Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

98results about How to "Eliminate Directionality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

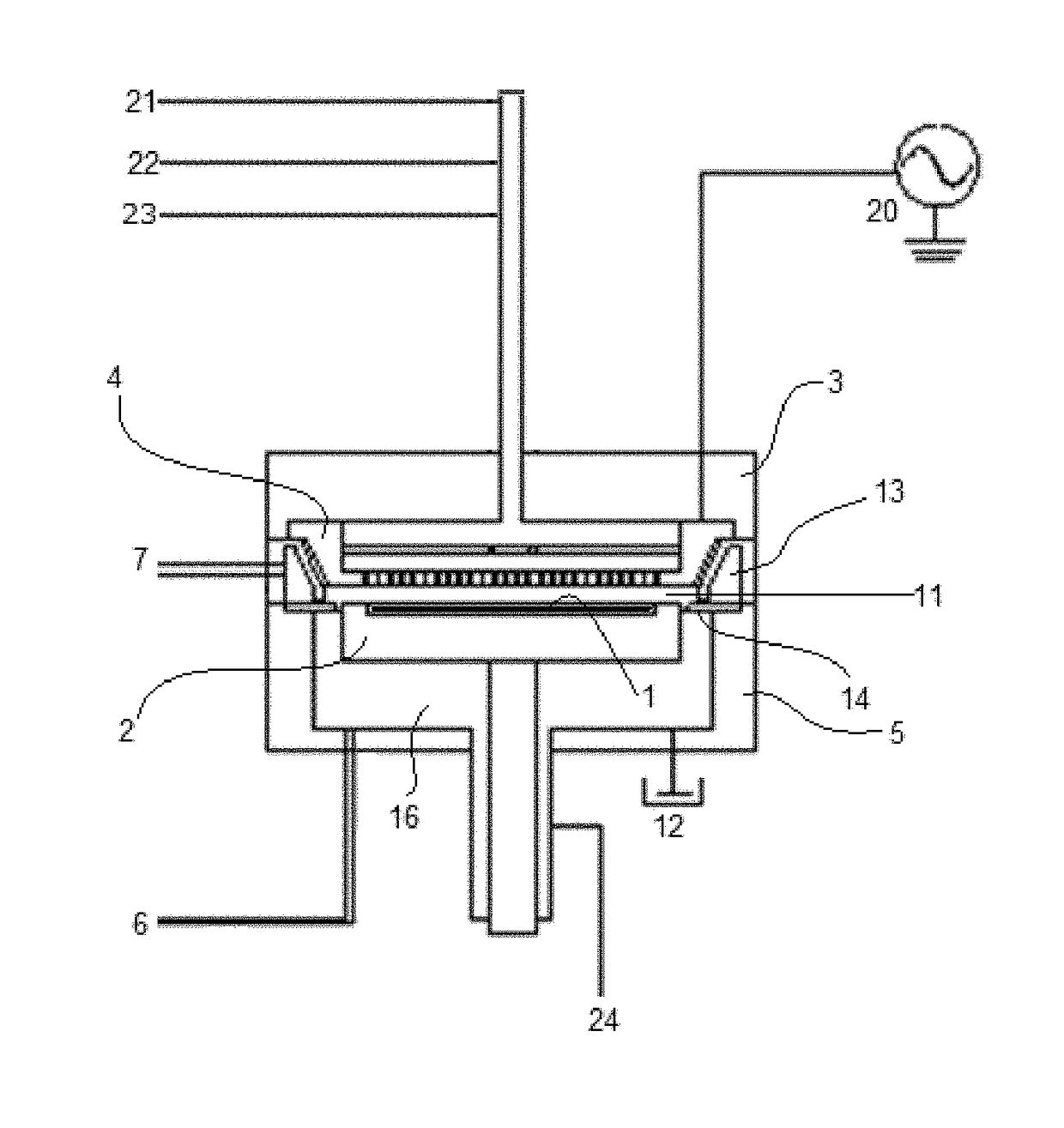

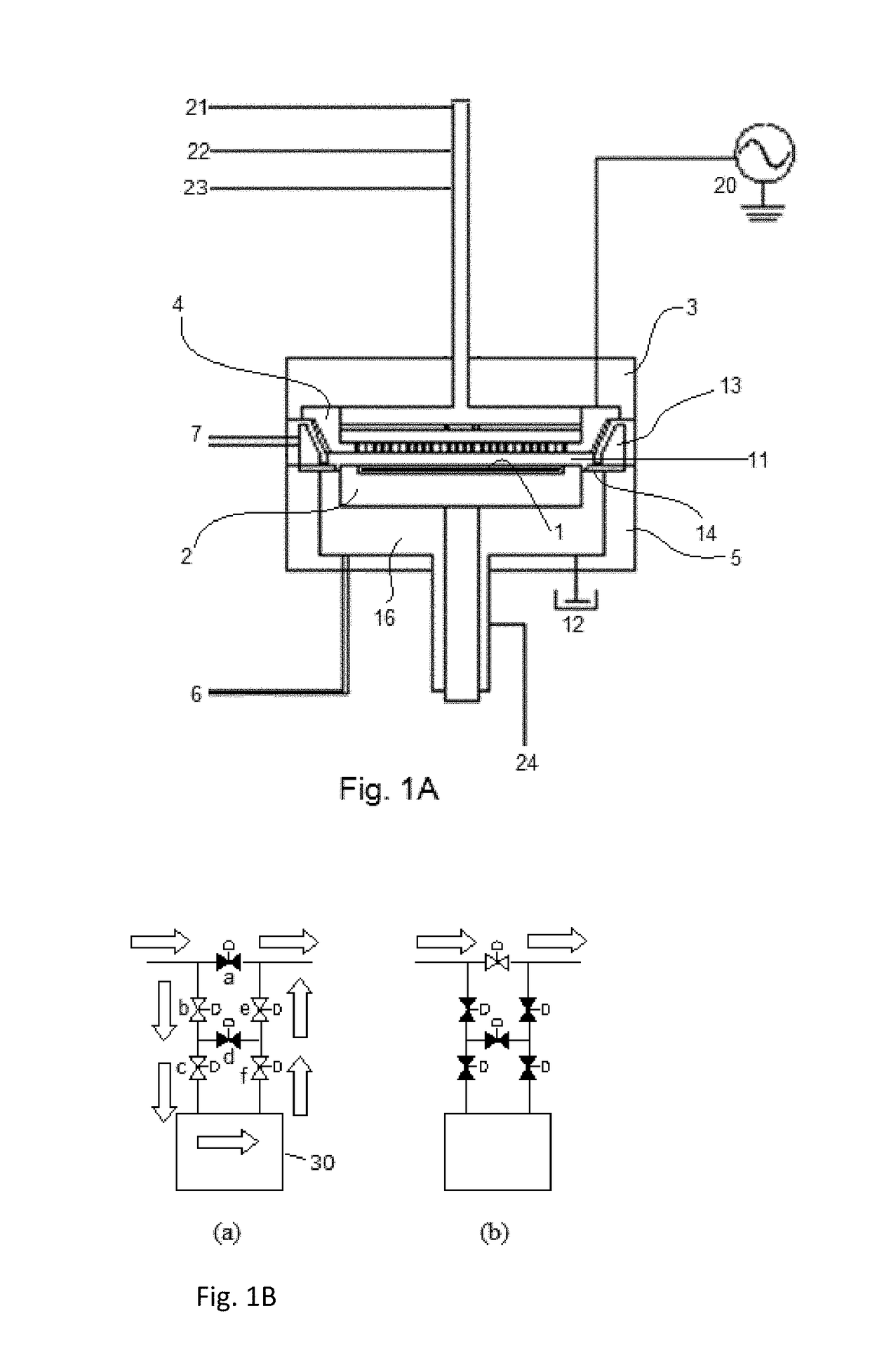

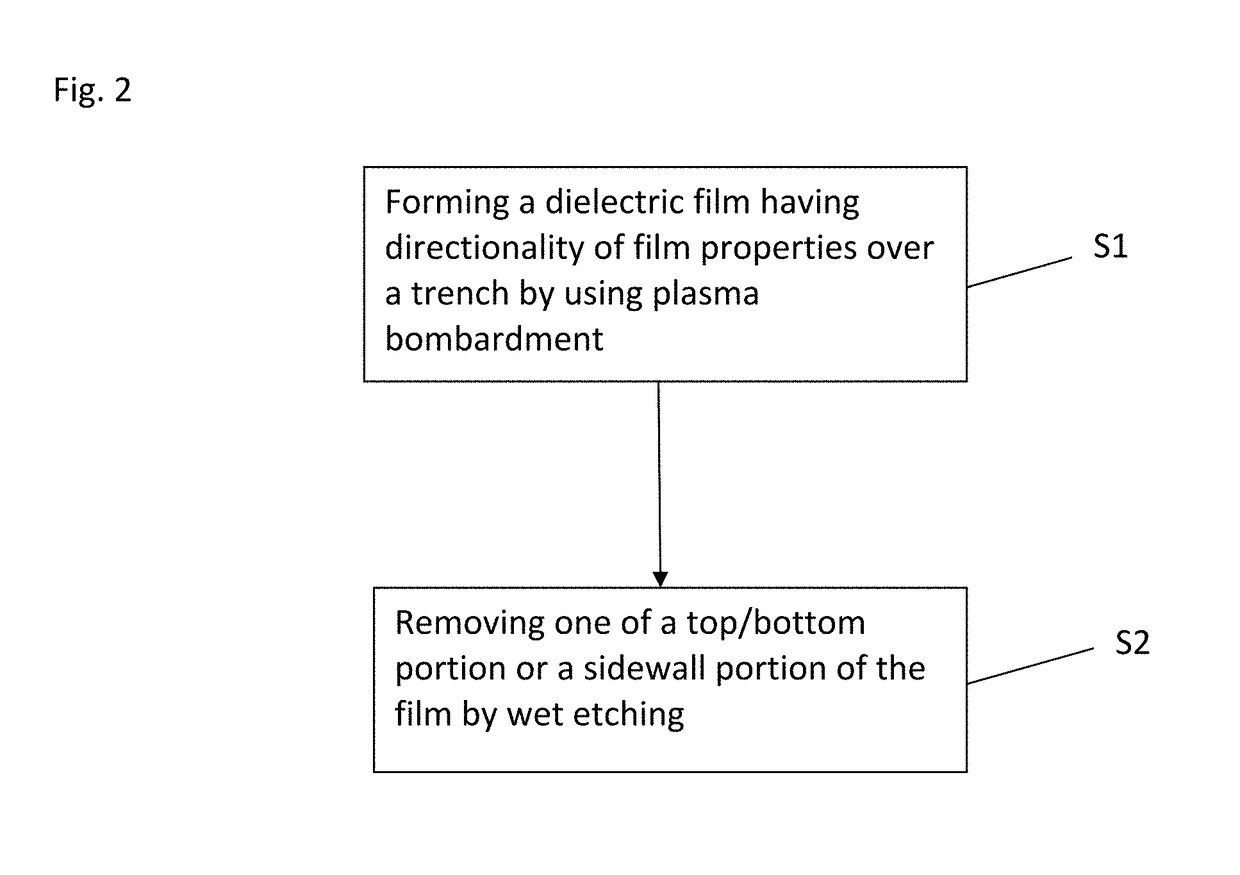

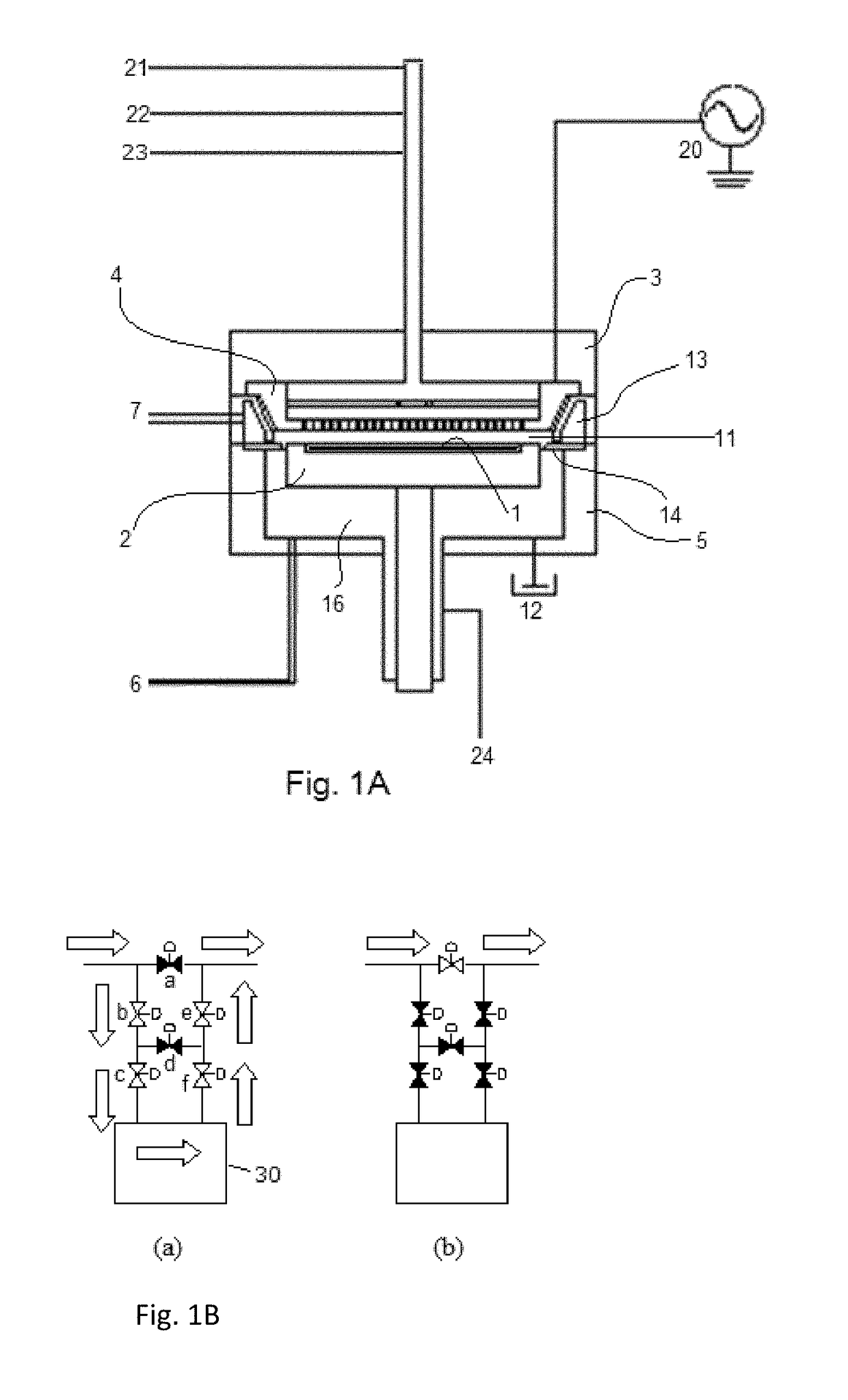

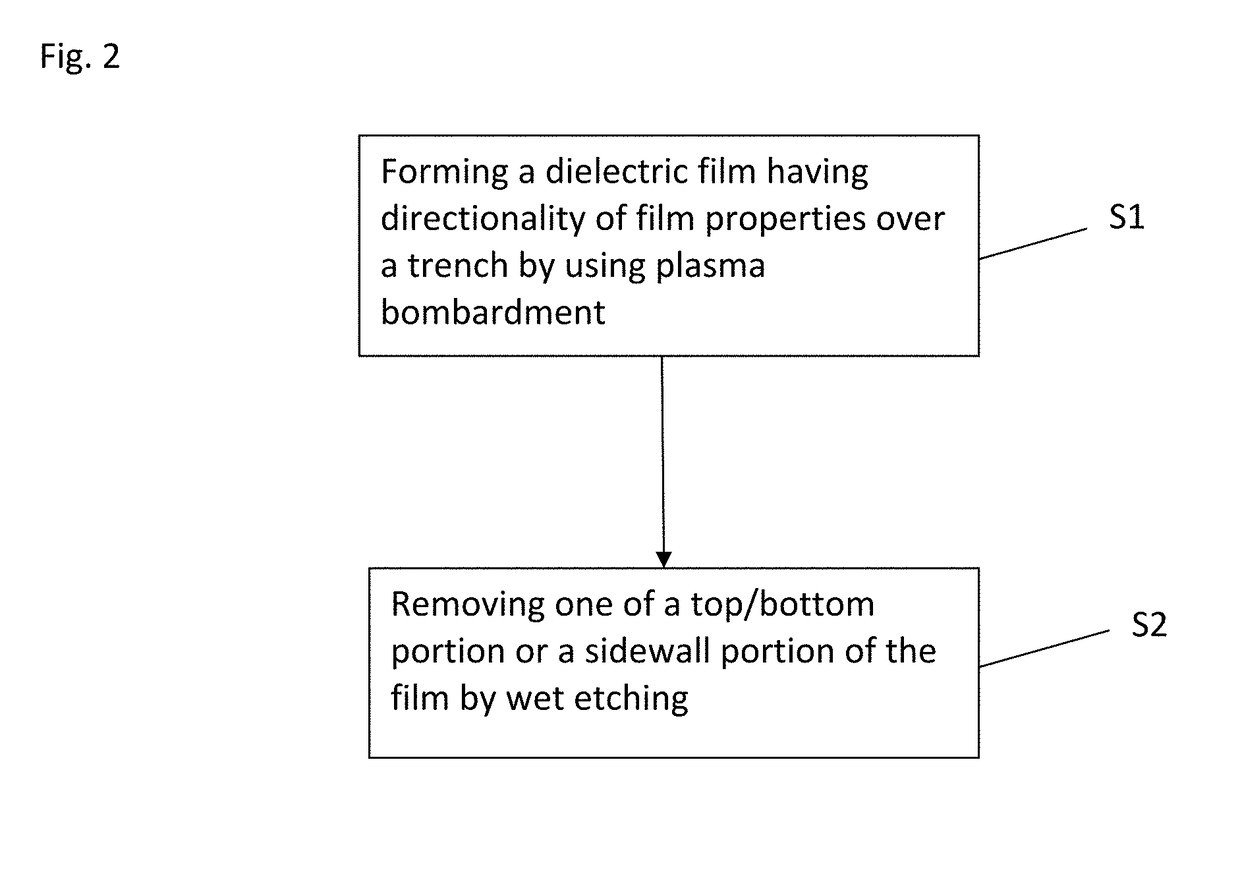

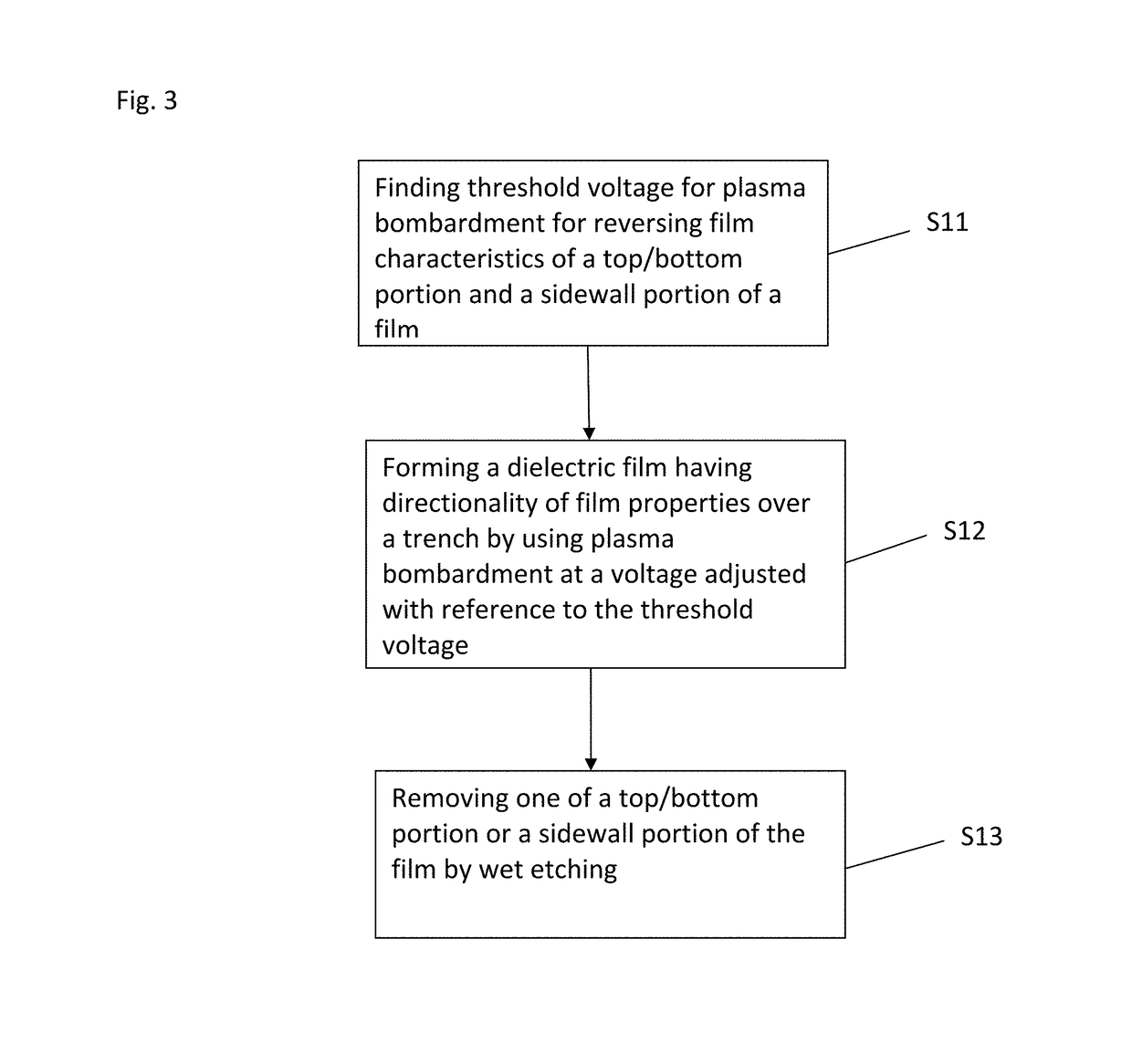

Method for forming silicon nitride film selectively on sidewalls or flat surfaces of trenches

ActiveUS9754779B1Low densityPlasma-enhanced chemical vapor depositionElectric discharge tubesSemiconductor/solid-state device manufacturingEtchingChemical resistance

A method for fabricating a layer structure in a trench includes: simultaneously forming a dielectric film containing a Si—N bond on an upper surface, and a bottom surface and sidewalls of the trench, wherein a top / bottom portion of the film formed on the upper surface and the bottom surface and a sidewall portion of the film formed on the sidewalls are given different chemical resistance properties by bombardment of a plasma excited by applying voltage between two electrodes between which the substrate is place in parallel to the two electrodes; and substantially removing either one of but not both of the top / bottom portion and the sidewall portion of the film by wet etching which removes the one of the top / bottom portion and the sidewall portion of the film more predominantly than the other according to the different chemical resistance properties.

