Sputtering apparatus and thin film formation method

A sputtering equipment and thin film technology, which is applied in the field of sputtering equipment and thin film formation, can solve different problems, achieve the effects of excellent uniformity, uniform gas distribution, and reduced substrate pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

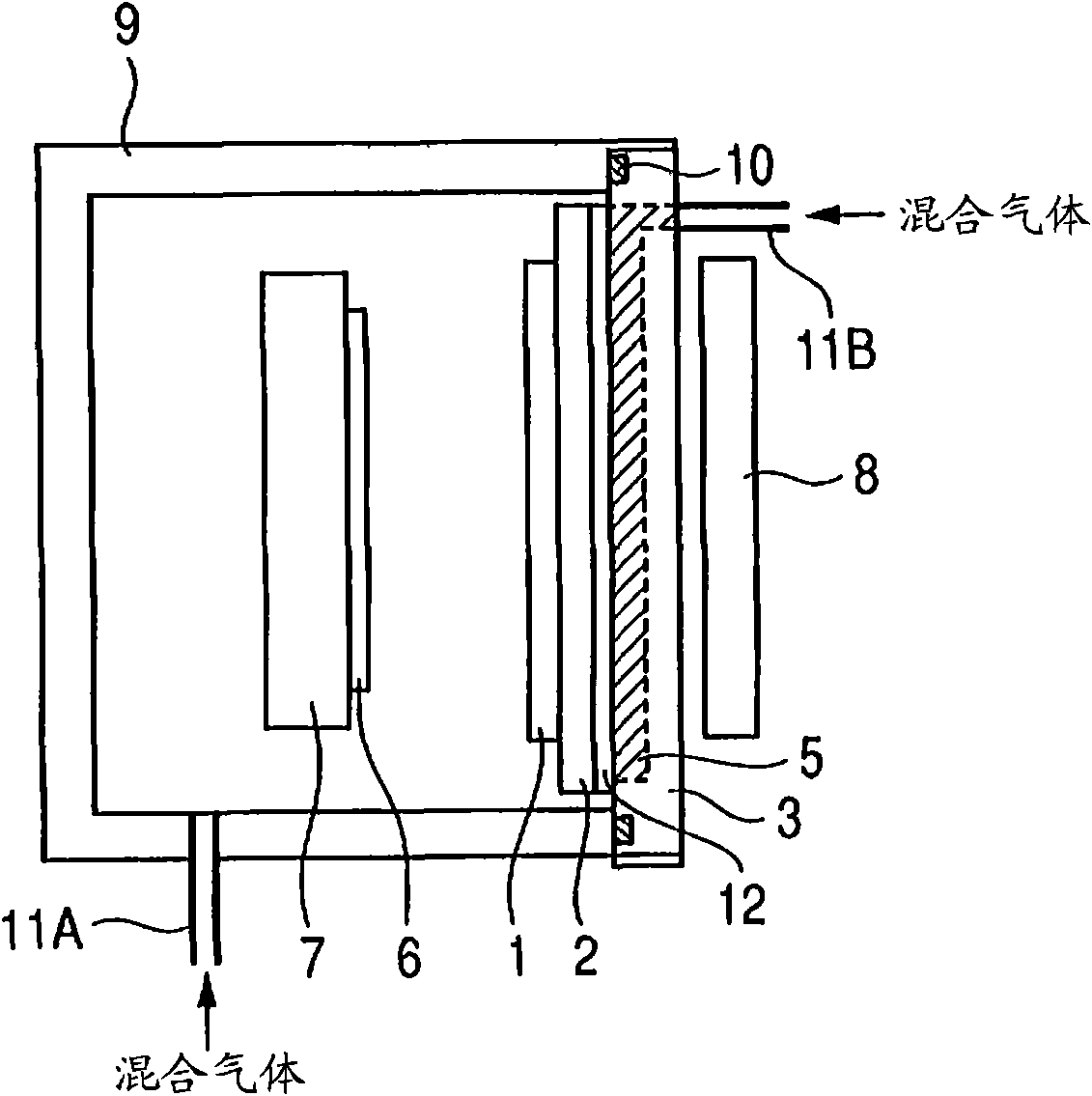

[0022] In the following, we will use Figure 1 to Figure 5 A sputtering device according to one embodiment of the present invention will be described.

