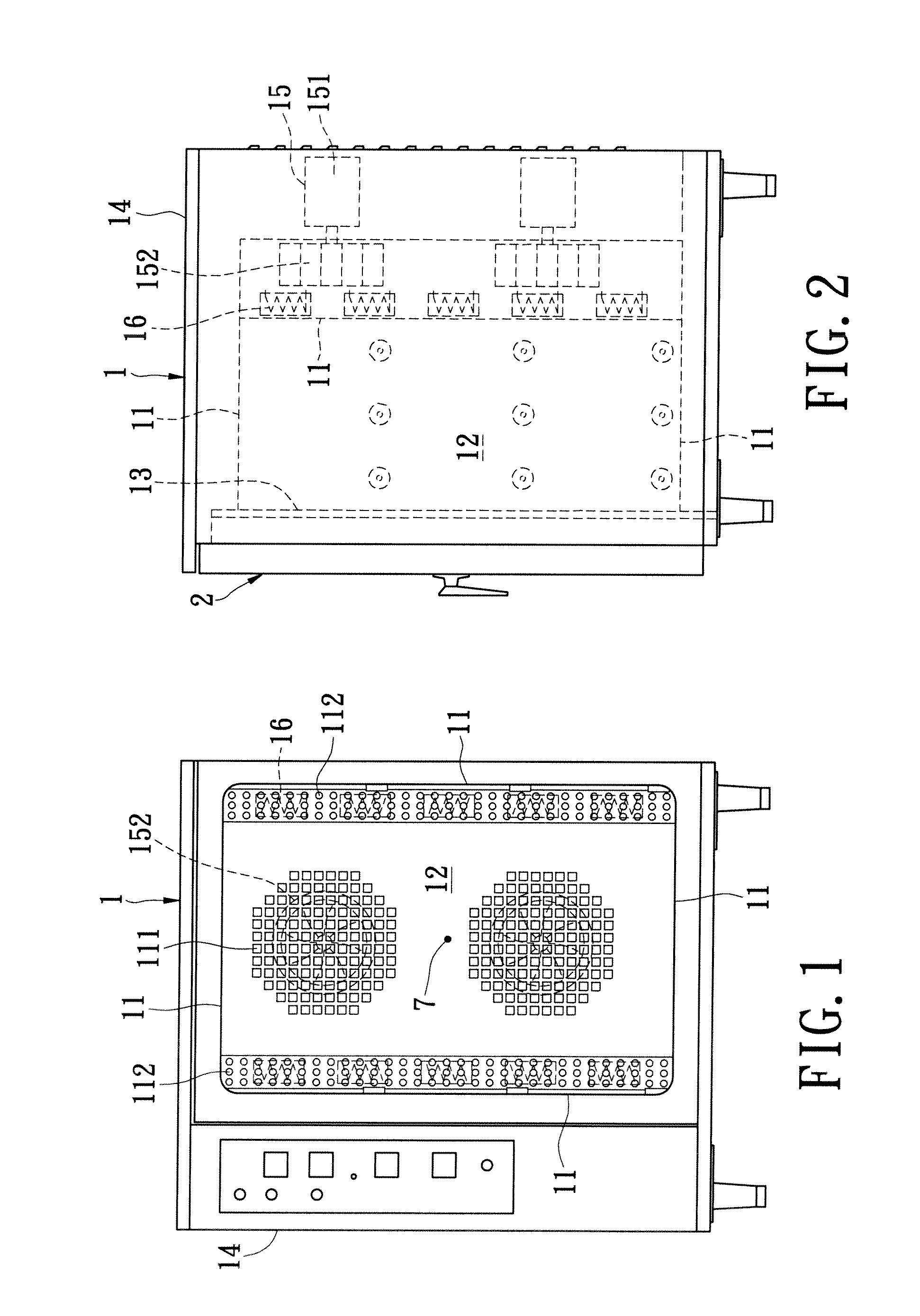

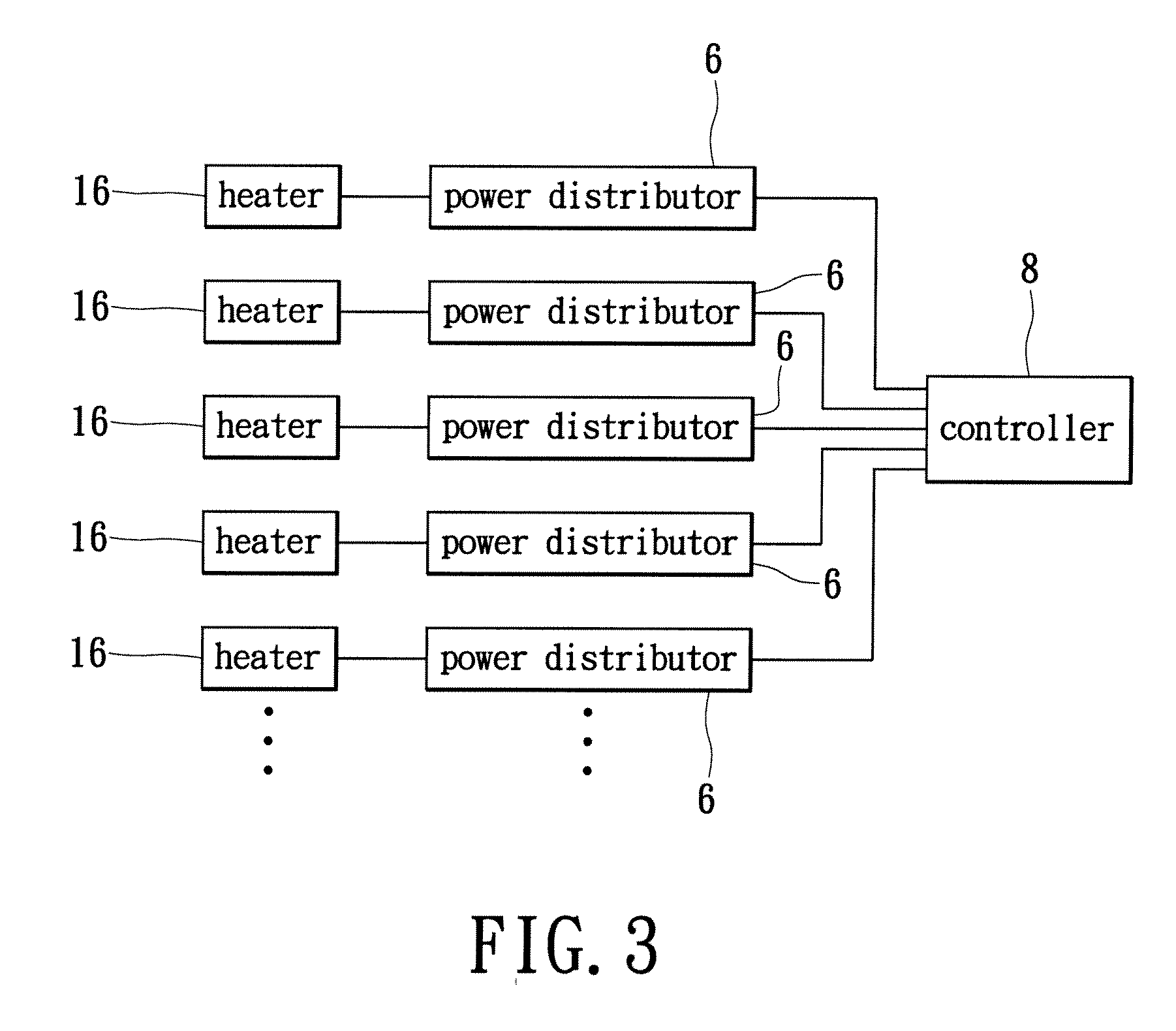

Heating device having a function of dynamical temperature-control

InactiveUS20110127252A1Evenly distributedReduce oxygen concentrationBaking ovenElectric heating for furnacesTemperature controlEngineering

A heating device with a function of dynamical temperature-control includes an oven housing, a door, at least one air-discharge device and a plurality of heaters. The oven housing has a plurality of walls, and the walls define a chamber. The door is pivoted disposed on the oven housing. The air-discharge device and the heaters are disposed on the oven housing. The heaters are respectively dynamical-adjustable and independent-operating heating elements to achieve the uniformity of chamber temperature.

Owner:TANGTECK EQUIP

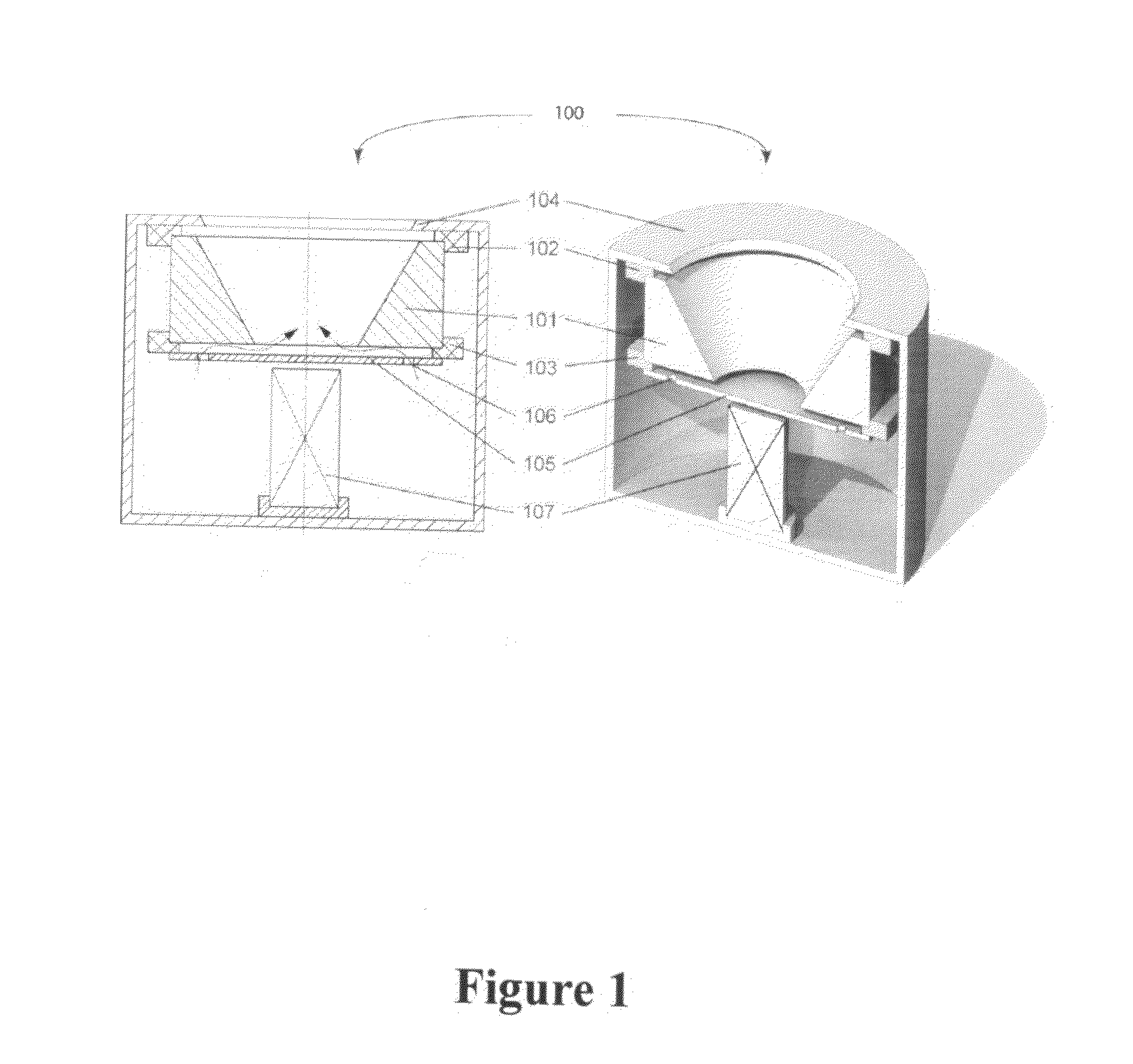

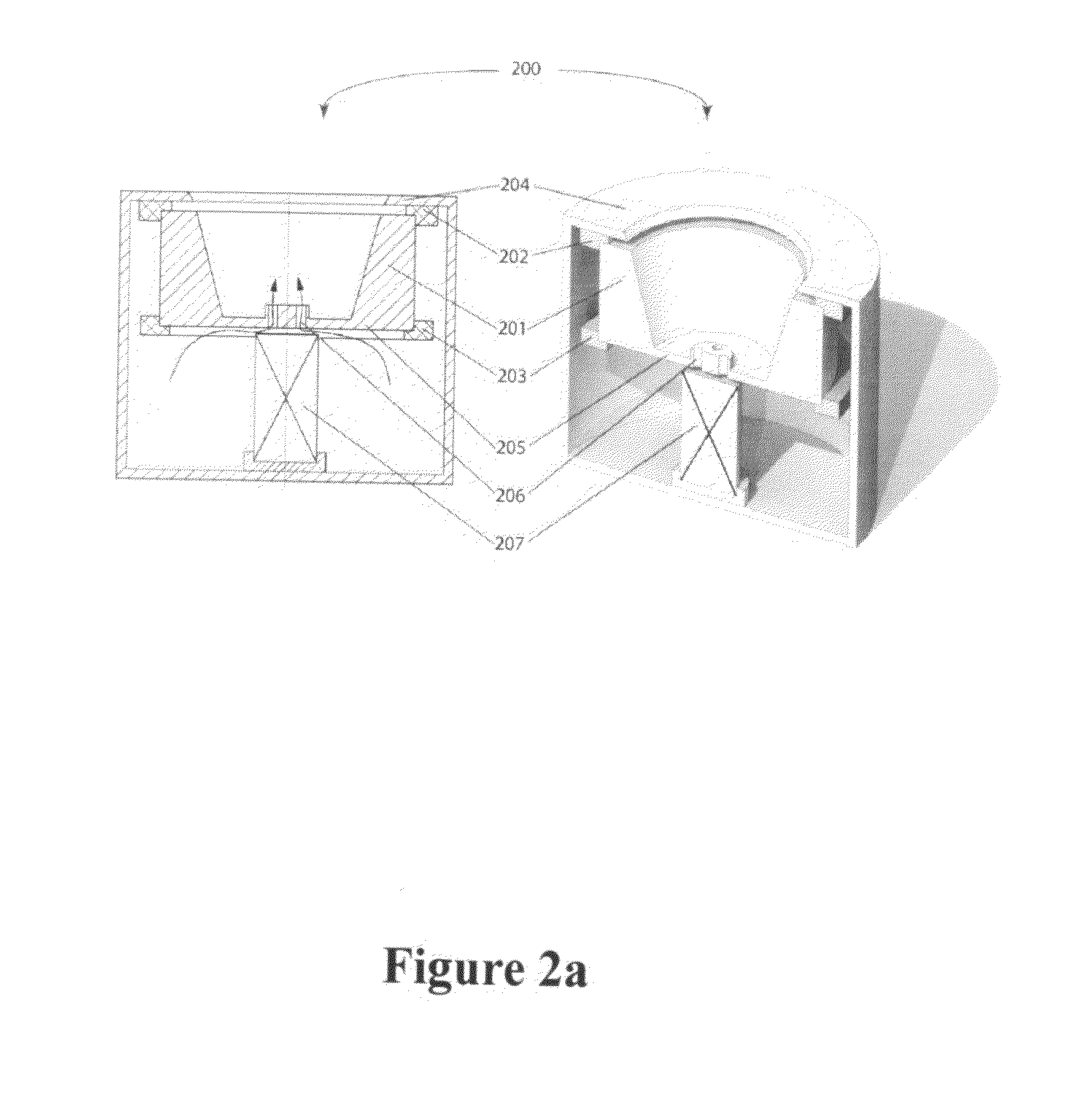

Hall-current ion source with improved ion beam energy distribution

InactiveUS20120025710A1Eliminate pollutionReduce transmissionElectric arc lampsIon beam tubesReactive gasIon beam

A Hall-current ion source with a narrow ion beam energy distribution is presented. A narrow ion beam energy distribution is provided by a utilization of a multi-chamber anode through which a working gas is applied and delivers a uniform working gas distribution in a discharge channel. Introduction of a working gas through a lower part of anode makes applied electric potential in a narrow area and leading to enhanced conditions for a working gas ionization, high ion beam current, high translation of a discharge voltage into a “monochromatic” ion beam mean energy distribution. A multi-chamber anode with a slit exit for introduction of a working gas into area under anode is utilized to prevent a backflow of insulating and dielectric depositions on anode parts, and under anode area makes a nominal operation with reactive gases without a phenomenon called as “anode poisoning” during long operating hours. The ion source with a shielded Hot Filament design shows very effective ion beam neutralization properties; it produces less heating of the substrate than a traditional one; it has a cleaner ion beam because its beam is not contaminated by the Hot Filament material particles. In the design with two Hot Filaments the ion source operation is extended for tens of hours.

Owner:KLYUEV EVGENY VITALEVICH +1

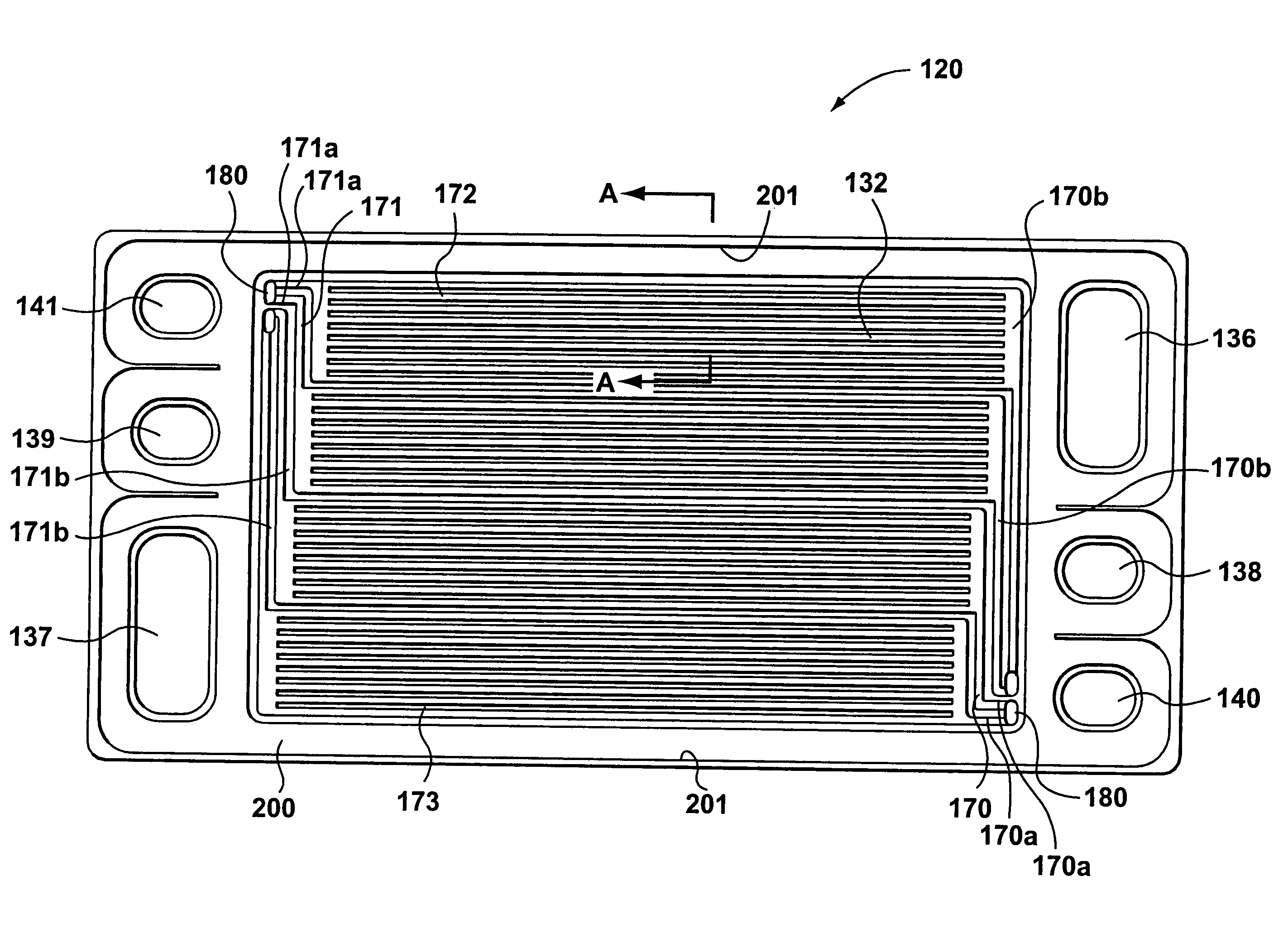

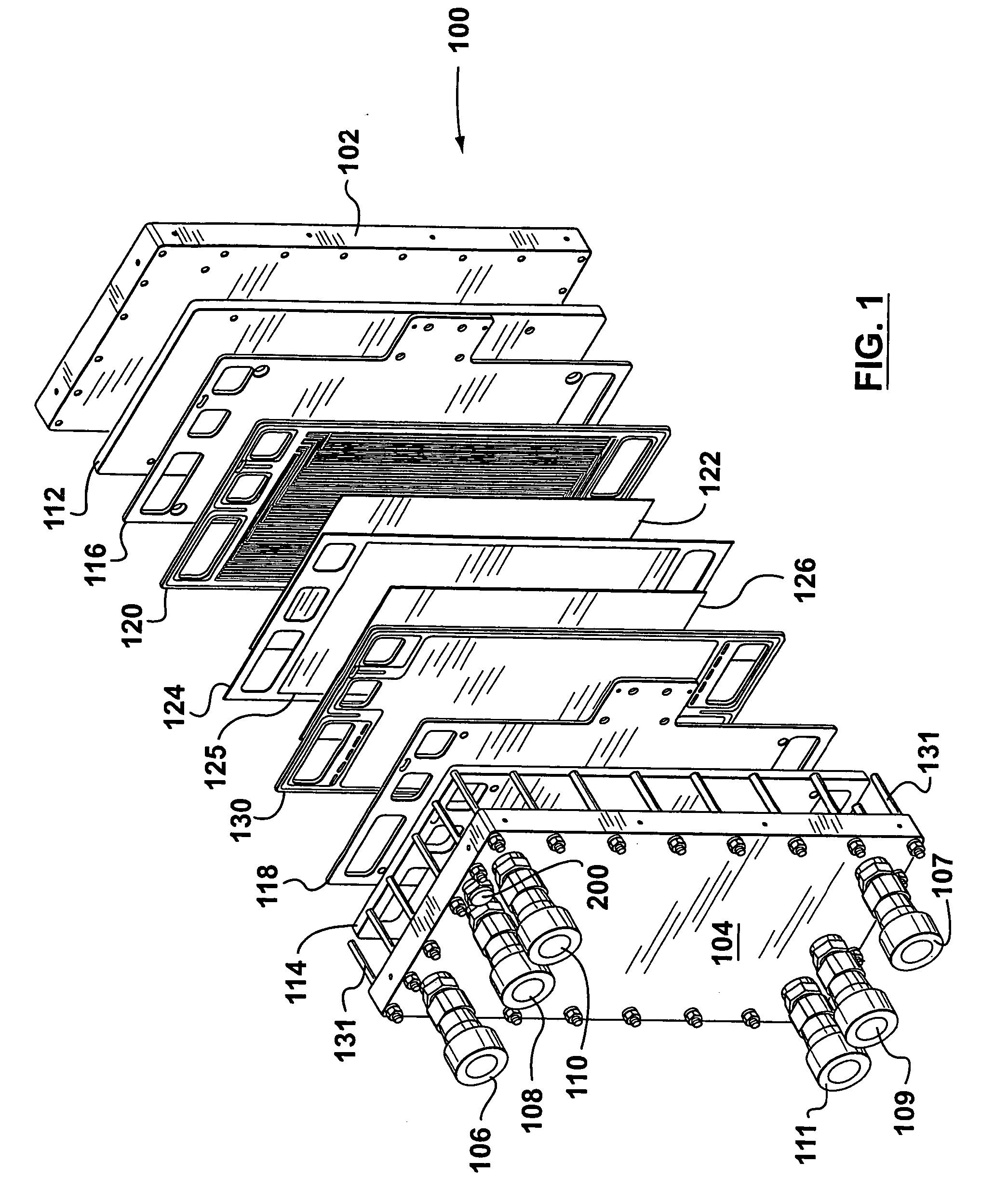

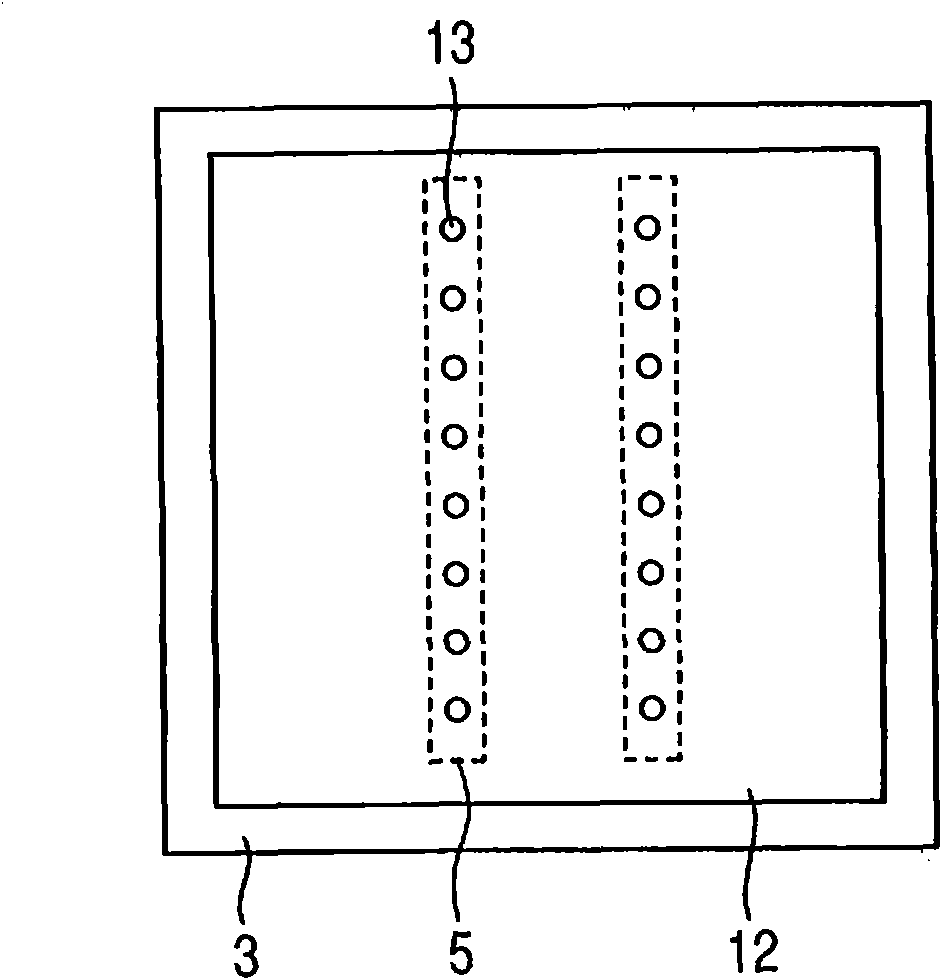

Fuel cell flow field plate

InactiveUS20050064272A1Lower overall pressure dropAvoid accumulationFuel cells groupingFuel cell auxillariesFuel cellsEngineering

A fuel cell stack comprising a plurality of fuel cells, each having an anode flow field plate, a cathode flow field plate and a membrane electrode assembly disposed between the flow field plates. The anode and cathode flow field plates have primary channels and ribs separating the primary channels. At least a portion of the anode and cathode primary channels are disposed directly opposite one another with a membrane exchange assembly therebetween and with at least some of the ribs on the anode and cathode flow field plates located directly opposite one another to sandwich the membrane exchange assembly therebetween. The flow field plates can also have inlet distribution and outlet collection channels. Each of these distribution and collection channels is connected to a plurality of the primary channels, preferably located centrally, so as to improve flow distribution of the reactants.