Owner:ASM IP HLDG BV

Method for forming silicon nitride film selectively on sidewalls of trenches

ActiveUS20190057857A1Low densityPlasma-enhanced chemical vapor depositionElectric discharge tubesSemiconductor/solid-state device manufacturingEtchingChemical resistance

A method for fabricating a layer structure in a trench includes: simultaneously forming a dielectric film containing a Si—N bond on an upper surface, and a bottom surface and sidewalls of the trench, wherein a top / bottom portion of the film formed on the upper surface and the bottom surface and a sidewall portion of the film formed on the sidewalls are given different chemical resistance properties by bombardment of a plasma excited by applying voltage between two electrodes between which the substrate is place in parallel to the two electrodes; and substantially removing the sidewall portion of the film by wet etching which removes the sidewall portion of the film more predominantly than the top / bottom portion according to the different chemical resistance properties.

Owner:ASM IP HLDG BV

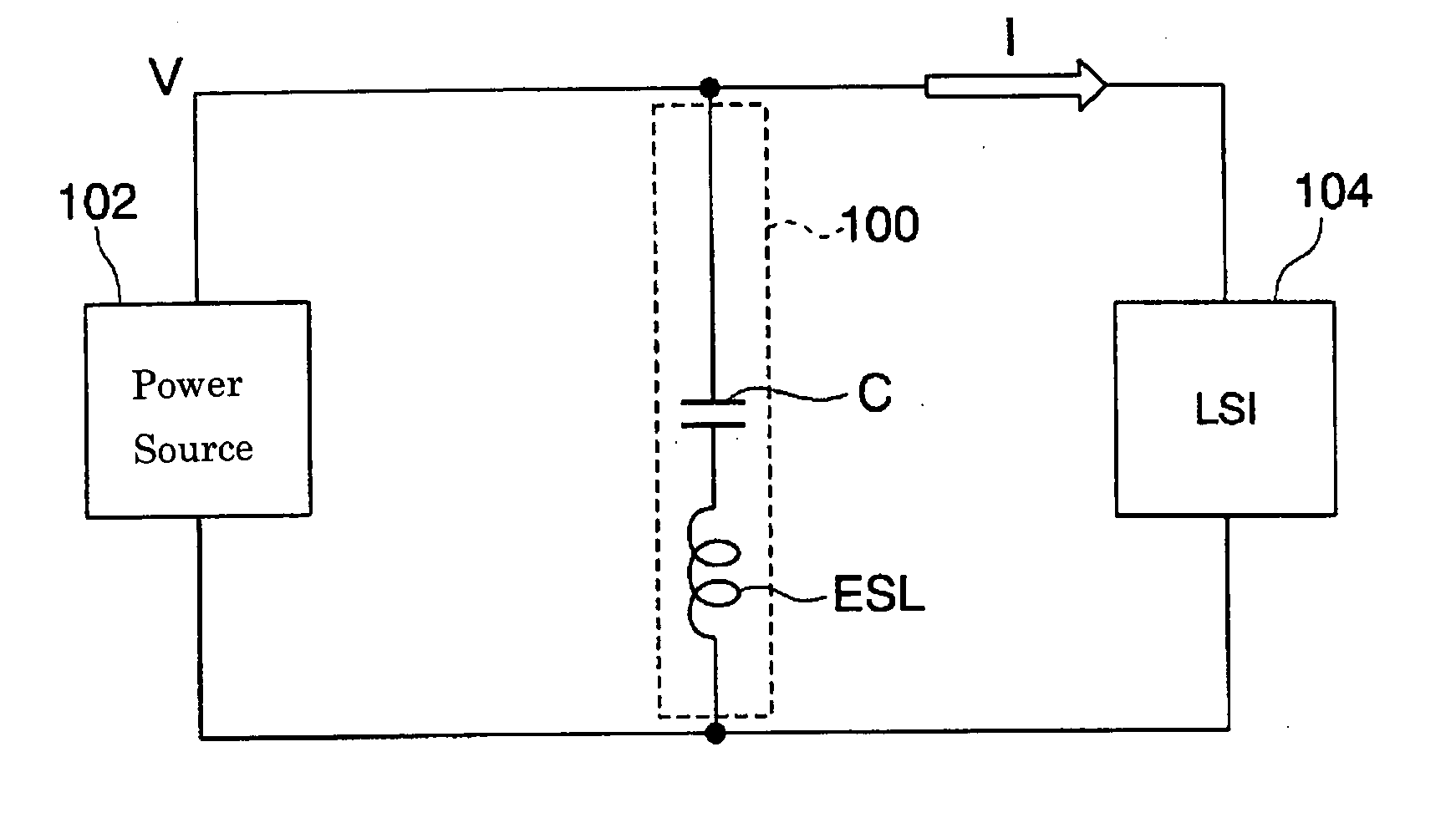

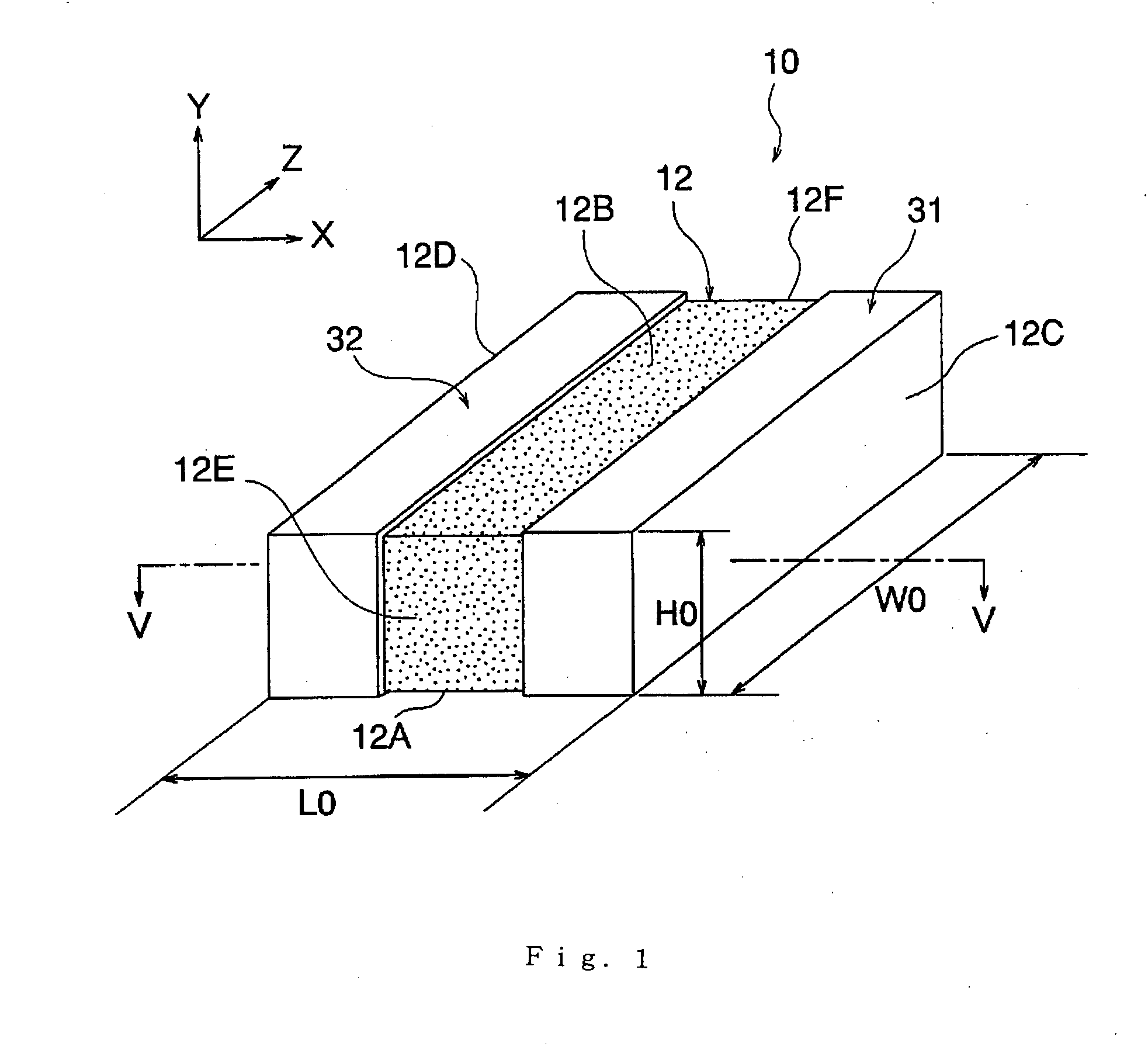

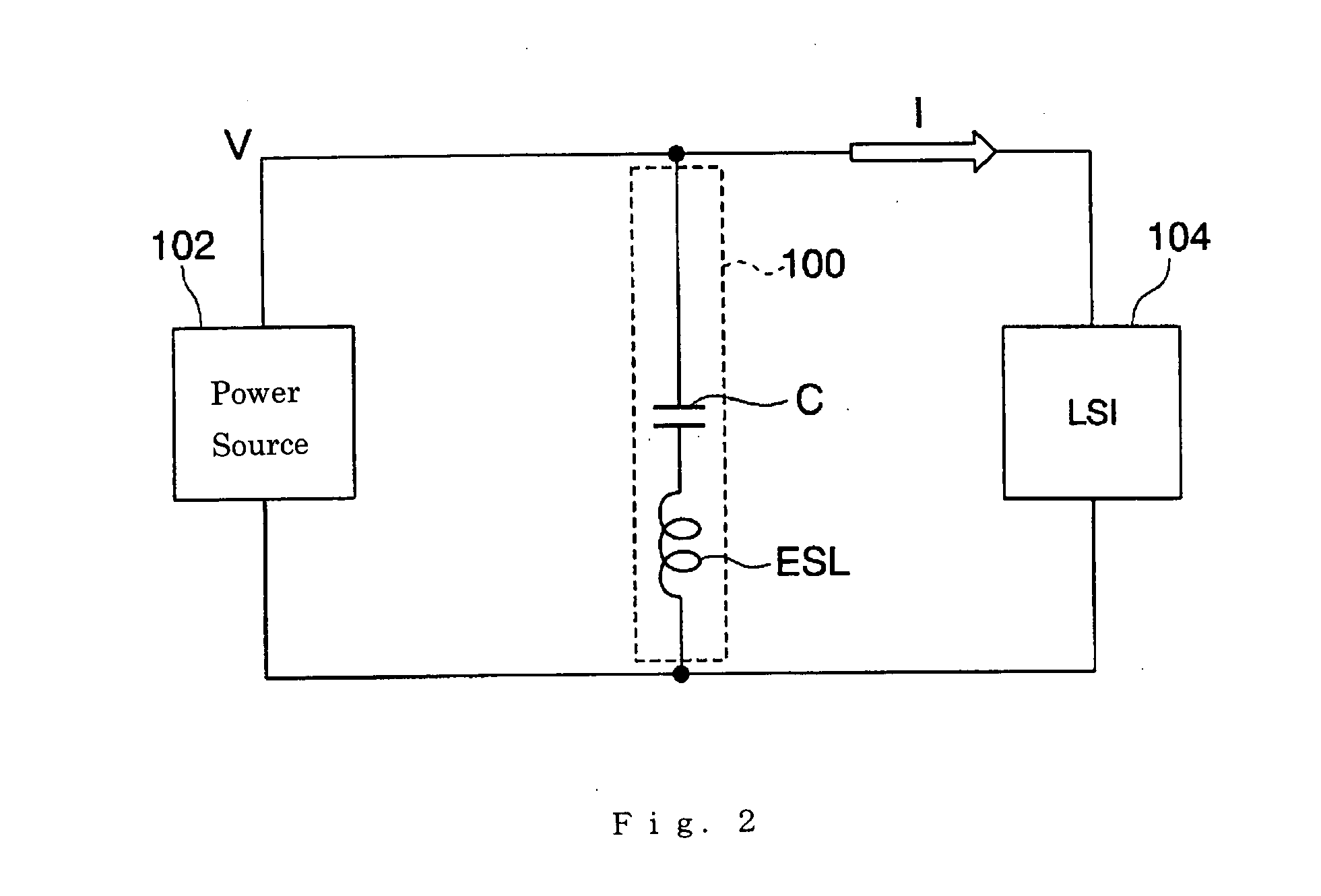

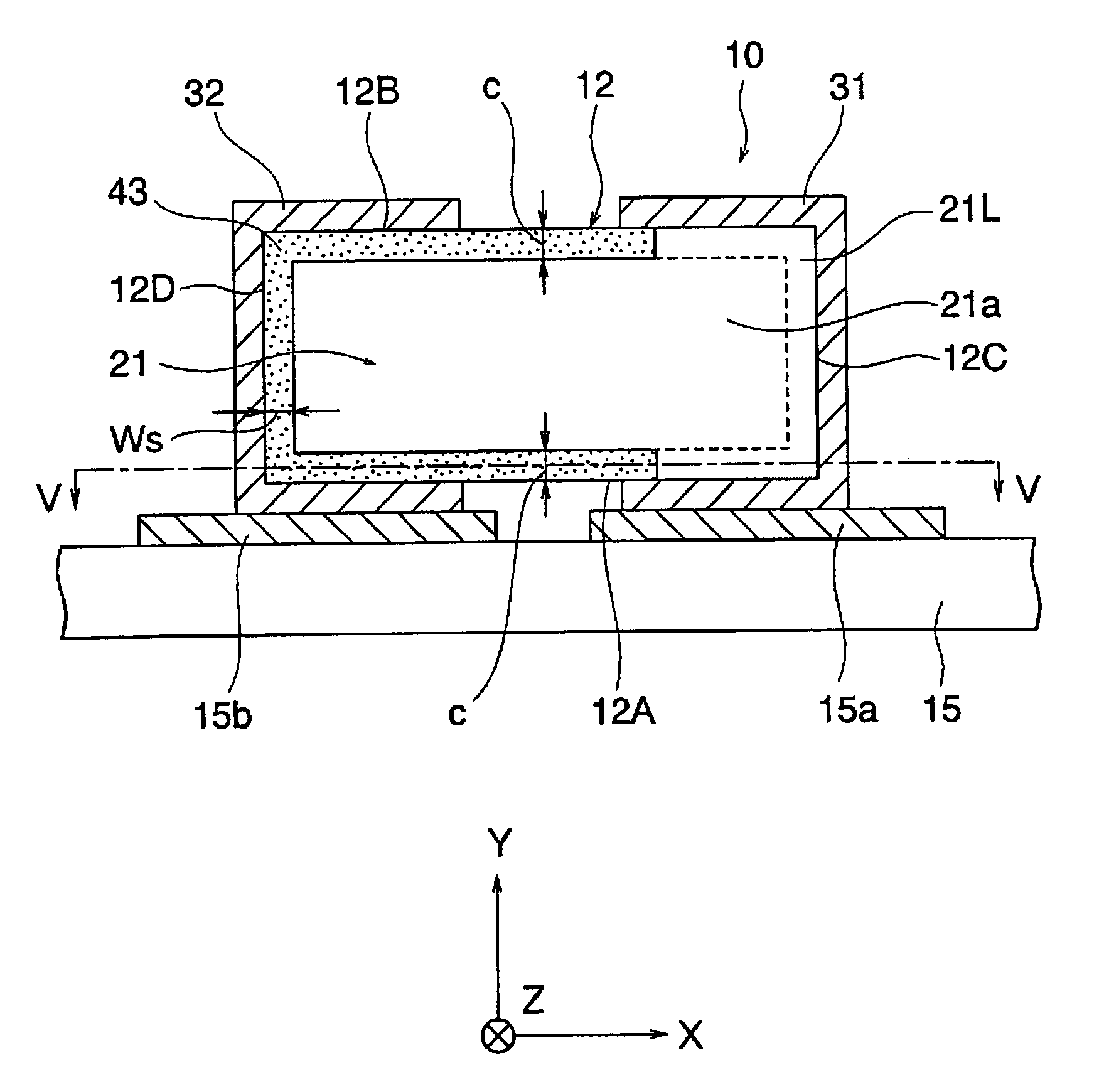

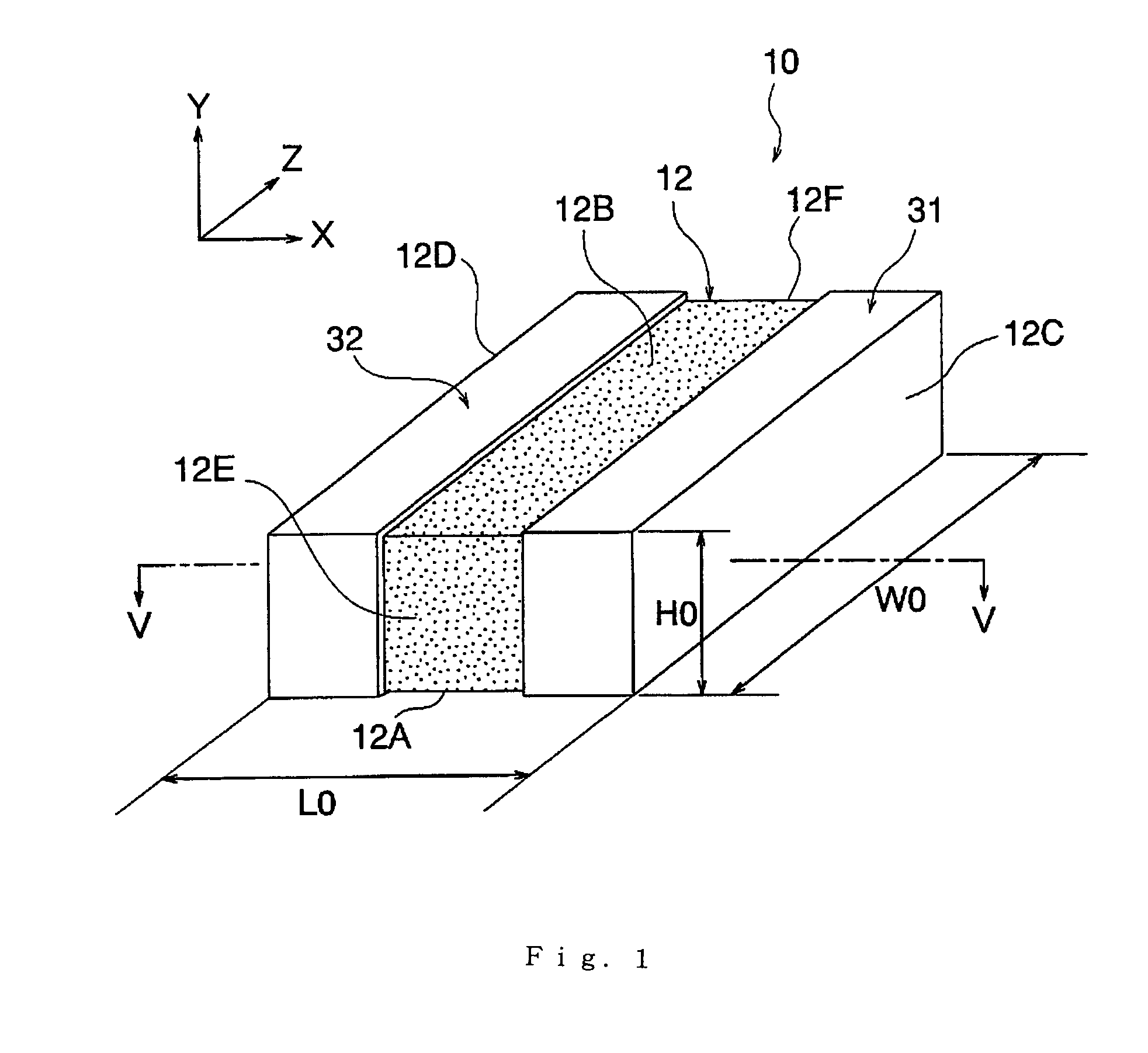

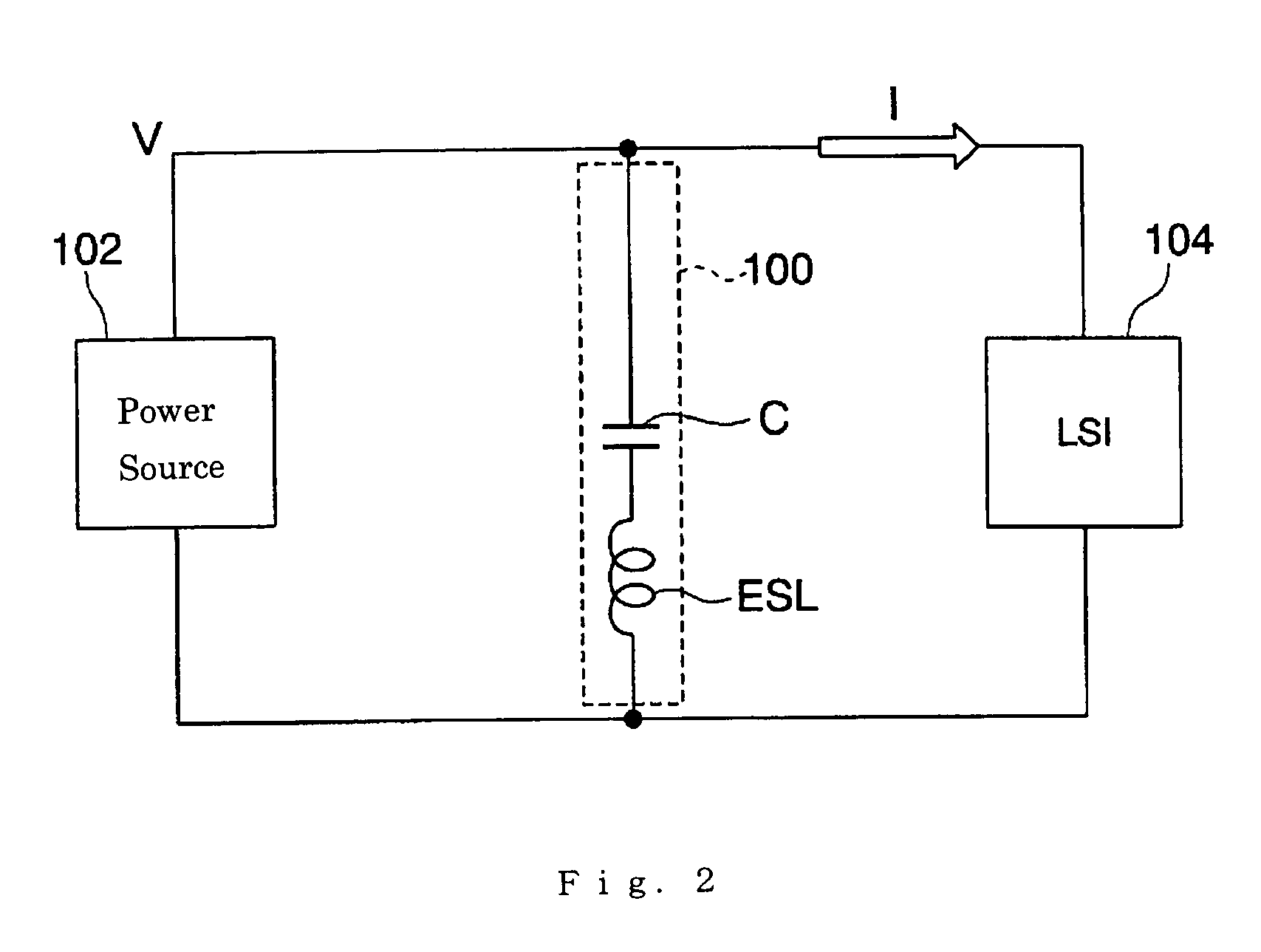

Multilayer capacitor

ActiveUS20080144253A1Reduce ESLLow manufacturing costFixed capacitor electrodesFixed capacitor dielectricElectrical conductorDielectric layer

A multilayer capacitor 10 comprising a dielectric body 12 having an approximately rectangular parallelepiped shape formed by alternately stacking a plurality of dielectric layer 12a, a first conductor layer 21, a second conductor layer 22, a first terminal electrode 31 and a second terminal electrode 32 formed on a first side face 12A of side faces 12 of the dielectric body in parallel to a stacking direction Z. The first conductor