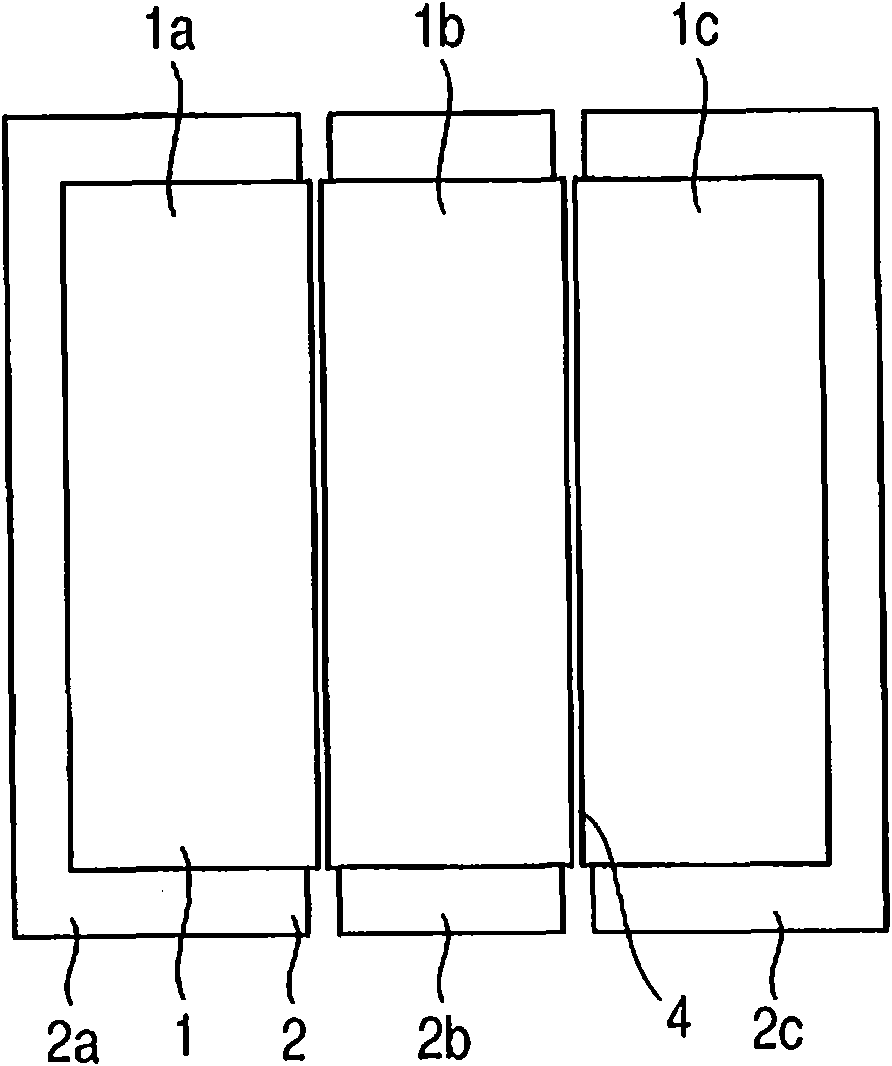

[0023] figure 1 is a side sectional view showing a schematic configuration of a sputtering apparatus according to a first embodiment of the present invention. The sputtering apparatus includes a vacuum container 9 , a substrate holder 7 provided in the vacuum container 9 to support the substrate, and a cathode mechanism positioned opposite to the substrate. The cathode unit has a backing plate 2 for supporting the target 1 . The target 1 is supported on this backing plate 2 .

