A system for producing carbonates and a method for producing carbonates using the system

A carbonic acid ester and ethylene carbonate technology, which is applied to a system for producing carbonic acid esters and the field of producing carbonic acid esters by using the system, can solve the problems of poor EC color of products, easy deactivation of catalysts, low product yields, etc., and shorten the residence time. , the effect of high production efficiency and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

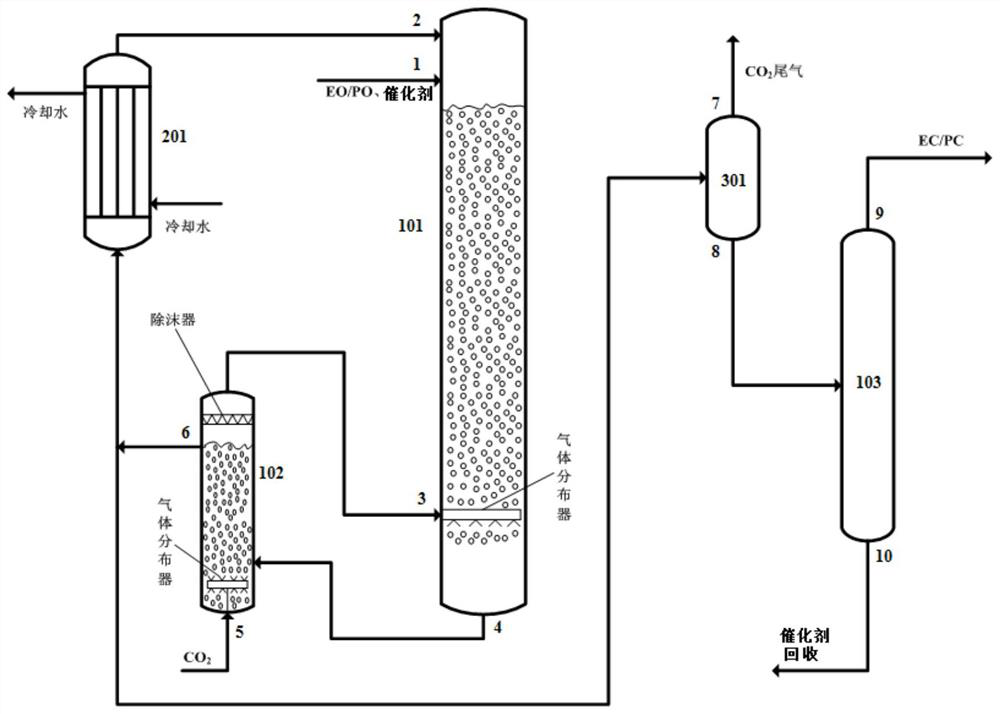

[0062] This embodiment provides a system for producing carbonate, the system includes a first bubble column 101, a second bubble column 102, a heat exchanger 201, a gas-liquid separator 301 and a vacuum distillation column 301, the first The top of bubble column 101 is provided with raw material and catalyst inlet 1 and the first circulation inlet 2 that communicates with heat exchanger 201 top outlets, and the bottom of described first bubble column 101 is provided with the second bubble column 102 top outlets. A connected second circulation inlet 3, the bottom of the first bubble column 101 is provided with a product outlet 4 communicating with the bottom of the second bubble column 102;

[0063] The bottom of the second bubble column 102 is provided with a gas inlet 5, the inside of the second bubble column 102 is provided with a demister near the top position, and the top of the second bubble column 102 is provided with an overflow outlet 6 , the overflow outlet 6 communic...

Embodiment 2

[0066] The present embodiment provides a kind of method adopting the system described in embodiment 1 to produce carbonate, described method comprises the following steps:

[0067] (a) feed the mixture of oxirane and homogeneous catalyst from raw material and catalyst inlet 1 to the first bubble column 101, and oxyethane enters the first from the second circulation inlet 3 under the effect of homogeneous catalyst CO of a bubble column 101 2 The gas undergoes a countercurrent reaction to produce ethylene carbonate EC;

[0068] (b) In the second bubble column 102 (turbulent bubbling state), the CO passed into from the gas inlet 5 2 The gas carries out mass exchange and heat exchange with ethylene carbonate from the first bubble column 101 (quiet bubbling state), which not only realizes CO 2 At the same time, the residual ethylene oxide in ethylene carbonate is replaced to realize the cycle of ethylene oxide;

[0069] According to the incoming CO 2 The gas volume and the amou...

Embodiment 3

[0077] The system and operating method adopted are the same as in Embodiment 1, the difference is the following operating conditions: CO in the first bubble column 101 2 The molar ratio to EO is 1.3:1, the bed temperature of the first bubble column 101 is 110°C, the countercurrent reaction pressure is 2MPa, and the total residence time is 2h.

[0078] The specific activity data are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com