layer 21 comprises a first lead portion 21L connected to the first terminal electrode 31, the second conductor layer 22 comprises a second lead portion 22L connected to the second terminal electrode 32. Between a length “a” of the first lead portion 21L and the second lead portion 22L in vertical direction to the stacking direction Z, a length “b” of conductor layers positioned at both ends of the dielectric body 12 in the stacking direction, a space length “c” of the first side face 12A and the first conductor layer 21, a total number of the conductor layers 22, 22, (a+c) / (b×n)≦0.035 is consisted.

Owner:TDK CORPARATION

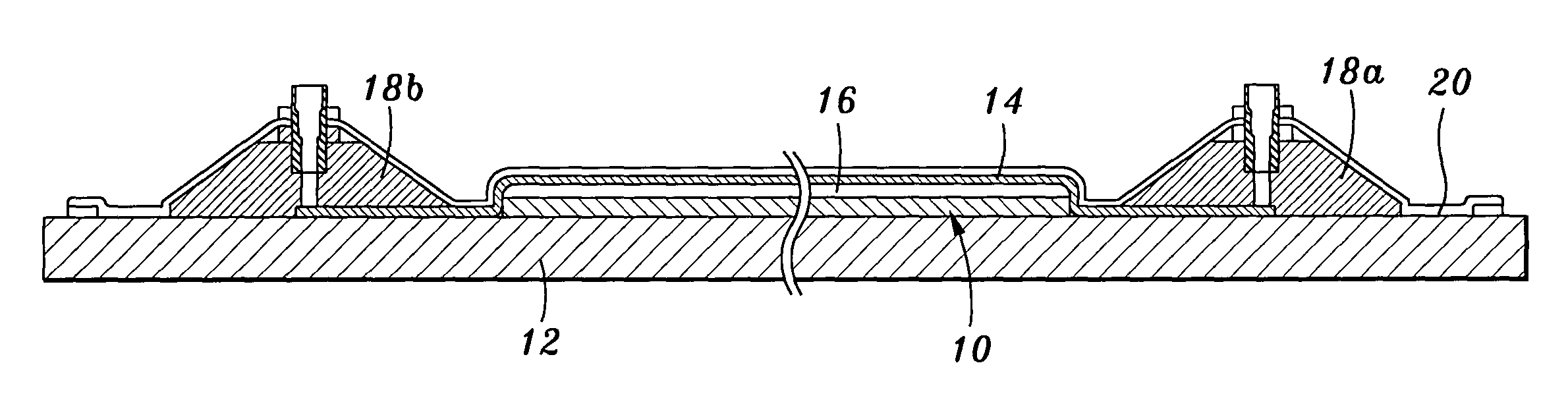

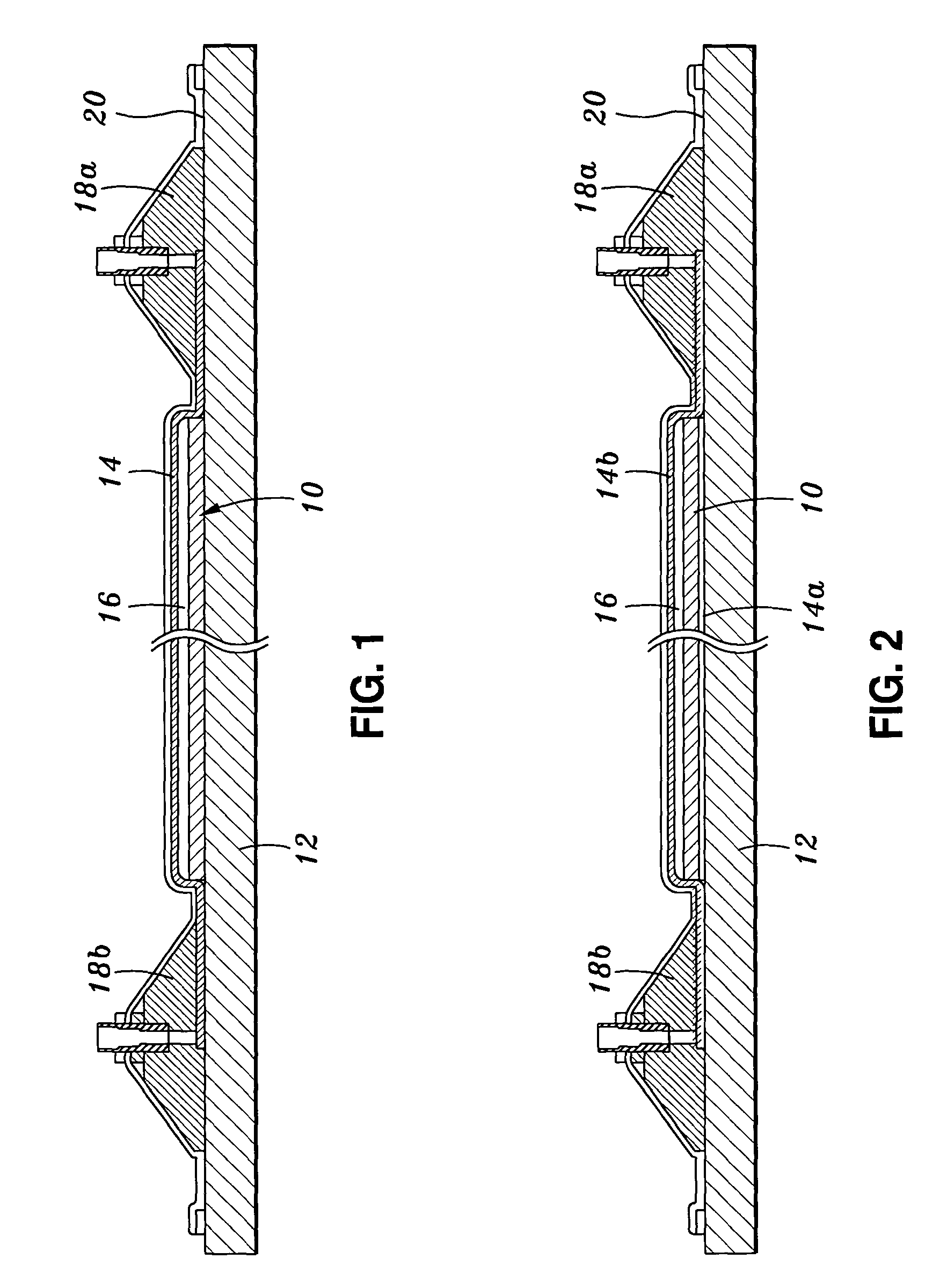

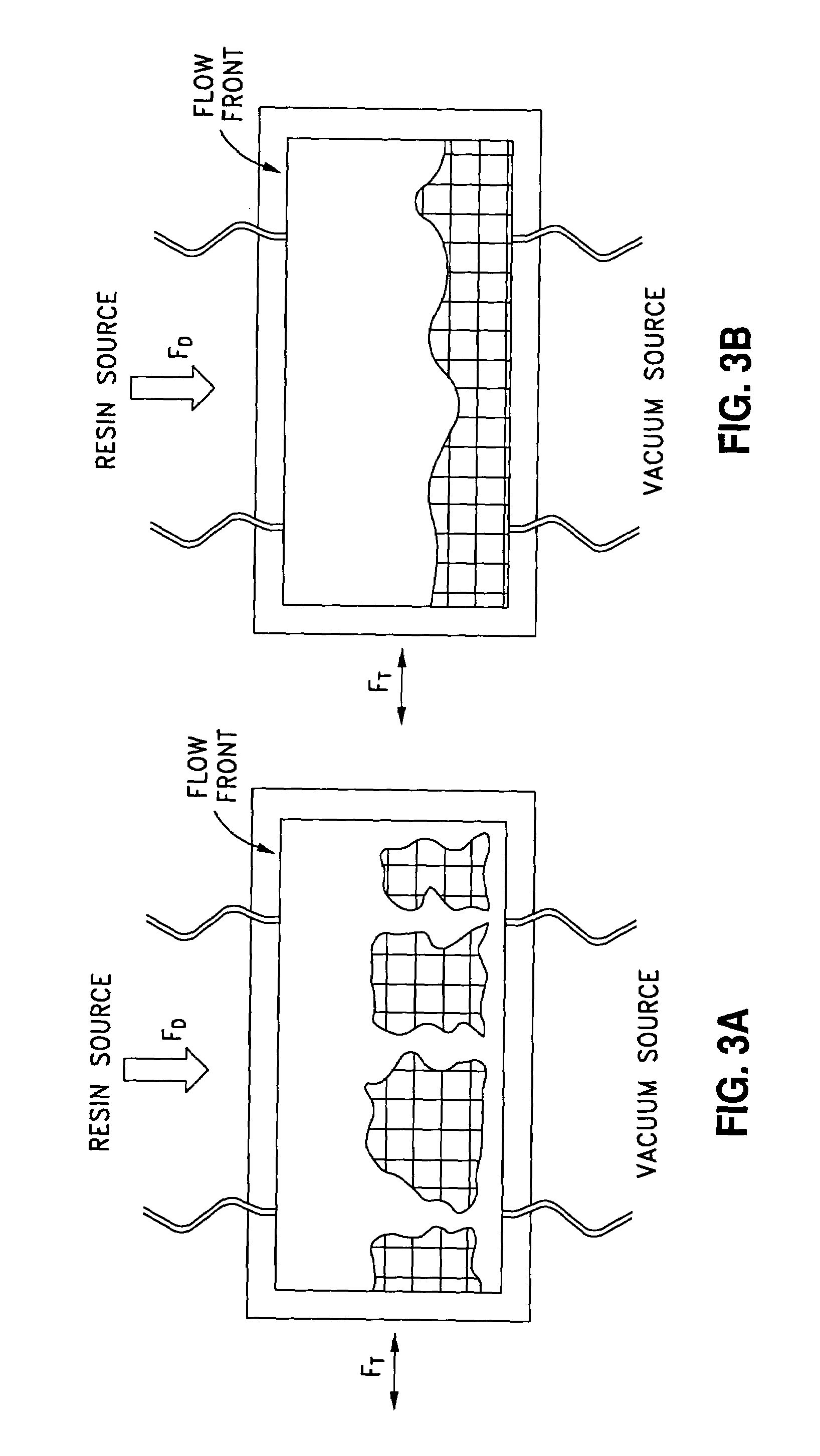

High-performance infusion system for VARTM fabrication

InactiveUS6964561B2Reduce processing timeImprove permeabilityConfectioneryWood working apparatusVacuum assistedModular unit

In the field of vacuum-assist-resin-transfer-mold (VARTM) processing, a new system is provided to lower production times and to create a high permeability mold cavity with reduced directionality to yield an optimum flow-front. The system comprises the use of a high permeability layer to evacuate air from the mold cavity and may include a reusable port-runner device for introduction of resin into the fiber mat. In the preferred embodiment, the high permeability layer is a “felt-like” material constructed of synthetic fibers, and the reusable port device is a flat, modular unit. In another embodiment, the high permeability layer is a fluid-impervious material with sporadic protrusions, and the reusable port-runner device is a flexible, silicone unit. Other embodiments are comprised of any combination thereof. Each embodiment is designed to minimize set-up times and to create a mold cavity with a low resistance to fluid flow through the application of pressure differentials.

