Fuel cell flow field plate

a flow field plate and fuel cell technology, applied in the field of fuel cells, can solve the problems of significant affecting the performance of the fuel cell, unfavorable gas distribution along the tortuous flow path, and design problems, so as to facilitate gas distribution, reduce pressure drop, and prevent the accumulation of water and impurities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

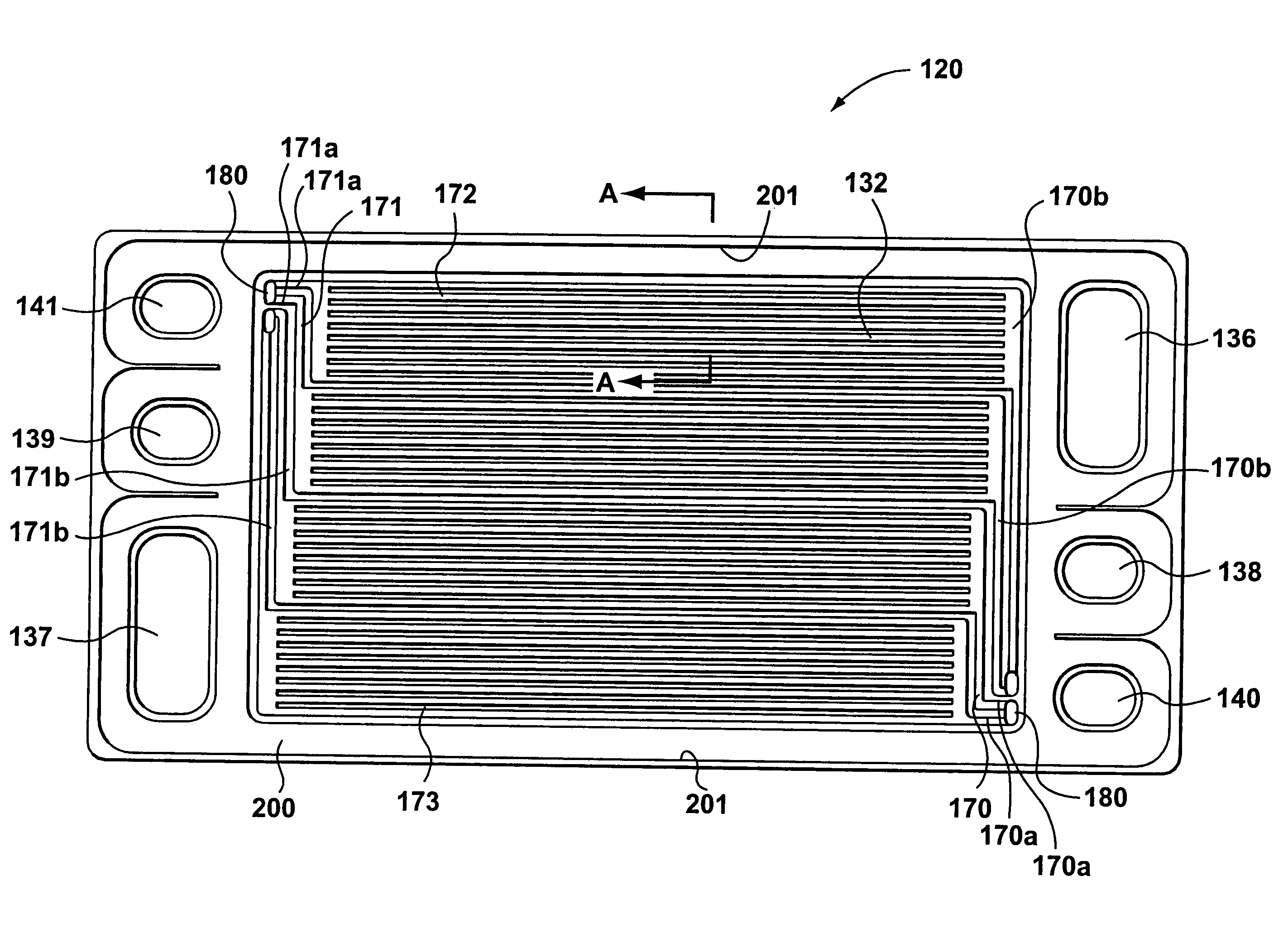

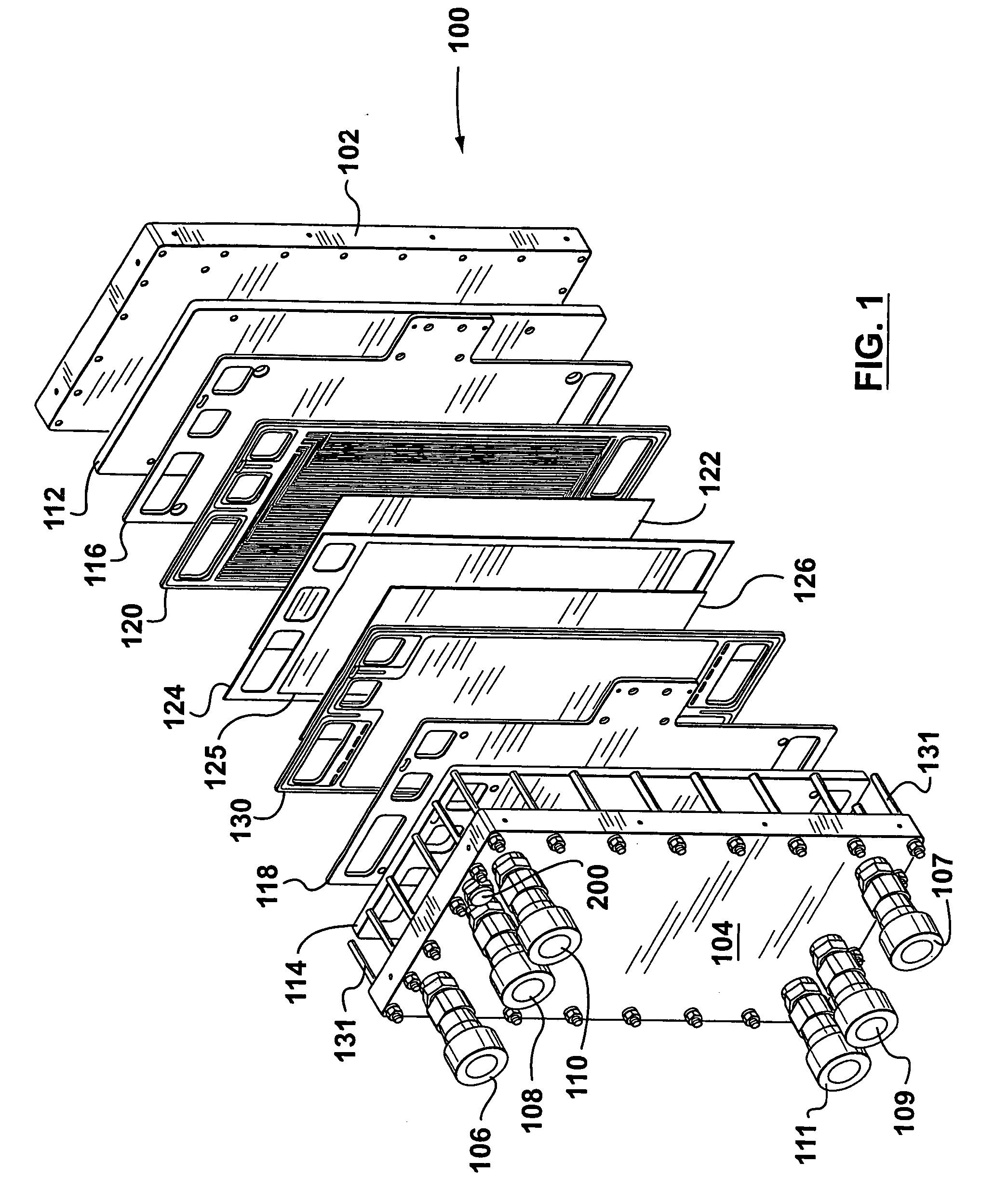

