Method for improving selectivity of ethylene propylene

An ethylene-propylene, selective technology, applied in ethylene production, chemical instruments and methods, molecular sieve catalysts, etc., can solve difficult problems such as uniform distribution of raw materials, complex contact conduit structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

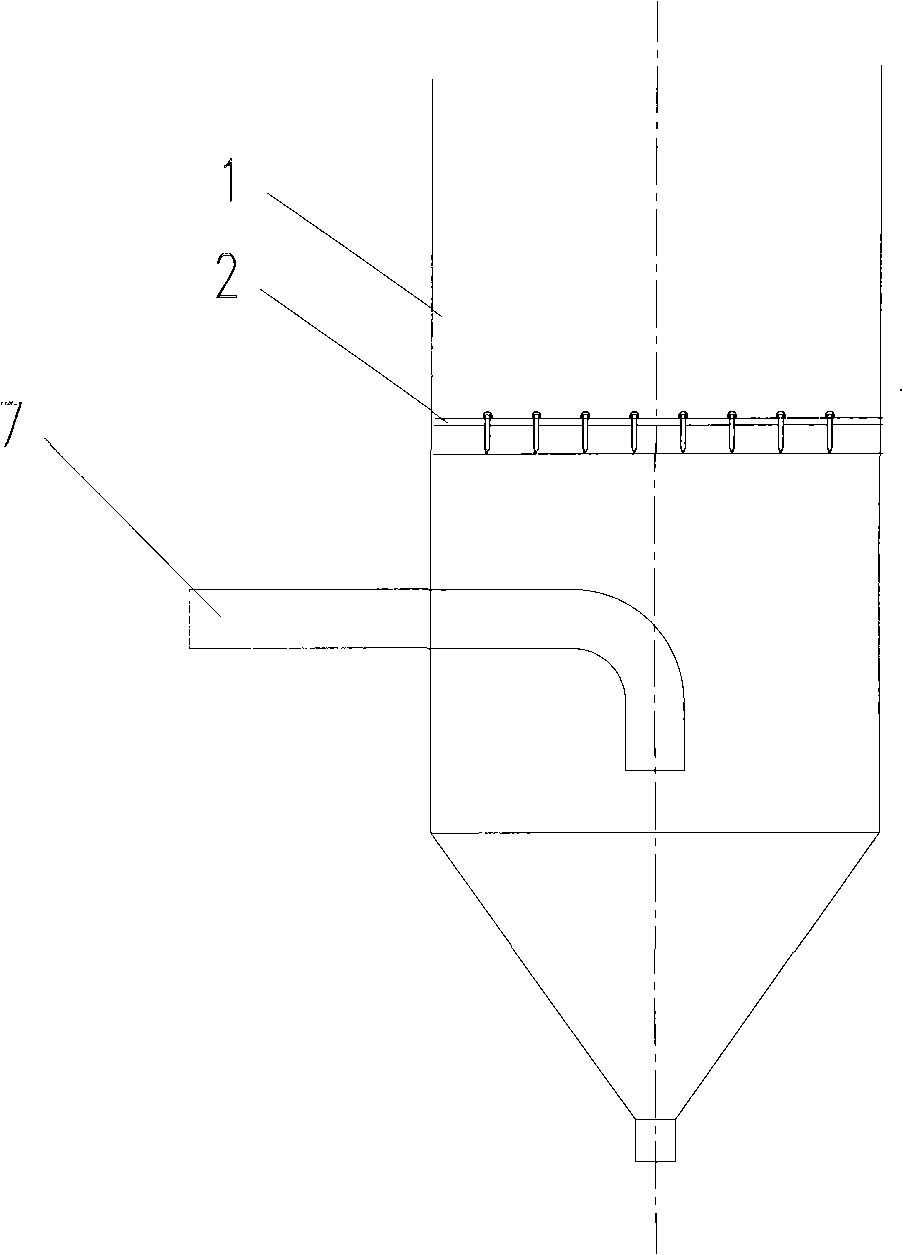

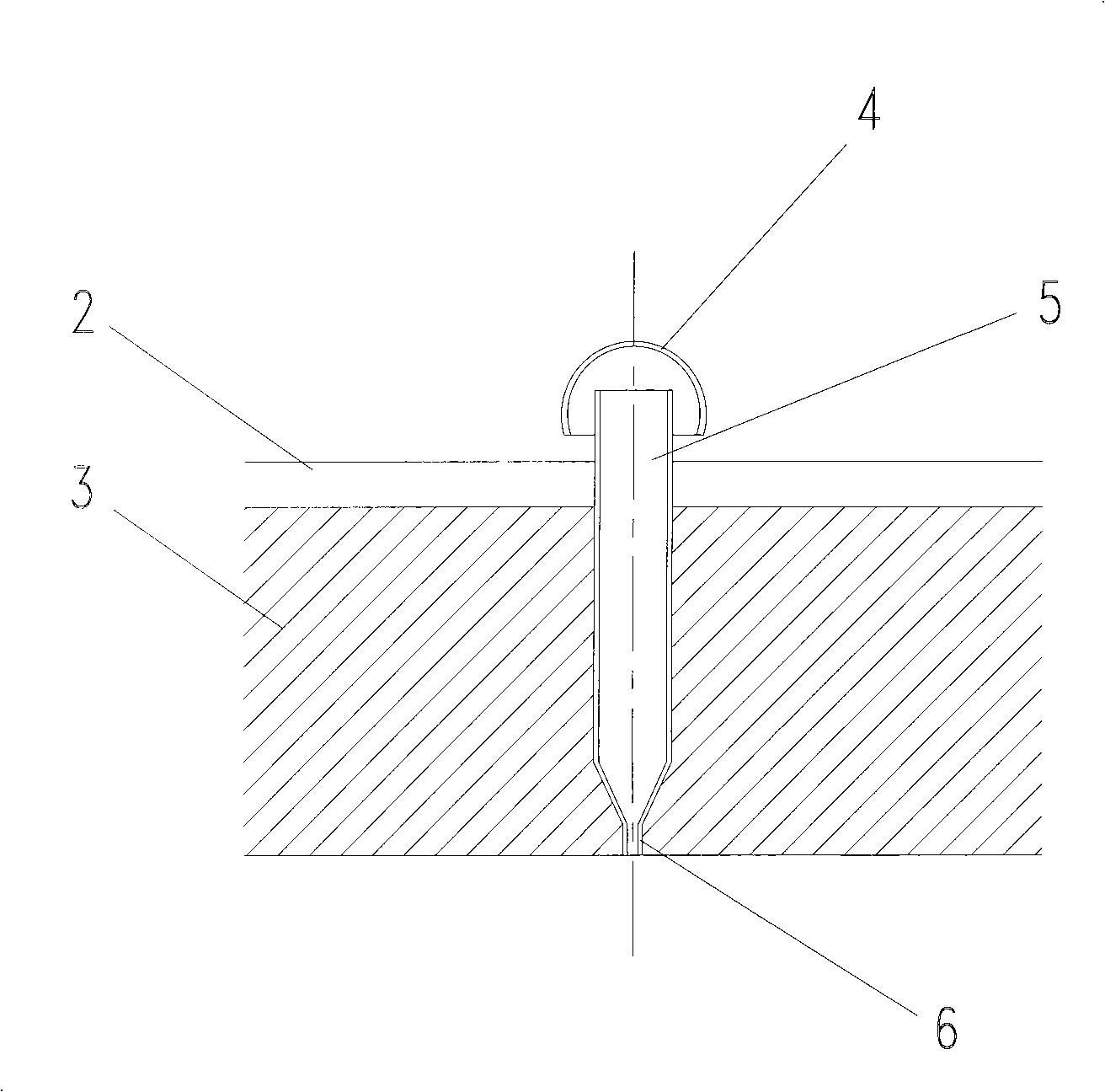

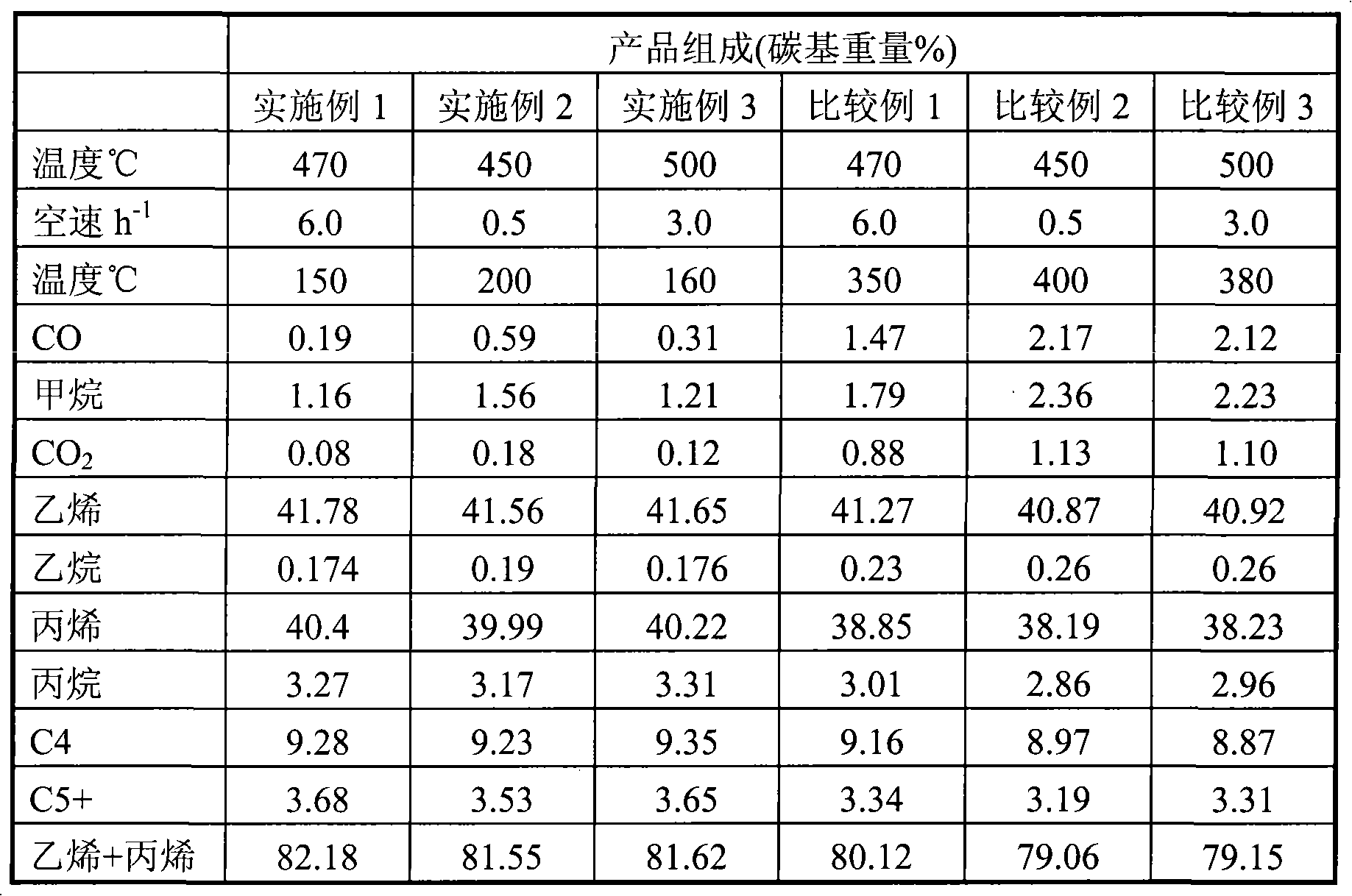

[0017] 200,000 tons / year of methanol to produce low-carbon olefins figure 1 The fluidized bed reactor shown. The diameter of the reactor is 3100 mm, the distribution plate is covered with insulating material high alumina bricks, the thickness is 200 mm, the pressure is 0.06 MPaG, the reaction temperature is 470 ° C, and the space velocity is 6.0 hours -1 , the perforation