Owner:V SYST COMPOSITES

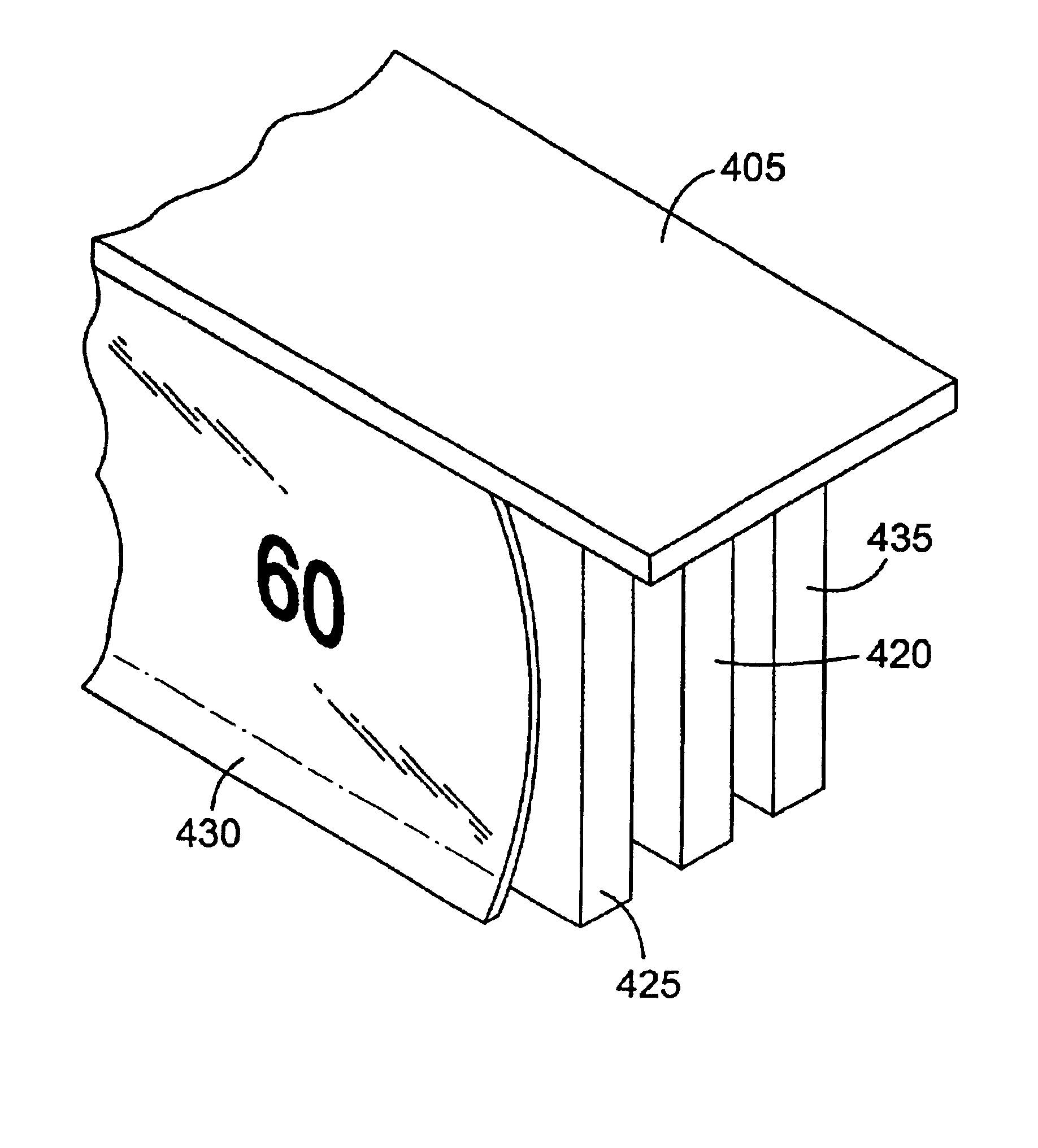

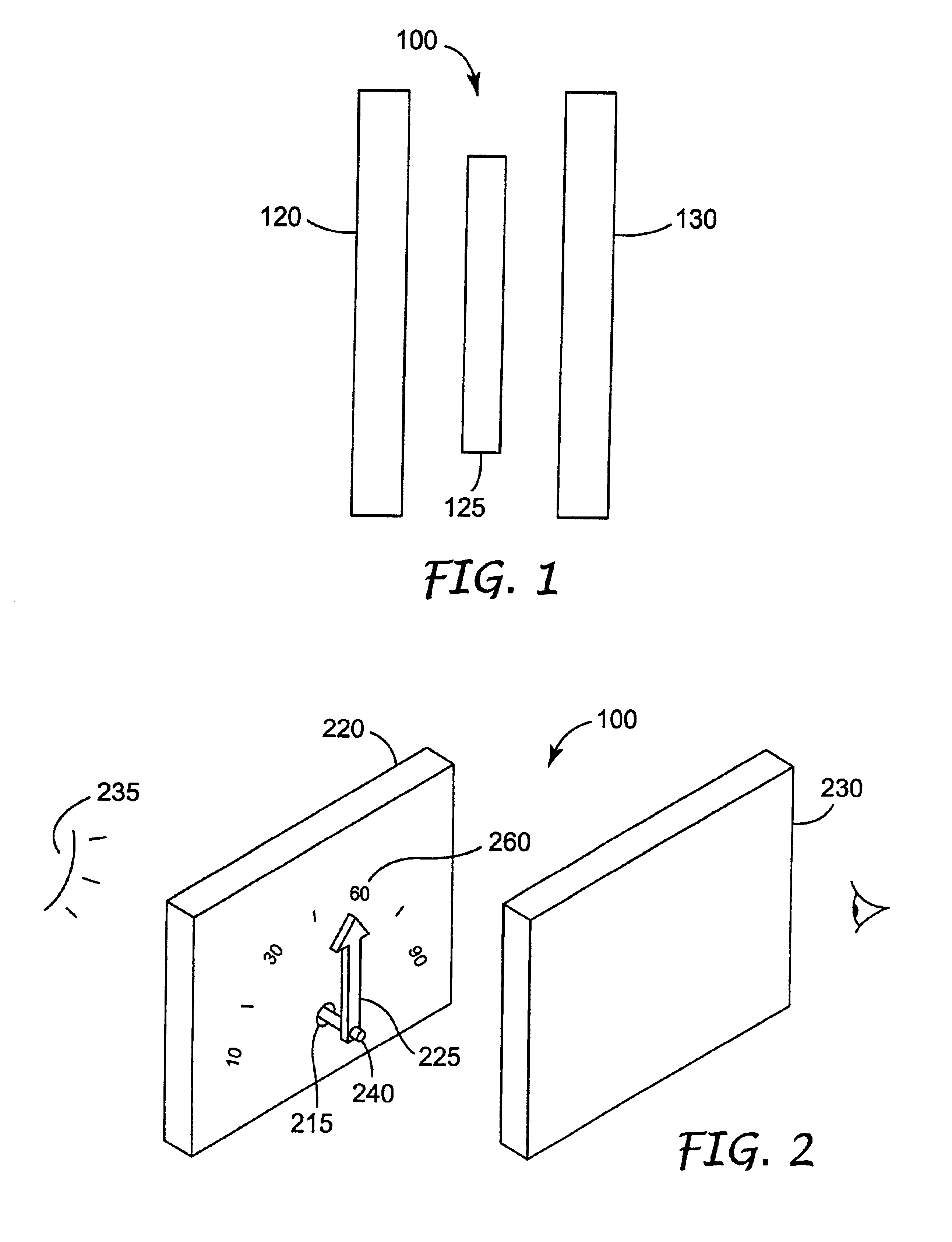

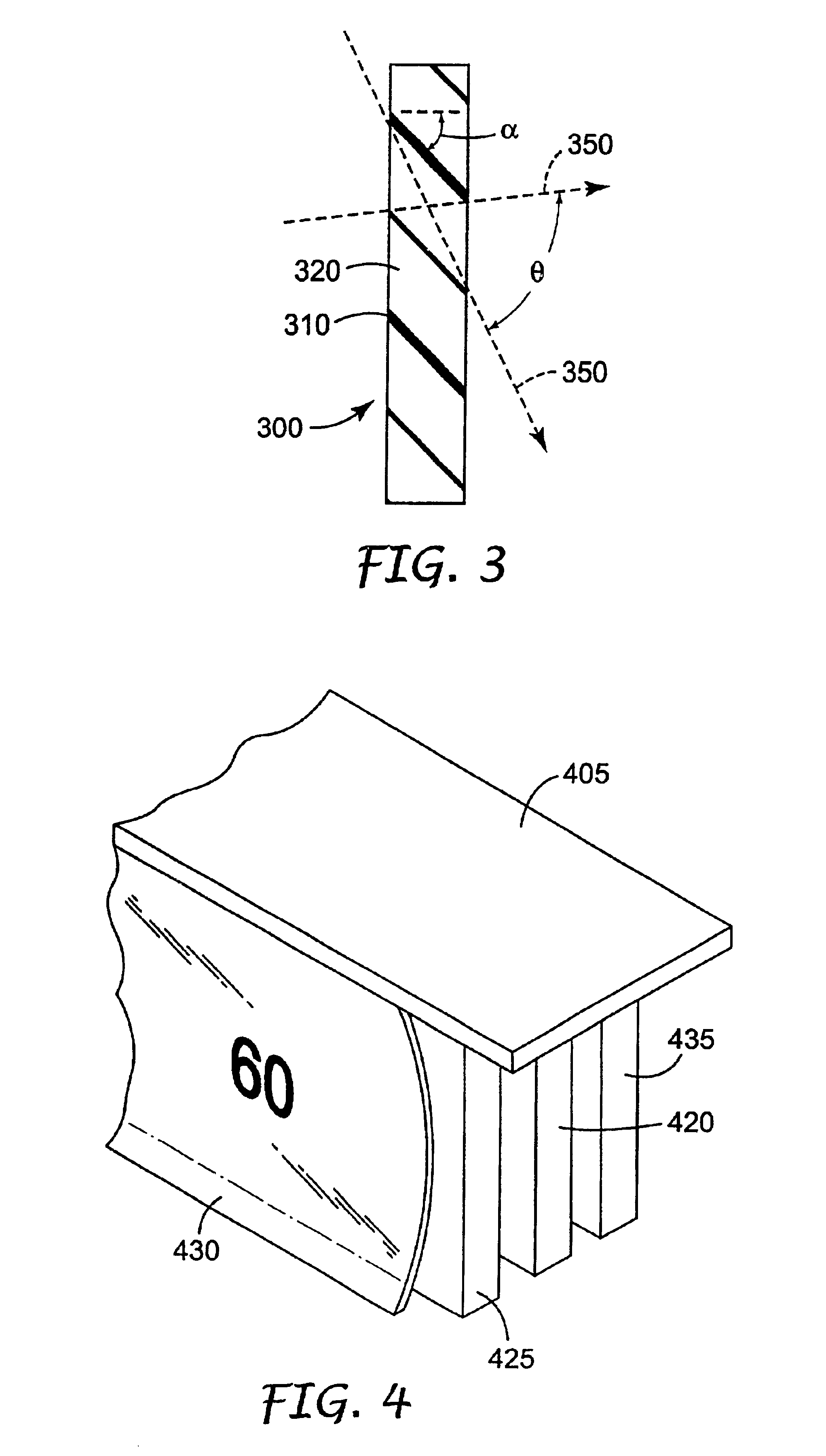

Display device

InactiveUS6905219B2Limited directionalityEliminate DirectionalityThermometer detailsMeasurement apparatus componentsOptoelectronicsDisplay device

A display device having an indicator interposed between two light controlling elements. The light controlling elements act in cooperation to restrict the viewing angle of the display in at least two directions. Only one of the light collimating elements restricts the angle of ambient light entering the display.

Owner:3M INNOVATIVE PROPERTIES CO

Organic electroluminescent element and electronic instrument

ActiveUS20150236300A1Directionality of be lowLight increaseSolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceSine wave

The first electrode has a convexo-concave structure including a plurality of convex portions and a plurality of concave portions at an interface with the organic compound layer. The convexo-concave structure has at least one cross section in a thickness direction of the light-transmissive substrate, the cross section being shaped in a sine-wave curve or a curve represented by a sum of a plurality of sine waves having different amplitudes or angles. A distance between a convex portion and an adjacent convex portion forming the convexo-concave structure is equal to or more than a peak wavelength of light radiated from the emitting layer and is equal to or less than a propagation distance (Lsp) of surface plasmon at the interface between the first electrode having the convexo-concave structure and the organic compound layer.

Owner:IDEMITSU KOSAN CO LTD

Golf club head

InactiveUS20110159987A1Maintaining light weightAvoid recoveryGolf clubsRacket sportsEllipseArcuate shape

A hollow golf club head has a head body having a face aperture part and a face member held to the face aperture part by welding, the face member formed by forging a rolled material of a titanium alloy having an α phase, and the face member comprising a thick-material part positioned in the center of the face member, an outer peripheral part positioned at the periphery of the thick-material part, and a thin-material part partially positioned between the thick-material part and the outer peripheral part. The thick-material part is formed in an area having a shape obtained by depressing a substantially elliptical or substantially circular shape in a substantially arcuate shape toward the center of the ellipse at two opposite sides thereof. The thick-material part, the thin-material part, and the peripheral part are formed by the forging so as to destroy an orientation of the α-phase.

Owner:BRIDGESTONE SPORTS

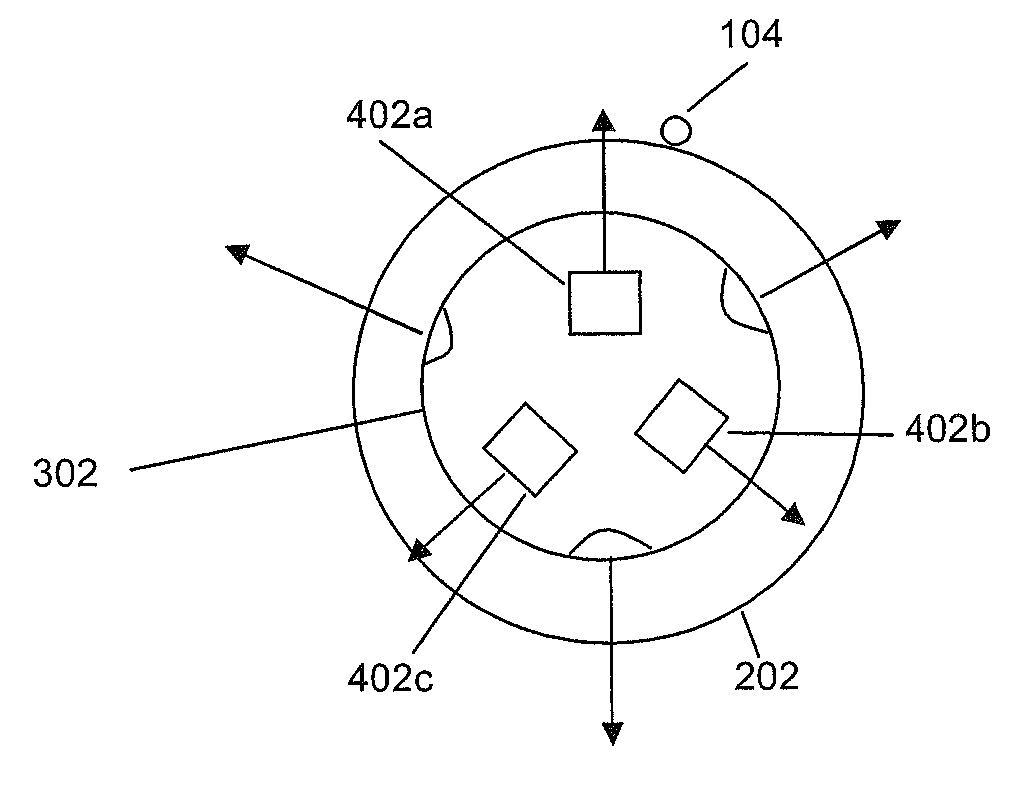

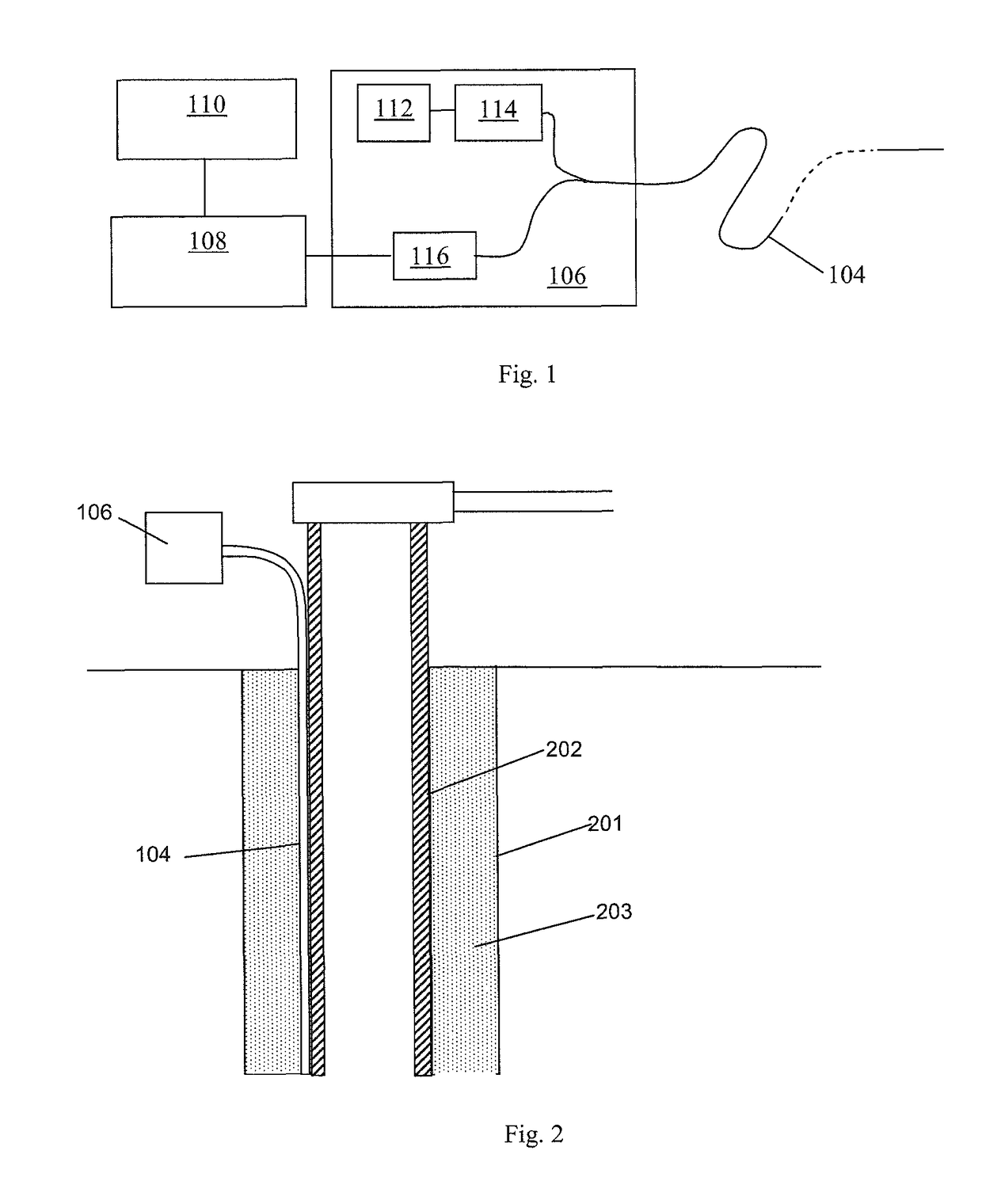

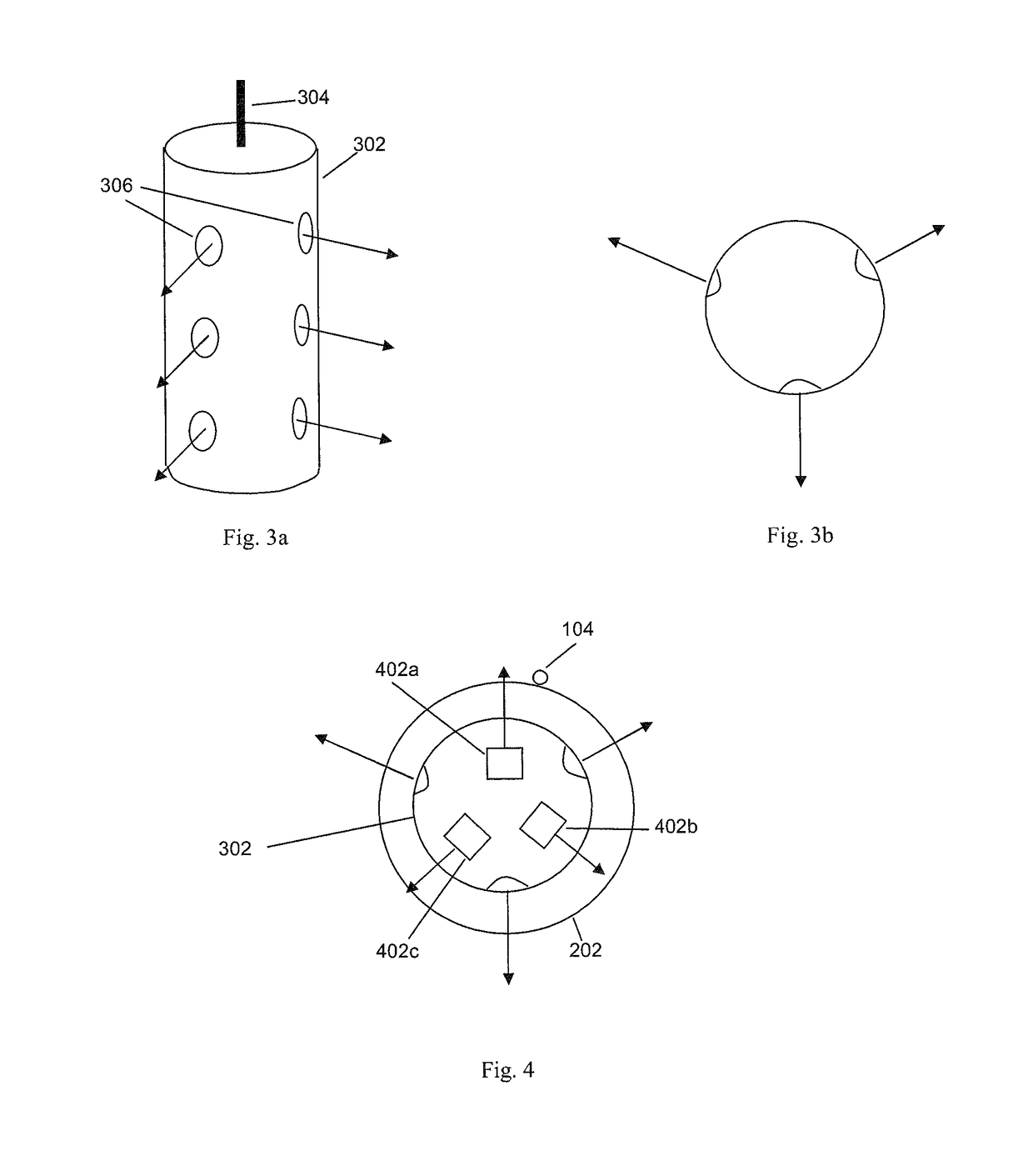

Determining perforation orientation

ActiveUS9945215B2Reduce disadvantagesIncrease intensitySurveyConstructionsDistributed acoustic sensingRelative intensity

A method and apparatus for determining the relative orientation of objects downwell, and especially to determining perforator orientation, involves varying the orientation of an object, such as a perforator gun (302) in the wellbore (202) and activating at least one directional acoustic source (402a-c). Each directional acoustic source is fixed in a predetermined location to the object and transmits an acoustic signal preferentially in a known direction. The directional acoustic sources are activated so as to generate sound in a plurality of different orientations of said object. An optical fiber (104) is interrogated to provide distributed acoustic sensing in the vicinity of the object; and the acoustic signals detected by the optical fiber are analyzed to determine the orientation of the at least one directional acoustic source relative to the optical fiber, for instance by looking at the relative intensity in the different orientations.