Owner:HYDROGENICS CORP

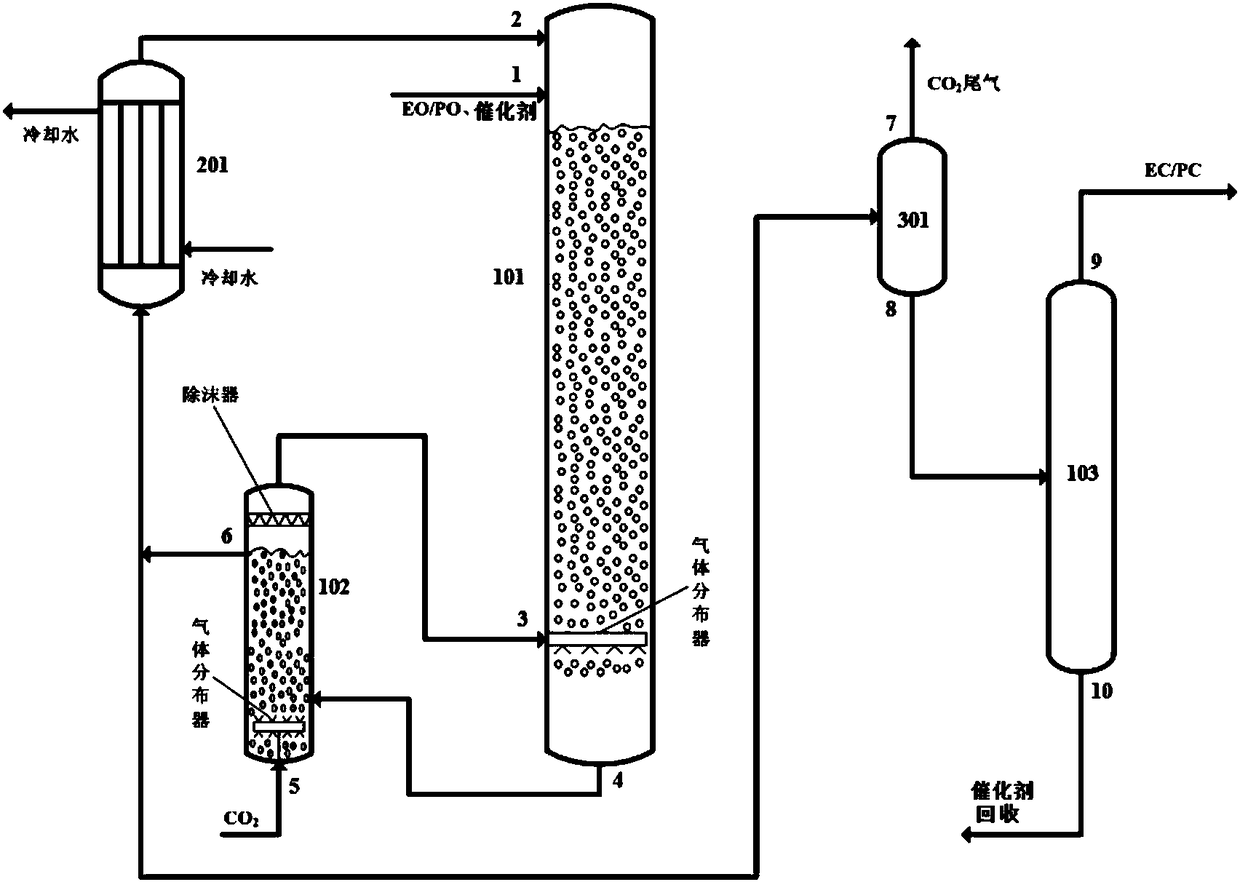

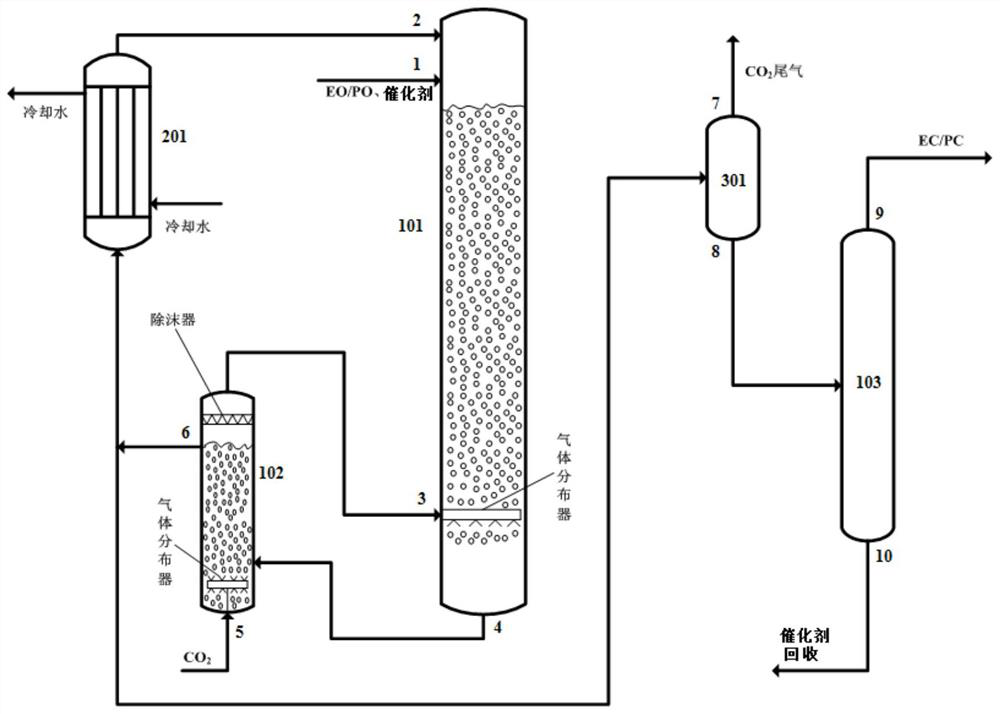

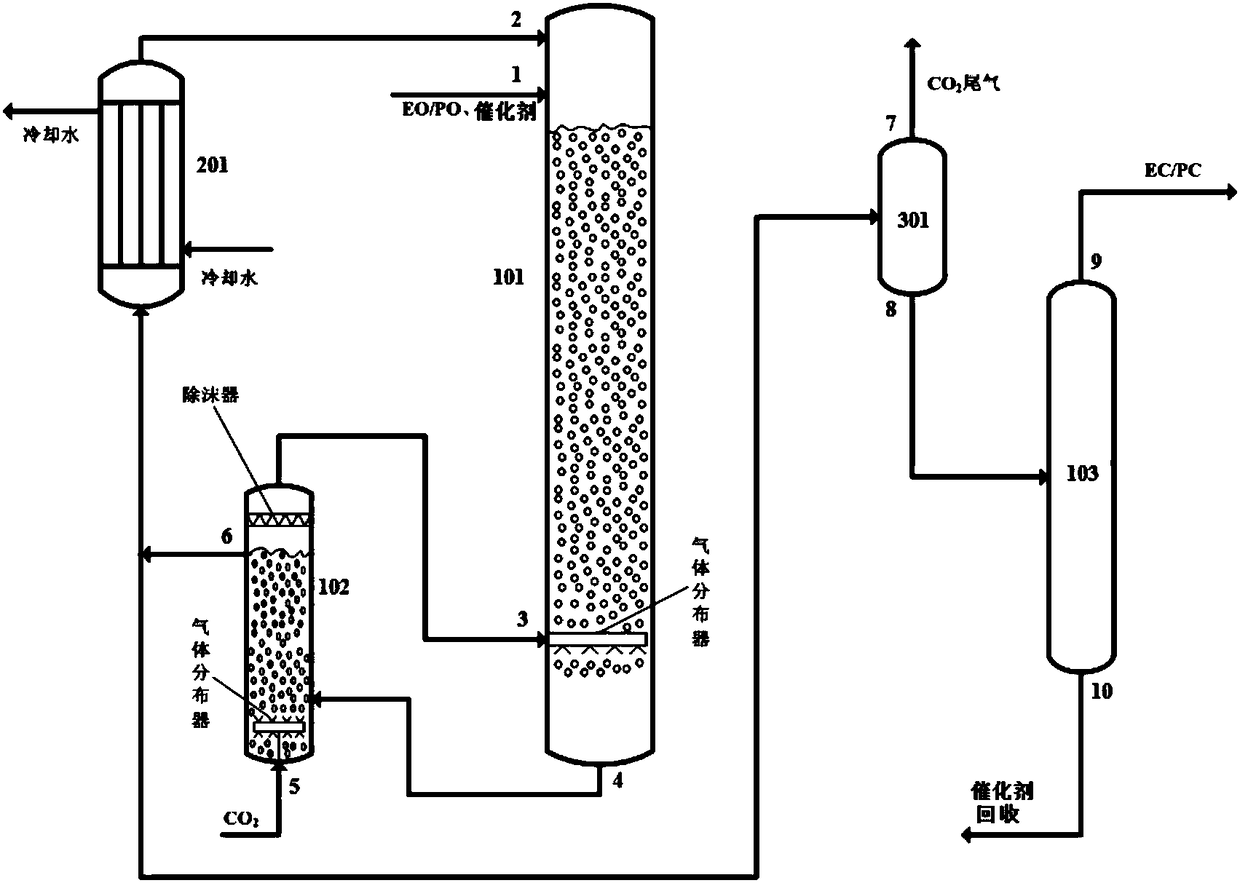

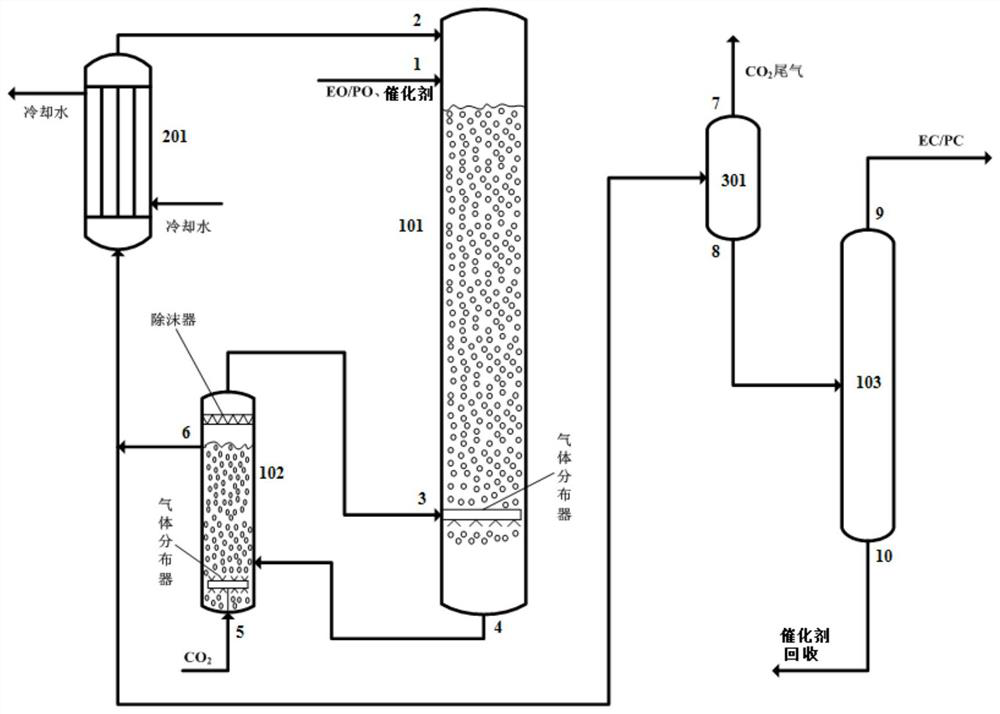

System for producing carbonic ester and method for producing carbonic ester by utilizing system

ActiveCN108484565AAchieving a reverse concentration differenceImprove conversion rateOrganic chemistryChemical/physical processesEthylene oxideCarbonate ester

The invention relates to a system for producing carbonic ester and a method for producing the carbonic ester by utilizing the system. The system comprises a first bubble tower, a second bubble tower and a heat exchanger, wherein the upper part of the first bubble tower is provided with a raw material and catalyst inlet and a first circulation inlet communicated with an outlet in the top of the heat exchanger, the lower part of the first bubble tower is provided with a second circulation inlet communicated with an outlet in the top of the second bubble tower, and the bottom of the first bubbletower is provided with a product outlet communicated with the lower part of the second bubble tower; the bottom of the second bubble tower is provided with a gas inlet, the upper part of the second bubble tower is provided with an overflow outlet, and the outflow outlet is communicated with the bottom of the heat exchanger and a discharge opening. By adopting the system to produce the carbonic ester, the standing time can be shortened, the reaction temperature and pressure can be lowered, the reaction efficiency and an EO (ethylene oxide) conversion rate can further be improved, and even 'zero' emission is realized, so that ethylene carbonate can be prepared from ethylene oxide and carbon dioxide in an environment-friendly mode.

Owner:CHINA NAT OFFSHORE OIL CORP +4

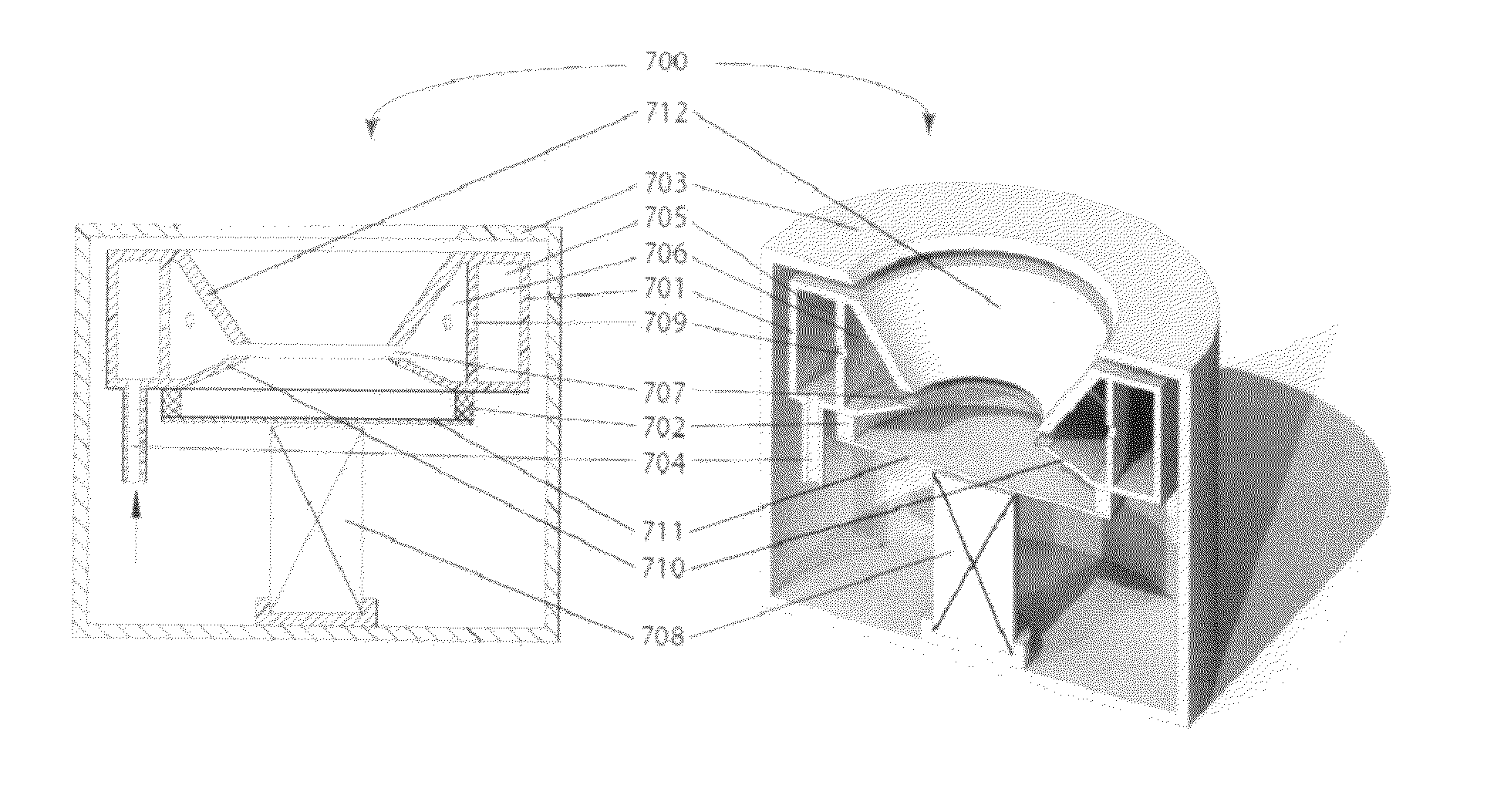

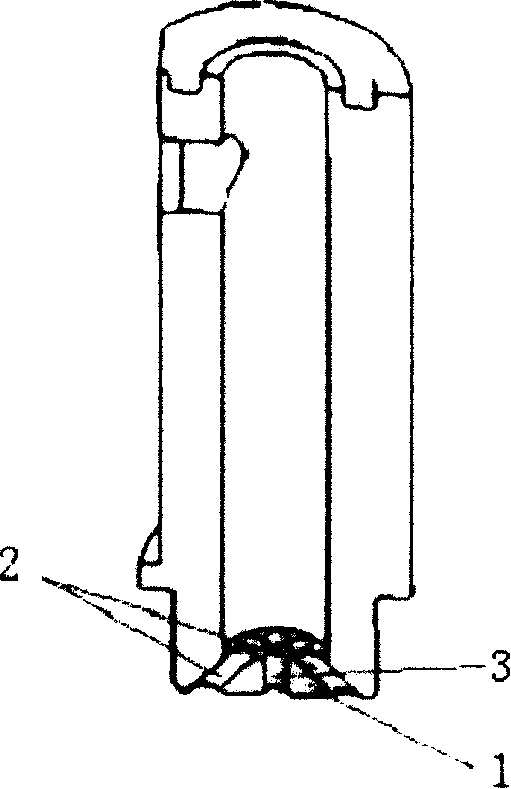

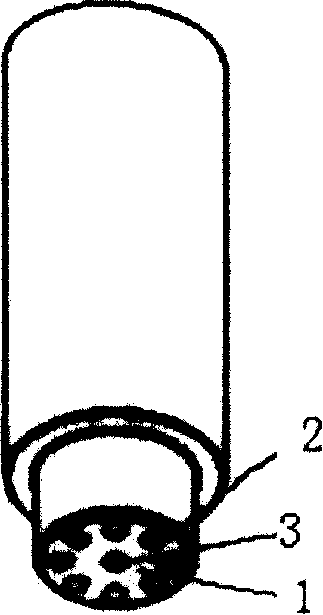

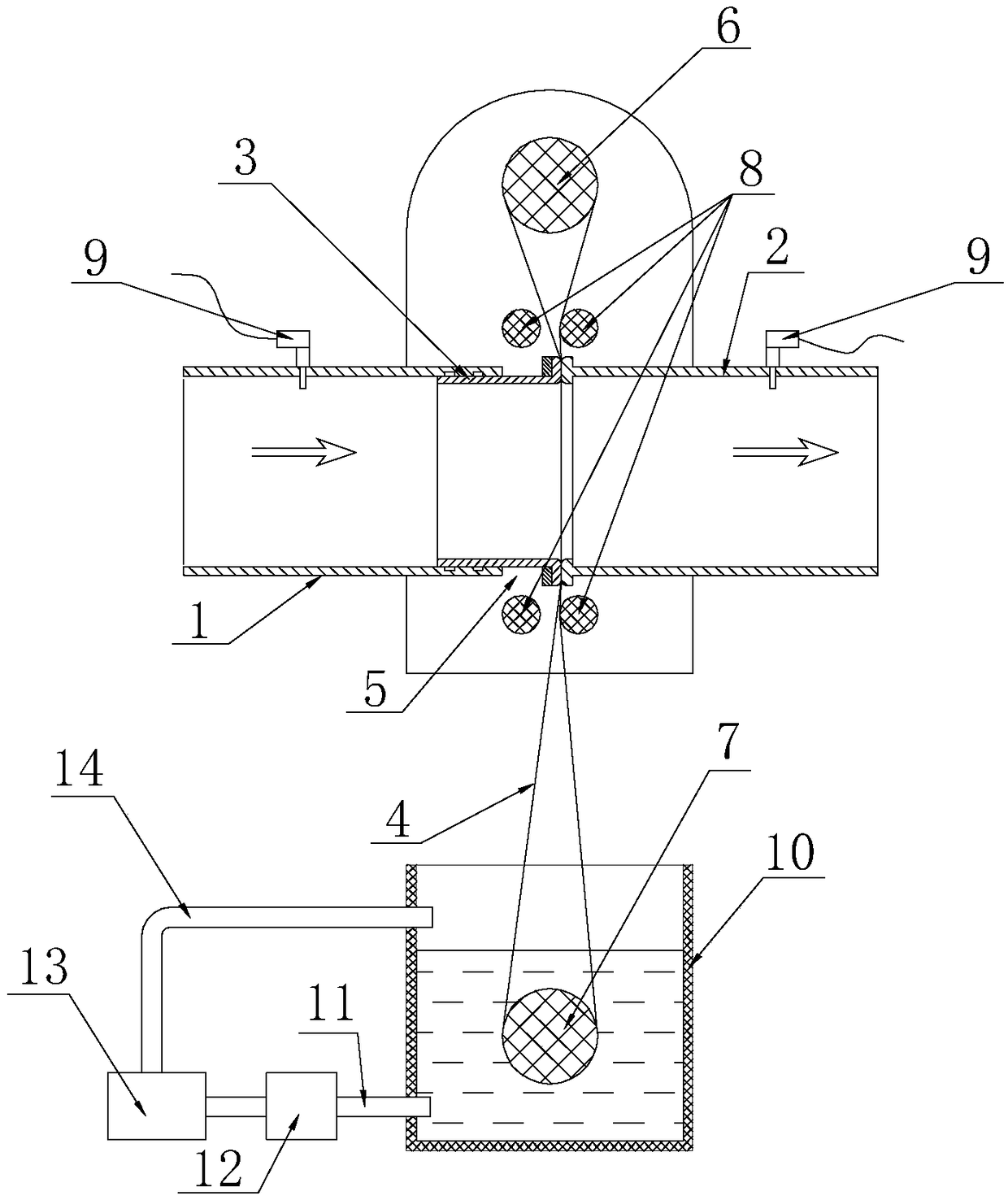

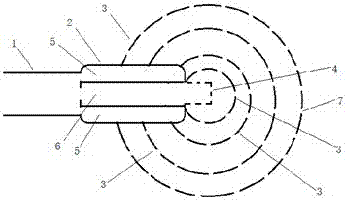

Gas injection apparatus

ActiveCN101174542AEven gas distributionReduce blind spotsElectric discharge tubesSemiconductor/solid-state device manufacturingGas passingEngineering

The invention discloses a gas injection device used for feeding gas to a reaction chamber, which comprises a body, a gas channel arranged in the body, a nozzle with arch-shaped surface arranged at the front end of the body, and a plurality of orifices arranged along the arch surface of the nozzle. The diameters of the orifices are 0.3 to 0.7 mm, and the gas is sprayed into the reaction chamber through the gas channel and via the orifices. The central orifice is arranged along the central axis direction of the gas injection device, the peripheral orifices are arranged on the periphery of the central orifice, and have 0 to 90 degree included angle with the central orifice. The peripheral orifices are radiated from the central orifice to the periphery, and the radiation angle is 15 to 30 degrees. The included angle between orifices is 5 to 15 degrees. The invention has the advantages that the structure is simple, the gas injection covering area is large, and the gas is distributed evenly, thereby especially suitable for gas supply systems of semiconductor silicon wafer processing equipment, and also suitable for the gas supply in other occasions.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

