Fischer-Tropsch synthesis fluidized bed reactor

A fluidized bed reactor, Fischer-Tropsch synthesis technology, applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, chemical/physical processes, etc., can solve solid entrainment and catalyst wear, uneven fluid distribution, and service life. Shortage and other problems, to achieve good gas-solid separation effect, uniform gas distribution, and avoid short or biased flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

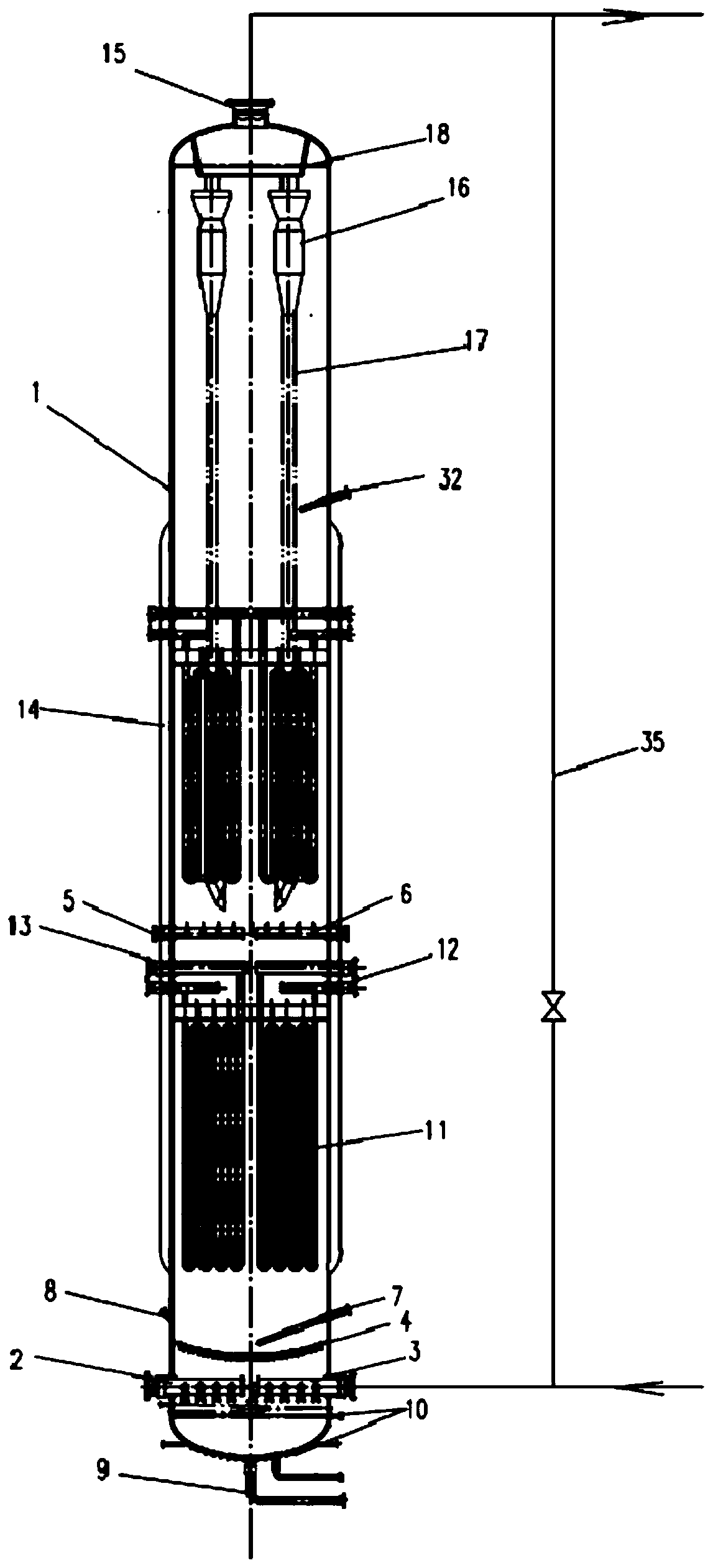

[0076] A fluidized bed reactor for Fischer-Tropsch synthesis, with a structure such as figure 1 As shown, it includes: the gas inlet pipe 2 of the first-level distributor, the inlet pipe 5 of the third-level gas distributor, the first-level gas distributor 3, the second-level gas distributor 4, the third-level gas distributor 6, and the internal exchange inside the reactor Heater 11, the external heat exchanger arranged on the outside of the reactor cylinder 1, specifically the lower heat exchanger 10, the upper heat exchanger 14, the cyclone separator 16 arranged in the upper gas phase of the reactor and the catalyst inside the reactor Circulation line 17, catalyst feed line 7 for online solid catalyst, and online lower catalyst discharge line 8 for solid catalyst disposed on the reactor barrel, upper catalyst discharge line 32, and bottom catalyst discharge line disposed at the bottom of the reactor The feed line 9 is set at the reactor top outlet 15 of the reactor and the p...