Owner:OPTASENSE HLDG LTD

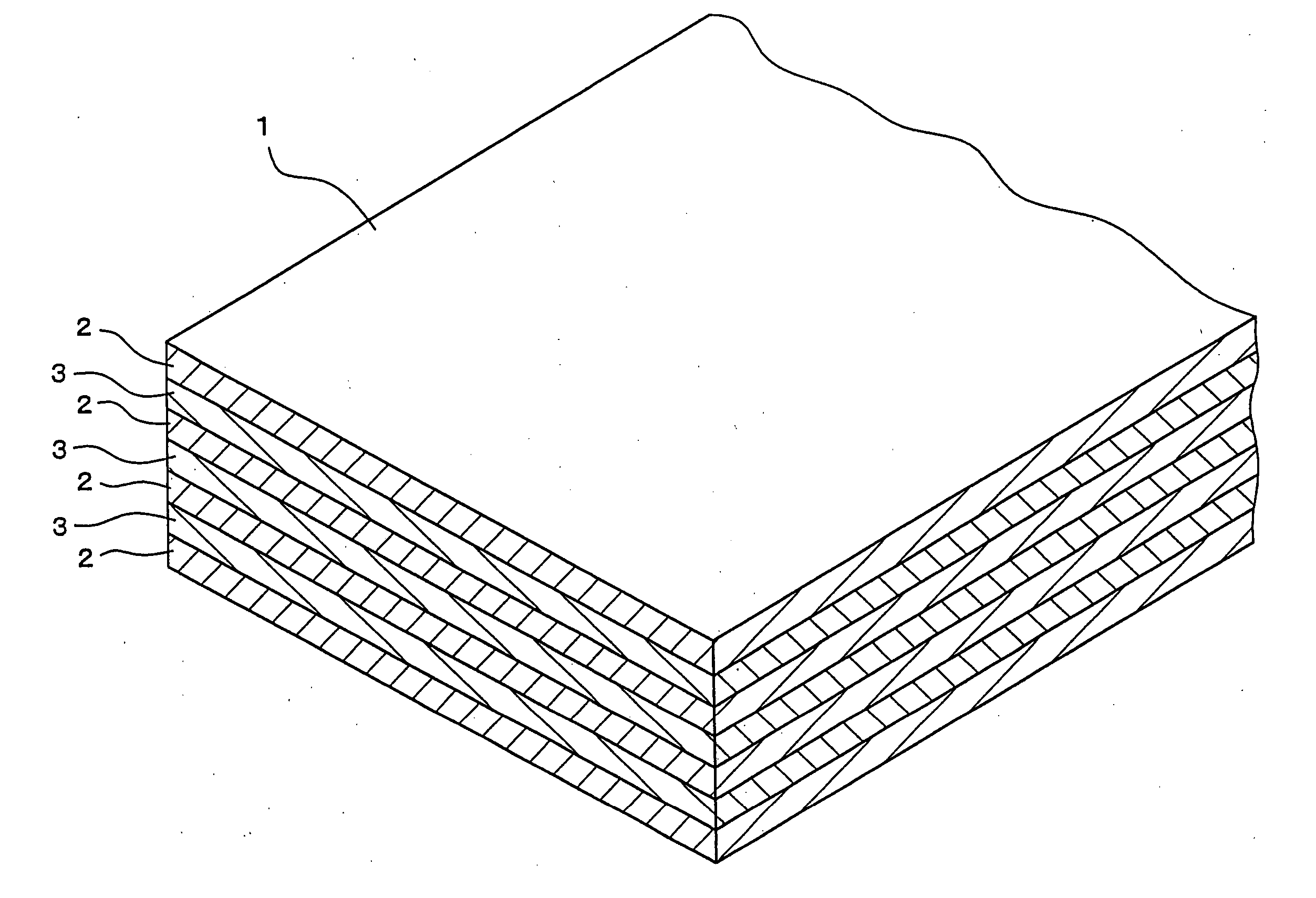

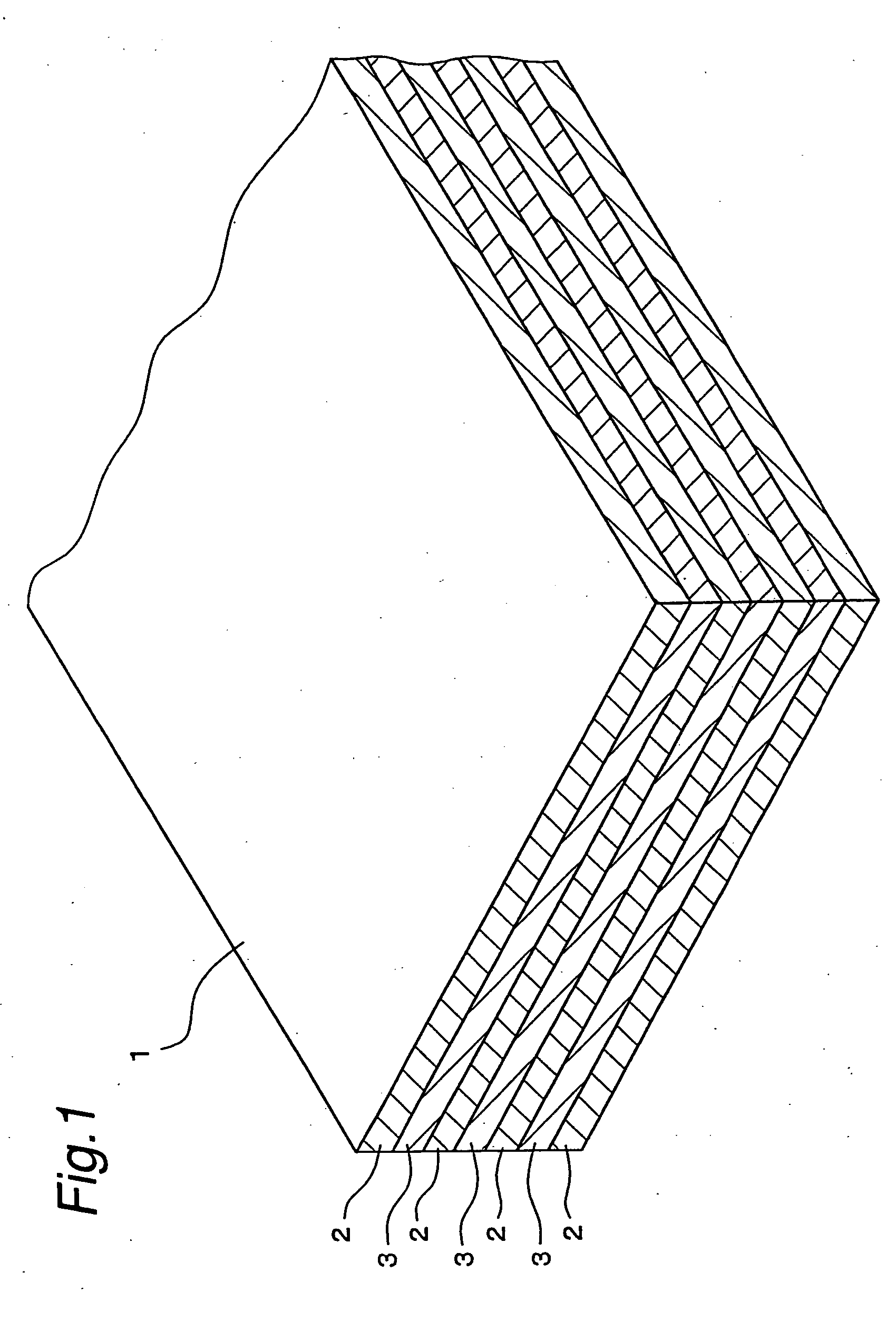

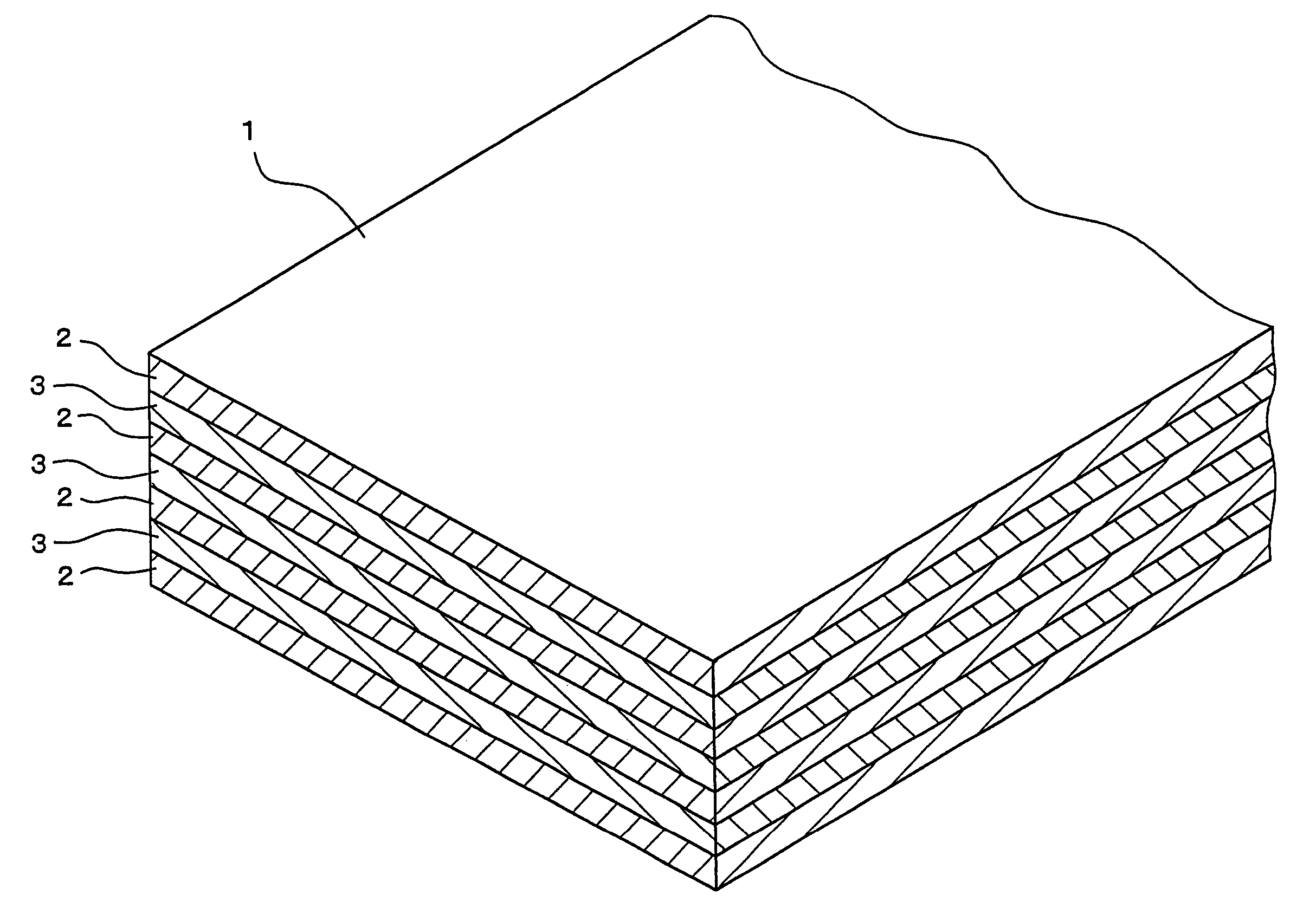

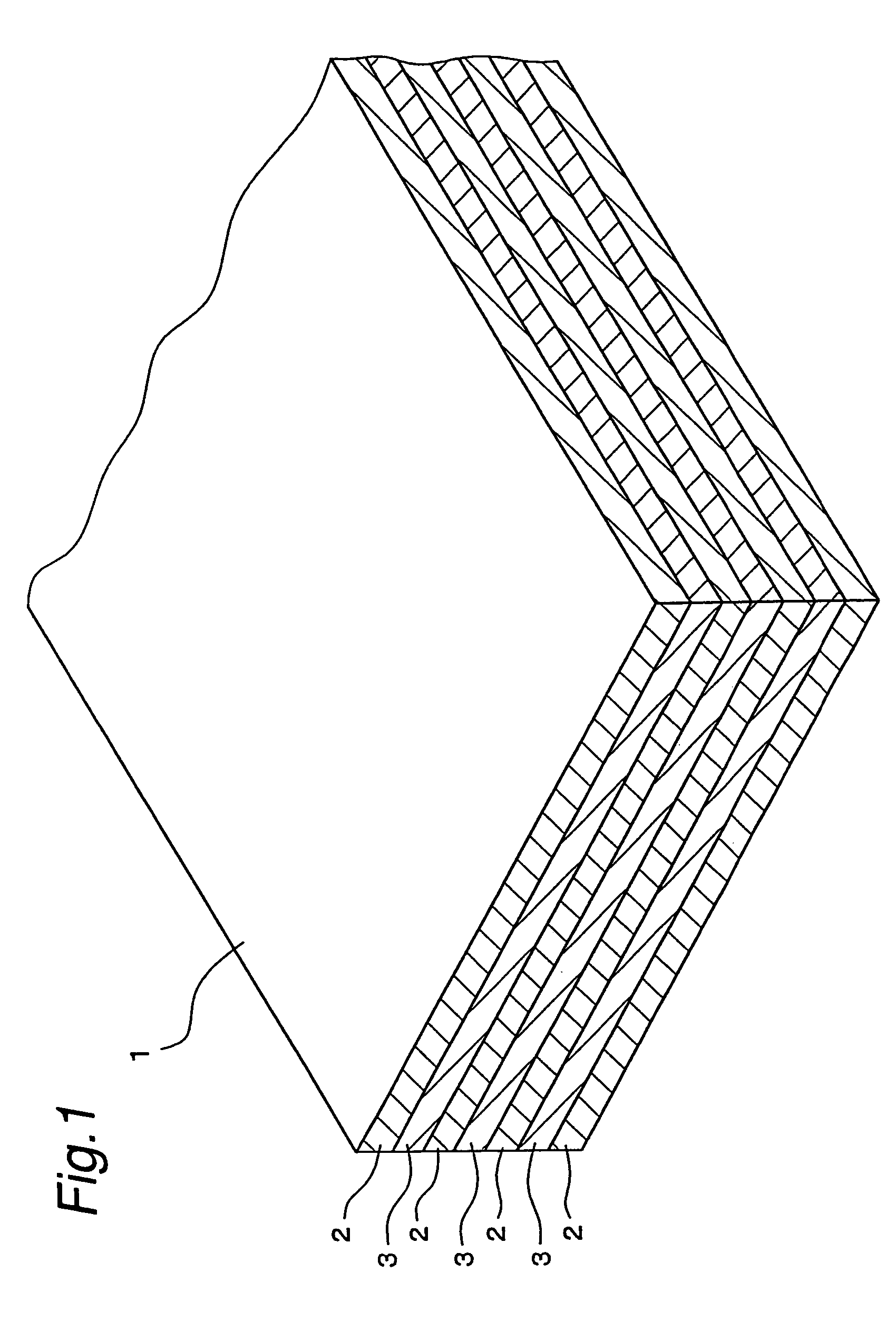

Laminated composite wooden material and method of manufacturing material

InactiveUS20050006003A1Light weightImprove bending strengthFoundation repairWood veneer joiningFlexural strengthComposite lumber

A seven-layered laminated composite lumber 1 is constructed by stacking veneers 2, whose oven-dry specific gravity is 0.6 or larger, alternately with veneers 3, whose oven-dry specific gravity is 0.4 or less, and by bonding them together. The invention can thus provide a laminated composite lumber that is light in weight, is substantially resistant to warping and distortion, and yet retains the desired bending strength and nail holding power, and a method of producing such a laminated composite lumber.