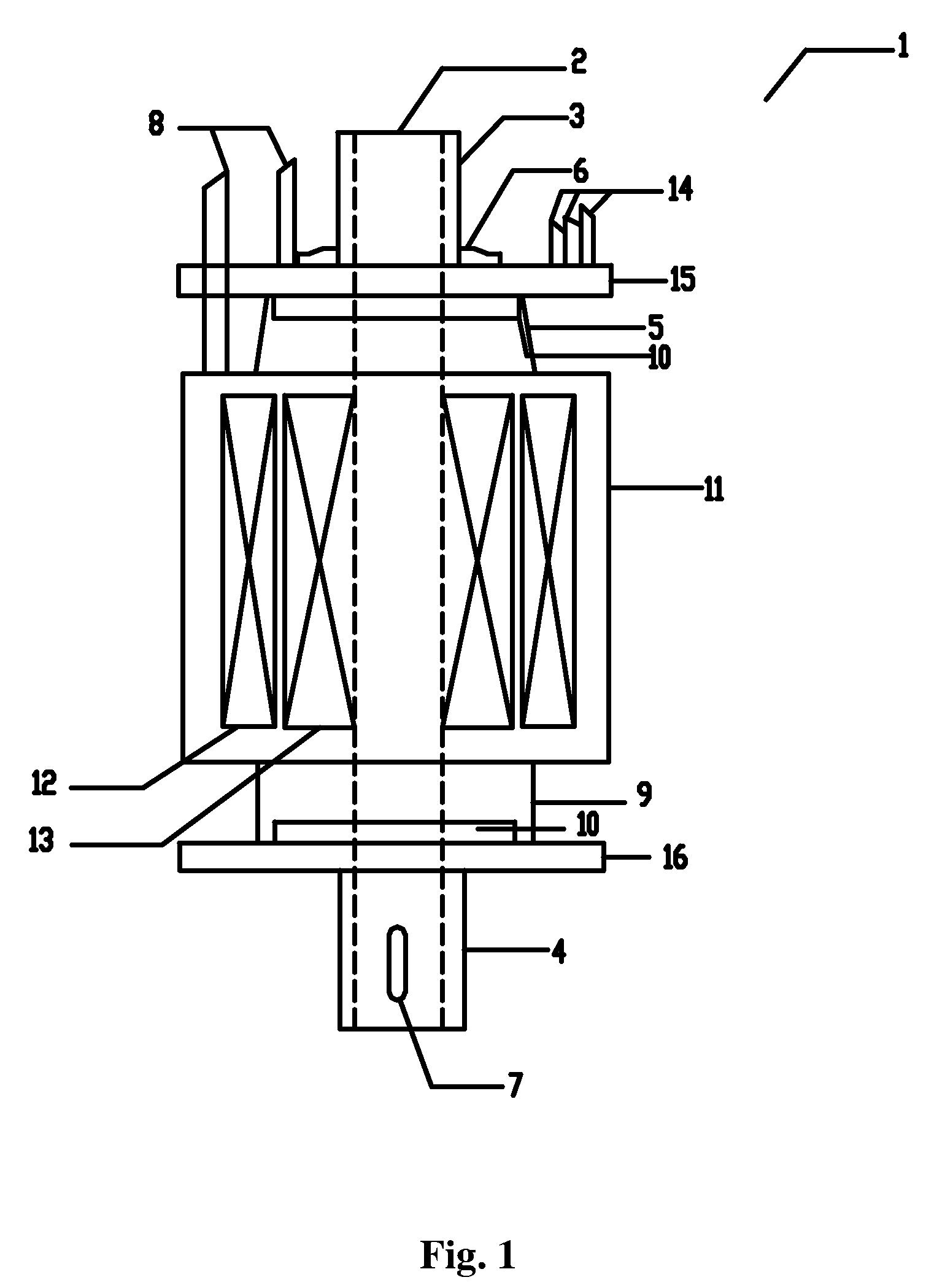

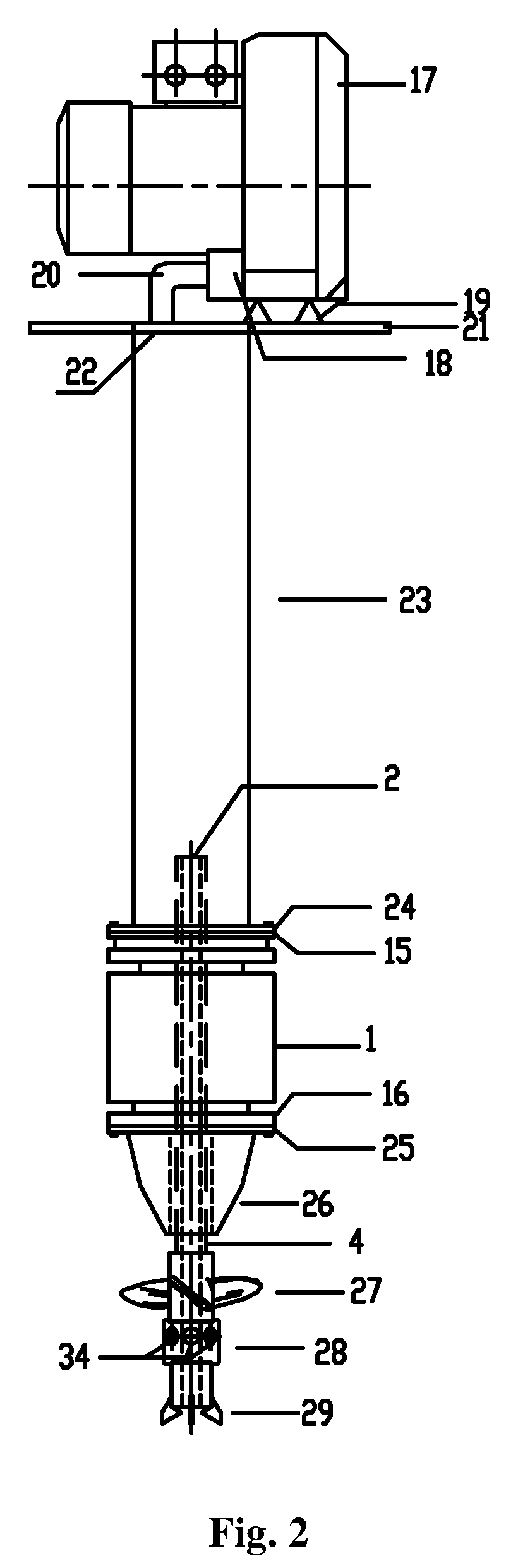

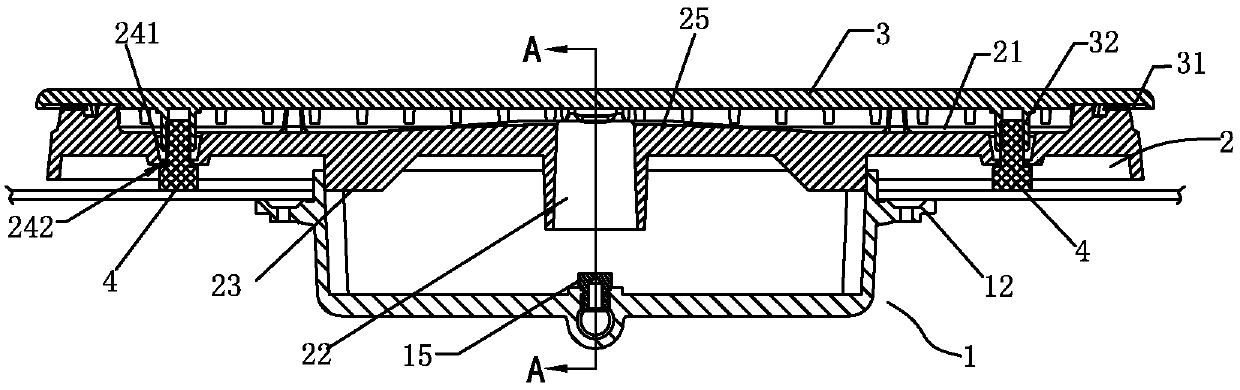

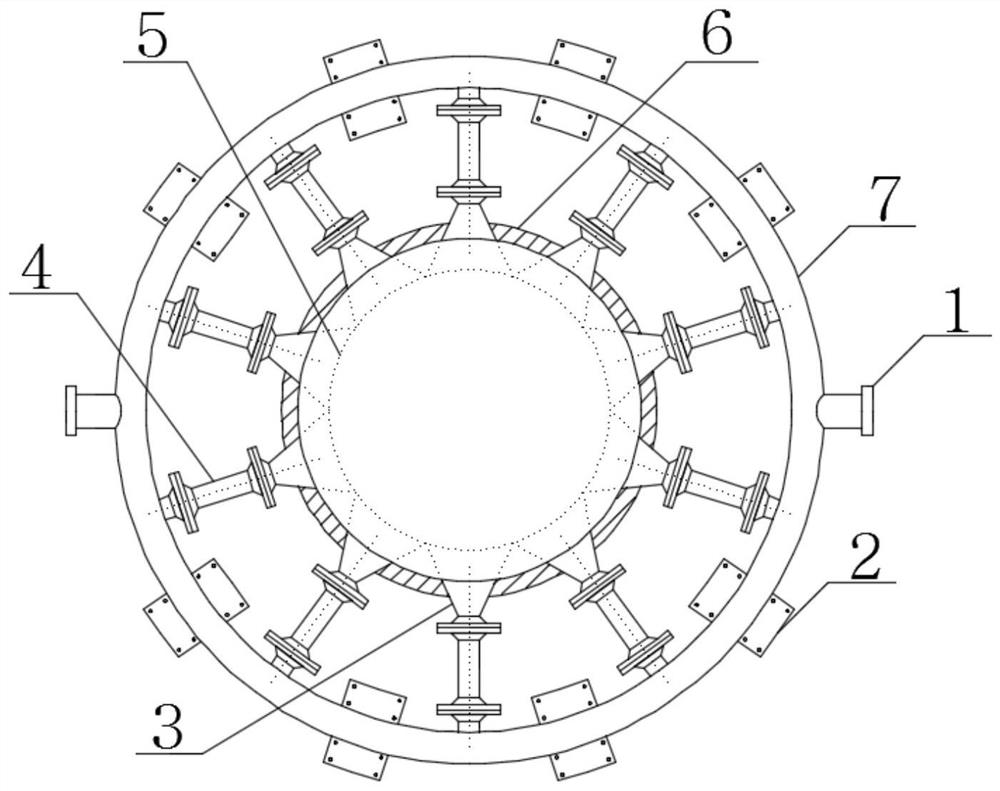

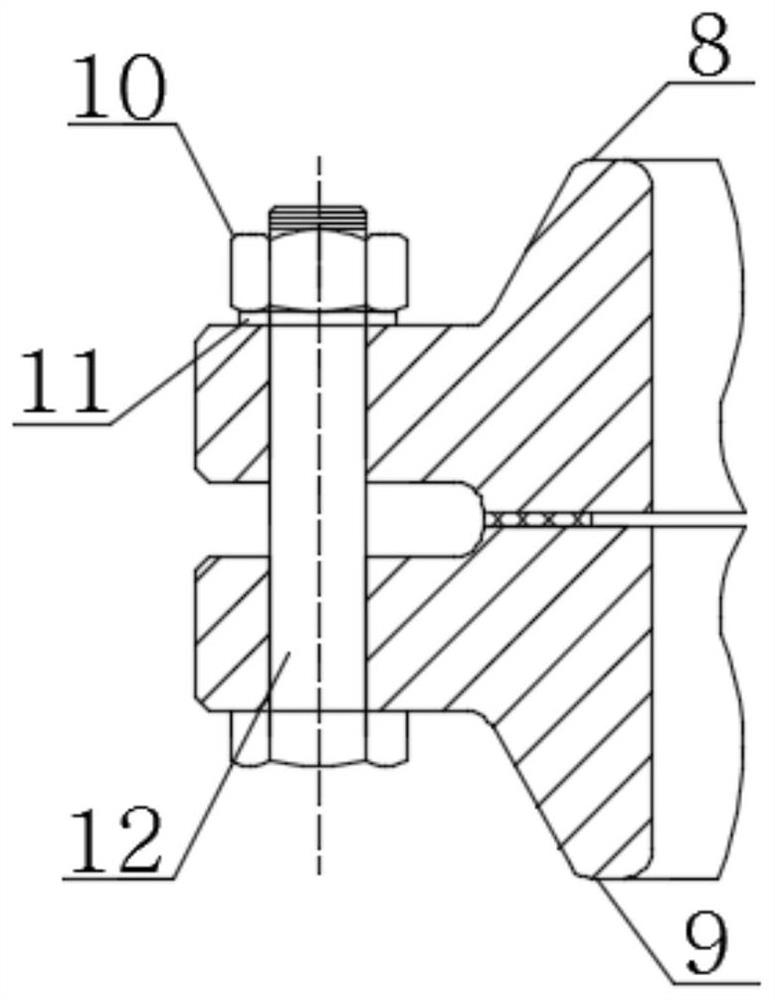

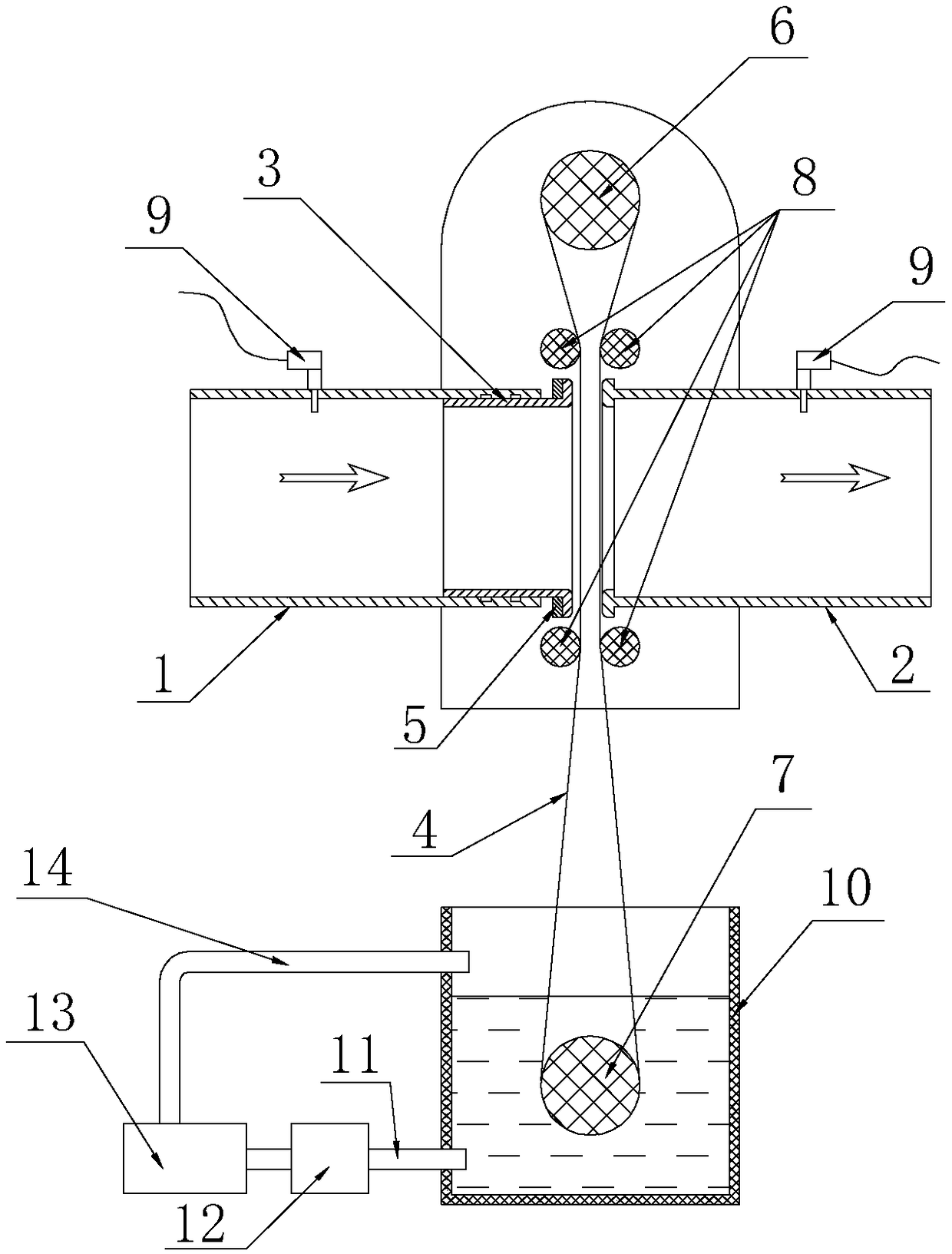

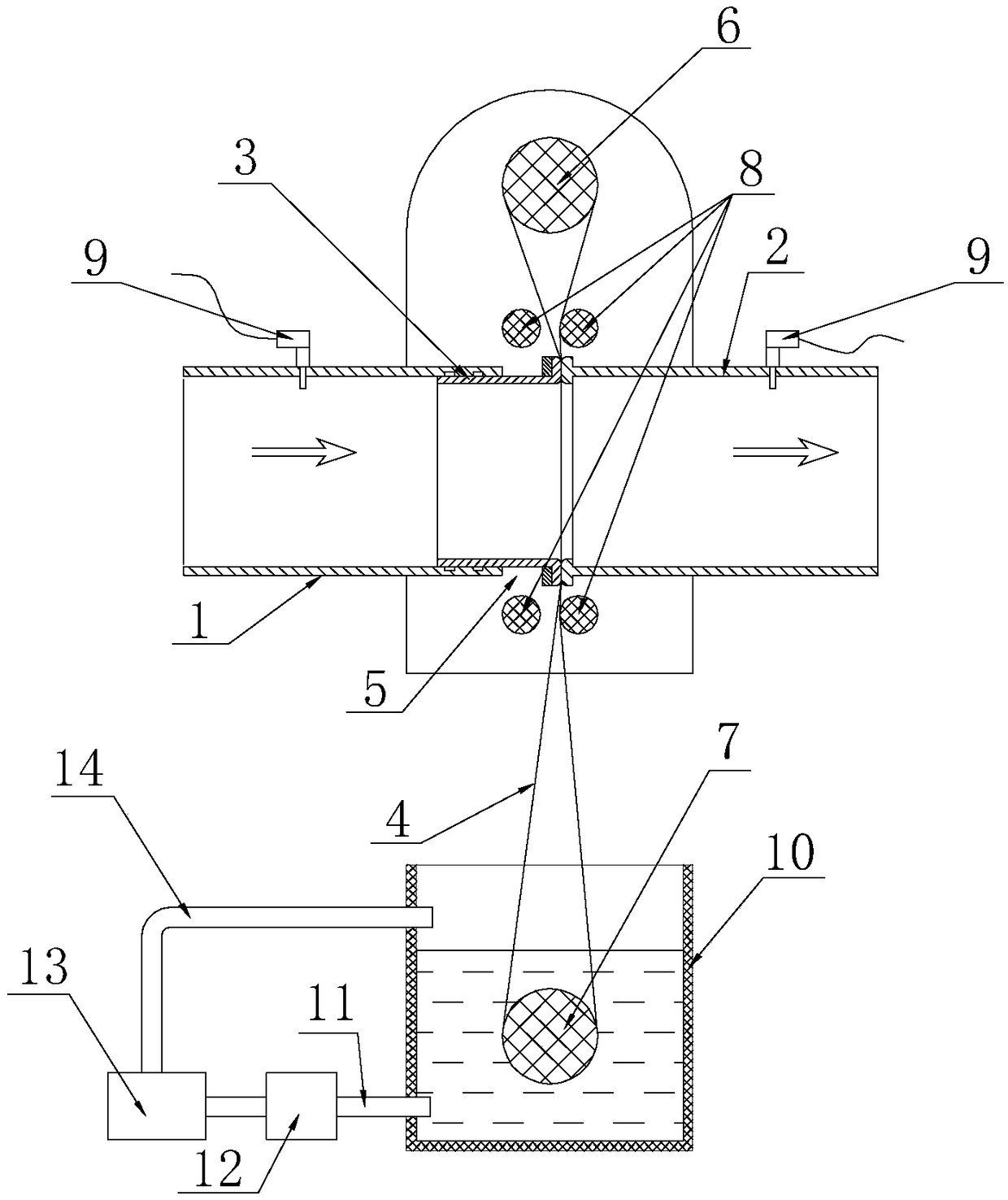

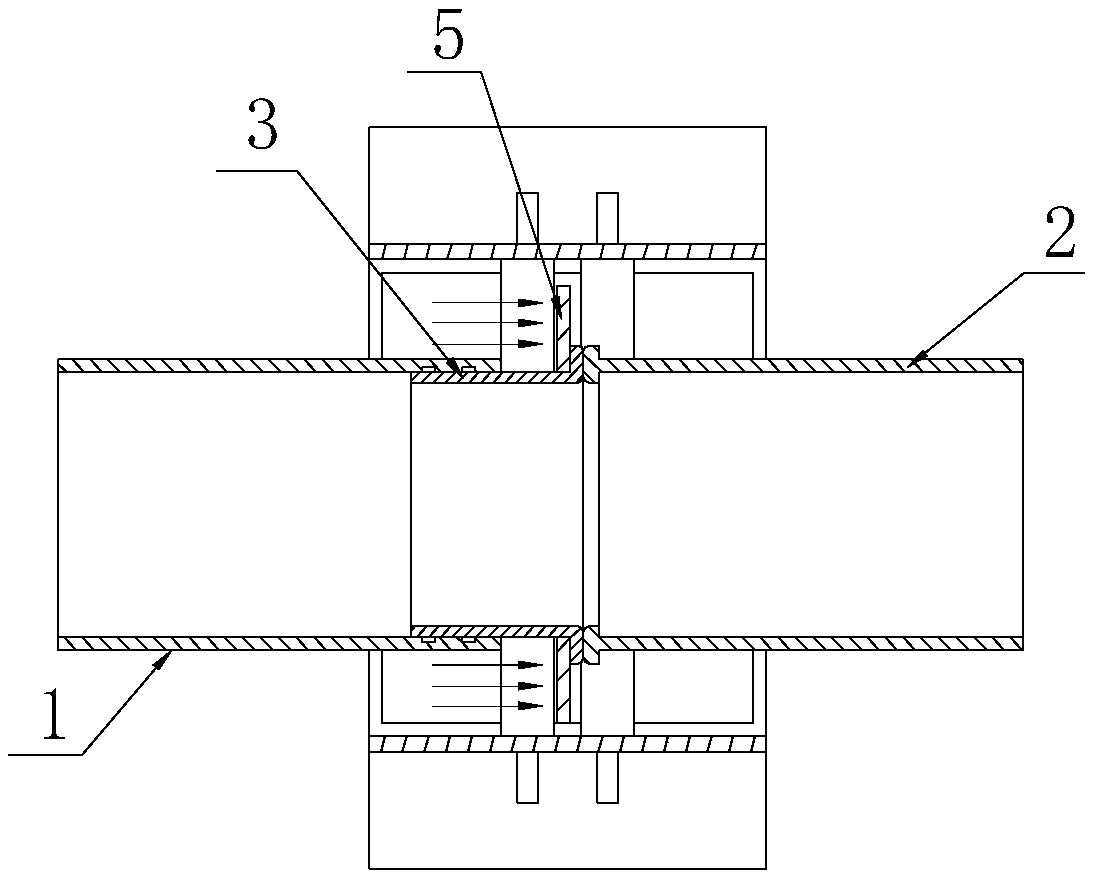

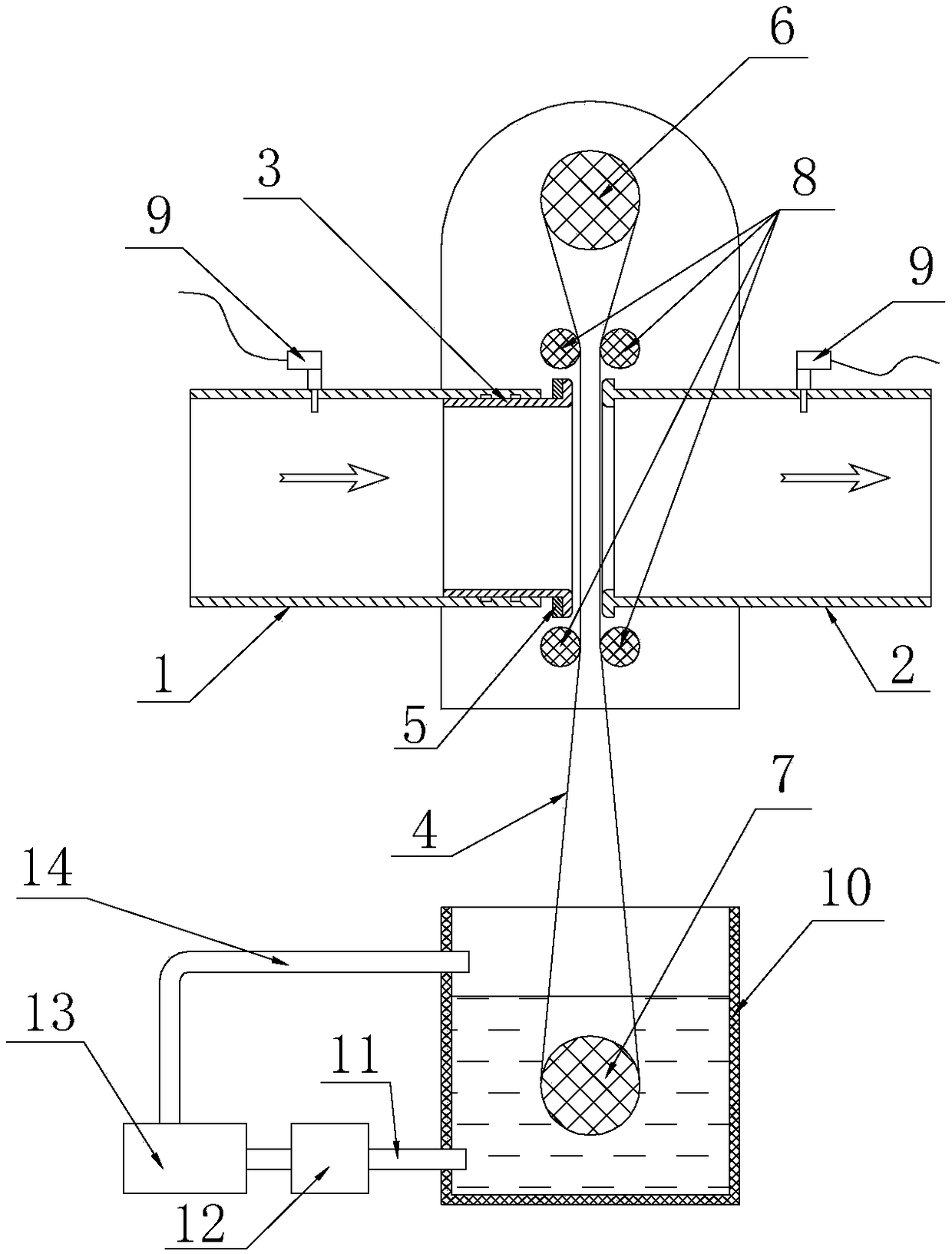

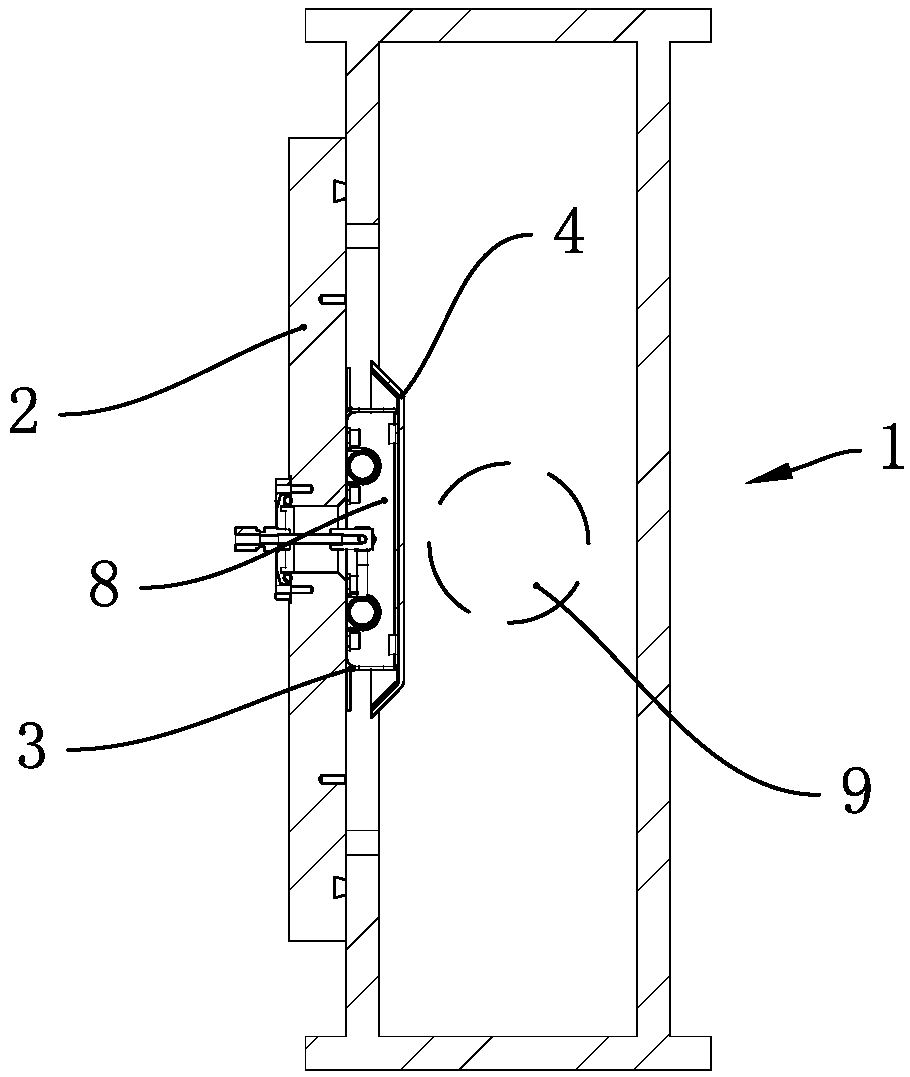

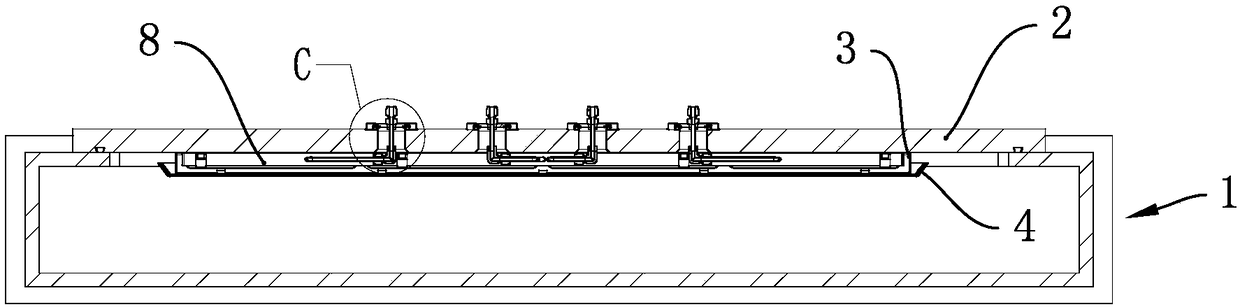

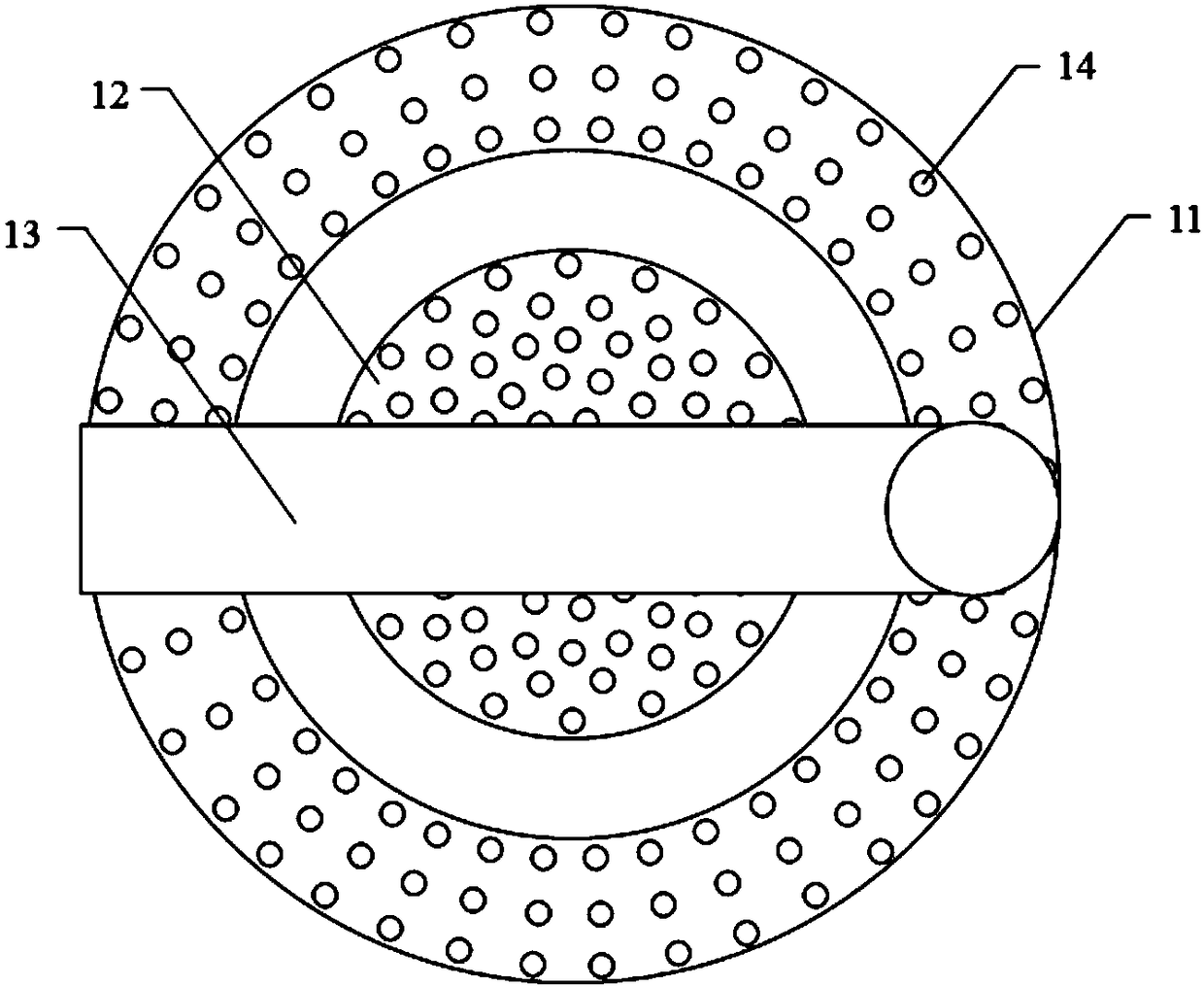

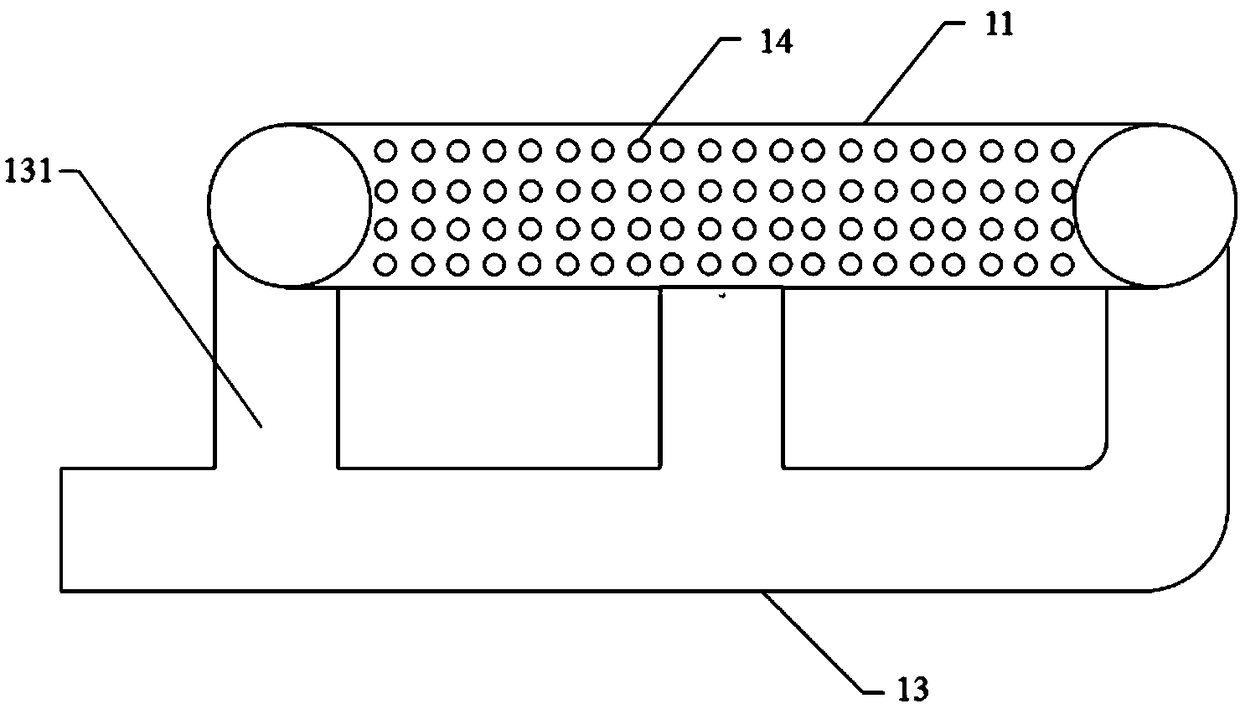

Submersible hollow shaft motor and submersible floating aerator comprising the same

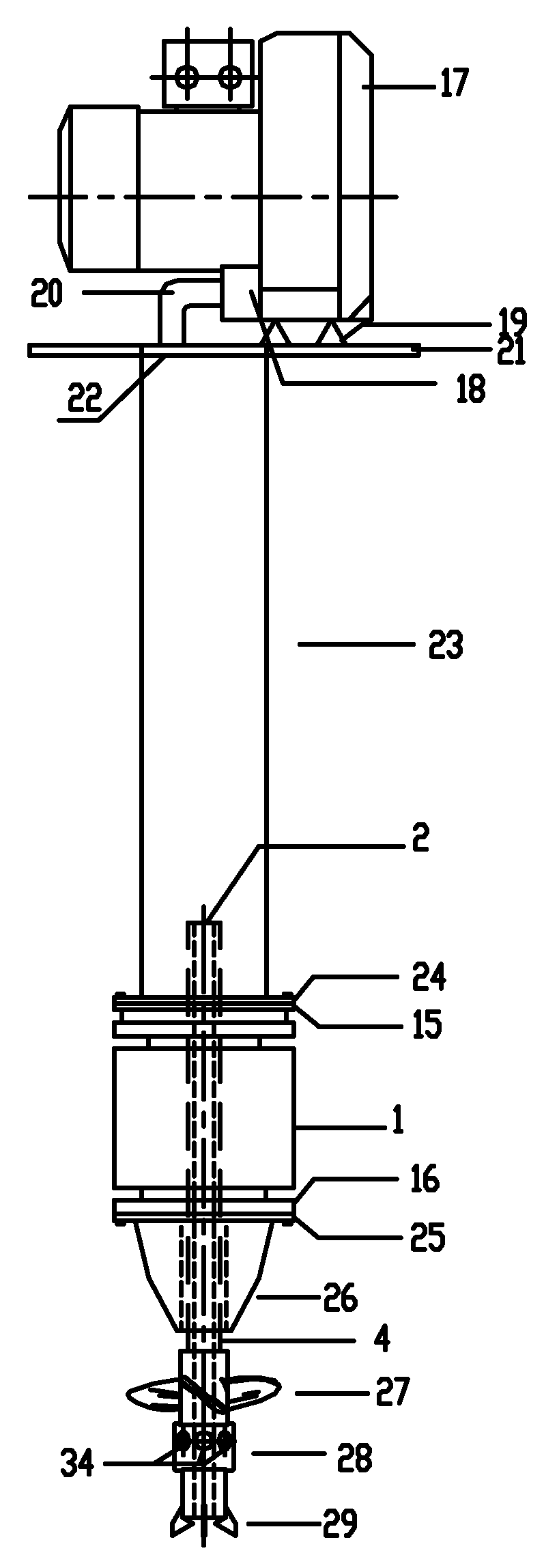

ActiveUS7661658B2Large aeration depthHigh utilization of oxygenSpace heating and ventilationRotary stirring mixersOxygen utilization ratePropeller

Provided is a submersible floating aerator, including a submersible hollow shaft motor (1) including a hollow shaft (2), a bottom shaft extension (4), a first motor flange (15), a second motor flange (16), a first flange (24) and a second flange (25), a gas-ring compressor (17), a base (21) having a gas inlet hole (22), a gas inlet tube (23), a dome (26), a propeller assembly (60) and an air outlet opening (18); wherein the base (21) is fixed on the top of the gas inlet tube (23), the gas-ring compressor (17) is fixed on the base (21) via a bracket (19); the air outlet opening (18) is connected to the gas-inlet hole (22) via a pipe (20); the gas inlet tube (23) is fixed to the first motor flange (15) via a first flange (24); the second motor flange (16) is fixed to the dome (26) via the second flange (25); the bottom shaft extension (4) is coaxially connected to the propeller assembly (60); and the hollow shaft (2) rotates along with the propeller assembly (60). The submersible floating aerator features large aeration depth, high utilization of oxygen, and uniform gas distribution.

Owner:SUN SHULIN +1

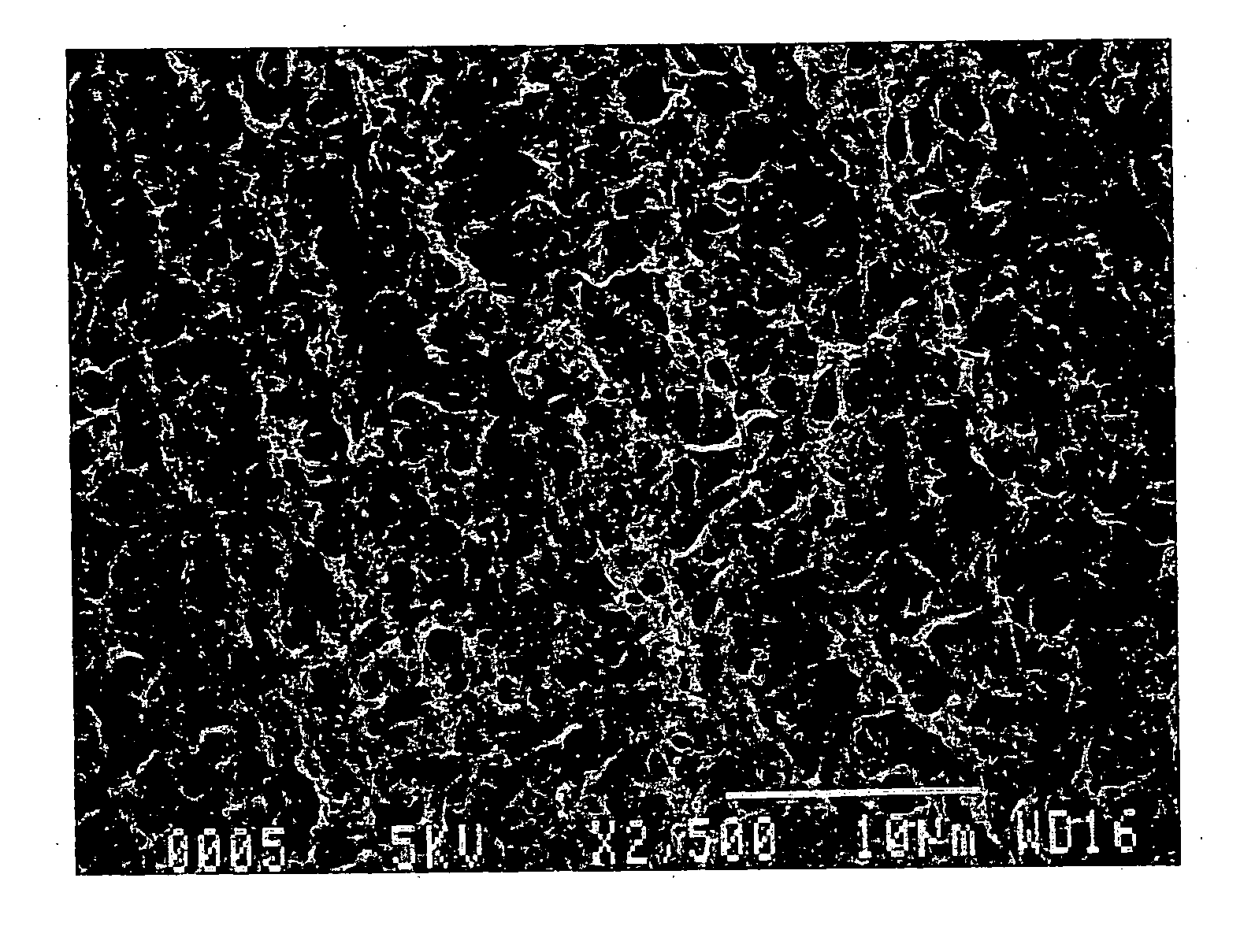

Electrode base material for fuel cell

InactiveUS20070082805A1Even gas distributionHigh electricalSolid electrolytesActive material electrodesPorosityO-Phosphoric Acid

Disclosed are a carbon porous membranous structure having fine interconnecting pores an average diameter of which is 0.05 to 10 μm and a porosity of 15 to 85% and a metal-dispersed carbon structure comprising that carbon porous membranous structure having dispersed therein fine particles of at least one kind of a metal and an alloy. The carbon porous membranous structures are useful as a component of fuel cells, particularly as an electrode base material of gas diffusion electrodes for solid polymer electrolyte fuel cells and phosphoric acid fuel cells.