Embodiment 2

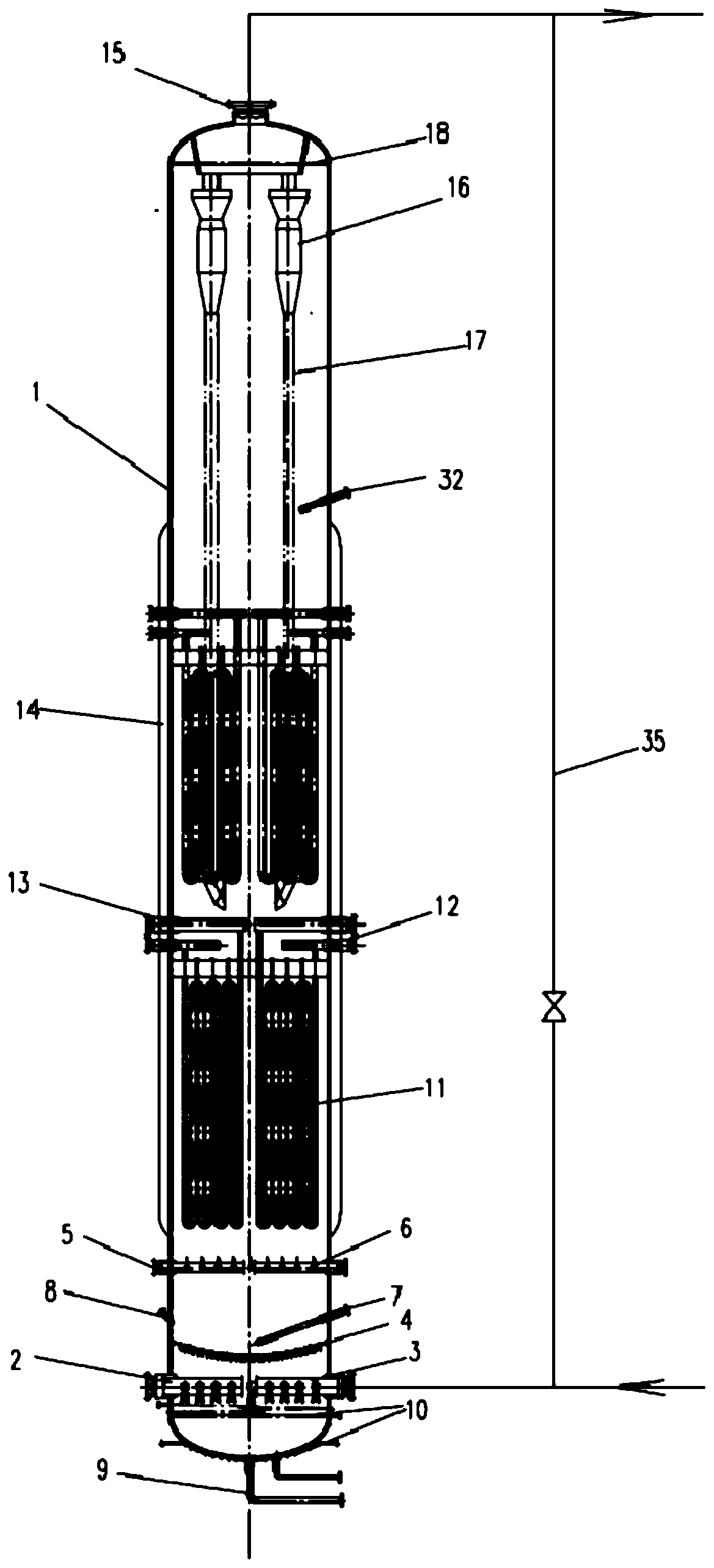

[0090] A fluidized bed reactor for Fischer-Tropsch synthesis is a high-temperature Fischer-Tropsch synthesis experimental device, which uses synthesis gas to produce liquid fuel; as figure 2 As shown, the main structure of this embodiment is the same as that of Embodiment 1, except that the three-stage gas distributor 6 of the present invention is arranged at the catalyst feed line 7 for online addition of catalyst and the lower catalyst discharge line 8 for online discharge of catalyst. Above, but below the inner heat exchanger 11.