Owner:UNI WOOD CORP

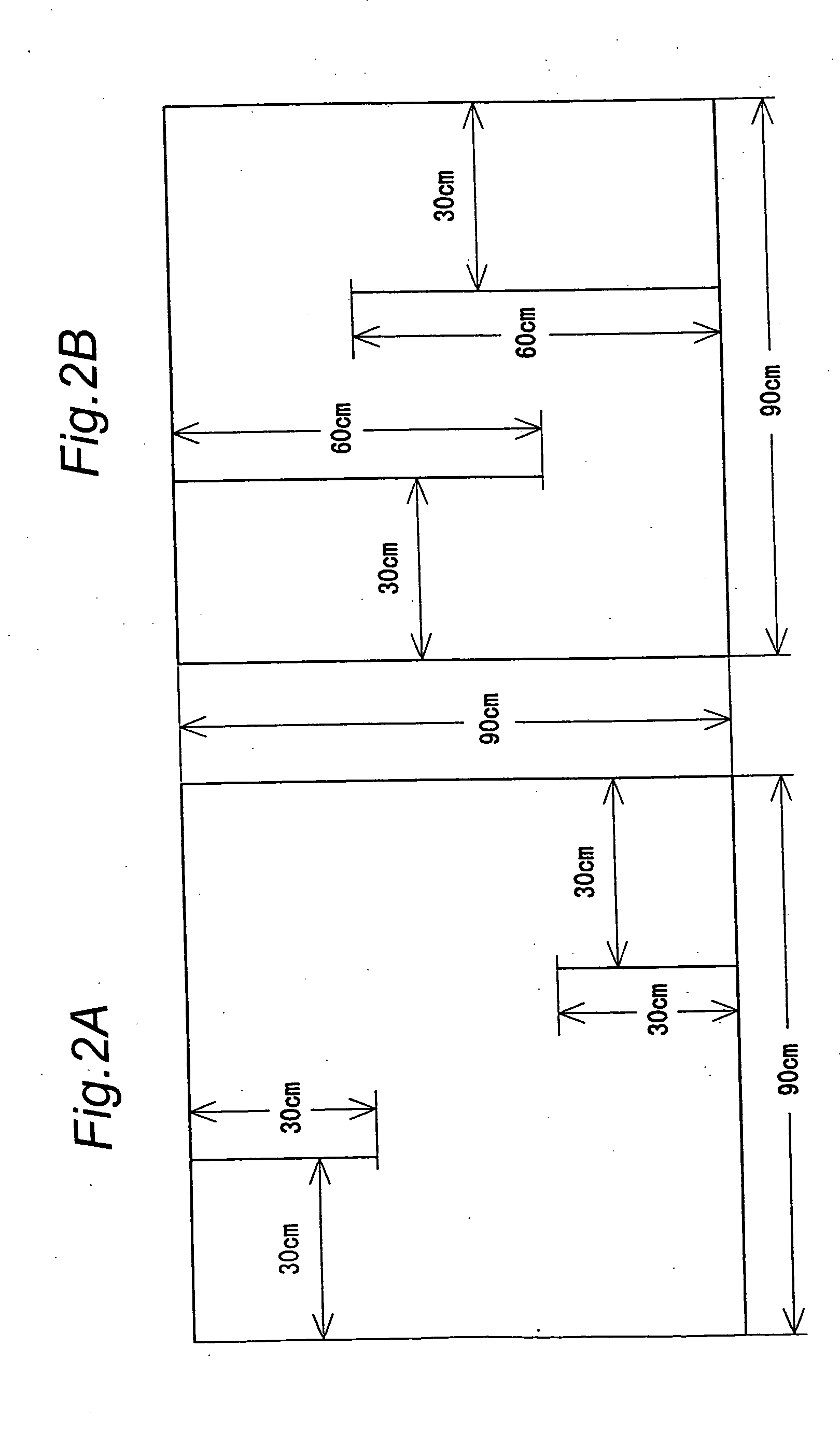

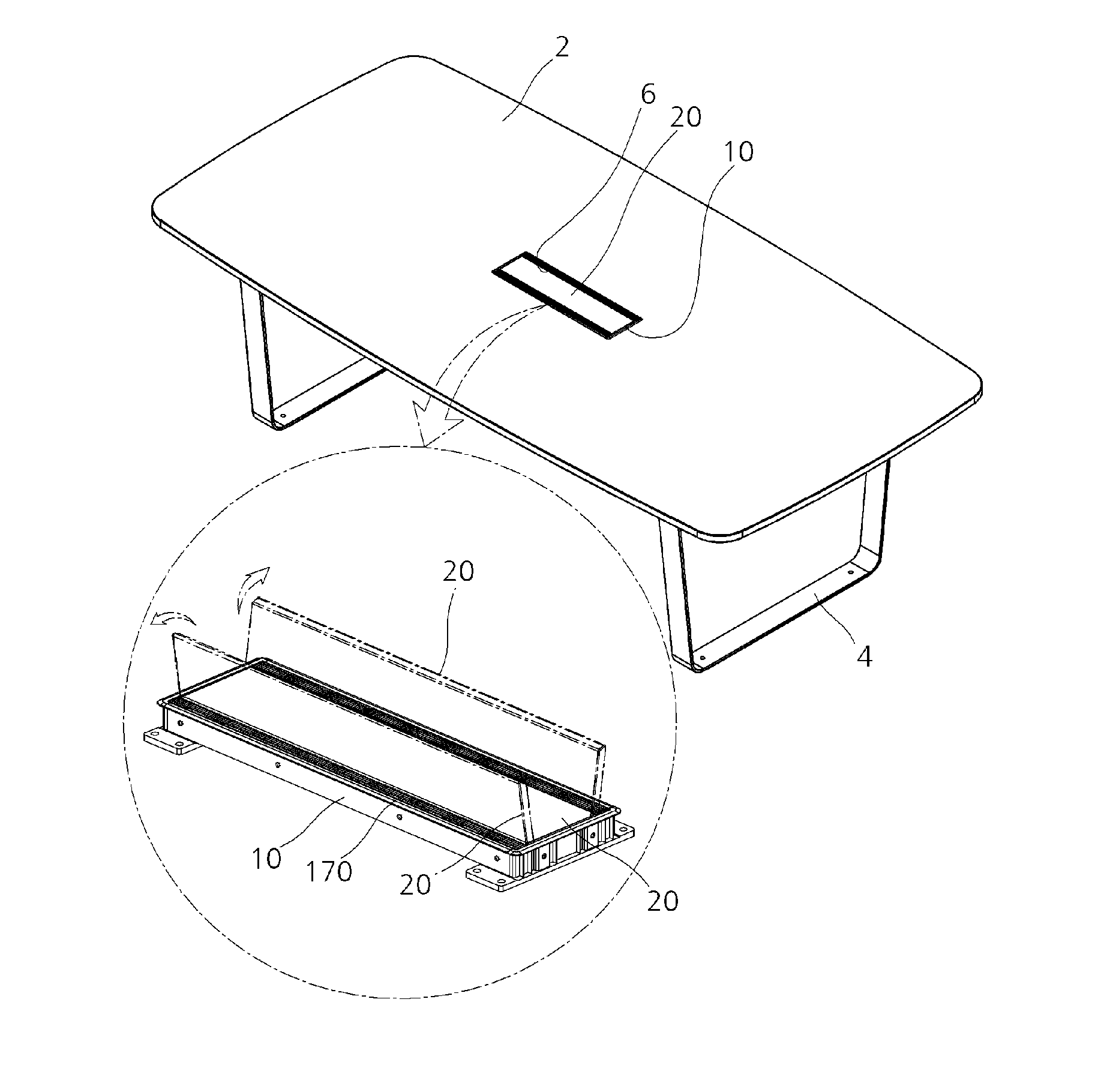

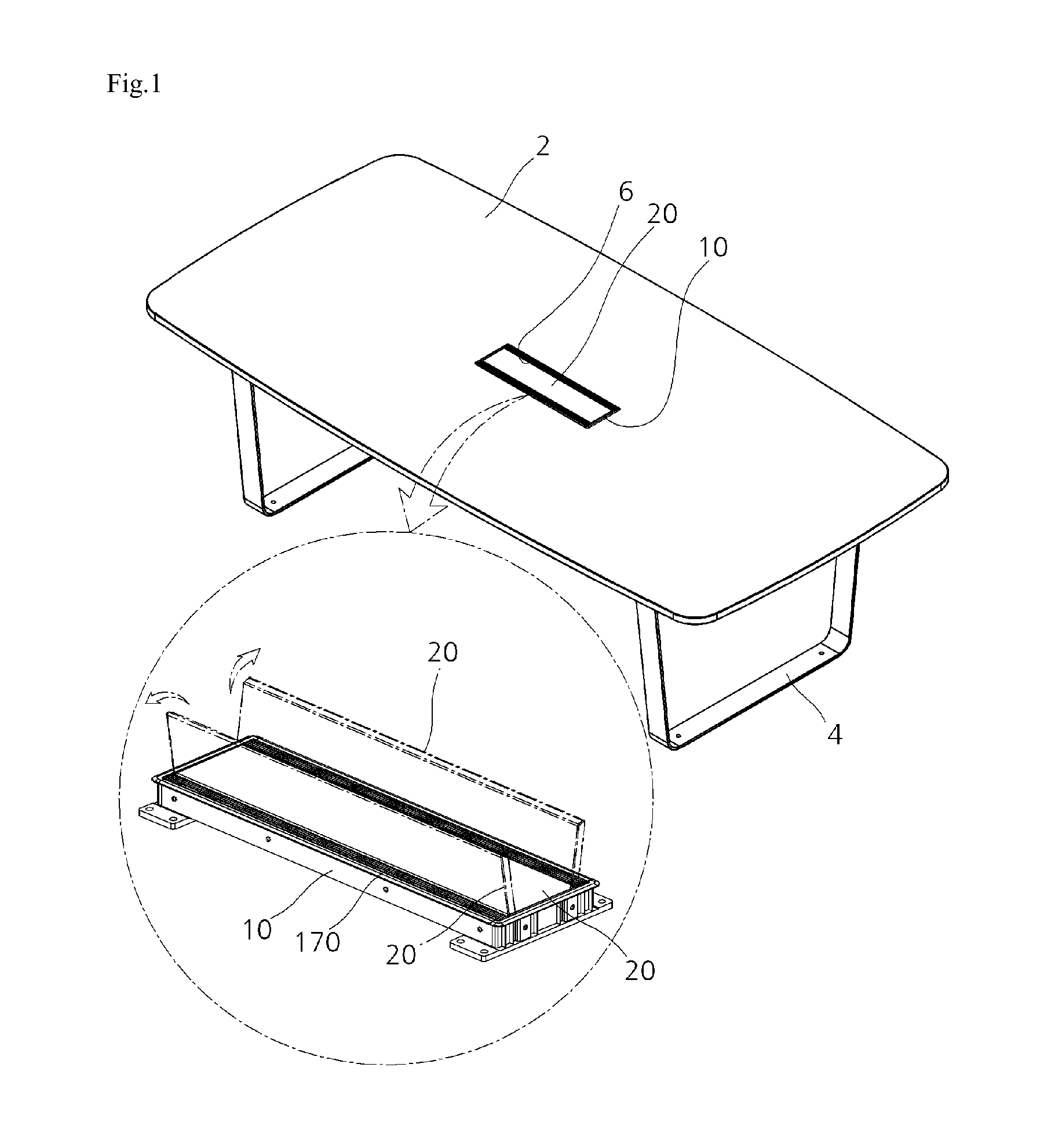

Bilateral rotation apparatus and furniture including the same

InactiveUS20130081559A1Lift restrictionsEliminate DirectionalityOffice tablesElectrical apparatusMechanical engineering

Owner:KOAS

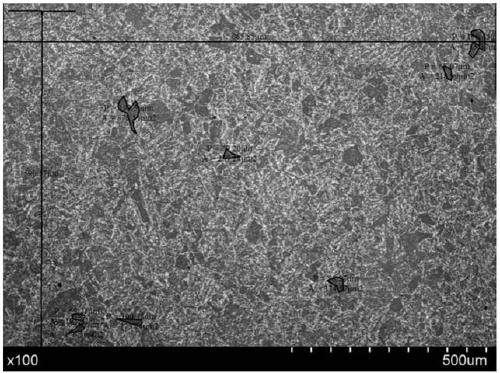

Method for improving low-temperature impacting power of 17-4 PH maraging stainless steel forged piece based on organization control

PendingCN109439870AEliminate DirectionalityHigh impact energy at low temperatureMetal-working apparatusDirectivitySmelting process

Owner:JIANGYIN HENGYE FORGING

Aluminum alloy welding wire and preparation method thereof

InactiveCN106238952AGood welding performanceImprove refinementWelding/cutting media/materialsSoldering mediaCrack resistanceWeld seam

The invention discloses an aluminum alloy welding wire and a preparation method thereof. The aluminum alloy welding wire consists of the following components in percentage by weight: 5.5-6% of Mg, 0.1-0.15% of Ti, 0.1-0.3% of Cr, 0.08-0.18% of Mn, 0.05-0.2% of Sc, 0.1-0.18% of Nd, 1-2% of Mo, 1-2% of W, 0.2-0.8% of V, 0.01-0.05% of Bi, 2-5% of Cu, 0.25-0.35% of Zr, 0.1-0.25% of Ag, less than or equal to 0.25% of Si, less than or equal to 0.2% of Fe, less than or equal to 0.20% of Zn, less than or equal to 0.15% of other impurity elements each being less than or equal to 0.05%, and the balance Al. The aluminum alloy welding wire disclosed by the invention is compact in tissue and is smooth in surface; and tensile strength, cracking resistance, wear resistance and corrosion resistance of a welding seam are good.

Owner:安徽飞弧焊业股份有限公司

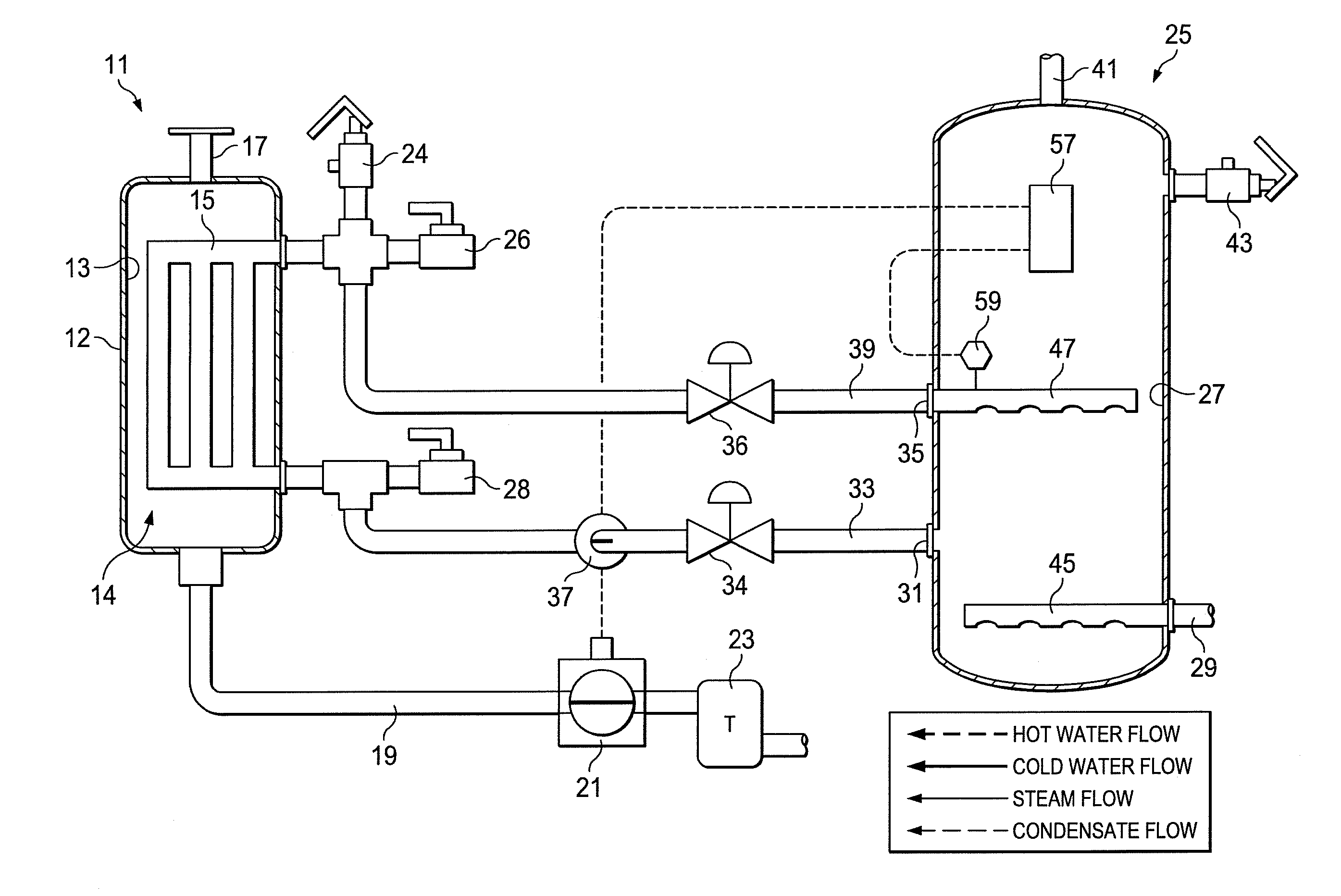

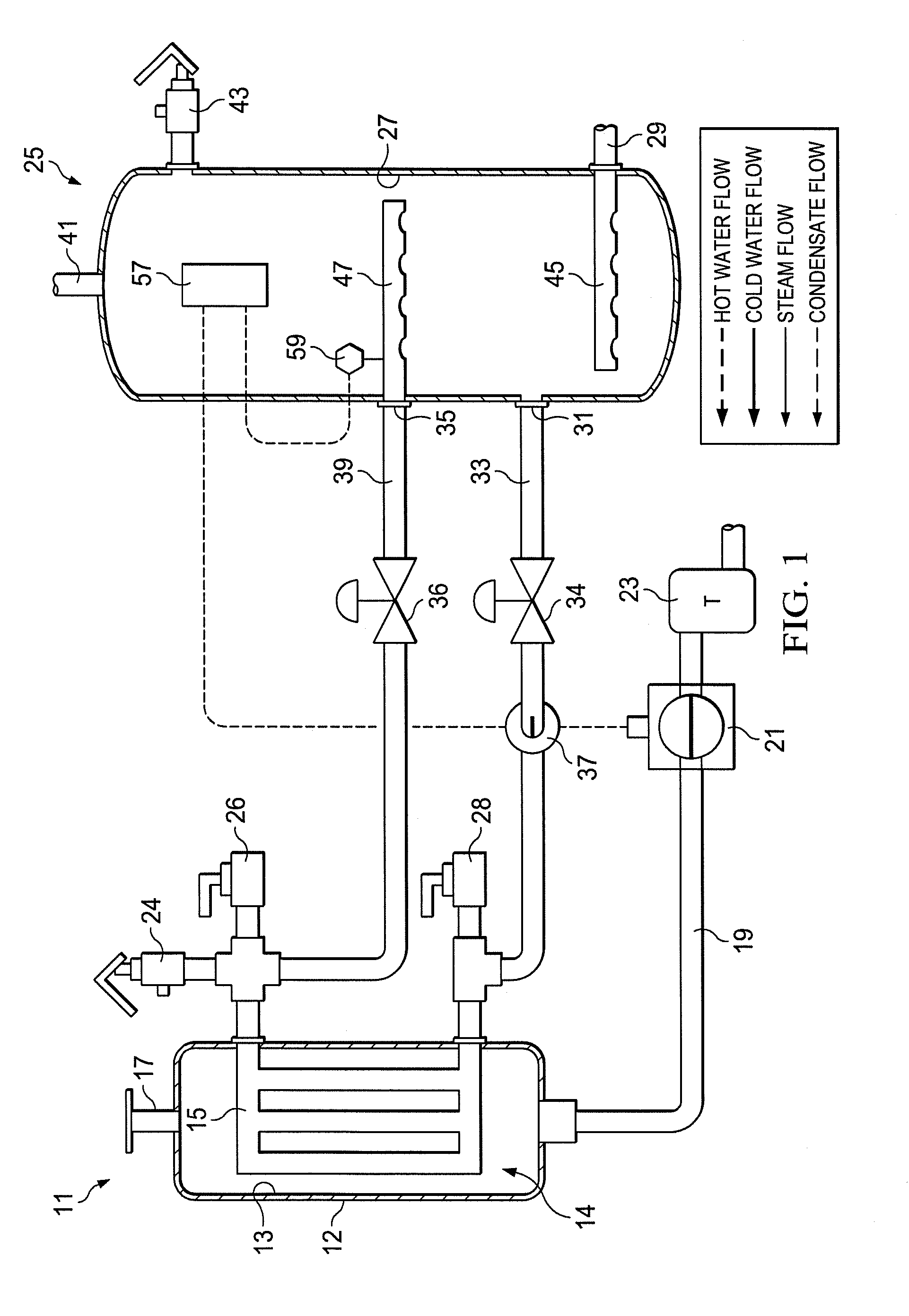

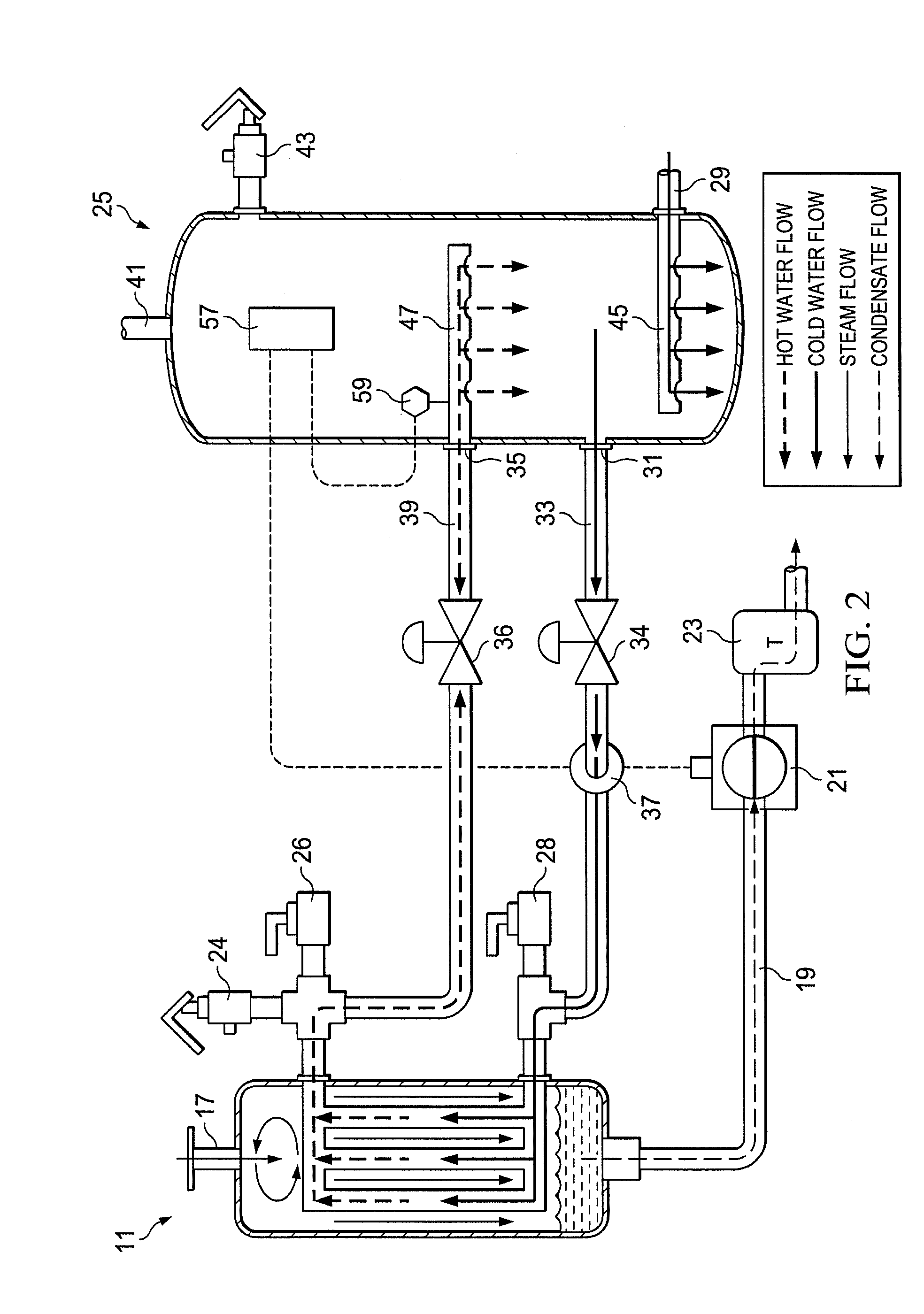

Indirectly Heated, Storage Water Heater System

InactiveUS20160003468A1Operational securityAvoid introducingDistrict heating systemHeating fuelWater storageElectronic controller

