High-pressure pipeline gas and liquid reactor for hydrogen sulfide treatment of oil well and treatment method thereof

A technology of gas-liquid reactors and high-pressure pipelines, which is applied to chemical instruments and methods, chemical methods for reacting liquid and gaseous media, and hydrocarbon oil treatment, which can solve the problems of huge equipment processing costs, long residence time, and mass transfer efficiency. Low-level problems, to achieve the effect of thorough desulfurization effect, convenient management and maintenance, and high efficiency of dissolved gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

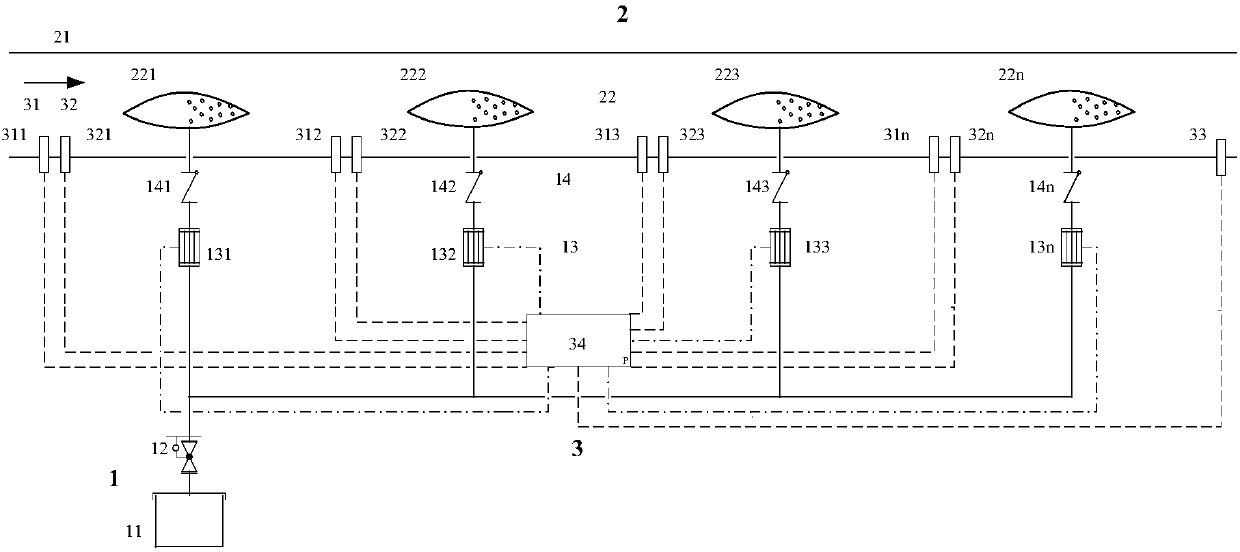

[0044] Well A in a block of Shengli Oilfield 12 , the fluid production of the oil well is 16m 3 / d, the hydrogen sulfide content in the produced fluid is 200mg / L, and this well is an oil well with high hydrogen sulfide content. The hydrogen sulfide in the well output fluid is processed online by using the invention.

[0045] The inner diameter of the high-pressure pipeline gas-liquid reactor is 65mm; the shape of the dissolved gas mixer is a spindle, the length is 100mm, and the height is 40mm. The diameter of the gas release hole on the spindle is 3μm, and the hole spacing is 2mm; the distance between the dissolved gas mixer The value of n is 1m, and the value of n is 4. The results of hydrogen sulfide, dissolved oxygen and air supply at each node in the produced fluid are shown in Table 1.

[0046] Table 1 Well A 12 The amount of hydrogen sulfide and dissolved oxygen and air supply at each node of the produced liquid

[0047] mixer

[0048] As can be seen from ...

Embodiment 2

[0050] Well A in a block of Shengli Oilfield 15 , the fluid production of the oil well is 30m 3 / d, the hydrogen sulfide content in the produced fluid is 750mg / L, and this well is an oil well with high hydrogen sulfide content. The hydrogen sulfide in the well output fluid is processed online by using the invention.

[0051] The inner diameter of the high-pressure pipeline gas-liquid reactor is 80mm; the shape of the dissolved gas mixer is a hollow cylinder, the length is 120mm, and the height is 60mm. The diameter of the gas release hole on the hollow cylinder is 4μm, and the hole spacing is 1mm; the dissolved gas mixer The distance between them is 1.5m, and the value of n is 7. The results of hydrogen sulfide, dissolved oxygen and air supply at each node in the produced fluid are shown in Table 2.

[0052] Table 2 Well A 15 The amount of hydrogen sulfide and dissolved oxygen and air supply at each node of the produced liquid

[0053] mixer

[0054] As can be se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com