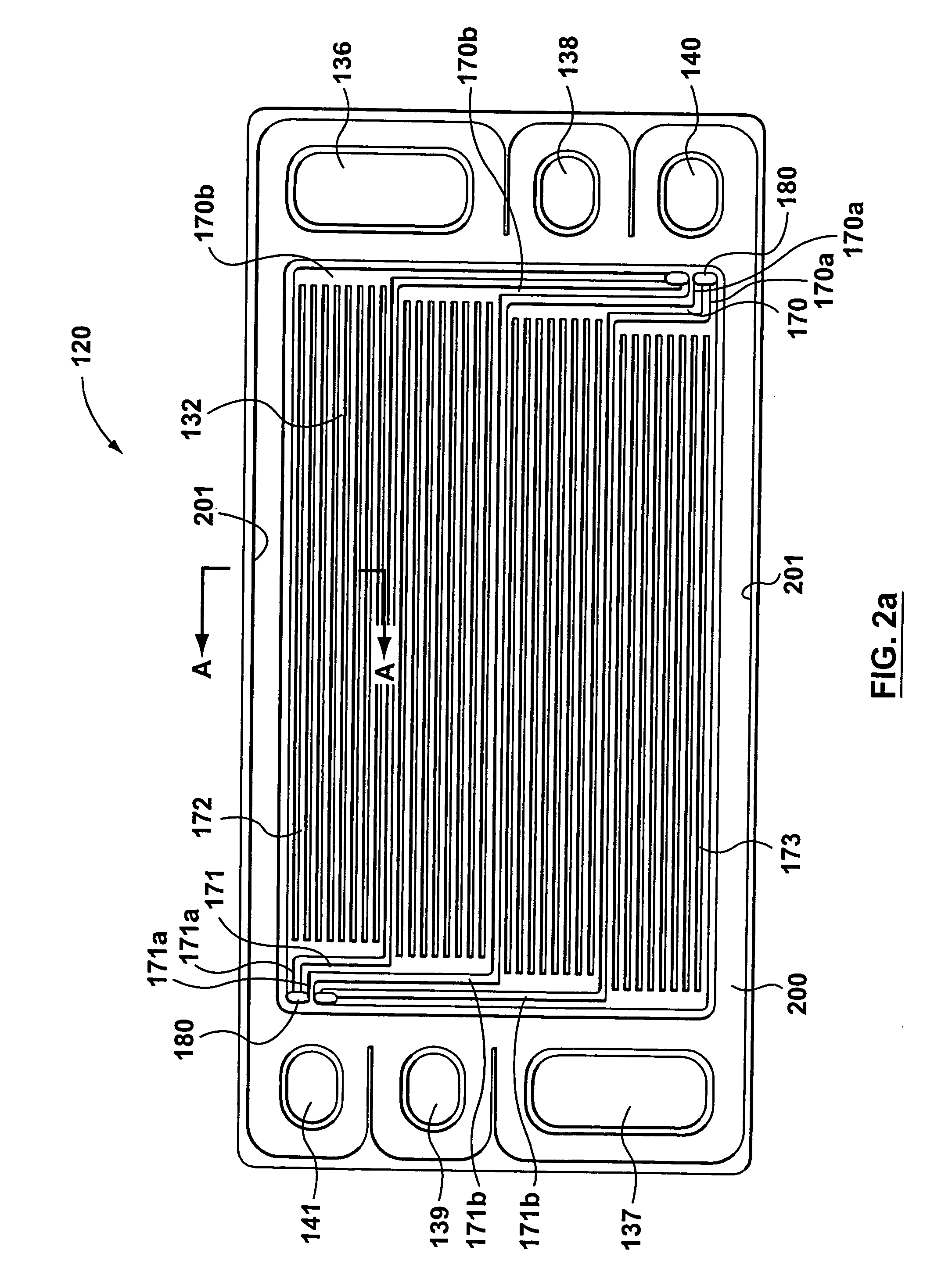

[0035] Referring first to FIG. 1, this shows an exploded perspective view of a single fuel cell unit 100 located within a fuel cell stack according to the present invention. It is to be understood that while a single fuel cell unit 100 is detailed below, in known manner the fuel cell stack will usually comprise a plurality of fuel cells stacked together. Each fuel cell of the fuel cell unit 100 comprises an anode flow field plate 120, a cathode flow field plate 130, and a membrane electrode assembly (MEA) 124 disposed between the anode and cathode flow field plates 120, 130. Each reactant flow field plate has an inlet region, an outlet region, and open-faced channels to fluidly connect the inlet to the outlet, and provide a way for distributing the reactant gases to the outer surfaces of the MEA 124. The MEA 124 comprises a solid electrolyte (i.e. a proton exchange membrane) 125 disposed between an anode catalyst layer (not shown) and a cathode catalyst layer (not shown). A first ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com