Owner:UBE IND LTD

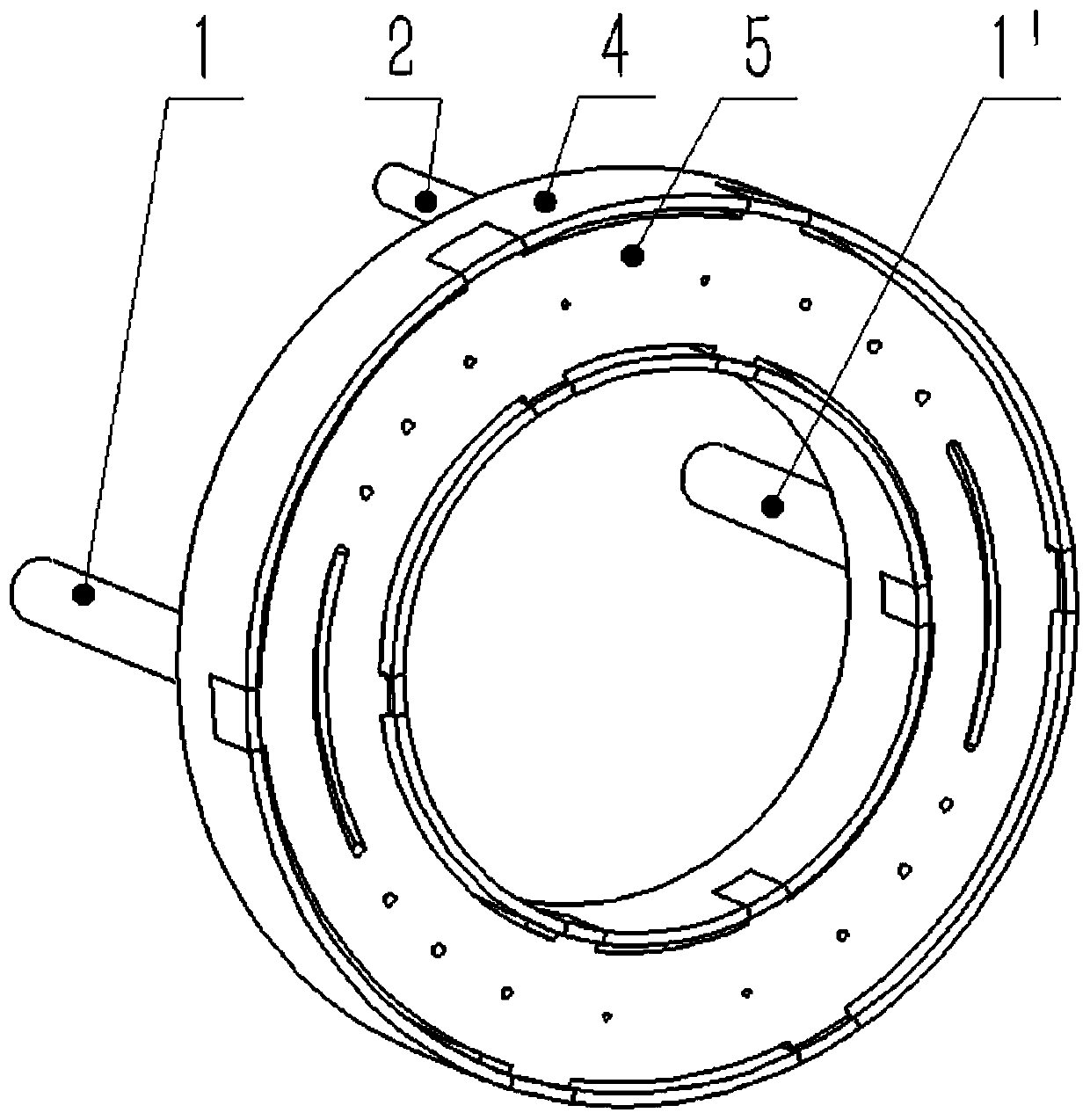

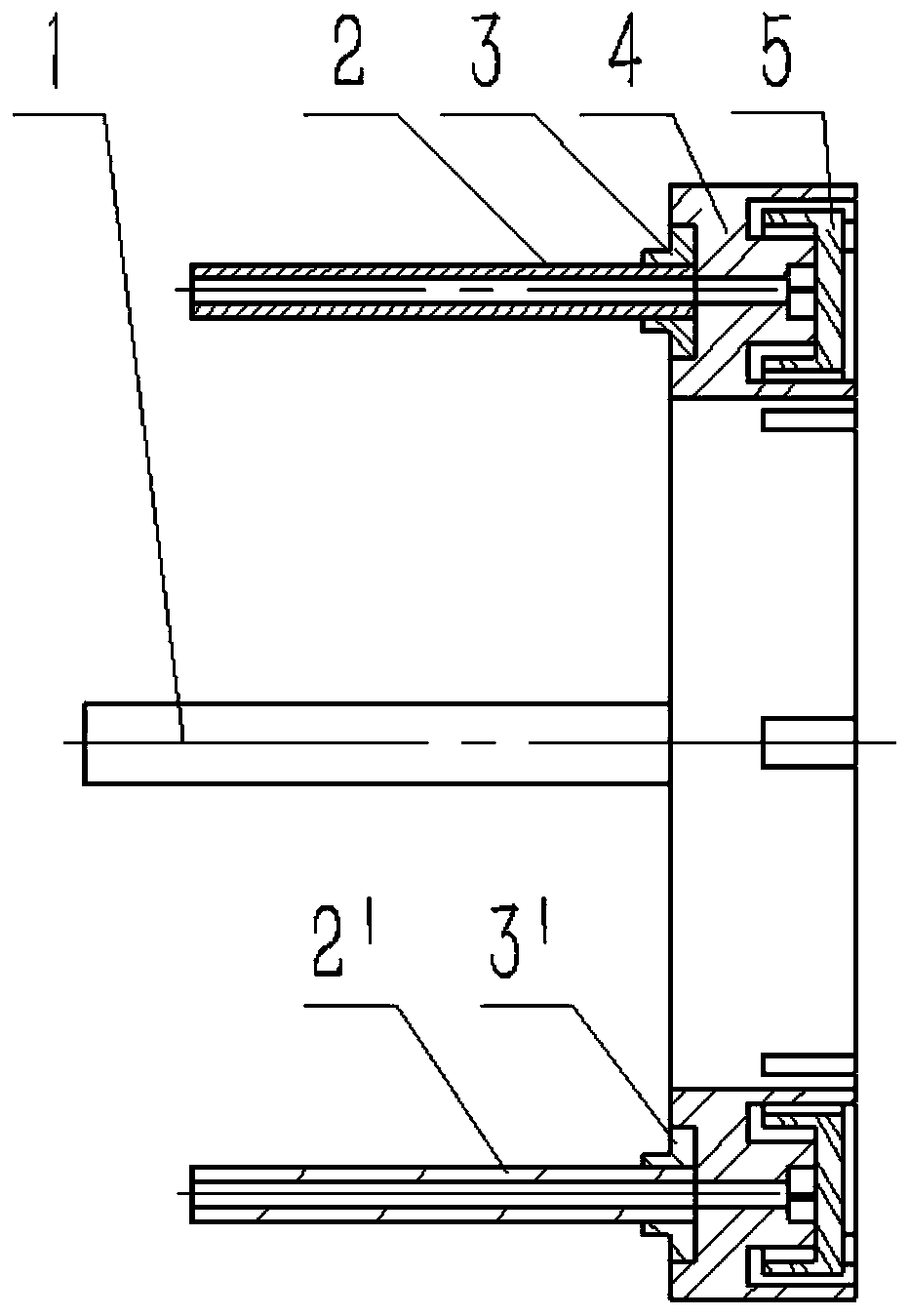

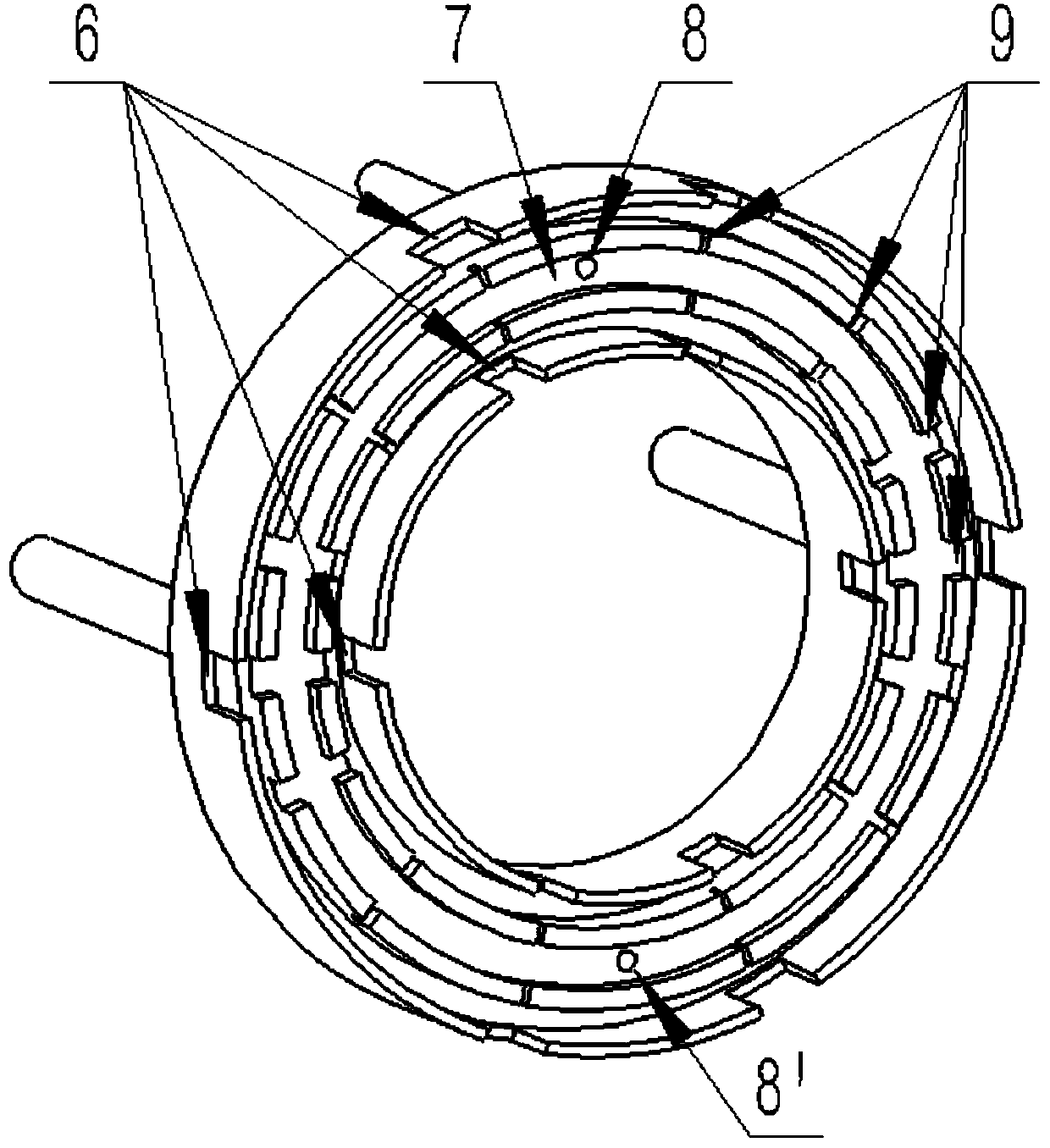

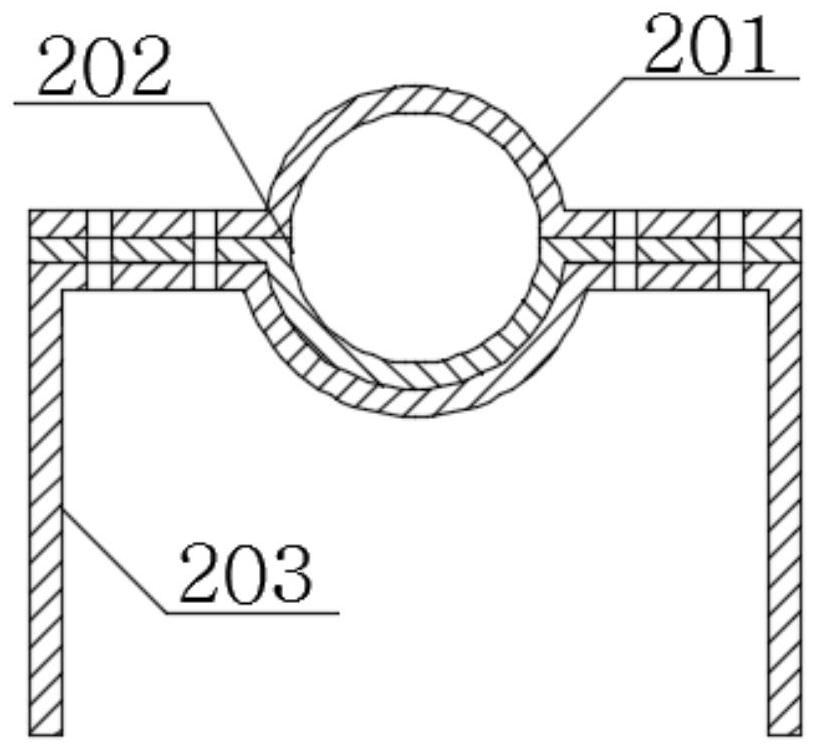

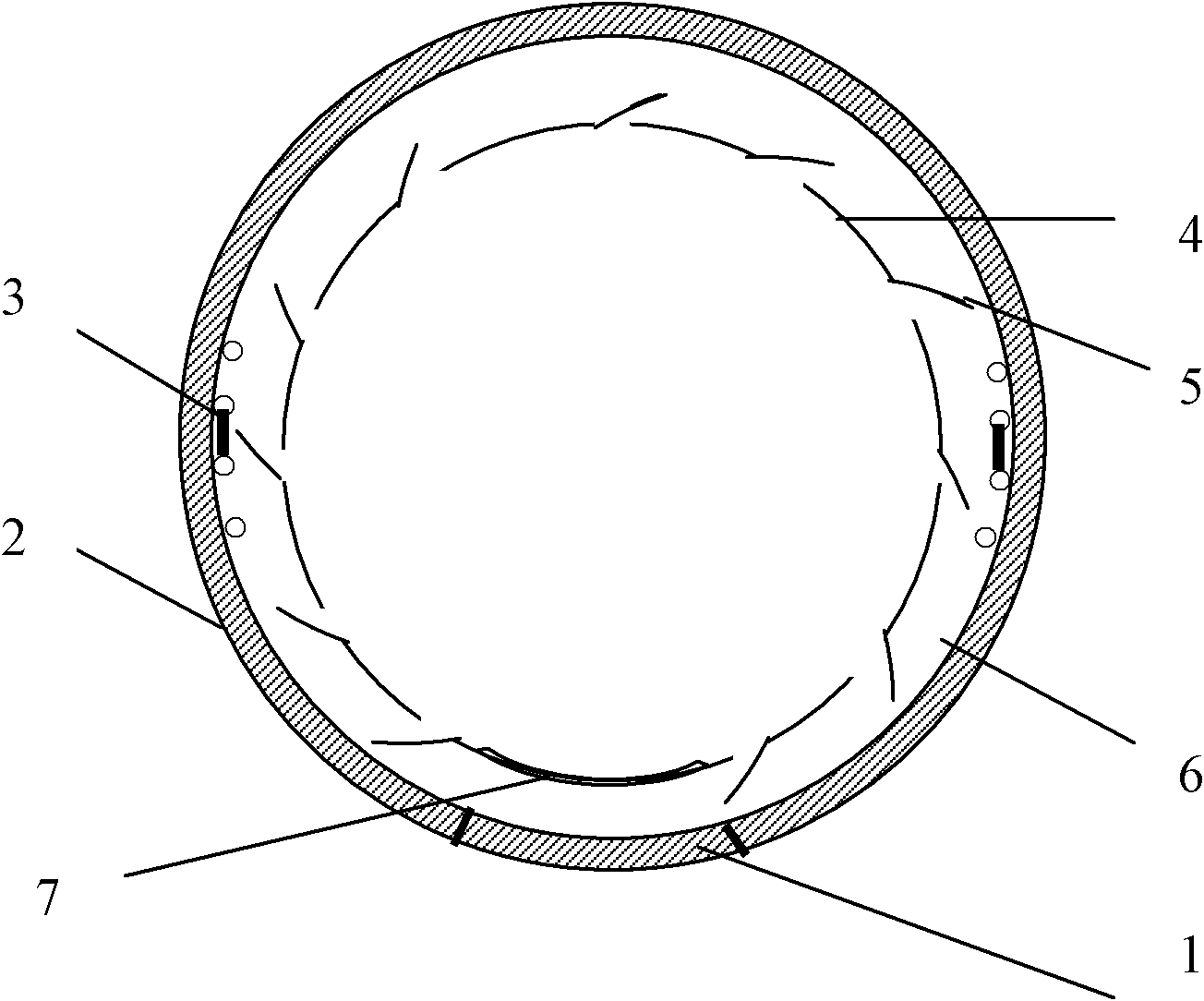

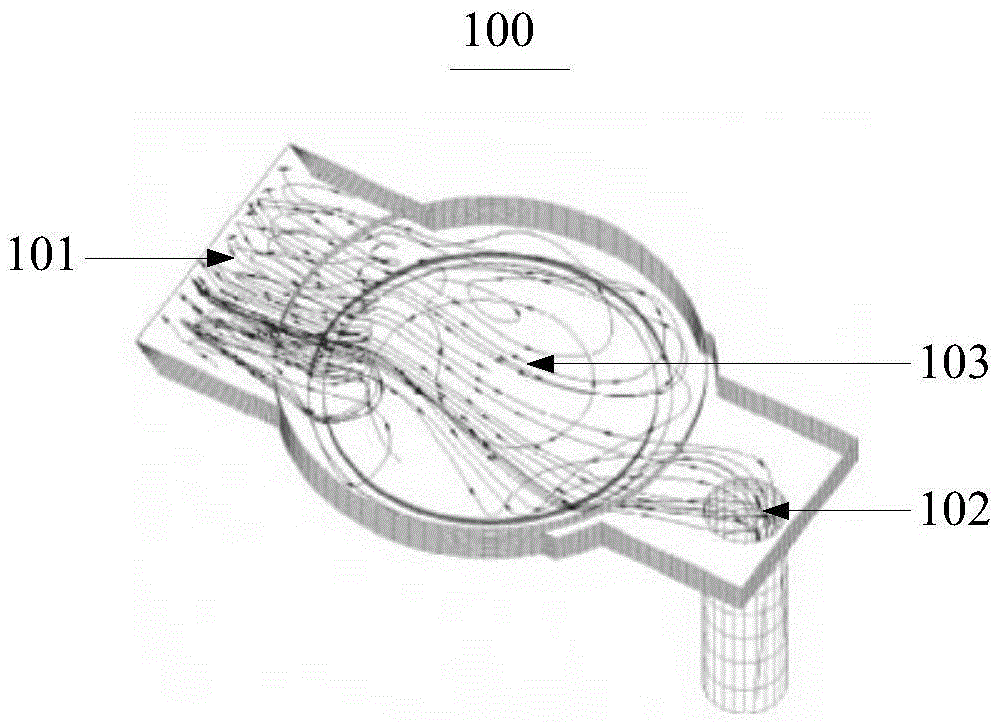

Electric thruster anode gas distributor

ActiveCN110360073AEnhanced inhibitory effectEven gas distributionMachines/enginesUsing plasmaDistributorAnode

The invention discloses an electric thruster gas distributor. The electric thruster gas distributor comprises a first welding screw, a second welding screw, a first gas inlet pipe, a second gas inletpipe, a first gas inlet pipe fixing seat, a second gas inlet pipe fixing seat, a distributor lower bottom and a distributor upper bottom, wherein a plurality of pairs of fixing key grooves, a circumferential gas conveying groove, a first gas inlet hole, a second gas inlet hole, a first counter bore, a second counter bore and radial gas conveying grooves are formed in the inner circumference and the outer circumference of the distributor lower bottom; and fixing keys corresponding to the plurality of pairs of fixing key grooves, a 0.32 mm jet hole, a 0.46 mm jet hole, a 0.56 mm jet hole, a 0.6mm jet slit and a 1 mm flow blocking plate are arranged on the inner circumference and the outer circumference of the distributor upper bottom. According to the technical scheme of the electric thruster gas distributor, the distribution of the gas flow can be controlled so as to achieve more uniform gas distribution, and a uniform and stable neutral particle environment is provided for an electricthruster.

Owner:BEIHANG UNIV

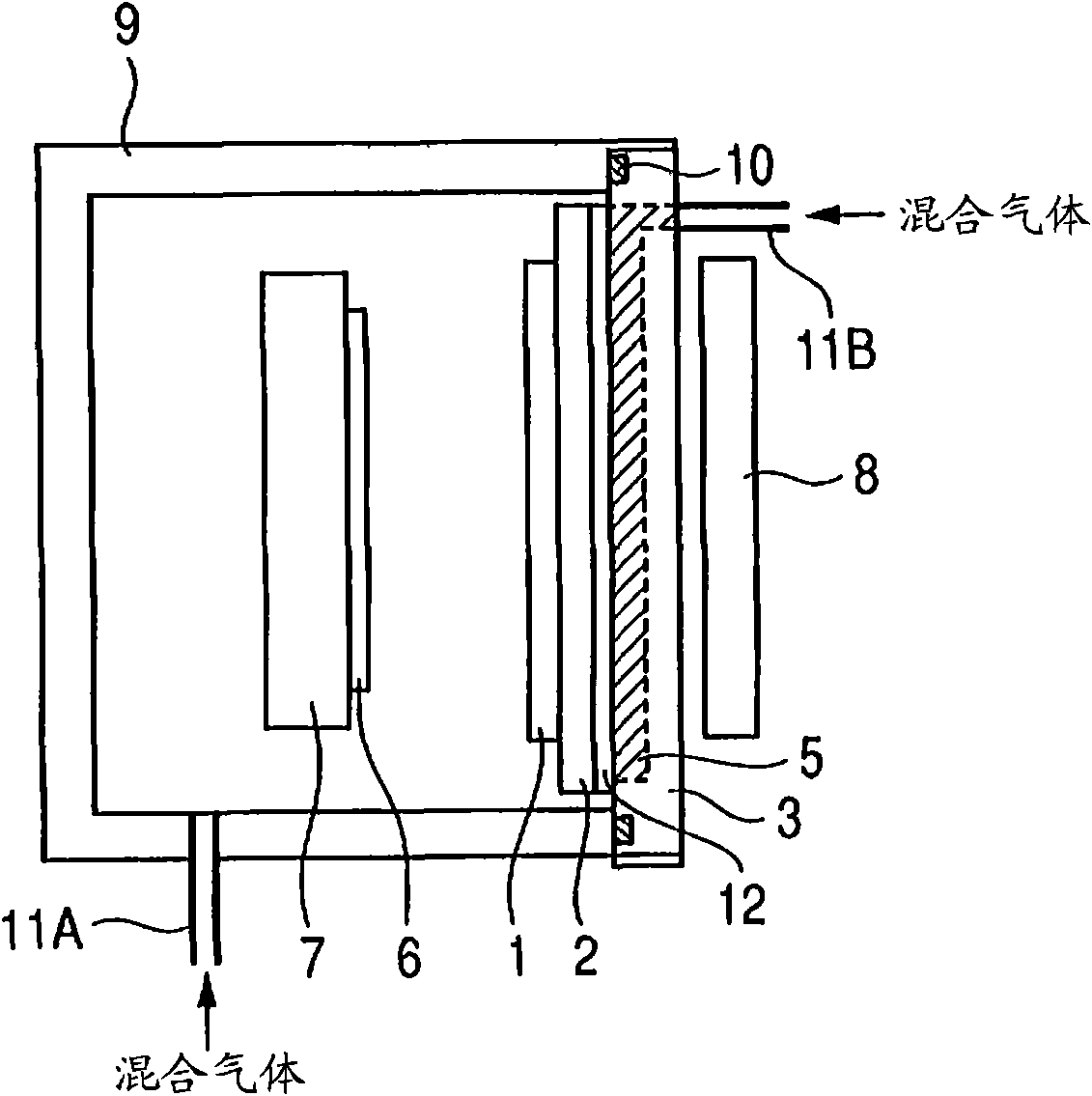

Sputtering apparatus and thin film formation method

ActiveCN101778961AEven gas distributionReduce sputteringElectric discharge tubesVacuum evaporation coatingSputteringEngineering

Owner:CANON ANELVA CORP

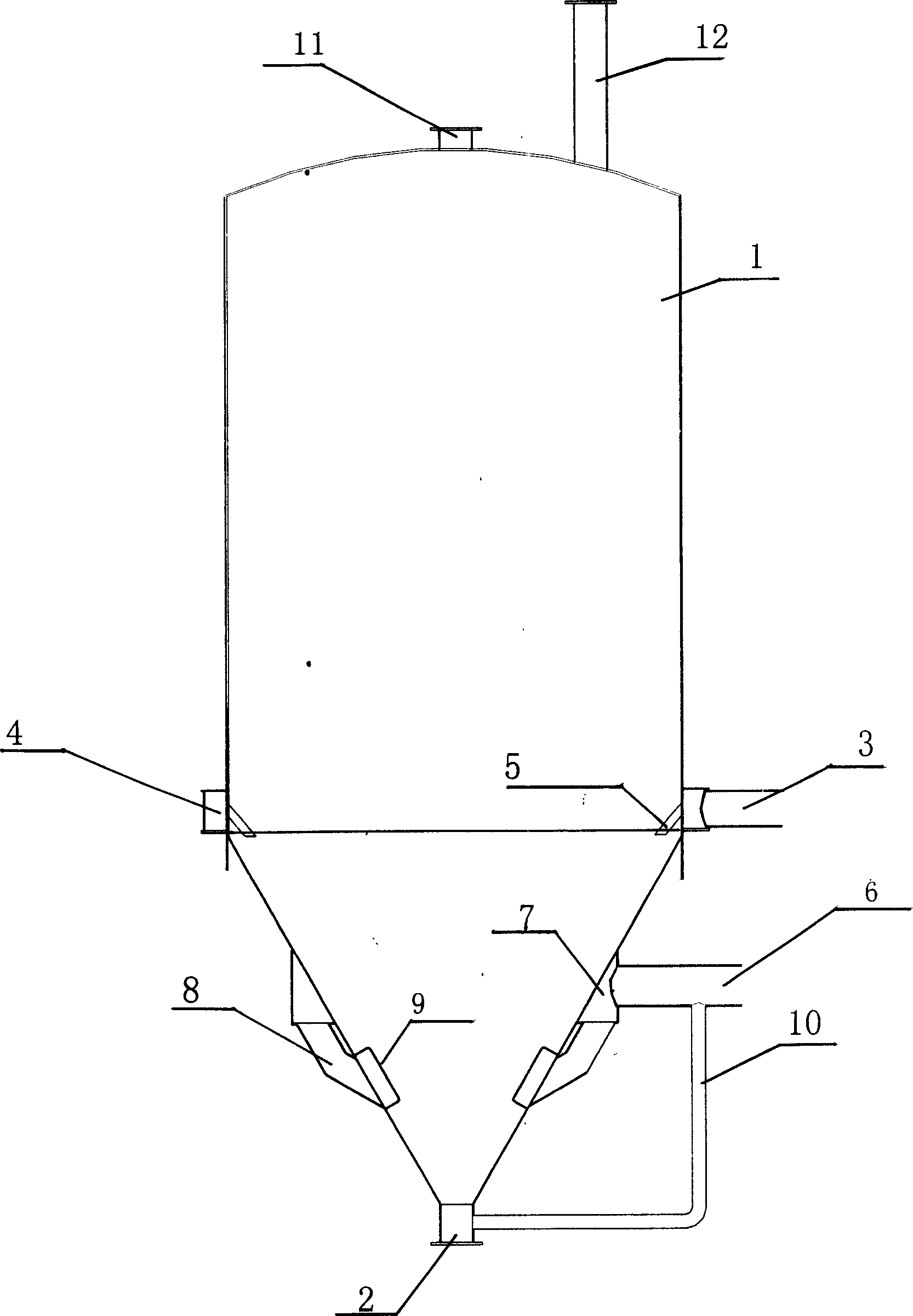

Ventilation uniform petrochemical bunker

The invention is a uniformly ventilating petroleum chemical bin. There is a taper section below the bin, a pouring opening at narrow end the taper section, a ring air pipe on the upper edge of the taper section, a main ventilating pipe of route one by a side of the ring pipe. Several counter-blowing tuyere noses are uniformly distributed along the ring air pipe. A feeding hole and an air gate is on the top of the bin and features that main ventilating pipe of route 2 installed on the same conical surface of route 1 connects with the ring air pipe, several counter-blowing tuyere noses of route 2 are uniformly distributed on the above cone, under these noses inside the taper section baffle board of route 2 tuyere noses is installed in a parallel with the conical surface, the pouring opening is connected to the route 2 main air pipe. The invention bin ventilates uniformly so to enhance the efficiency of exhausting, overcome the flaws of the existing bin that the ventilation is not uniform, dead band exists, the combustible gas can not be exhausted from the air gate, the gas inside the bin is hyper-concentrated, so that the bin is more safe.

Owner:CHINA PETROLEUM & CHEM CORP

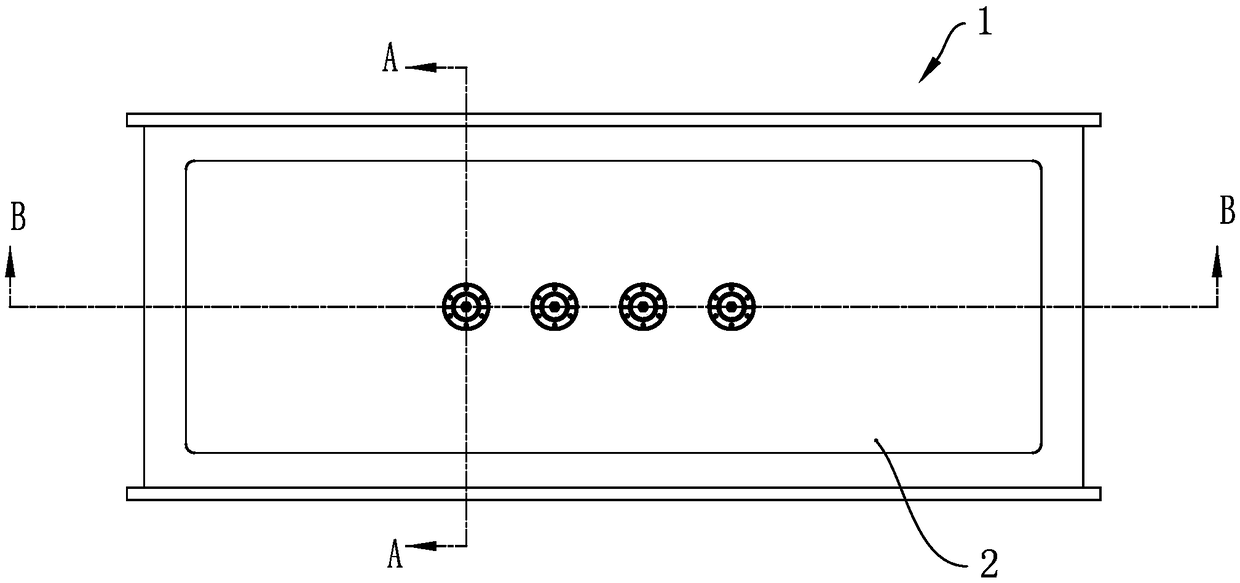

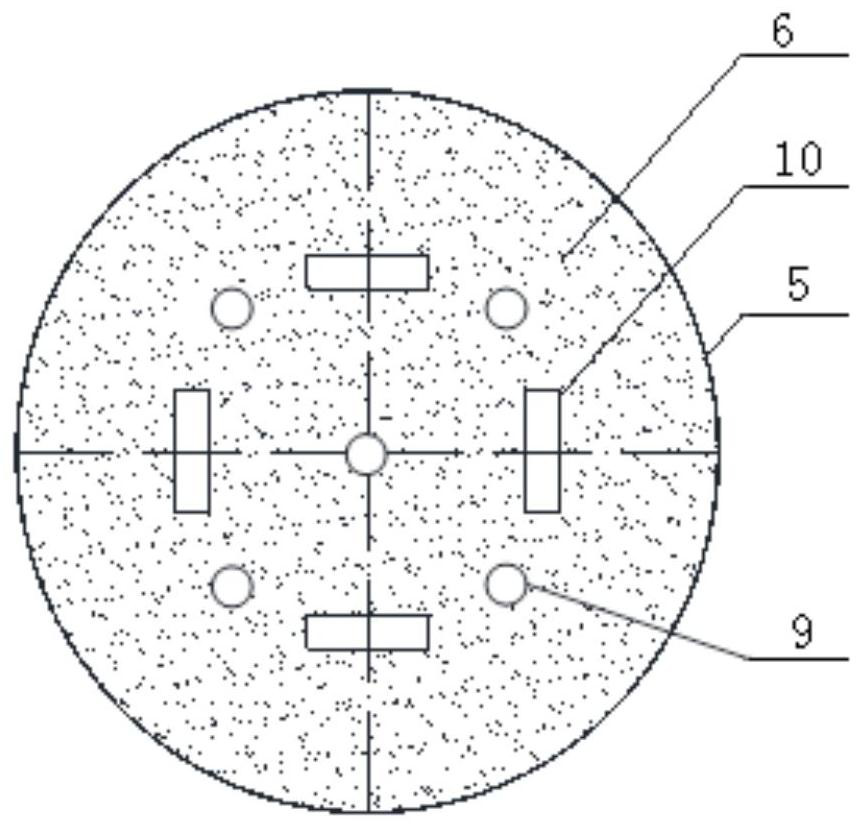

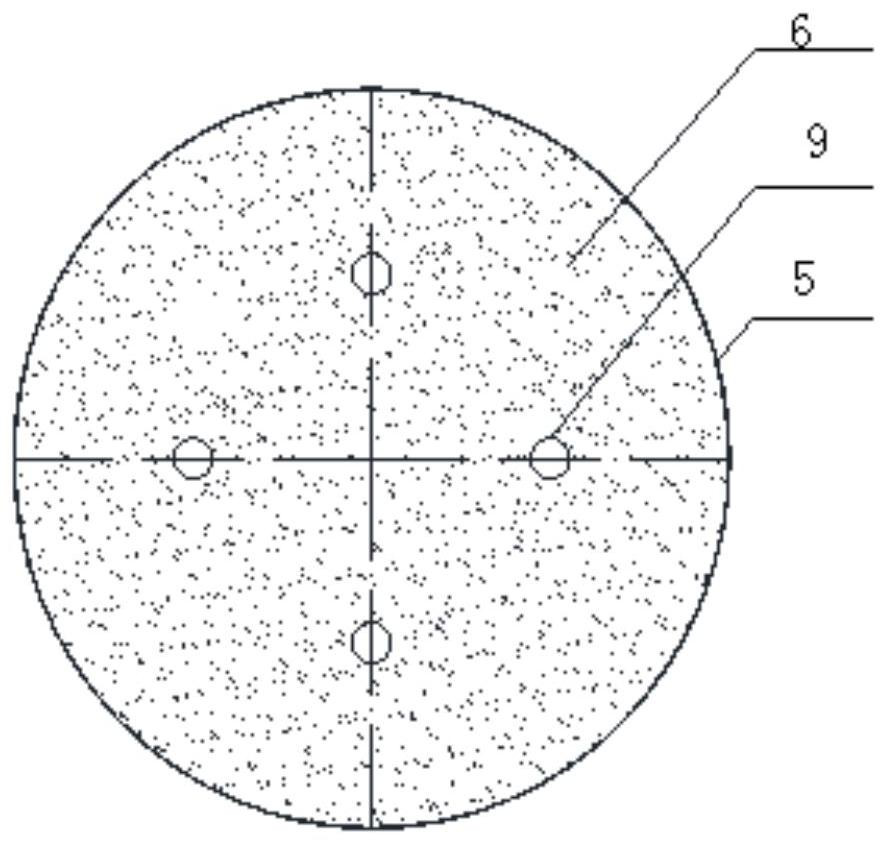

Fischer-Tropsch synthesis fluidized bed reactor

ActiveCN111286355AIncrease disturbancePlay a chilling roleLiquid hydrocarbon mixture productionChemical/physical processesPtru catalystFluidized bed

The invention relates to a Fischer-Tropsch synthesis fluidized bed reactor, wherein the fluidized bed reactor comprises a reactor cylinder and an internal component arranged in the reactor cylinder, and the internal component comprises a gas distribution mechanism, a heat exchange mechanism, a solid catalyst separation and circulation mechanism and a catalyst online feeding and discharging mechanism; the gas distribution mechanism comprises a first-stage gas distributor, a second-stage gas distributor and a third-stage gas distributor which is arranged in a main reaction dense-phase region ofthe fluidized bed reactor; the first-stage gas distributor and the second-stage gas distributor are arranged at the bottom of the reactor cylinder; a gas nozzle of the third-stage gas distributor transversely sprays gas to transversely cut longitudinally rising gas flow. Compared with the prior art, the reactor is reasonable in design structure and layout; the fluidized bed reactor is good in gas-solid contact in the reactor, uniform in fluid distribution, high in system heat transfer efficiency, uniform in temperature distribution, good in gas-solid separation effect, high in system operationflexibility and particularly suitable for design and operation of the large-scale Fischer-Tropsch synthesis fluidized bed reactor, and cavities in the fluidized bed reactor are avoided.

