Method for improving film thickness uniformity in gradient pressure mode

A gradient pressure and mode technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of occupying equipment usage time, reducing equipment usage efficiency, time control and equipment usage cost increase, etc., to improve quality , Improve work efficiency, reduce the effect of test steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

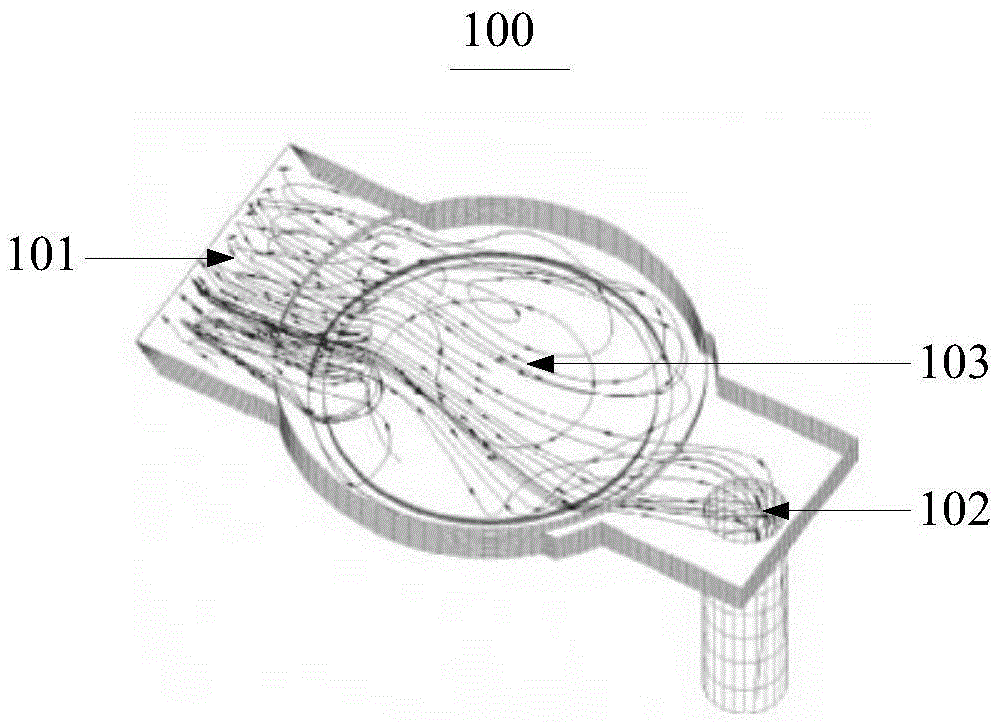

[0015] The present invention is described in detail below in conjunction with accompanying drawing:

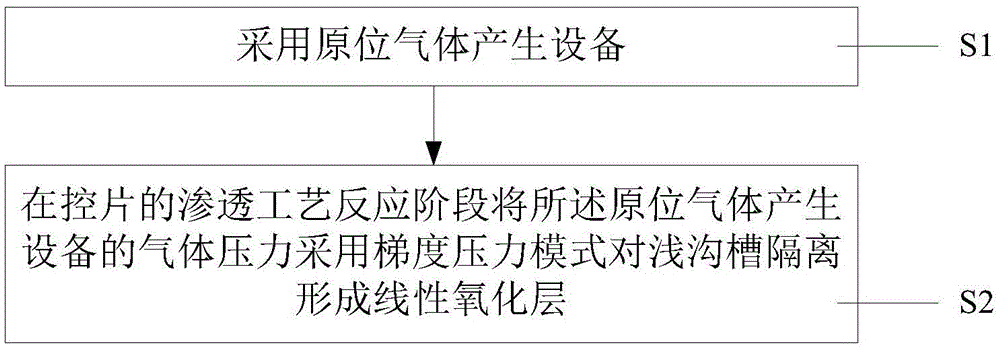

[0016] figure 2 It is a flowchart for forming a linear oxide layer with uniform film thickness. Please refer to figure 2 , the method for improving the uniformity of the film thickness in the gradient pressure mode provided by the present invention comprises the following steps:

[0017] Step S1, using in-situ gas generation equipment;

[0018] Step S2 , forming a linear oxide layer on the shallow trench isolation by using the gas pressure of the in-situ gas generation device in a gradient pressure mode during the infiltration process reaction stage of the control sheet.

[0019] The invention adopts the gradient pressure mode in the reaction stage of the infiltration process, avoids the influence of the constant pressure mode on the edge of the control plate, and thus obtains the trench isolation linear oxide layer with uniform film thickness.

[0020] Wherein, the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com