Ventilation uniform petrochemical bunker

A uniform and petrochemical technology, applied in the field of silos, can solve the problems of degassing dead zone, flash explosion and ignition of materials, and difficulty in establishing back pressure, so as to achieve uniform gas distribution, improve degassing efficiency, and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

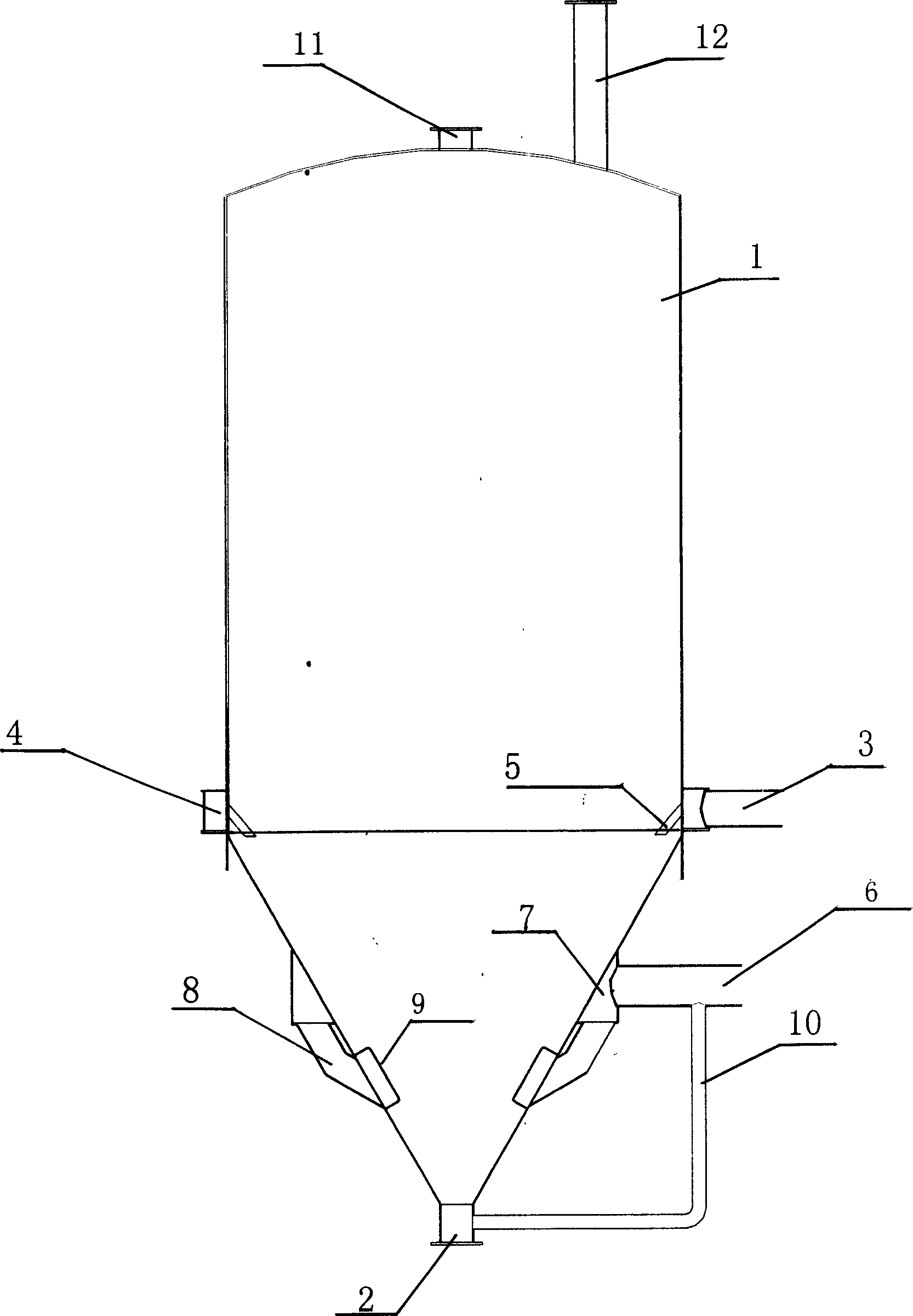

[0007] The silo of the present invention has a silo body 1, the lower end of the silo body 1 has a cone section, the tip of the cone section has a discharge port 2, the upper edge of the cone section is equipped with an annular air belt pipe 4, and one of the latter There is a main air duct 3 on the side, and 12 anti-blow air nozzles 5 are evenly distributed along the annular air belt duct 4. The upper part of the warehouse body 1 has a material inlet 11 and an air outlet 12. Two main air ducts 6 are installed on the conical surface on the same side, and there is an annular air belt pipe 7 around the cone section. Two-way reverse blowing tuyere 8, in the bottom of the two-way reverse blowing tuyere 8, a second-way reverse blowing tuyere baffle 9 parallel to the cone surface is installed inside the cone section, and the discharge port 2 passes through the reverse L-shaped The blowing pipe 10 communicates with the two-way main air pipe 6 .

[0008] When using the silo of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com