Owner:YANKUANG ENERGY R&D CO LTD

Method for preparing hydroxylamine

ActiveUS20070231240A1High yieldEnhanced mass transferOrganic chemistryNitrogen compoundsHydrogenHydroxylamine

A method for preparing hydroxylamine by reducing nitric acid or its salt with hydrogen gas in an aqueous medium in the presence of a catalyst, wherein reduction of nitric acid or its salt is performed in a reactor comprising a reaction section, a cooler disposed at the lower portion of the reactor, and a middle gas distributor and a lower gas distributor respectively disposed above and below the cooler for introducing hydrogen gas into the reaction section. According to the present invention, gas distribution become more uniform by disposing the gas distributors at different positions of the reactor, which results in higher yield of hydroxylamine.

Owner:CHINA PETROCHEM DEVMENT

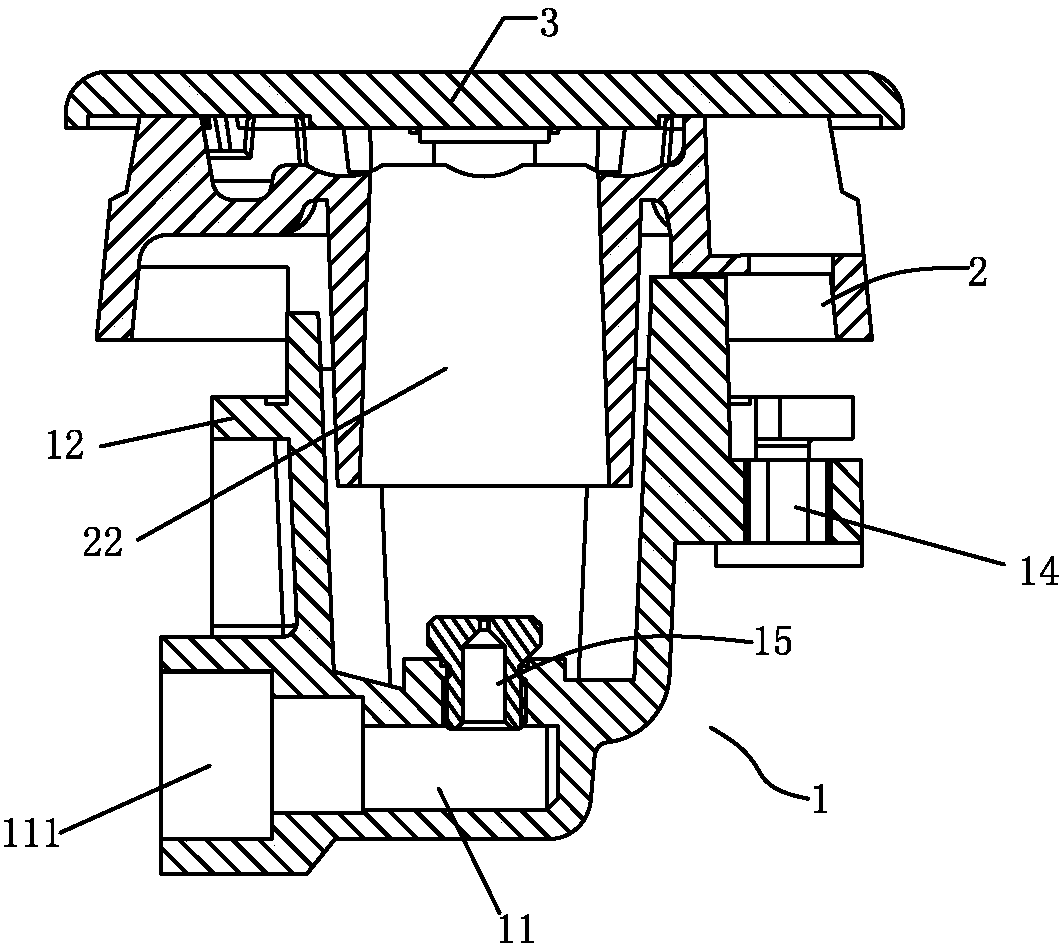

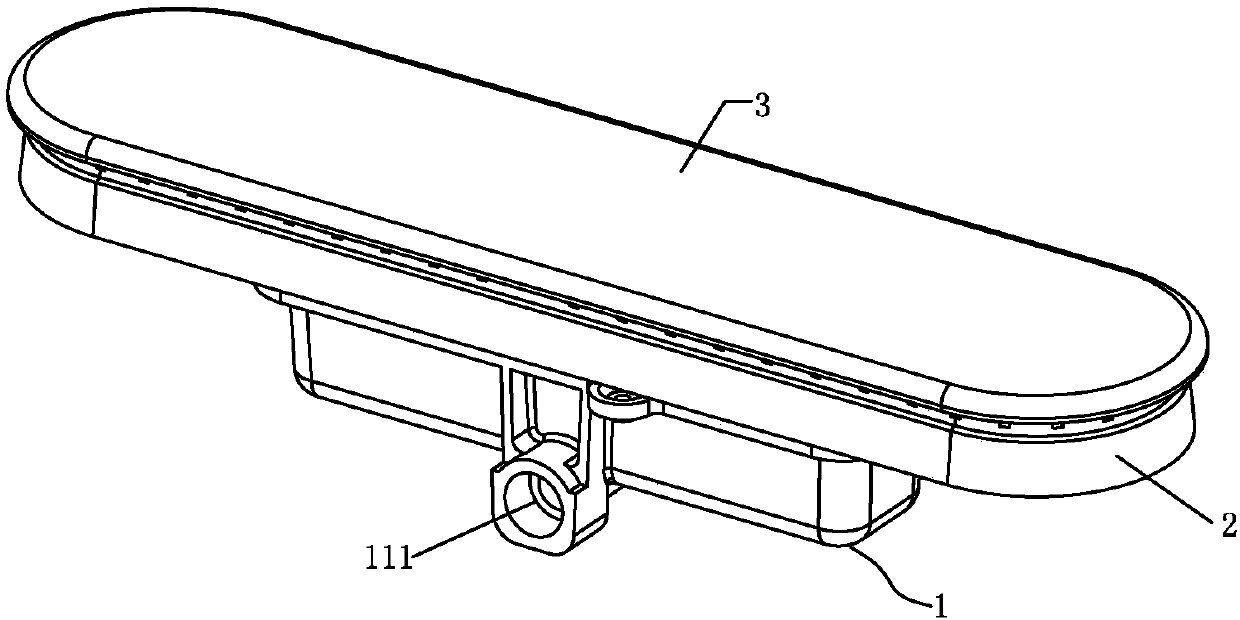

Strip-shaped stove combustor

PendingCN107741034AEven gas distributionNormal burningDomestic stoves or rangesCooking fumes removalCombustion chamberCombustor

The invention discloses a strip-shaped stove combustor. The strip-shaped stove combustor comprises a bottom cup with a top opening, a fire distributor and a combustor cap; the bottom cup comprises anair inlet channel, a flange, an ignition needle seat, a thermocouple seat and a spraying nozzle; an air inlet connector is arranged at an air inlet end of the air inlet channel; an air outlet end of the air inlet channel is positioned in the centre of the bottom plate of the bottom cup; the fire distributor comprises a combustion chamber with an upper opening, an injection pipe which communicateswith the combustion chamber and a bracket which is positioned on a lower surface; a combustion groove is formed in the wall of the combustion chamber; the bottom cup, the fire distributor and the combustor cap have length and width and are strip-shaped; an annular groove is formed in the lower surface of the combustor cap; flow division bumps are formed in the bottom plate of the combustion chamber; the flow division bumps extend to the two sides of the length direction by taking the centre in the length direction of the combustion chamber as a starting point; gaps between the flow division bumps and the combustor cap are increased gradually; the upper end of the combustion chamber extends into the annular groove. Gas in the combustion chamber is distributed uniformly and can combust normally; moreover, the combustion area is large; and the fire is strong.

Owner:中山市沙贝特科技有限公司

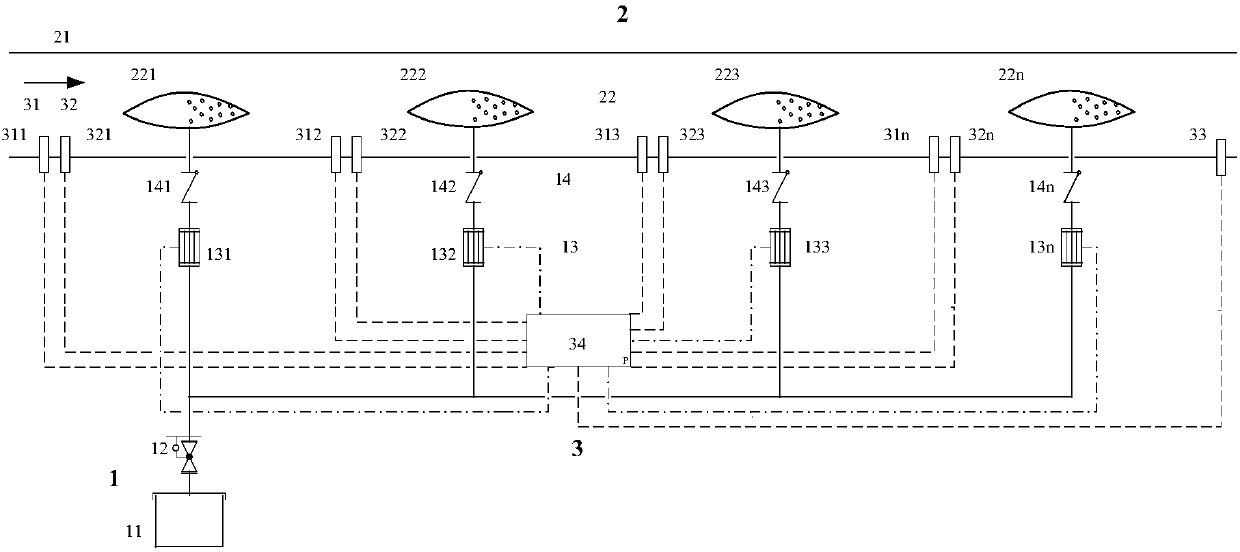

High-pressure pipeline gas and liquid reactor for hydrogen sulfide treatment of oil well and treatment method thereof

ActiveCN107913648AIncrease profitImprove solubilityRefining with non-metalsLiquid-gas reaction processesAutomatic controlTherapeutic effect

The invention belongs to the field of safety production and environment protection, and particularly relates to a high-pressure pipeline gas and liquid reactor for hydrogen sulfide treatment of an oilwell and a treatment method thereof. The high-pressure pipeline gas and liquid reactor consists of a gas supply unit, a dissolved gas mixing reaction unit and an automatic control unit, wherein the gas supply unit is connected with the dissolved gas mixing reaction unit, and is used for supplying required oxygen for the dissolved gas mixing reaction unit; the automatic control unit is used for detecting the contents of hydrogen sulfide and dissolved oxygen in each node of the dissolved gas mixing reaction unit, and controlling the supply amount of oxygen in each node of the dissolved gas mixing reaction unit. The high-pressure pipeline gas and liquid reactor has the advantages that the equipment is compact, and the land occupation area is small; the automation degree is high, and the maintenance is convenient; the treatment is performed at high pressure, the pressure-relief releasing and pressurizing transportation process of the hydrogen sulfide gas is not needed, and the energy consumption is low; by adopting the multiple stages of gas supply, the gas is uniformly distributed, the gas dissolving efficiency is high, the utilization rate of the gas is high, the treatment effect isgood, and the removal rate of the hydrogen sulfide reaches 99.5% or above; the high-pressure pipeline gas and liquid reactor can be widely applied into the hydrogen sulfide treatment technology of the oil well.

Owner:CHINA PETROLEUM & CHEM CORP +1

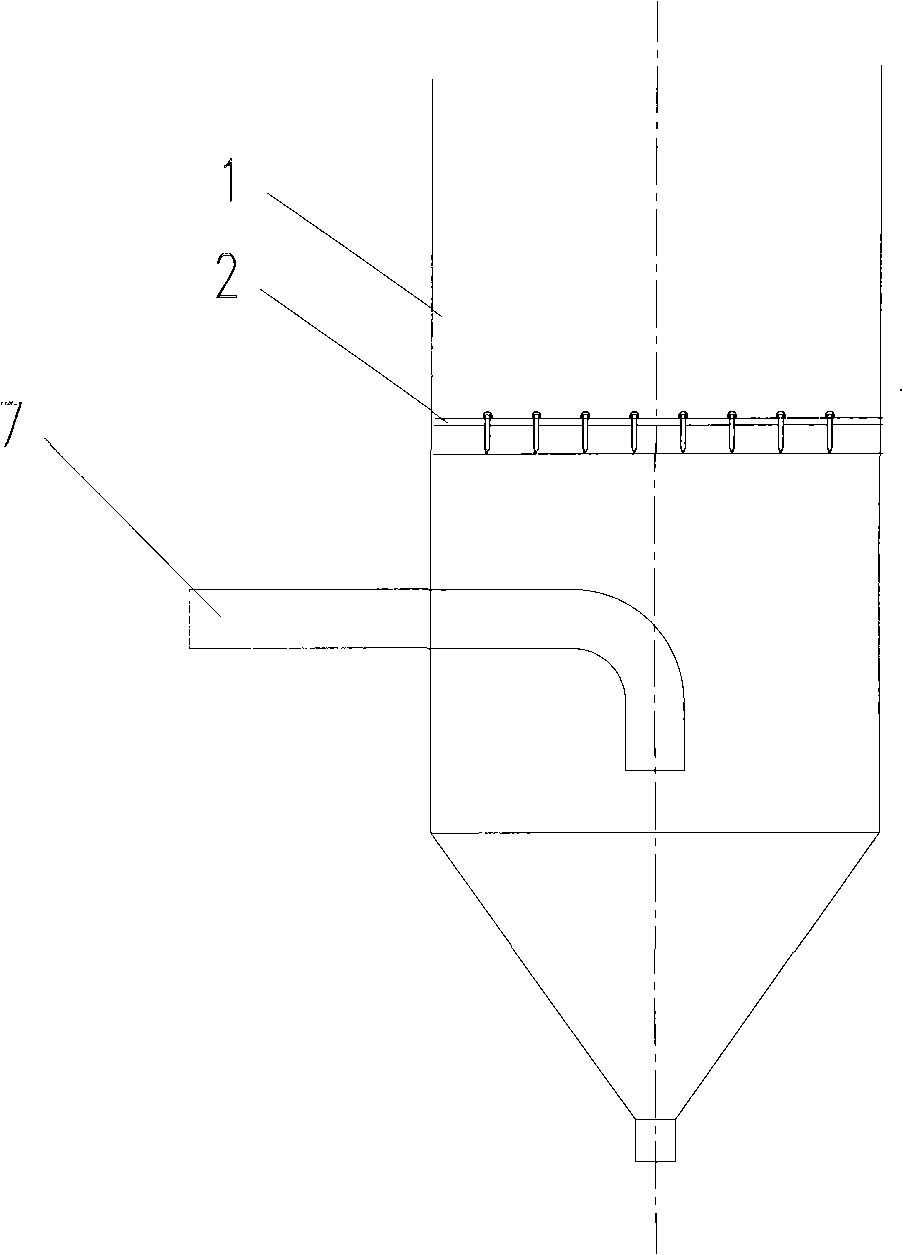

Up-flow reactor and application thereof

ActiveCN101632911BEvenly distributedSimple structureHydrocarbon oils refiningChemical/physical processesWaxShortest distance

The invention discloses an up-flow reactor, which comprises an initial distributor positioned at the bottom of the reactor and an intermediate distributor above the initial distributor. The initial distributor consists of a conical traverse baffle and a sieve plate positioned above the conical traverse baffle; and the intermediate distributor consists of an open pore sieve plate and a sieve platestring structure. The up-flow reactor provided by the invention can realize even distribution of gas in the reactor in short distance so as to improve the utilization rate of a catalyst and increase the space of a catalyst bed layer in the reactor. The up-flow reactor of the invention is particularly applied to a hydrogenation process of heavy oil (comprising wax oil, residual oil, coal liquefiedoil and the like).

Owner:CHINA PETROLEUM & CHEM CORP +1

Desulfurization tower flow field simulation method

InactiveCN111760445AEven gas distributionImprove desulfurization efficiencyGas treatmentDispersed particle separationEngineeringPorous medium

The invention provides a desulfurization tower flow field simulation method. The method is characterized in that a flow field simulation experiment system is established on the basis of a uniform gasinlet device, and detailed flow field analysis is carried out on a desulfurization tower. The uniform gas inlet device can improve the gas distribution in the desulfurization tower, so that the desulfurization efficiency is improved. According to the simulation method based on the experiment system, the measured spraying layer pressure drop serves as the simulation pressure drop, the resistance coefficient of a porous medium is determined through formula fitting, and a data basis is provided for equivalent replacement of the spraying layer, so simulation is more rigorous and accurate. In the simulation process, pressure sampling is carried out through section point taking, and the pressure drop of the spraying layer of the experiment system can be accurately obtained; the E value is used as a standard for judging the distribution uniformity of the gas in the tower, and the change condition of the E value of each section in the tower along with the tower height is obtained through quantitative calculation, so that the uniformity analysis result is intuitive and clear.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

A system for producing carbonates and a method for producing carbonates using the system

ActiveCN108484565BAchieving a reverse concentration differenceImprove conversion rateOrganic chemistryChemical/physical processesThermodynamicsPtru catalyst

The invention relates to a system for producing carbonic ester and a method for producing the carbonic ester by utilizing the system. The system comprises a first bubble tower, a second bubble tower and a heat exchanger, wherein the upper part of the first bubble tower is provided with a raw material and catalyst inlet and a first circulation inlet communicated with an outlet in the top of the heat exchanger, the lower part of the first bubble tower is provided with a second circulation inlet communicated with an outlet in the top of the second bubble tower, and the bottom of the first bubbletower is provided with a product outlet communicated with the lower part of the second bubble tower; the bottom of the second bubble tower is provided with a gas inlet, the upper part of the second bubble tower is provided with an overflow outlet, and the outflow outlet is communicated with the bottom of the heat exchanger and a discharge opening. By adopting the system to produce the carbonic ester, the standing time can be shortened, the reaction temperature and pressure can be lowered, the reaction efficiency and an EO (ethylene oxide) conversion rate can further be improved, and even 'zero' emission is realized, so that ethylene carbonate can be prepared from ethylene oxide and carbon dioxide in an environment-friendly mode.

Owner:CHINA NAT OFFSHORE OIL CORP +4

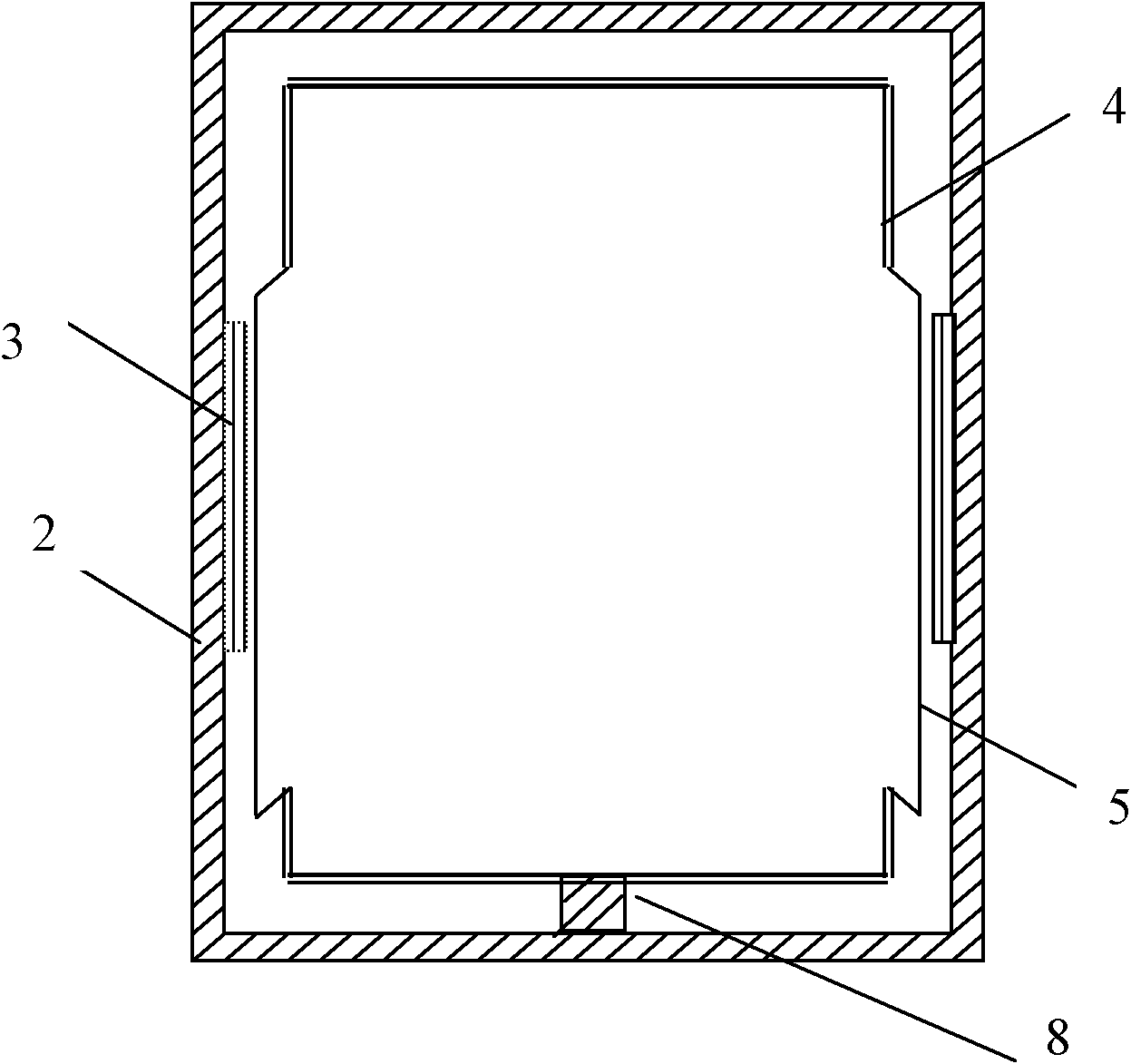

Centrifugal fruit and vegetable air-conditioning preservation box

InactiveCN101927869AAvoid chillingEven gas distributionLiving organism packagingPackaging under vacuum/special atmosphereEngineeringForced-air

The invention discloses a centrifugal fruit and vegetable air-conditioning preservation box, which comprises an outer-layer box body, an outer box body door, a rotating shaft, an inner cavity, an inner cavity door, a plurality of closable air windows and a plurality of groups of condensation pipes, wherein the outer-layer box body is cylindrical; the outer box body door is arranged on the outer-layer box body; the rotating shaft is arranged in the center of the bottom in the outer-layer box body; the inner cavity is cylindrical, and the center of the outside bottom is arranged on the rotating shaft; the inner cavity door and the closable air windows are formed on the inner cavity; and the plurality of groups of condensation pipes are arranged on the inner peripheral surface of the outer-layer box body. In the centrifugal fruit and vegetable air-conditioning preservation box, the inner cavity provided with the closable air windows rotates to force air in the box to flow, and the air in the inner cavity is exchanged with air in an interlayer through the closable air windows, so the cold damage possibly caused by direct contact of fruits and vegetables and strong cold air can be avoided, and the air in the whole preservation box is distributed uniformly; therefore, the preservation effect is good.