A system is shown for providing domestic hot water for potable use. The energy source is a steam powered heat exchanger. Water is heated in a heat engine package including the heat exchanger, a temperature operated pump and a condensate control valve. The heat package works in conjunction with a water storage package including a water storage tank and an electronic controller which controls the operation of the pump and condensate control valve. The electronic controller is operated so that the control of steam supplied to the system and flow of water through the heat exchanger ensures that steam is only present in the heat exchanger when there is a predetermined high flow rate of water.

Owner:PVI IND

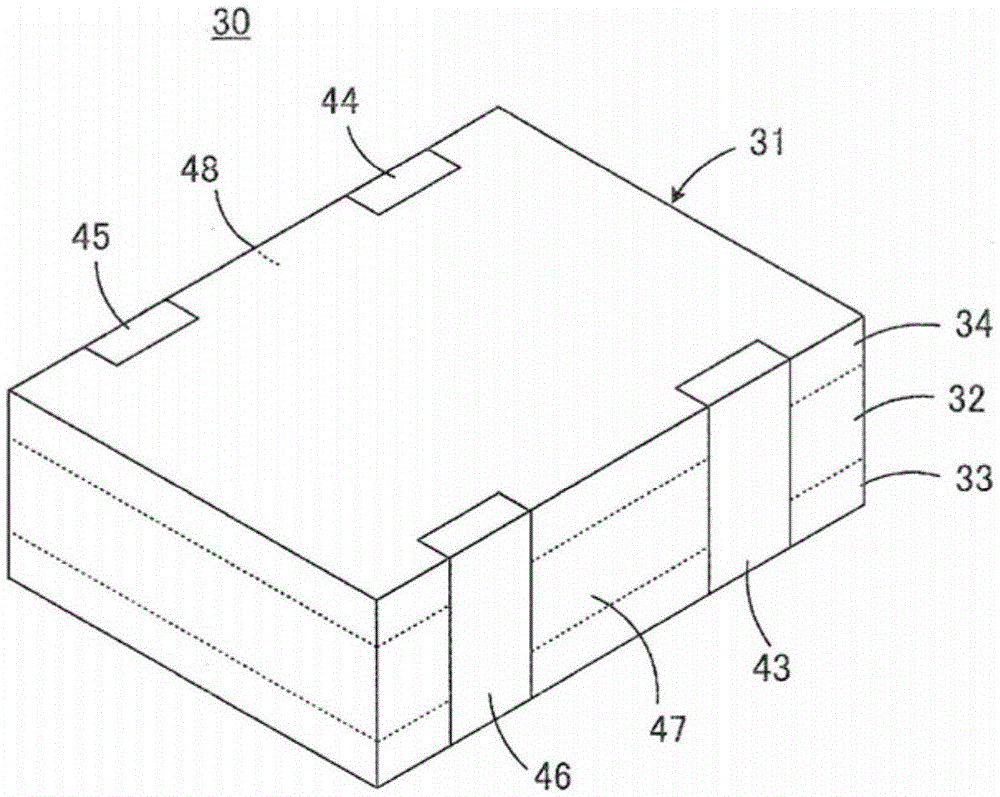

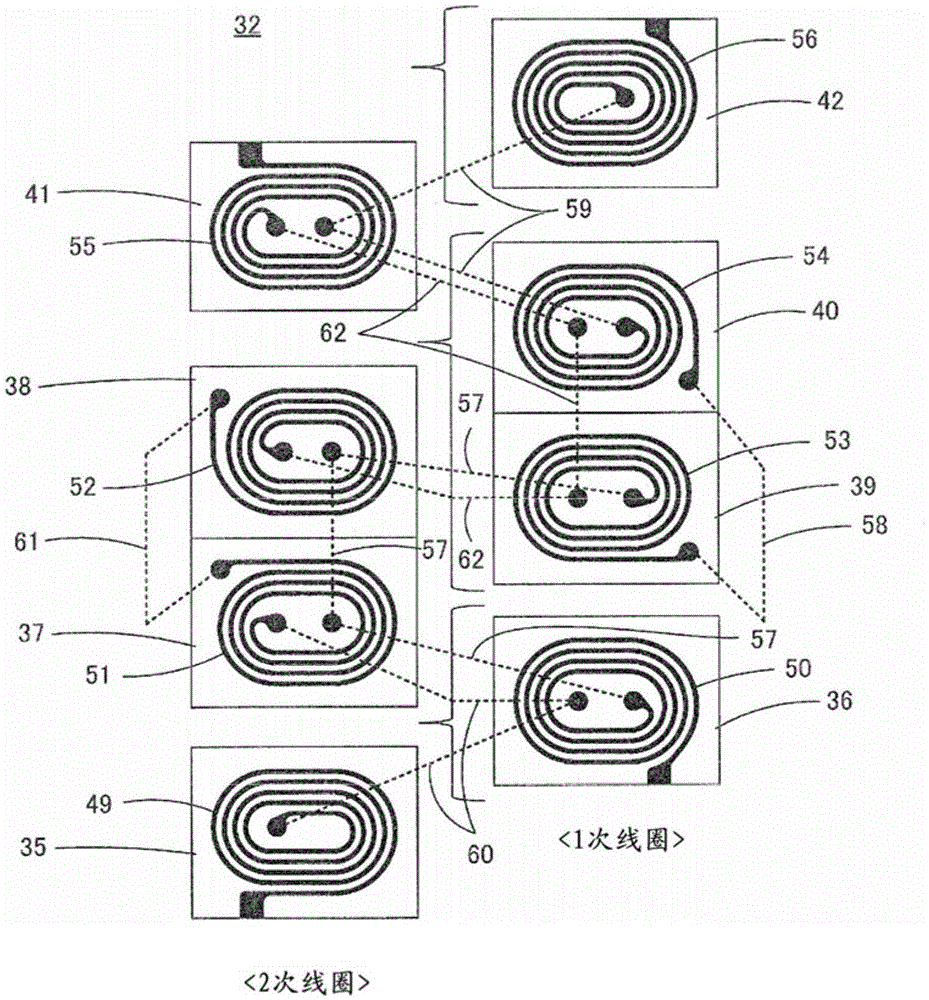

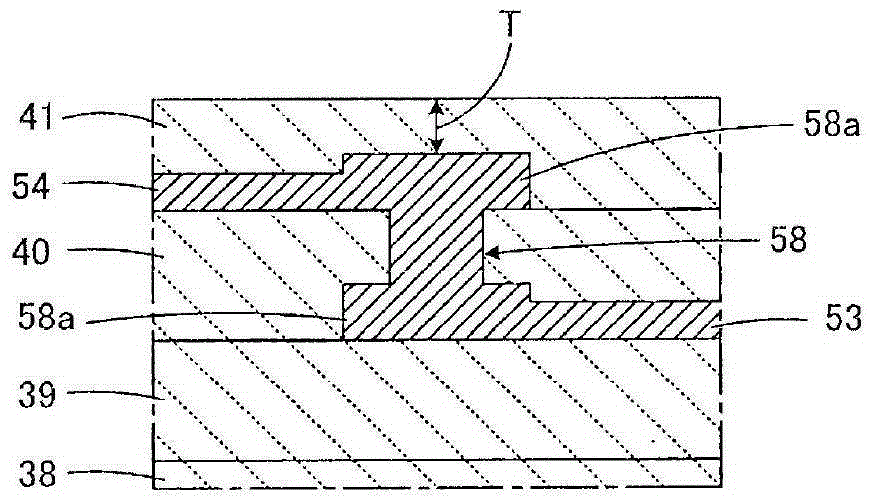

Common mode choke coil

ActiveCN105590733AInhibited DiffusionReduced withstand voltage and reduced reliabilityTransformers/inductances coils/windings/connectionsPrinted inductancesEngineeringConductive materials

The present invention provides a common mode choke coil which includes a laminated-type coil that has high breakdown voltage reliability. Coil conductors (51, 52) and a coil conductor (55) for a secondary coil are laminated so as to be respectively interposed between, coil conductors for a primary coil, two coil conductors (50, 53) connected to each other by an inner circumferential side via hole conductor (57) and two coil conductors (54, 56) connected by an inner circumferential side via hole conductor (59). Meanwhile, in the primary coil, an outer circumferential side via hole conductor (58) is provided so as to pass through only one insulation layer (40), and accordingly, a length of the outer circumferential side via hole conductor in an axis line direction thereof is reduced. As a result, an amount of conductive material used for the outer circumferential side via hole conductor that diffuses during firing can be reduced, and a drop in a thickness of the insulation layers can be suppressed.

Owner:MURATA MFG CO LTD

Multilayer capacitor

ActiveUS8310808B2Lower ESLReduce manufacturing costFixed capacitor electrodesFixed capacitor dielectricElectrical conductorEngineering

A multilayer capacitor includes a dielectric body formed by a plurality of dielectric layers, a first conductor layer, a second conductor layer, a first terminal electrode, and a second terminal electrode formed on a first side face of side faces of the dielectric body in parallel to a stacking direction Z. The first and second conductor layers respectively include first and second lead portions connected to the first and second terminal electrodes. A relation (a+c) / (b×n)≦0.035 is formed between a length “a” between the first and second lead portions in a vertical direction to the stacking direction Z, a length “b” between conductor layers positioned at both ends of the dielectric body in the stacking direction, a space length “c” between the first side face and the first conductor layer, a total number “n” of the conductor layers.