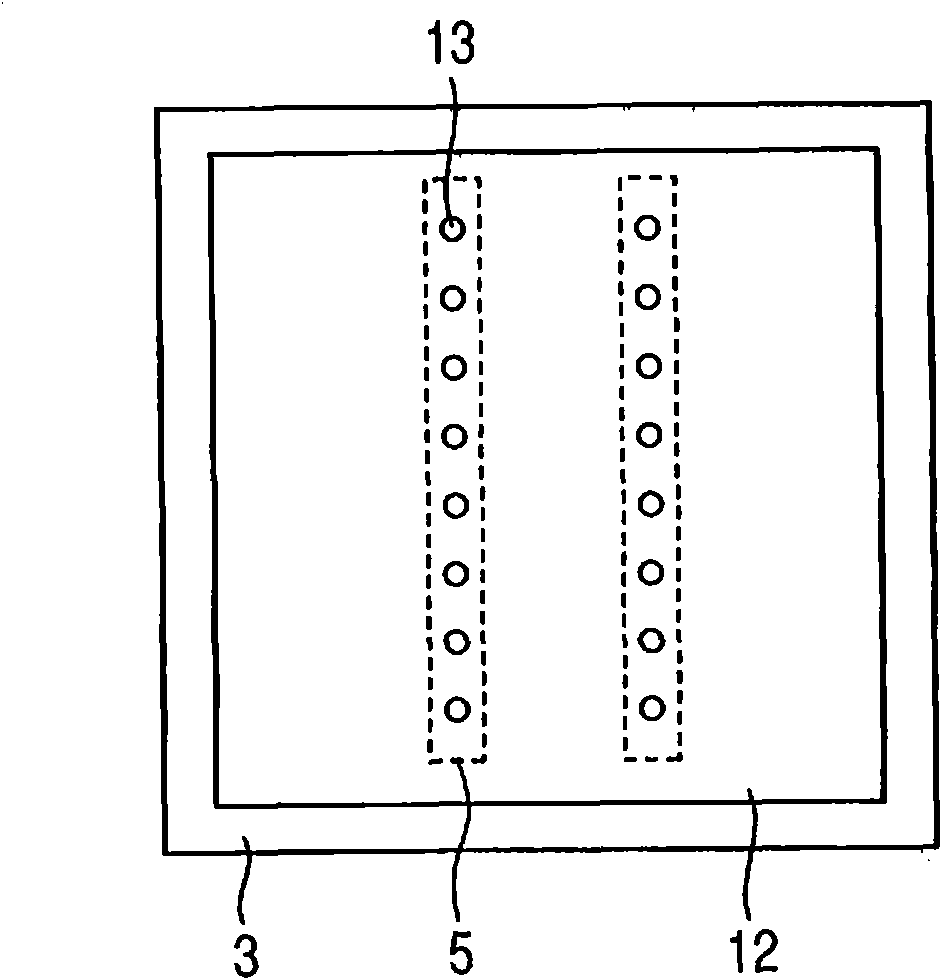

[0024] In addition, a first gas introduction mechanism for introducing gas from the gas supply pipe 11A to the vacuum container 9 and a second gas introduction mechanism for introducing gas from the gas introduction pipe 11B to the vacuum container 9 are provided in the sputtering apparatus. The first gas introduction mechanism is positioned apart f...

no. 2 approach

[0048] In the first embodiment, a form including both the first gas introduction mechanism and the second gas introduction mechanism has been described. In this embodiment, a form in which the first gas introduction mechanism is not provided will be described.

[0049] When the mixed gas containing the inert gas and the reactive gas is introduced from the second gas introducing means, both the inert gas and the reactive gas are introduced between the cathode means and the substrate 6 in the vacuum vessel 9 . In addition, the second gas introduction mechanism is designed to supply gas so as to reduce the concentration gradient of the reaction gas in the plasma-generating region between the cathode mechanism and the substrate 6 . Therefore, the inert gas and the reaction gas can be supplied to the region where plasma is generated without providing the first gas introduction mechanism including the gas introduction pipe 11A. In addition, the concentration gradient of the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com