Owner:TIANJIN JIESHENG DONGHUI FRESH PRESERVATION TECH

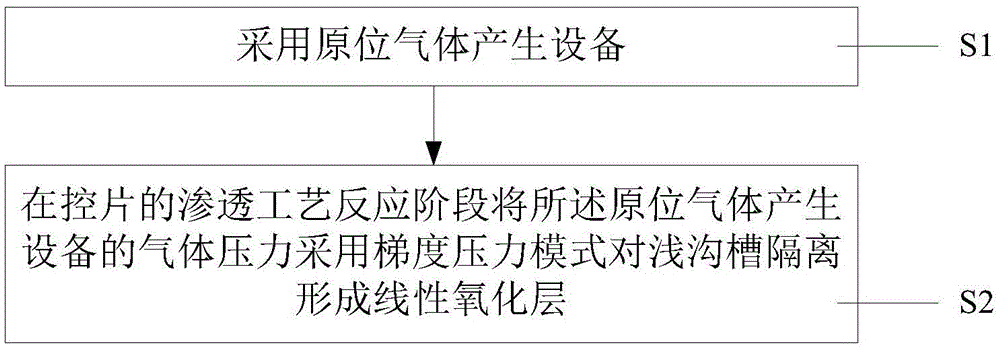

Method for improving film thickness uniformity in gradient pressure mode

ActiveCN105655287ALow costReduce test stepsSemiconductor/solid-state device manufacturingSteam pressureEngineering

The invention discloses a method for improving film thickness uniformity in a gradient pressure mode. The method comprises the following steps: S1, ISSG (in-situ steam generation) equipment is adopted; S2, in STI (shallow trench isolation) is realized through steam pressure of the ISSG equipment with the gradient pressure mode so as to form a liner oxidation layer in a penetration process reaction stage of a wafer. The film thickness uniformity of the liner oxidation layer for STI is improved, and the method has the effects that the cost is reduced, the working efficiency is increased and the product quality is improved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Device for composite adsorption microwave recovery or pyrolysis treatment of organic waste gas

ActiveCN109331564AEfficient removalImprove cleanlinessGas treatmentDispersed particle filtrationMicrowaveSorbent

The invention relates to an environmental protection device, and discloses a device for composite adsorption microwave recovery or pyrolysis treatment of organic waste gas. The device comprises a pretreatment unit and a plurality of parallel microwave treatment units; wherein the microwave treatment unit comprises a reaction box, an inlet tube, ceramic tubes, a microwave generator, a connecting tube, an outlet tube and a heat exchanger; the ceramic tubes are arranged in parallel in the reaction box; and the ceramic tubes are filled with active carbon layers and zeolite layers at intervals. Thepretreatment unit can automatically clean a filter medium contaminated. The microwave treatment units have high recovery and pyrolysis efficiency for organic pollutants, and the adsorbent can be repeatedly regenerated for use; and the device is simple, energy-saving, and low in operating cost. The device has great advantages in small and medium-sized volatile organic waste gas recovery and treatment projects.

Owner:义乌市爱釜义自动化科技有限公司

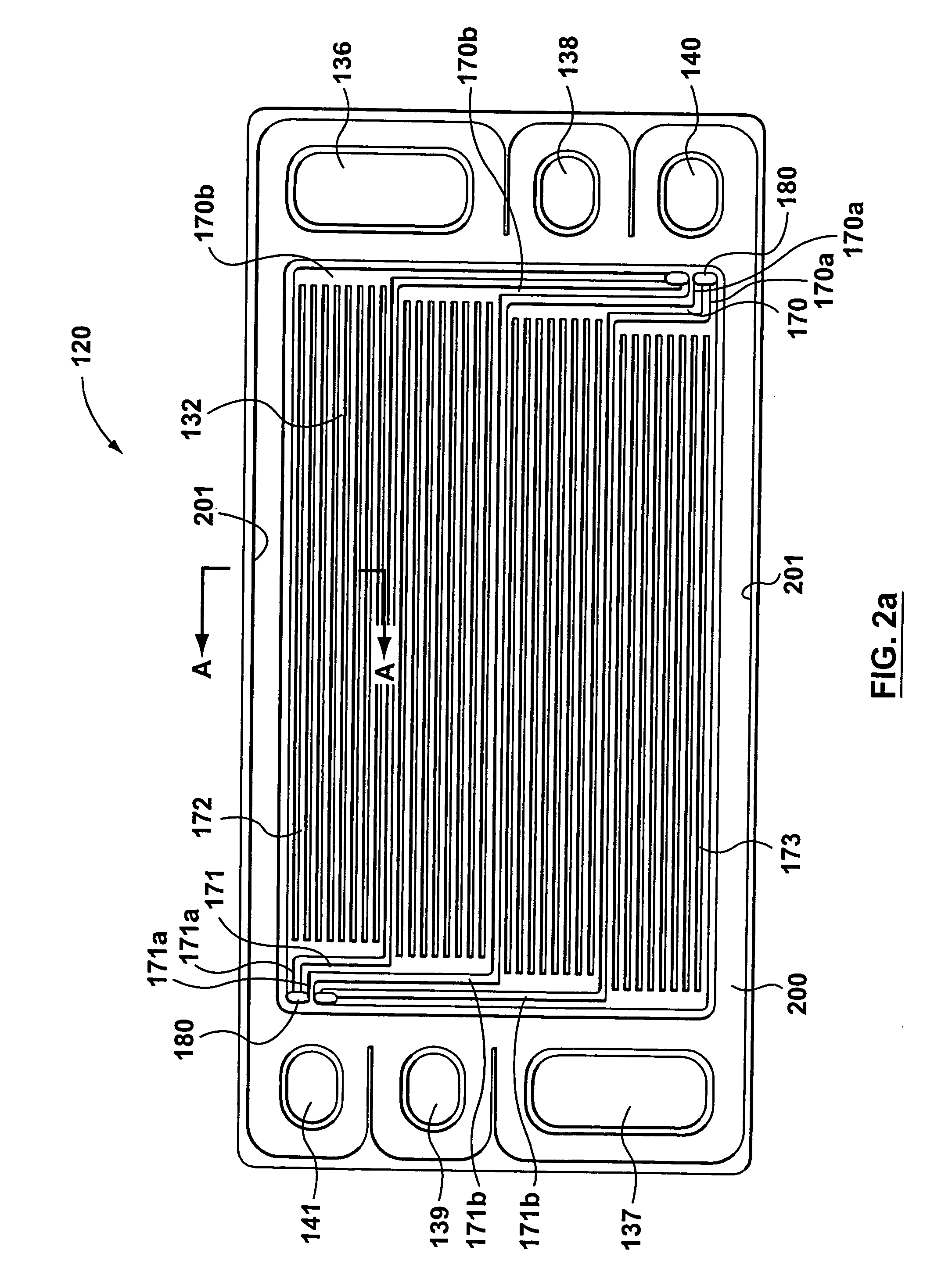

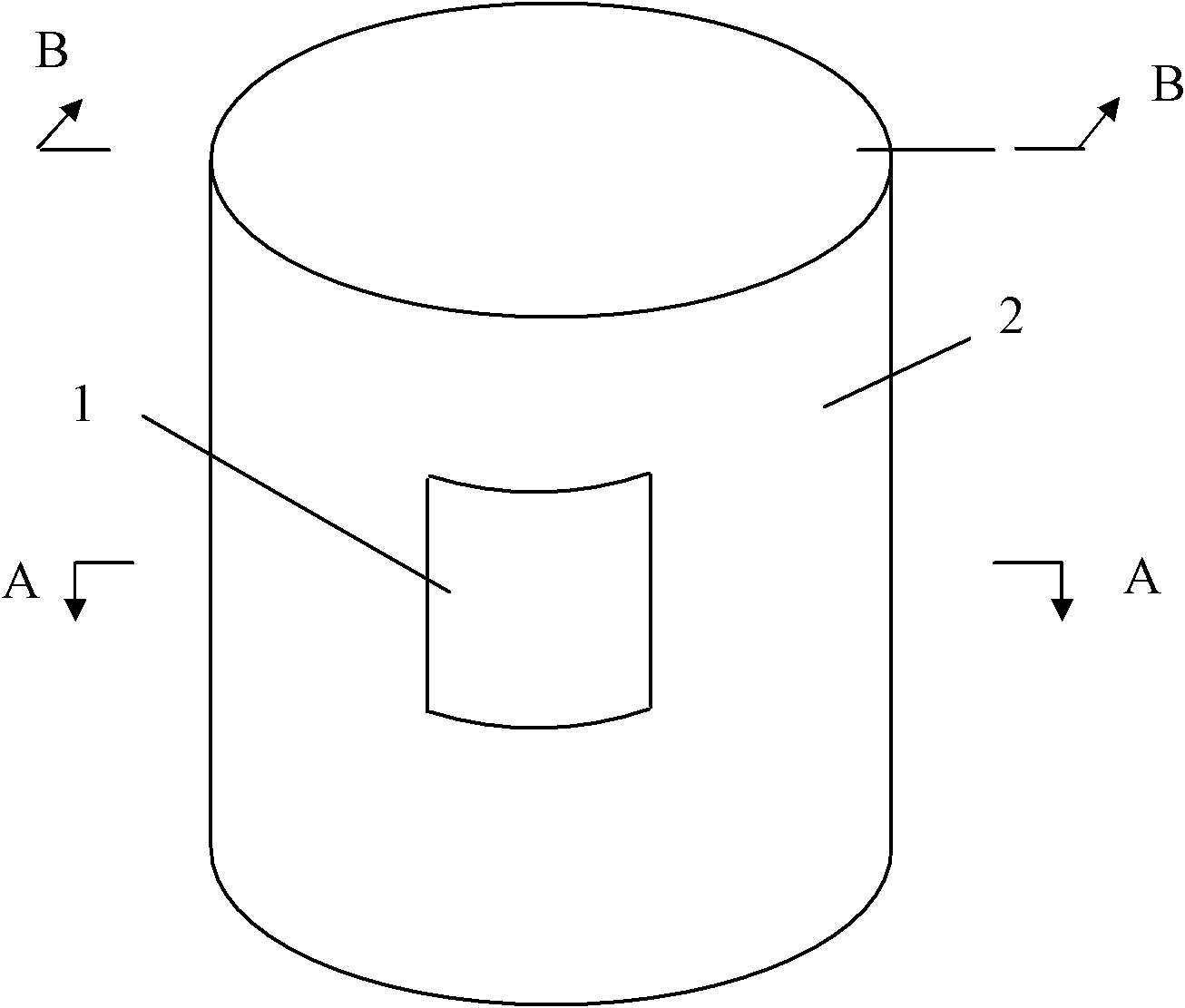

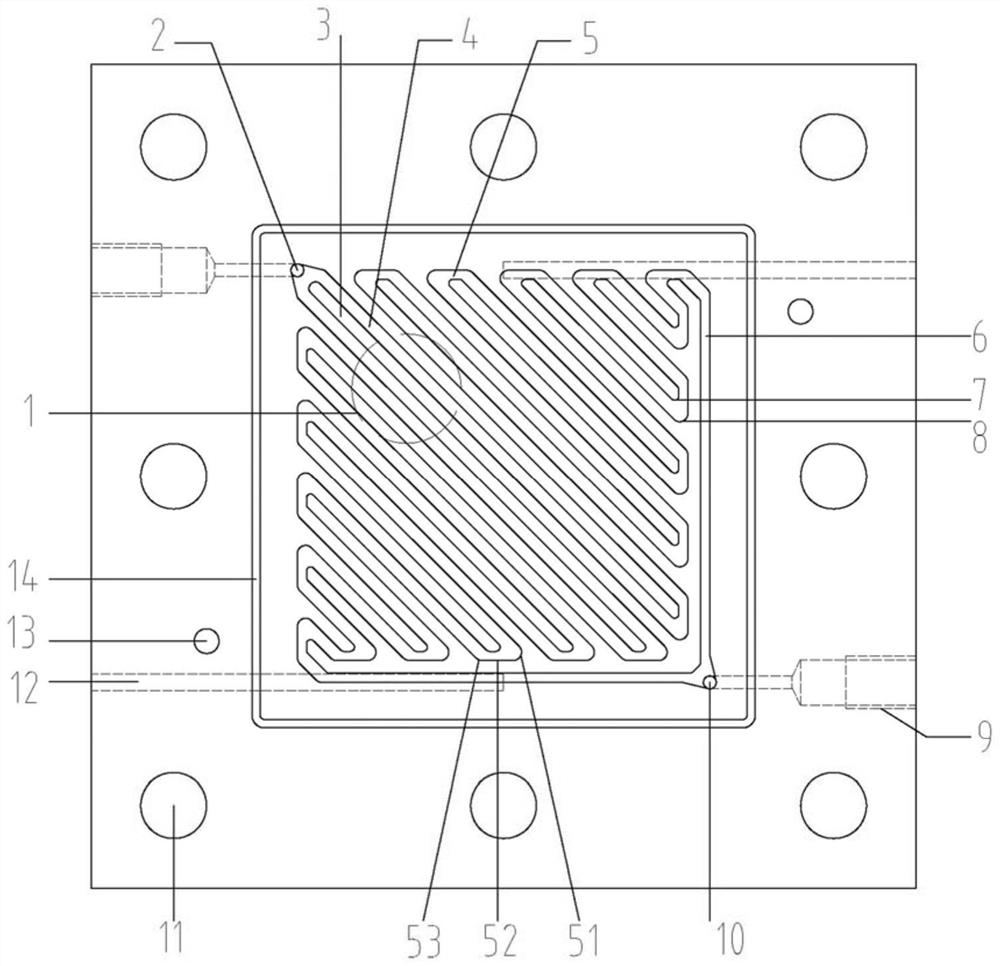

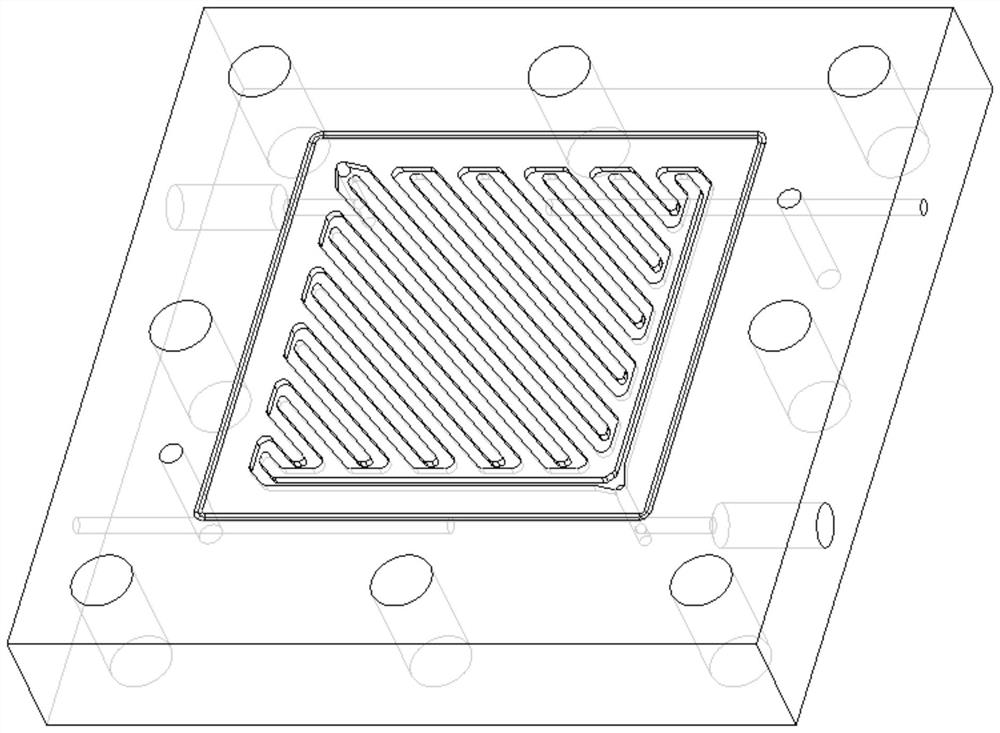

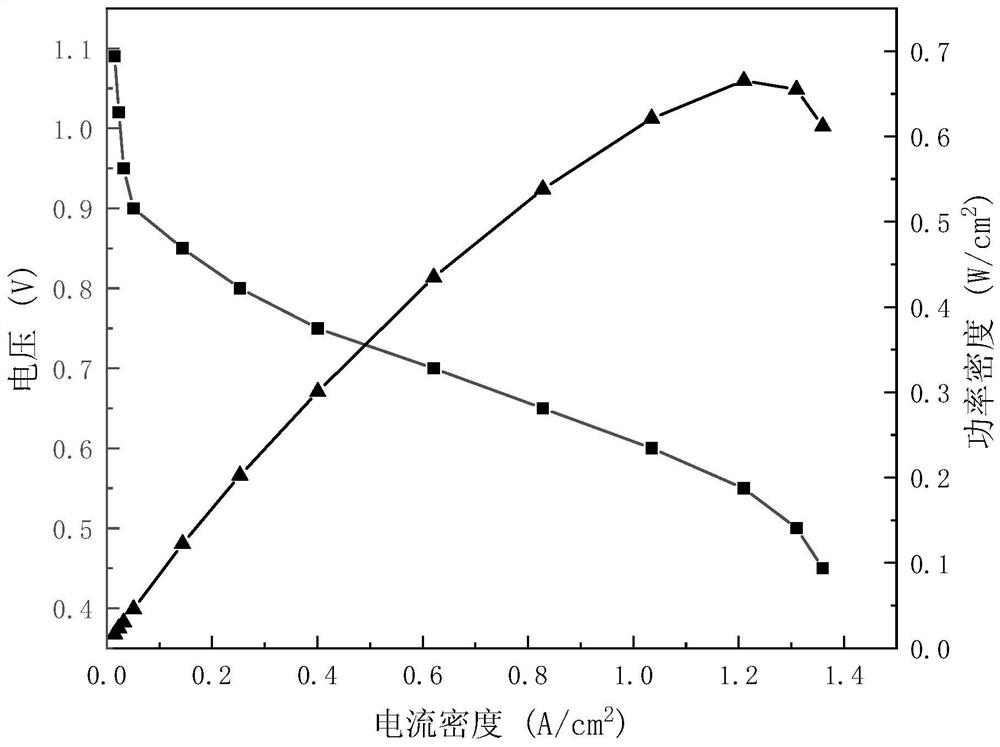

Proton exchange membrane fuel cell bipolar plate based on symmetrical serpentine structure flow field

ActiveCN112103531AImprove transmission performanceEven gas distributionWater management in fuel cellsGas transmissionMechanics

The invention discloses a proton exchange membrane fuel cell bipolar plate based on a symmetrical serpentine structure flow field. The bipolar plate comprises a gas flow field (1) and is characterizedin that the gas flow field (1) is symmetrically distributed in a serpentine shape; a reaction gas inlet (2) and a generated product outlet (10) of the gas flow field (1) are respectively positioned at two ends of one diagonal line of the gas flow field (1) and are diagonally distributed, and a ridge (3) positioned in a connecting line of the reaction gas inlet (2) and the generated product outlet(10) divides a flow channel starting from the reaction gas inlet (2) into two parts of snake-shaped flow channels which are symmetrically arranged. Compared with a traditional snakelike flow field, the symmetrical snakelike structure flow field overcomes the defect that the pressure drop of the snakelike flow field is large, enhances the gas transmission performance, enables the gas distributionto be more uniform, improves the generated water discharge performance of the fuel cell, enables the overall current density distribution to be more uniform, and thus improves the overall performanceof the fuel cell.

Owner:NANJING UNIV OF TECH

Method for composite adsorption microwave recovery or pyrolysis treatment of organic waste gas

ActiveCN109331565AEfficient removalImprove cleanlinessGas treatmentDispersed particle filtrationActivated carbonHigh concentration

The invention relates to an environmental protection device, and discloses a method for composite adsorption microwave recovery or pyrolysis treatment of organic waste gas. Volatile organic pollutantsin the waste gas are adsorbed by a composite adsorbent loaded in a ceramic tube, so that the method is suitable for the treatment of both low-concentration large-volume organic waste gas and high-concentration organic waste gas. The low-concentration organic waste gas can be firstly adsorbed, enriched, then desorbed and pyrolyzed (or recovered); and the high-concentration organic waste gas can beadsorbed, desorbed and pyrolyzed simultaneously, in order to achieve the highest efficiency with the lowest energy consumption. Active carbon and zeolite are arranged at intervals, thereby avoiding the disadvantage that the radiation depth of microwave is affected by the fact that the single active carbon used at present absorbs the microwave, and improving the efficiency of the microwave.

