Strip-shaped stove combustor

A long-strip, burner technology, applied in burners, gas fuel burners, combustion methods, etc., can solve problems such as insufficient combustion, tempering, and small combustion area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

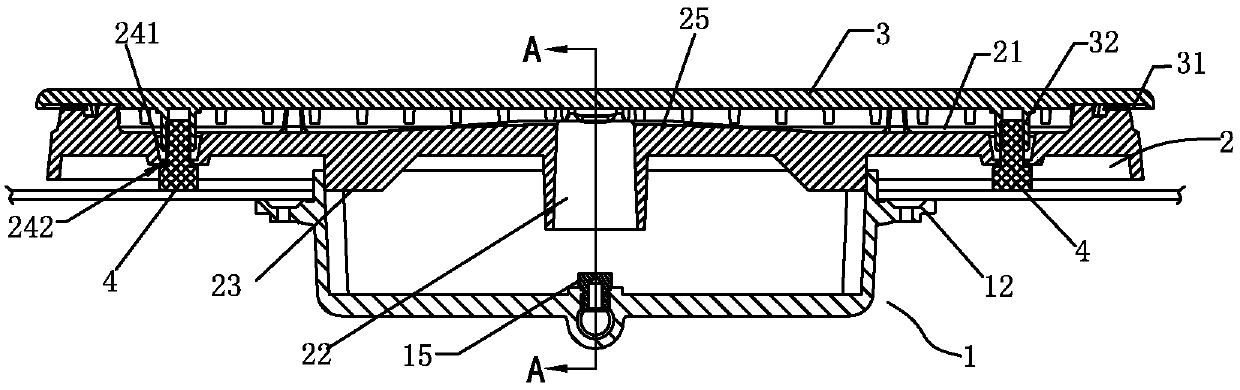

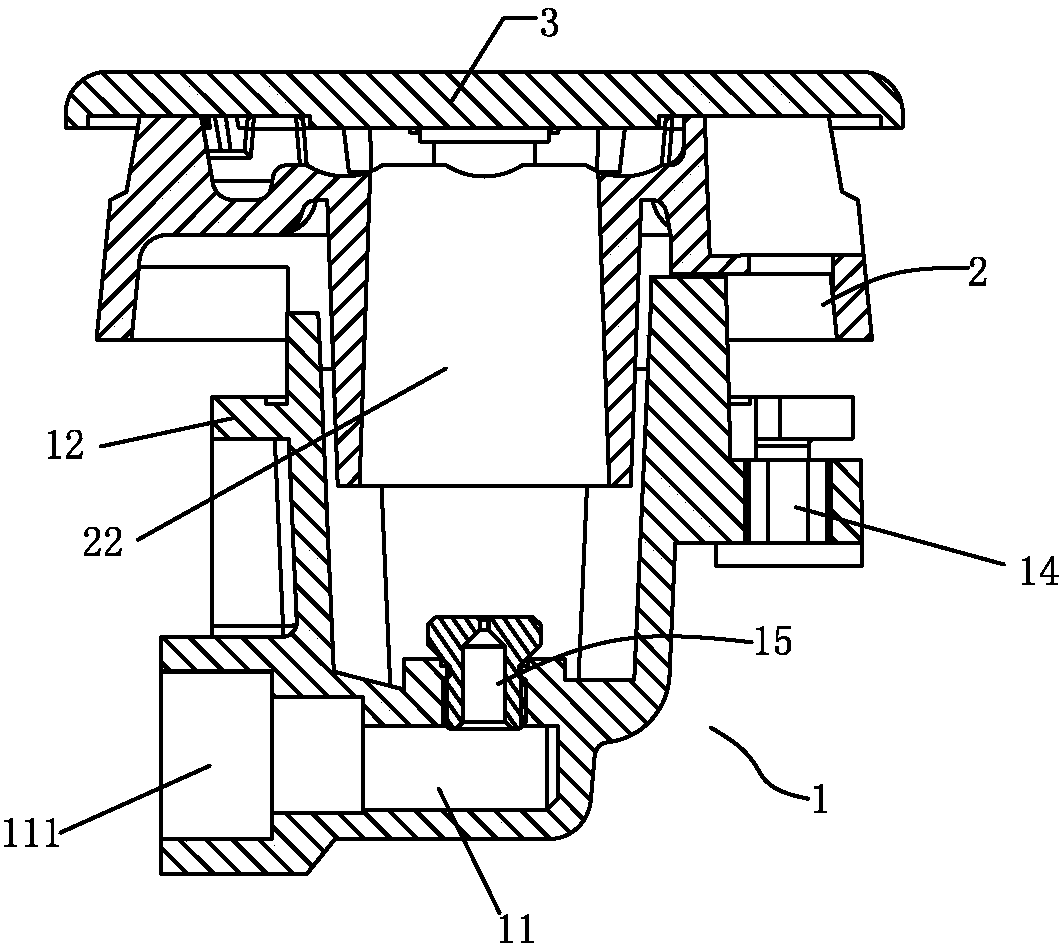

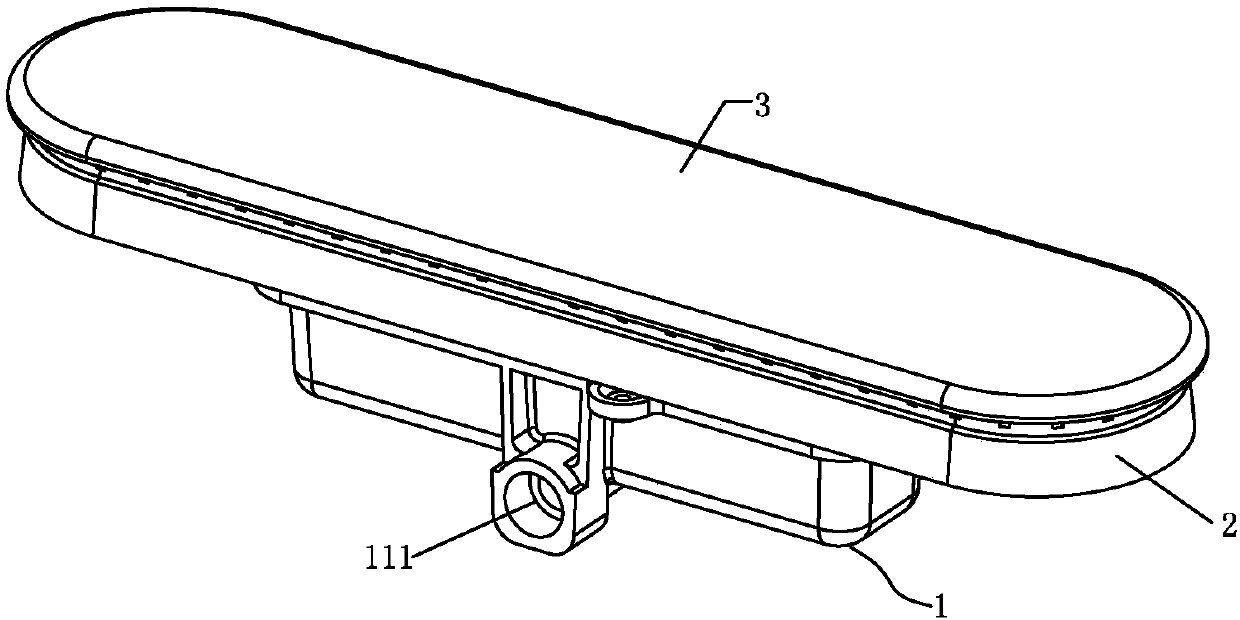

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] Such as figure 1 , figure 2 As shown, a strip-shaped cooker burner includes a bottom cup 1 with an upper opening, a fire distributor 2 and a fire cover 3. The bottom cup 1 includes an air intake passage 11, a flange 12, an ignition needle seat 13, and a thermocouple seat 14. And nozzle 15, the inlet end of air intake channel 11 is provided with air inlet interface 111, the center of the base plate that outlet is positioned at bottom cup, and outlet end is provided with nozzle 15; Distributor 2 comprises the combustion chamber 21 of upper opening, communicates with combustion chamber The injection pipe 22 and the bracket 23 positioned on the lower surface are provided with a combustion groove on the wall of the combustion chamber 21; the bracket 23 cooperates with the bottom cup 1, the injection pipe 22 cooperates with the nozzle 15, and the fire cover 3 covers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com