Embodiment 3

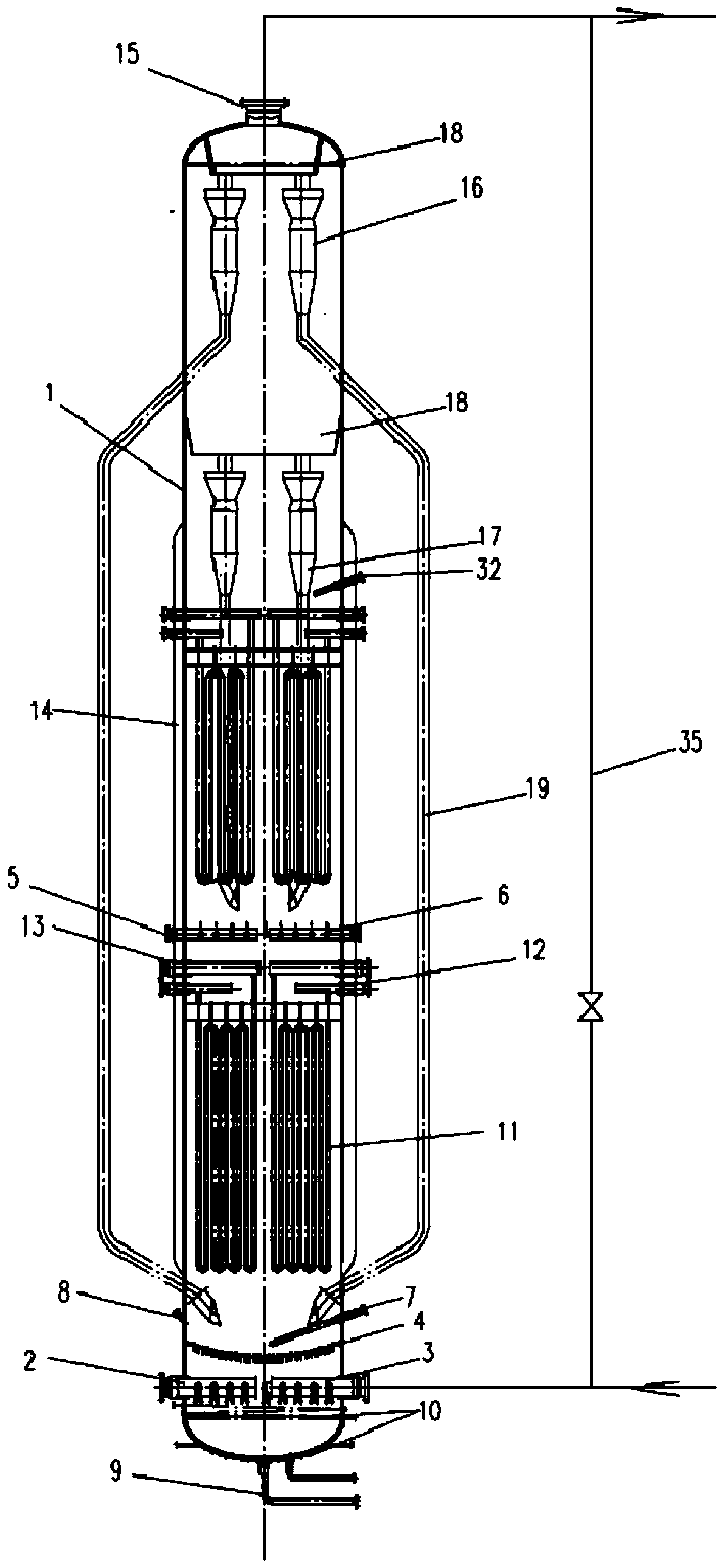

[0092] A fluidized bed reactor for Fischer-Tropsch synthesis is a high-temperature Fischer-Tropsch synthesis experimental device, which uses synthesis gas to produce liquid fuel; as image 3 As shown, the main structure of this embodiment is the same as that of Embodiment 1, the difference lies in. The fluidized bed reactor adopts the first and second two-stage solid catalyst separation unit (the reactor is from the bottom to the first stage and the second stage), and the two-stage solid catalyst separation unit has a combination of multiple cyclone separators connected in parallel. The upper part of the first-stage cyclone separator is equipped with a gas collection chamber, and the catalyst circulation line 17 of the first-stage solid catalyst separation unit is arranged inside the reactor and transports the solid separated by the gas-solid separator to the main reaction zone of the reactor, and the second-stage solid catalyst The catalyst circulation line 19 outside the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com