speed is 186.8 m / s, the speed of the side slot is 8.5 m / s, the SAPO-34 molecular sieve catalyst is used, the reaction raw material is pure methanol, the temperature of the raw material before contacting the catalyst is 150 ° C, the selectivity of ethylene + propylene 82.18%.

Embodiment 2

[0019] 300,000 tons / year of methanol production of low-carbon olefins figure 1 The fluidized bed reactor shown. The diameter of the reactor is 3900 mm, the distribution plate is covered with insulating material high-temperature calcium silicate, the thickness is 110 mm, the pressure is 0.06 MPaG, the reaction temperature is 450 ° C, and the space velocity is 0.5 hours -1 , the perforation speed is 142.1 m / s, the speed of the side slot is 12.0 m / s, the SAPO-34 molecular sieve catalyst is used, the reaction raw material is pure methanol, the temperature of the raw material before contacting the catalyst is 200 ° C, the selectivity of ethylene + propylene 81.55%.

Embodiment 3

[0021] 300,000 tons / year of methanol production of low-carbon olefins figure 1 The fluidized bed reactor shown. The diameter of the reactor is 3900 mm, the distribution plate is covered with insulating material silicon oxide-alumina ceramics, the thickness is 160 mm, the pressure is 0.06 MPaG, the reaction temperature is 500 ° C, and the space velocity is 3.0 hours -1 , the perforation speed is 101.5 m / s, the speed of the side slot is 22.8 m / s, the SAPO-34 molecular sieve catalyst is used, the reaction raw material is pure methanol, the temperature of the raw material before contacting the catalyst is 160 ° C, the selectivity of ethylene + propylene 81.87%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com