Owner:义乌市爱釜义自动化科技有限公司

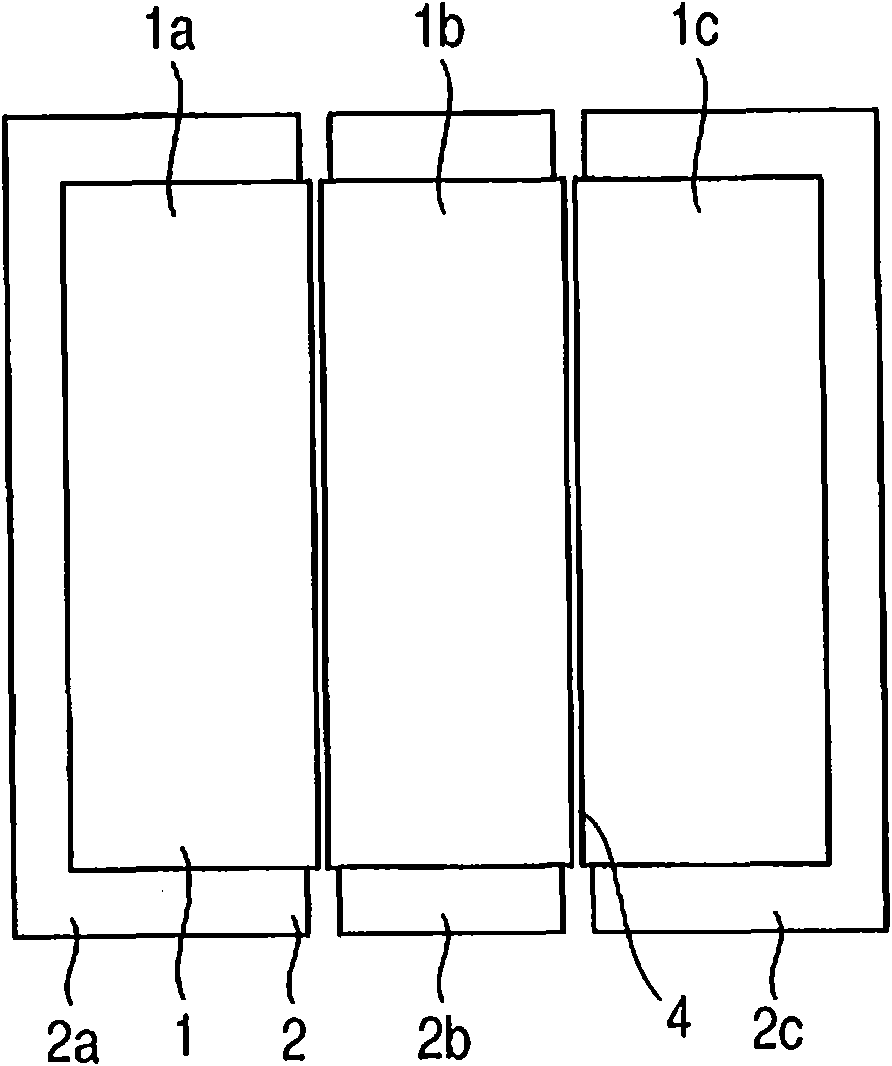

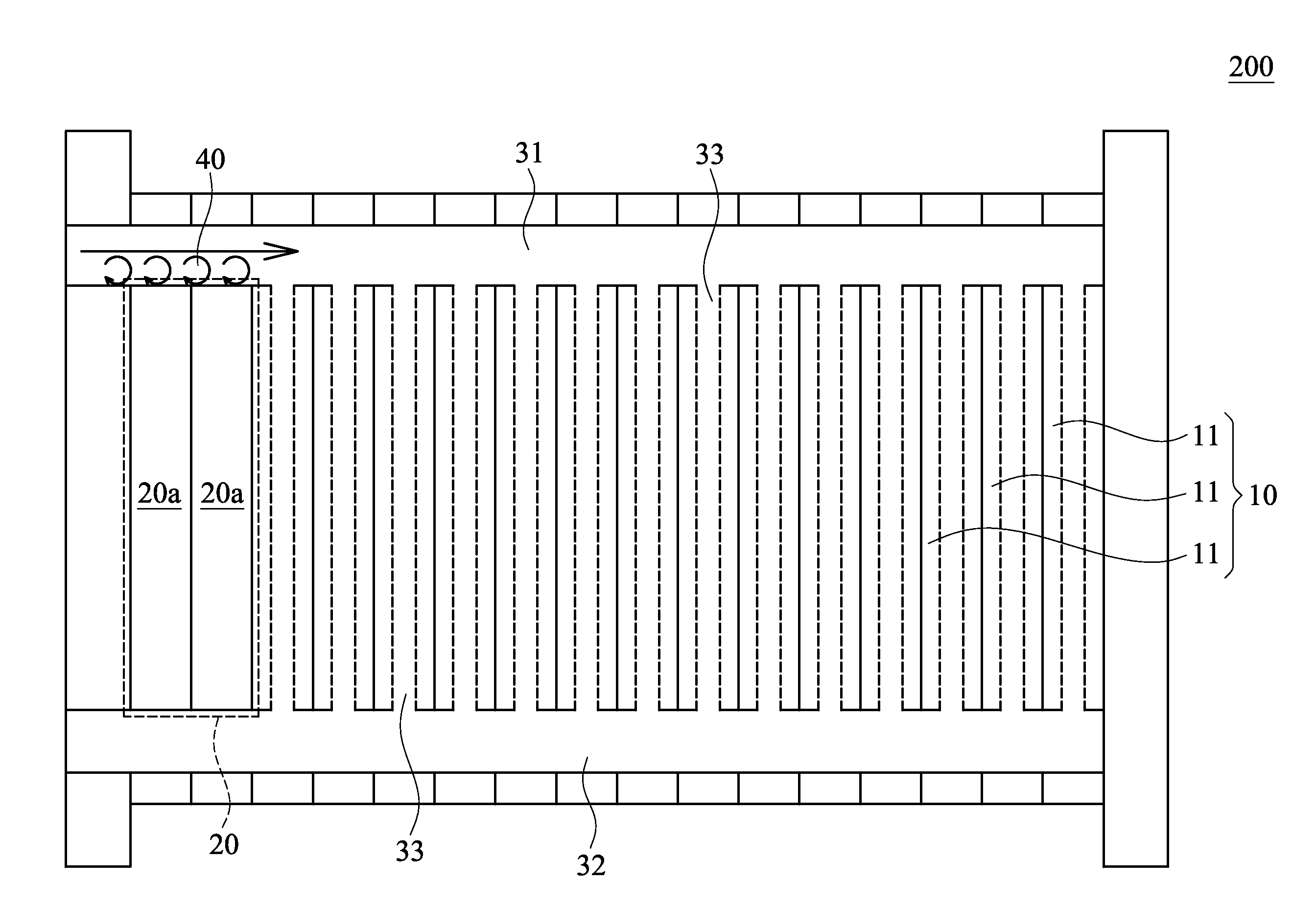

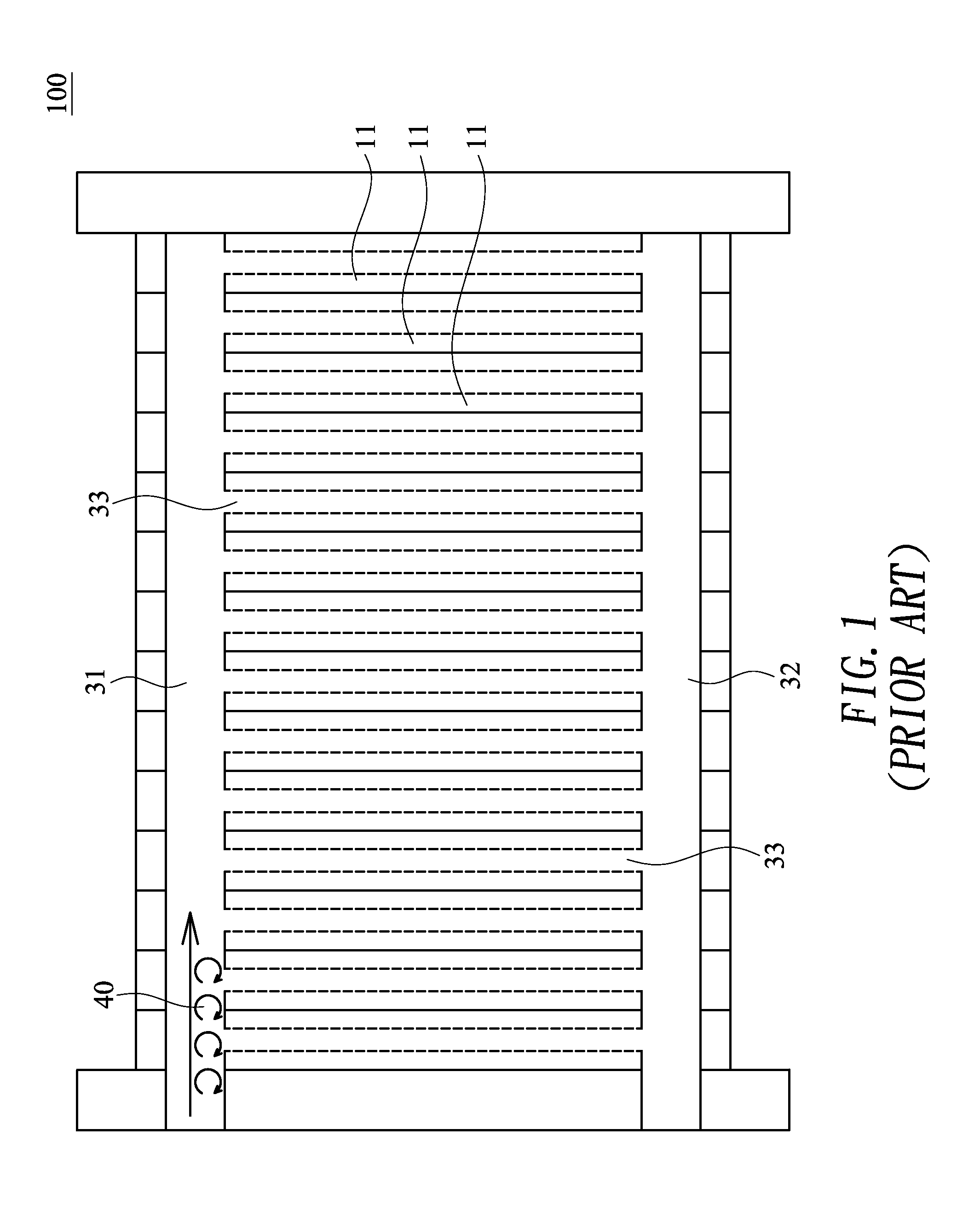

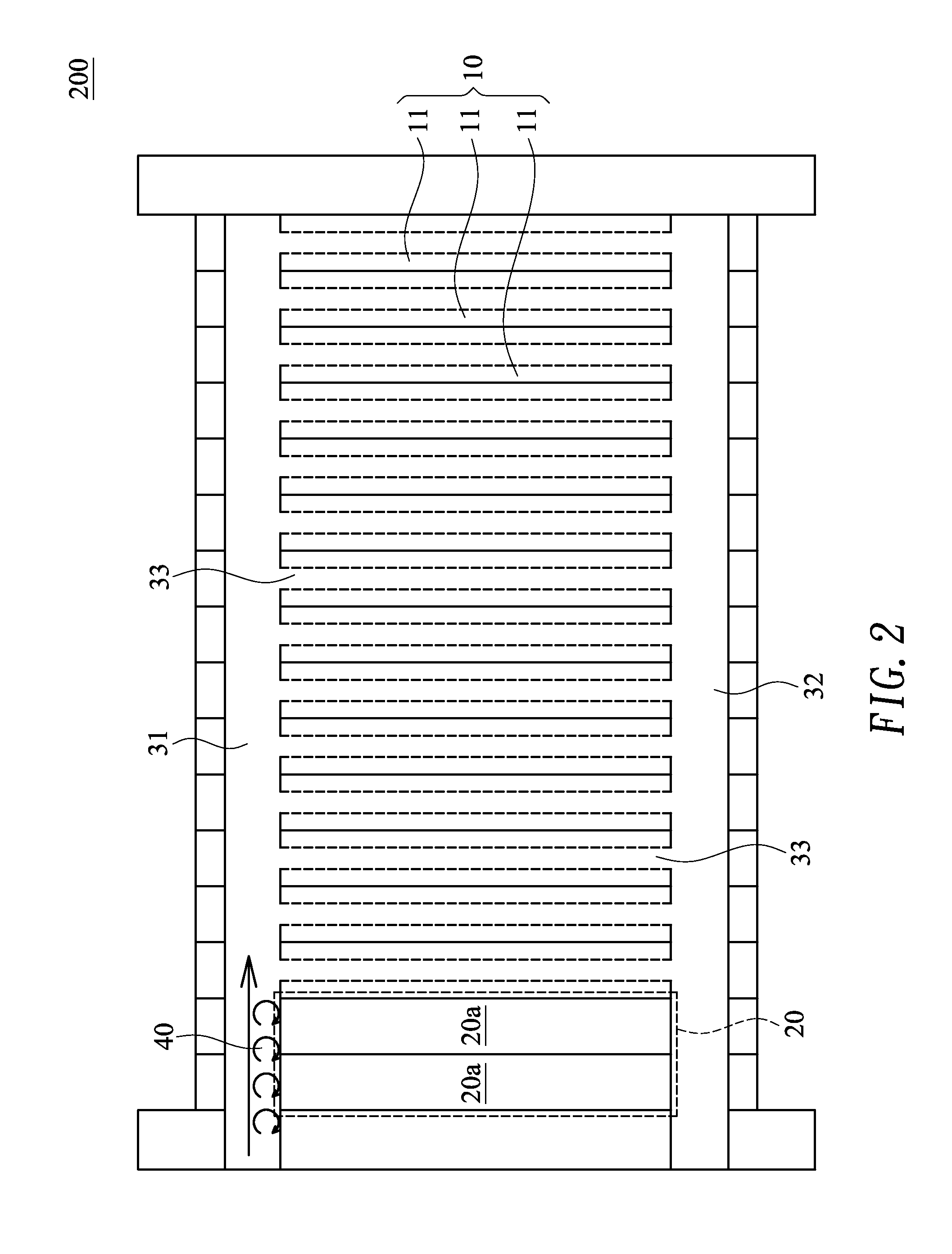

Fuel cell stack with uniform gas distribution in main flow channels thereof

InactiveUS20110223511A1Avoid it happening againImprove powerFuel cells groupingCell component detailsFuel cellsEngineering

A fuel cell stack with uniform gas distribution in main flow channels thereof includes a cell stack and an anti-eddy current unit. The cell stack is composed of a plurality of cell units and has an admission flow channel for importing fuel gas. The anti-eddy current unit is provided in the cell stack and situated at the admission end of the admission flow channel to promote fuel gas distribution uniformly in the cell units, thereby increasing the electric power generation efficiency of the fuel cell stack.

Owner:CHUNG HSIN ELECTRIC & MACHINERY MFG

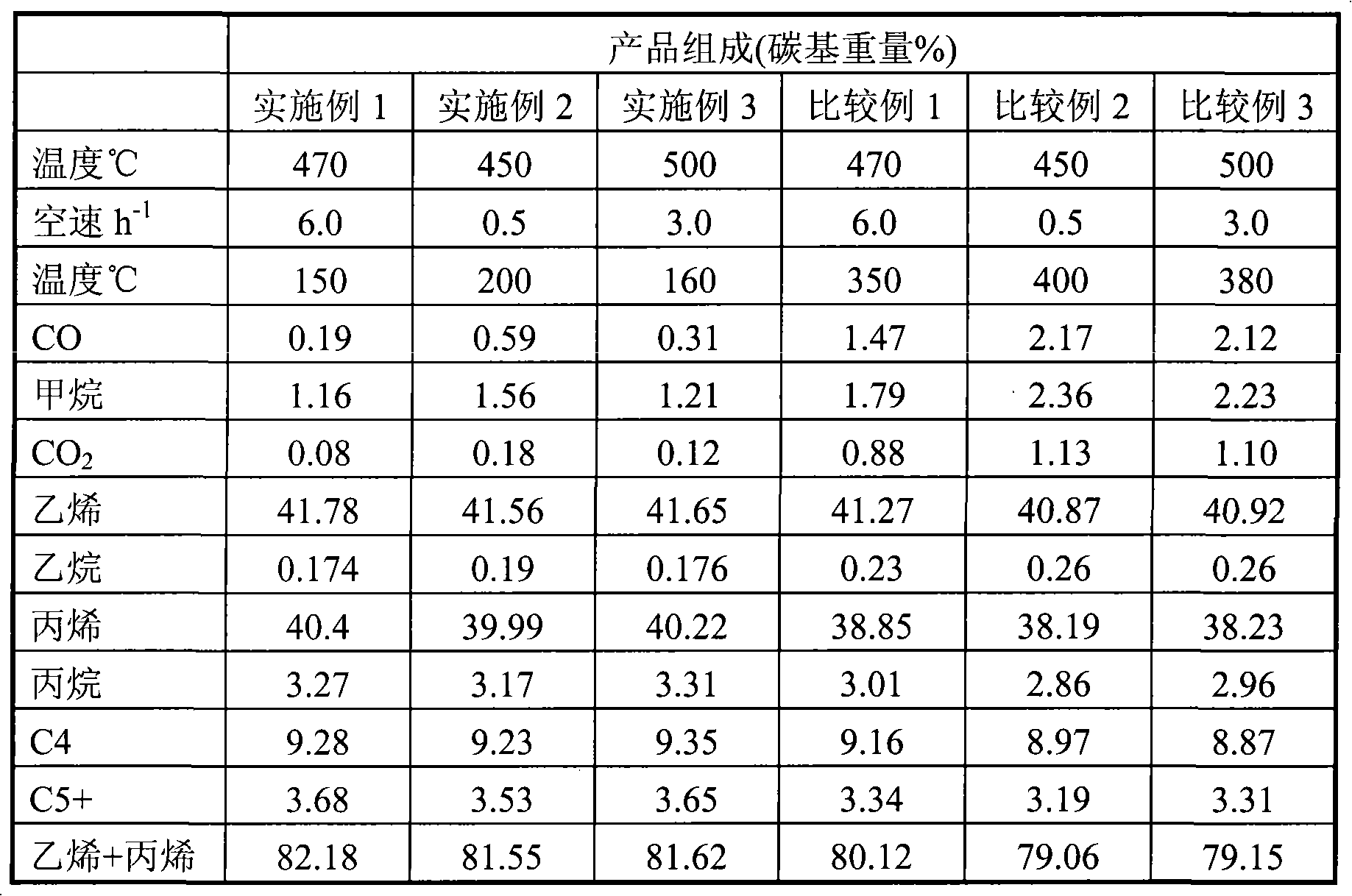

Method for improving selectivity of ethylene propylene

ActiveCN101279871ASimple componentsHigh selectivityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsChemistryMethanol

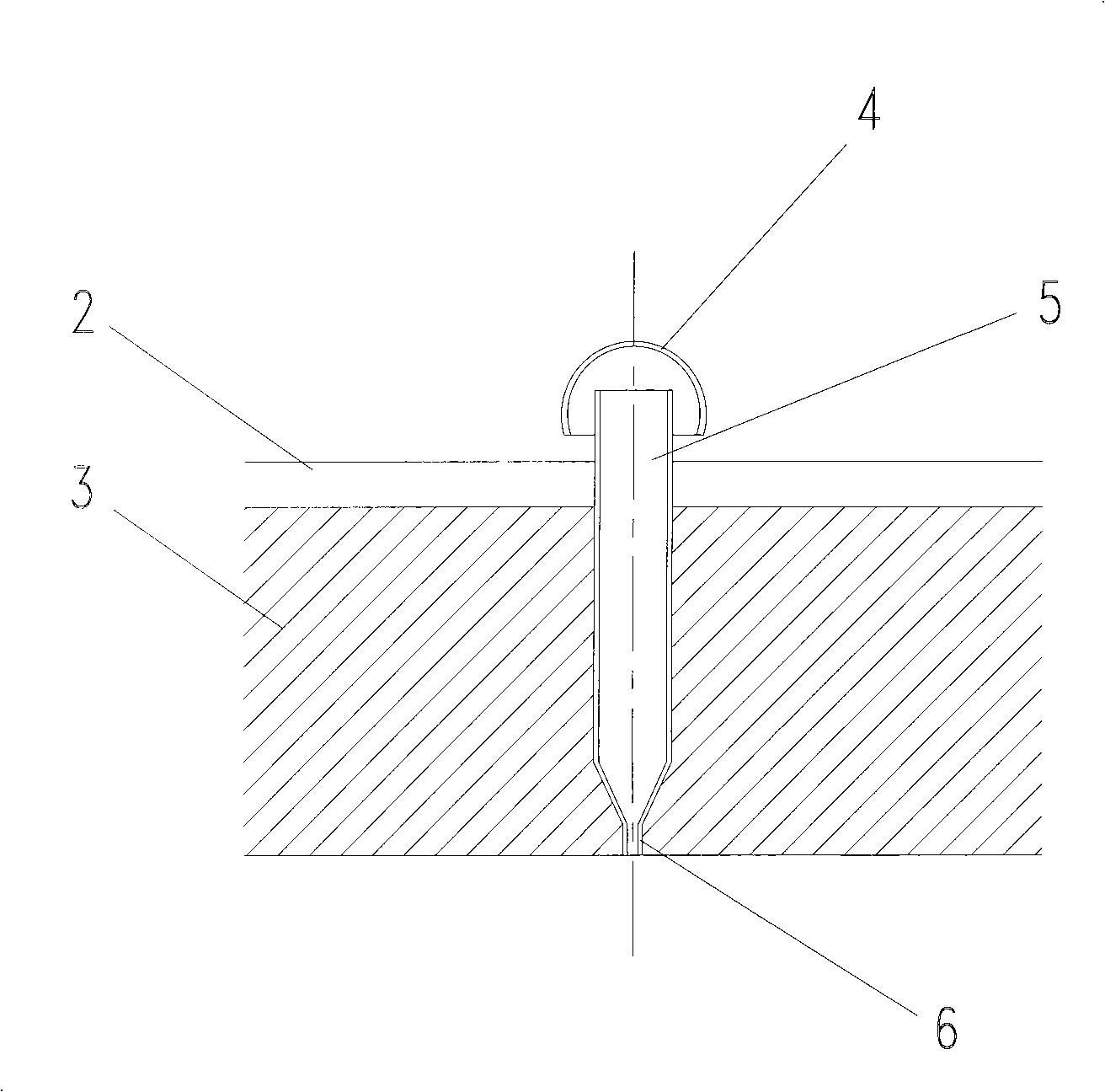

The invention relates to a method for improving the selectivity of ethylene propylene, which mainly solves the problems that the temperature is rather high before a methanol enters a reactor to contact with a catalyst in the process of low carbon olefin production by methanol, then partial methanol is decomposed to produce a by-product, and the selectivity of the low carbon olefin is reduced. The invention well solves the problems by adopting the technical proposal that an insulating material (3) is covered at the lower part of a gas distribution plate (2) of a fluidized bed reactor (1) to maintain the temperature under 200 DEG C before the raw material contacts with the catalyst, and the method can be used for the industrial production of producing the low carbon olefin by methanol.

Owner:SHANGHAI RES INST OF PETROCHEMICAL TECH SINOPEC

Gas distributor and adsorption tower

ActiveCN107252615AEven gas distributionImprove efficiencyGas treatmentDispersed particle separationChemistrySorbent

The invention relates to a gas distributor of an adsorption tower, and mainly solves the technical problems in the prior art that gas is unevenly distributed in an adsorbent bed layer and the adsorption effect is bad. The gas distributor of the adsorption tower is adopted and comprises a feed pipe (1), a pre-distributor (2) and a gas distribution pipe (3), one end of the pre-distributor (2) is connected with the feed pipe, the other end of the pre-distributor (2) goes deep into the interior of the adsorption tower, the pre-distributor (2) comprises an annular clearance (5) and a middle escape pipe (6), the middle escape pipe (6) is provided with a round hole near the diameter of the adsorption tower, the gas distribution pipe (3) is connected onto the pre-distributor (2) and is communicated with the annular clearance (5), and a round open hole (7) is formed in the gas distribution pipe (3). The technical scheme better solves the problems and can be applied to the industrial production of the gas adsorption tower.

Owner:铜陵泰富特种材料有限公司 +1

Magnetron sputtering vacuum coating equipment for uniformly distributing process gas

PendingCN109402585AAvoid disturbanceEven gas distributionVacuum evaporation coatingSputtering coatingTuyereTextile

The invention discloses magnetron sputtering vacuum coating equipment for uniformly distributing process gas. The magnetron sputtering vacuum coating equipment for uniformly distributing process gas comprises a vacuum chamber, wherein the process gas is fed into the vacuum chamber and a target material is placed in the vacuum chamber during coating; a mixing baffle is arranged between a gas inletside of the vacuum chamber and the target material; a gap as a gas mixing buffer chamber is formed between the mixed baffle and the inner wall of the gas inlet side of the vacuum chamber; a gas outletis formed in a side of the gap; a plurality of gas distributing tubes are arranged in the gas mixing buffer chamber; and gas distribution holes are formed in each gas distributing tube. The mixing baffle is arranged in the vacuum chamber, the process gas blown out from the gas distributing tubes collides with the front surface of the mixing baffle at first, thus, the gas is fully mixed in the gasmixing buffer chamber, after the gas is uniform, the gas is then blown out slowly from the gas outlet of the side surface, disturbance to the gas in the vacuum chamber is avoided, and thus, the gas in the vacuum chamber is distributed uniformly.

Owner:ZHEJIANG SHANGFANG ELECTRONICS EQUIP

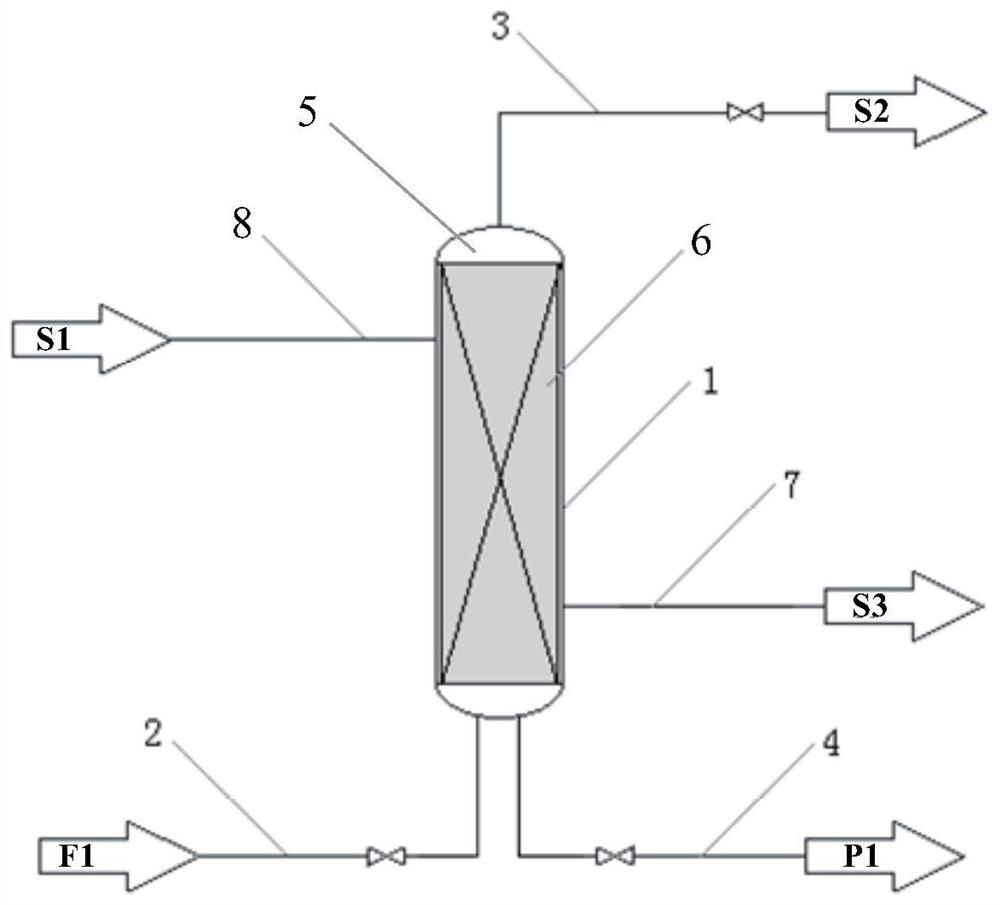

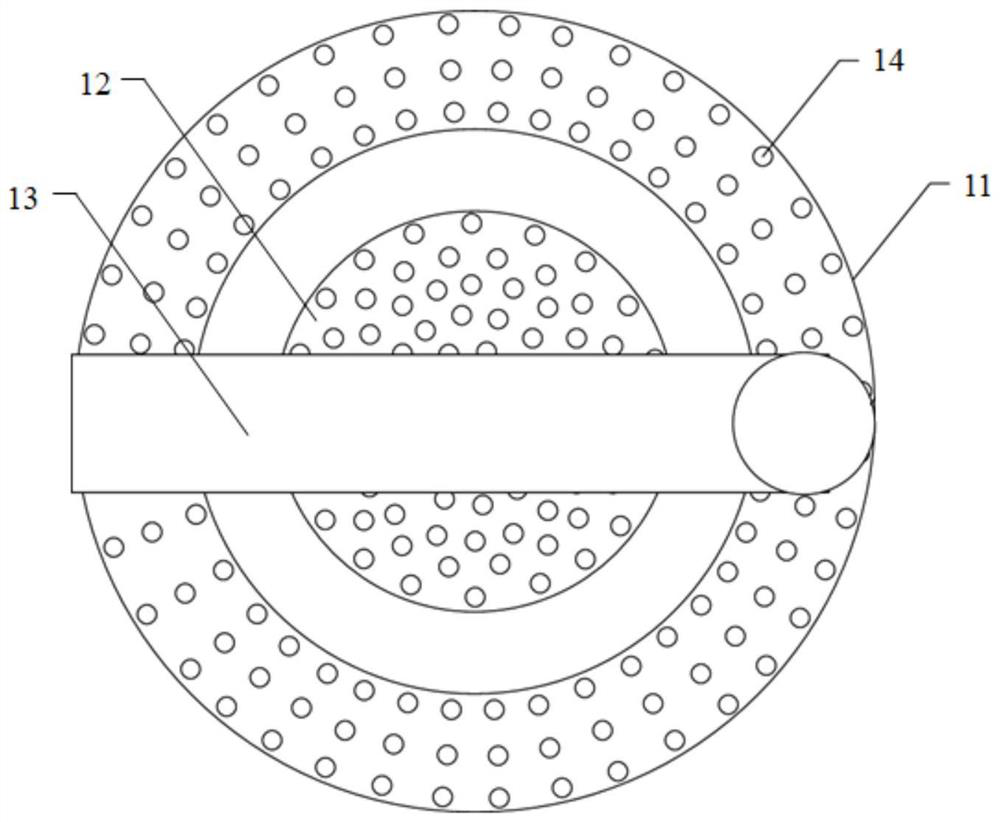

Gas distributor and system comprising gas distributor

ActiveCN108261988ASimple structureEasy to operateLiquid-gas reaction processesProduct gasProcess engineering

The invention relates to a gas distributor and a system comprising the gas distributor. The gas distributor comprises an annular gas distribution pipe, an intra-annular gas distribution box positionedin the annular gas distribution pipe, and a gas inlet pipe respectively connected with the gas distribution pipe and the gas distribution box, wherein the gas inlet pipe is connected with the gas distribution pipe and the gas distribution box through at least two branched gas inlet branches, so that the fixation and the gas inlet of the gas distribution pipe and the gas distribution box are realized; gas holes are formed in the surfaces of the gas distribution pipe and the gas distribution box. The structure of the gas distributor is simple; the operation is stable; the uniform distribution performance is good.

Owner:CHINA NAT OFFSHORE OIL CORP +4

A rare gas adsorption and trapping device and its adsorption and trapping process and application

ActiveCN111467929BIncreased regeneration depthShorten the work cycle of adsorption and captureComponent separationDispersed particle separationTrappingSorbent

The invention belongs to the application field of gas adsorption and separation, in particular to a rare gas adsorption and trapping device and its adsorption and trapping process and application. Including shell, forward air intake pipeline, forward exhaust pipeline, reverse exhaust pipeline, adsorber is placed in the shell, the adsorber is a radial flow or axial flow adsorption bed, and the adsorber has built-in adsorbent and heat exchange Assemblies, the cooling / heating medium pipeline I and the cooling / heating medium pipeline II are arranged on both sides of the shell. The adsorbent is a high thermal conductivity adsorbent, and the high thermal conductivity adsorbent is a mixture of a porous material and a thermal conductivity agent. Through the operation process of raw material gas adsorption and cooling, raw material gas pressure boost, forward adsorption, forward decompression and exhaust, temperature rise and reverse vacuum desorption, the components in the raw material gas are adsorbed and separated. The thin gas adsorption and trapping device provided by the invention has short process flow, strong raw material gas adaptability, and high concentration multiple, which solves the problems of low efficiency and long cycle in the existing thin gas concentration detection and rapid purification of toxic and harmful gases.

Owner:CTBT BEIJING NAT DATA CENT

A gas distributor and a system comprising the gas distributor

ActiveCN108261988BSimple structureEasy to operateLiquid-gas reaction processesThermodynamicsEngineering

Owner:CHINA NAT OFFSHORE OIL CORP +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com