Up-flow reactor and application thereof

A reactor, up-flow technology, used in chemical instruments and methods, petroleum industry, chemical/physical processes, etc., can solve the problems of limited gas distribution effect, easy blockage of small pore structure by impurities, and high requirements for distributor level. , to overcome the effect of bubble drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

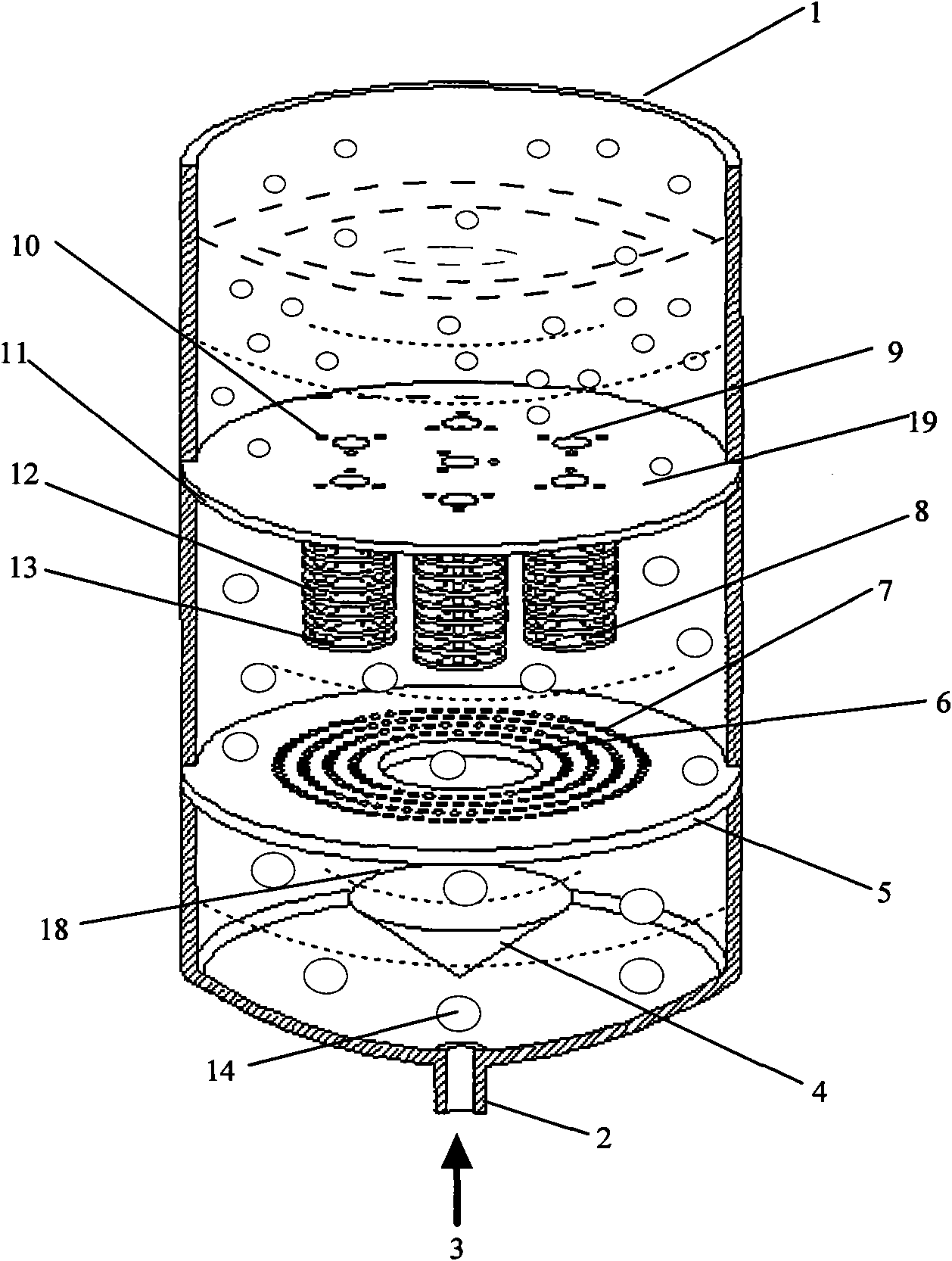

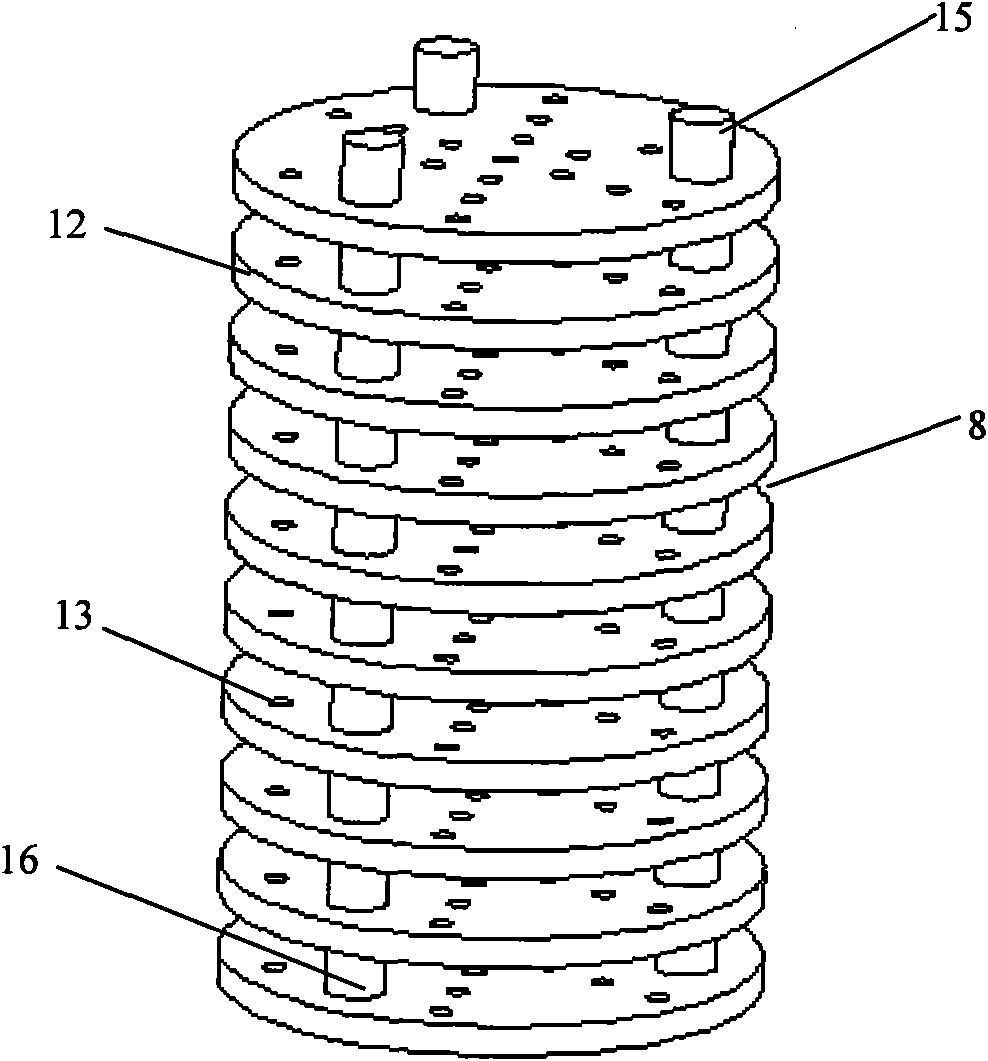

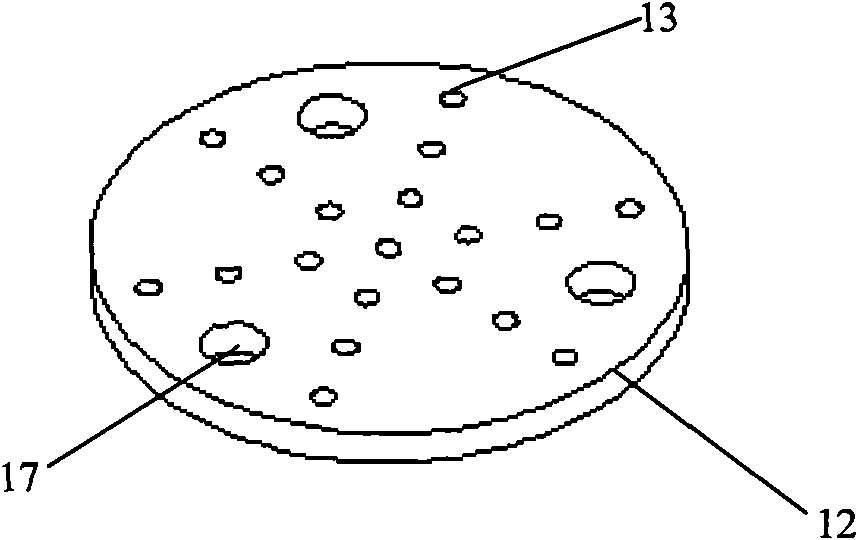

[0036] first combined with Figure 1~3 The intermediate distributor 19 will be described. like figure 2 and image 3 As shown, the sieve plate string structure 8 is composed of 10 small sieve plates 12, the small sieve plates 12 have hole structures 13, and the hole structures 13 are distributed in concentric circles here; there are bolt positioning holes 17 on the side of the small sieve plates 12 , use the positioning bolt 15 to pass through the hole 17, and then put on the distance tube 16 whose inner diameter is larger than the diameter of the hole 17, and then pass through another small sieve plate and another distance tube in turn, and the plate string can be made after multiple operations Structure 8; then pass the positioning bolts 15 through the bolt positioning holes 10 on the perforated sieve plate 11 and fix them to complete the manufacture of the intermediate distributor 19.

[0037] The following is attached by figure 1 The present invention will be describe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com