Owner:TDK CORPARATION

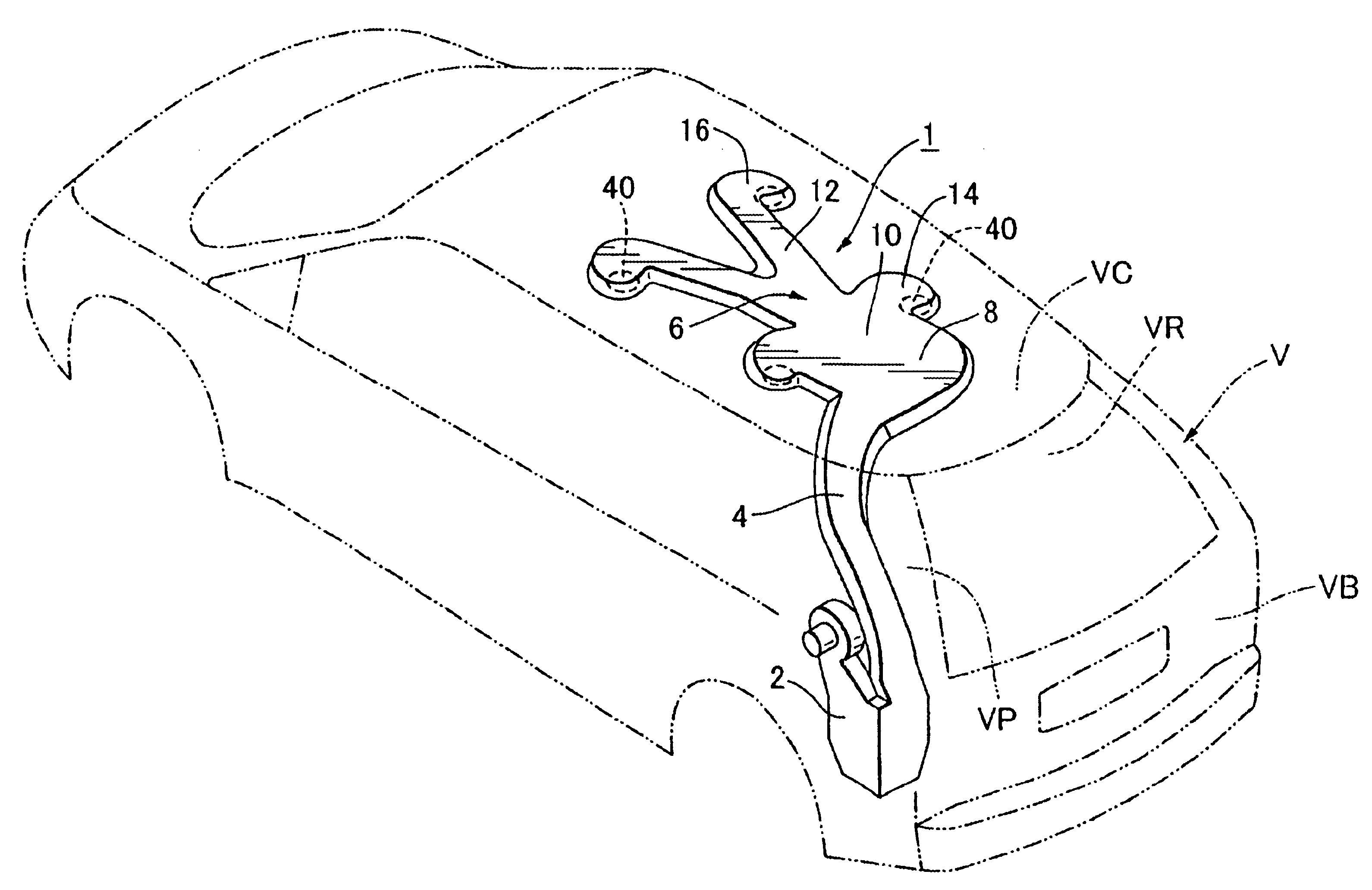

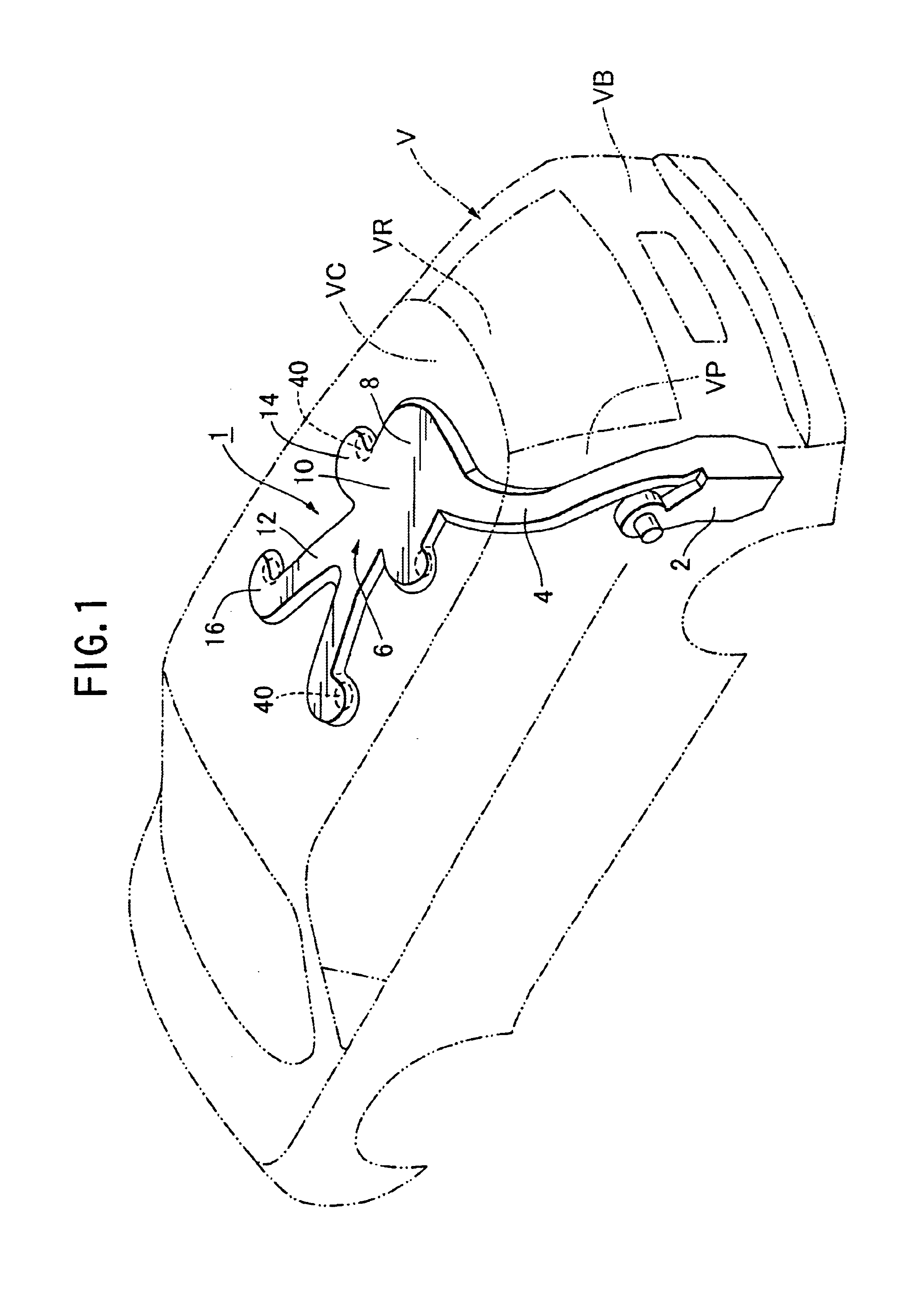

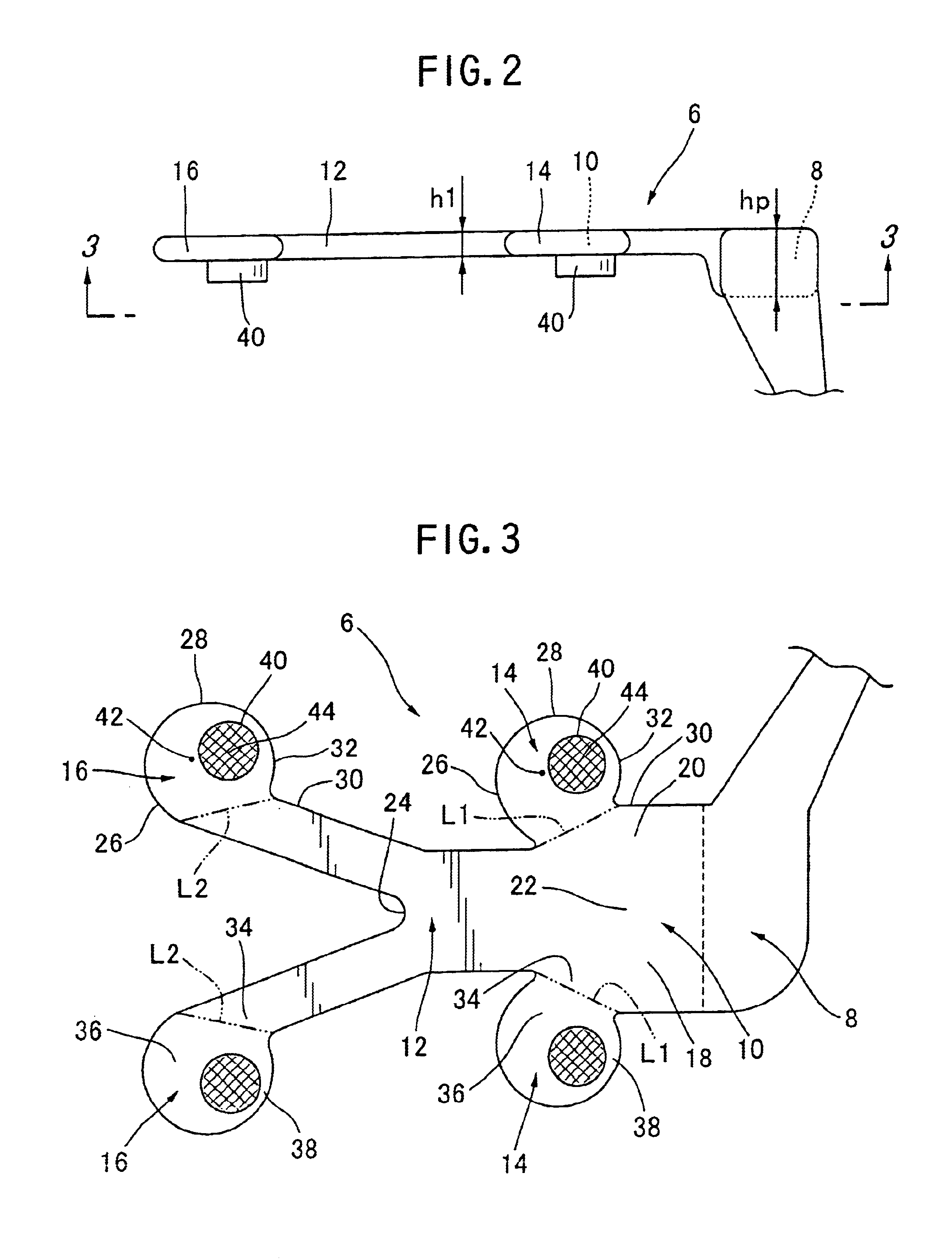

Air-conditioning apparatus

InactiveUS6932693B2Minimize changesMinimizes change in speed and volumeAir-treating devicesVehicle heating/cooling devicesAir conditioningWaste management

An air-conditioning apparatus 1 for a vehicle has an air supply duct 6 for supplying air and a vent 40 communicating with the air supply duct 6 for blowing the air into a compartment of the vehicle. The direction of the air blown from the vent 40 is adjustable. The air supply duct 6 includes a branch chamber 14, 16 for reducing flow speed of the air flowing through the air supply duct 6 so that the speed-reduced air in the branch chamber 14, 16 is blown from the vent 40.

Owner:MITSUBISHI HEAVY IND LTD

Method for preparing tungsten-molybdenum alloy by doping beneficial elements

ActiveCN106591613AImprove recrystallization temperature and high temperature performanceAvoid segregationTungstenPraseodymium

A method for preparing tungsten-molybdenum alloy by doping beneficial elements comprises the following steps: preparing doped molybdenum powder; preparing doped tungsten powder; and preparing the tungsten-molybdenum alloy through 82-87.5% of doped molybdenum powder, 11-15% of doped tungsten, and 1.5-3.0% of vanadium oxide. The tungsten-molybdenum alloy prepared by the method is outstanding in high-temperature creep resistance and tensile strength, and high in low-temperature strength; after being plastically deformed, lanthanum oxide and praseodymium oxide are dispersed into fine second-phase particles under high temperature and are regularly arranged, so that the strengthening effect can be achieved.

Owner:LUOYANG KEWEI MOLYBDENUM & TUNGSTEN

Erbium and ytterbium containing aluminum alloy welding wire

InactiveCN106334880AHigh hardnessHigh tensile strengthWelding/cutting media/materialsSoldering mediaAlloyErbium

The invention discloses an erbium and ytterbium containing aluminum alloy welding wire which is prepared from the following components in percentage by mass: 2-3.5 percent of Mg, 0.12-0.2 percent of Ti, 0.15-0.3 percent of Cr, 0.08-0.2 percent of Mn, 0.01-0.05 percent of Ce, 0.05-0.15 percent of Te, 0.01-0.1 percent of B, 0.05-0.2 percent of Er, 0.05-0.2 percent of Yb, 0.2-0.5 percent of Zr, 0.05-0.15 percent of Ge, 0.1-0.8 percent of Sn, 0.5-2.5 percent of Mo, 1-3 percent of W, 0.5-1.5 percent of V, 4-5.8 percent of Cu, smaller than or equal to 0.3 percent of Fe plus Si, smaller than or equal to 0.2 percent of Zn, smaller than or equal to 0.05 percent of single content of other purity elements, smaller than or equal to 0.15 percent of total content of other purity elements and the balance of Al.

Owner:安徽飞弧焊业股份有限公司

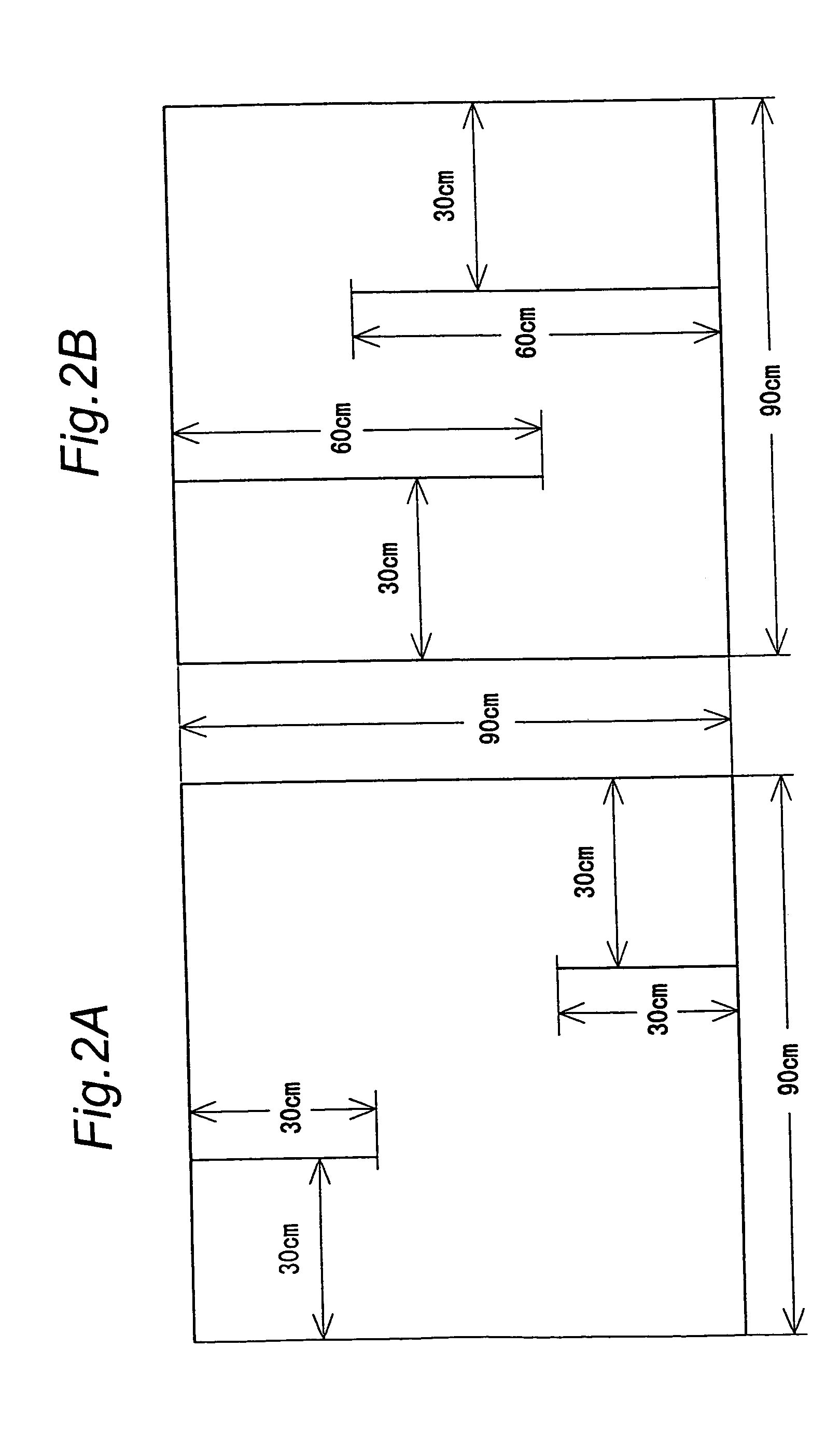

Preparation method for solar double-glass component

ActiveCN106449825AEliminate DirectionalityReduce displacementFinal product manufacturePhotovoltaic energy generationVacuum pumpingVacuum pump

The invention discloses a preparation method for a solar double-glass component. The method comprises the following steps: paving a glass layer, an EVA coating layer and a battery layer; performing EL test for the first time; laminating; performing EL test for the second time. A plurality of scratches are horizontally and longitudinally carved on the upper surface of the EVA coating in contact with a battery piece; a circle of scratch is carved along the edge of the battery piece; a layer of coating is paved at each of the four corners; in a laminating stage, the vacuum pumping is firstly performed, and then the vacuum pumping for a lower chamber is maintained, an upper chamber is aerated, the pressure is maintained and the coating is heated and molten. According to the preparation method, the directionality of EVA contraction can be reduced, the displacement resistance of the battery piece can be increased, and meanwhile, the gaps between the glass and the battery piece and between the battery pieces can be more effectively filled, so that the interior and four corners of the component can be prevented from generating bubbles, the yield of the products is increased, the operation is simple and the method is suitable for volume production.

Owner:无锡乐峰太阳能科技有限公司

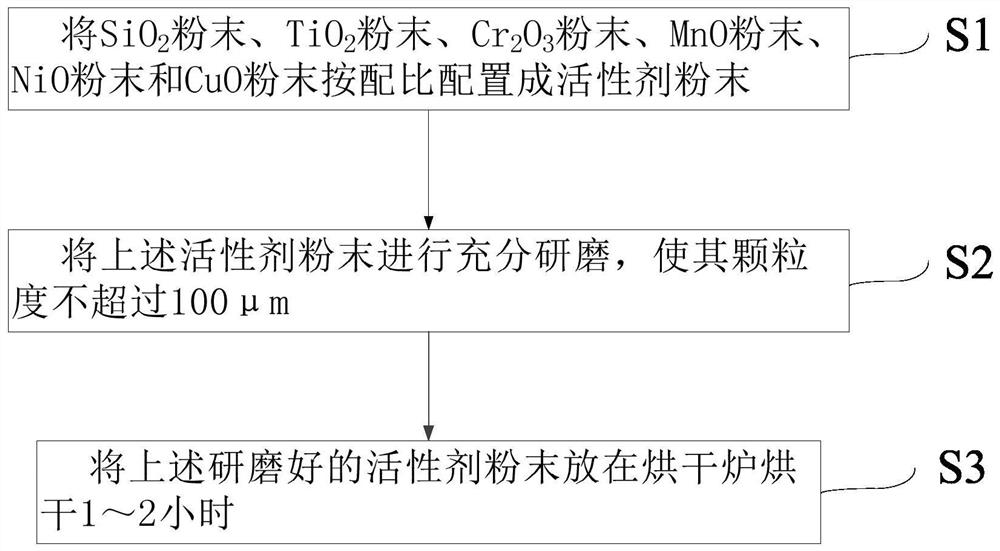

Stainless steel argon tungsten-arc welding active agent and preparation method and application thereof

InactiveCN111604618AQuality improvementLow costArc welding apparatusWelding/cutting media/materialsActive agentSS - Stainless steel

The invention belongs to the field of active agents for welding, and particularly relates to a stainless steel argon tungsten-arc welding active agent and a preparation method and application thereof.The stainless steel argon tungsten-arc welding active agent is prepared from the following components in percentage by weight: 35-45% of SiO2 powder, 20-25% TiO2 powder, 8-12% of Cr2O3 powder, 5-10%of MnO powder, 5-10% of NiO powder and 10-15% of CuO powder. The stainless steel argon tungsten-arc welding active agent does not contain precious metal, is low in cost, is non-poisonous and environmentally friendly, compared with methods such as general argon tungsten-arc welding, and the efficient active agent performs A-TIG welding on stainless steel and has the advantages of deep weld penetration, high production efficiency and reliable quality. The active agent is coated on the surface to be welded, the weld penetration is increased, the welding joint mechanical performance is obviously improved at the same parameter, 13mm welding by one side and molding by two sides can be realized, expensive welding equipment is not required, and good economic benefits and wide application prospectsare achieved.

Owner:JIUJIANG HAITIAN EQUIP MFG CO LTD

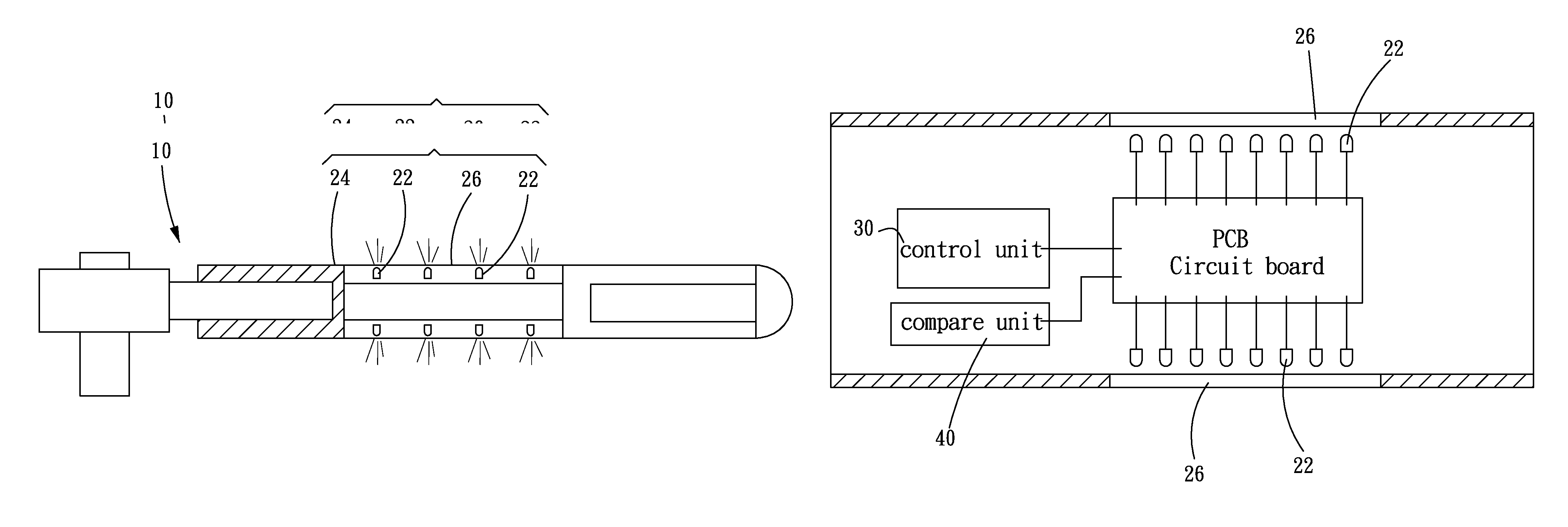

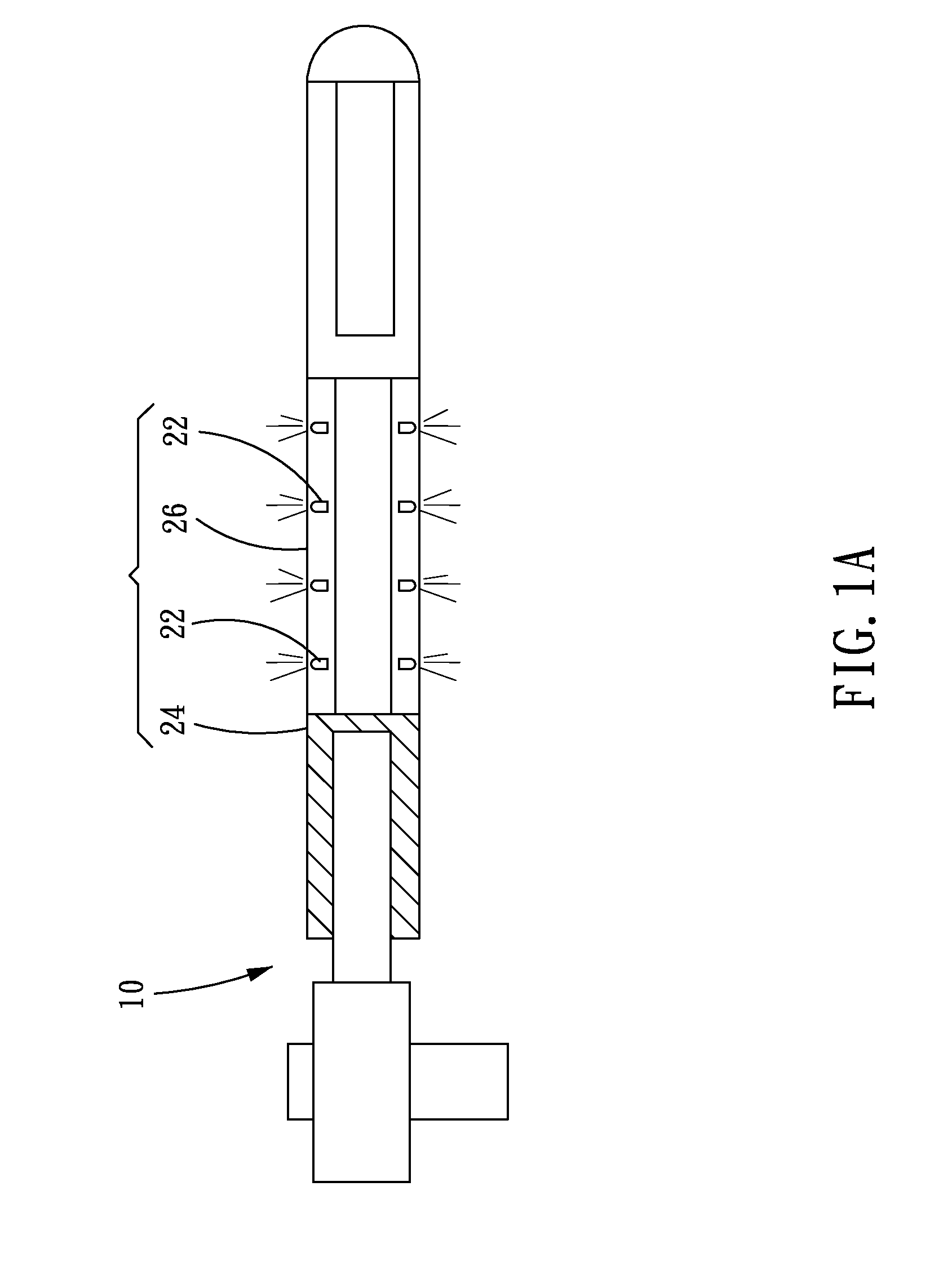

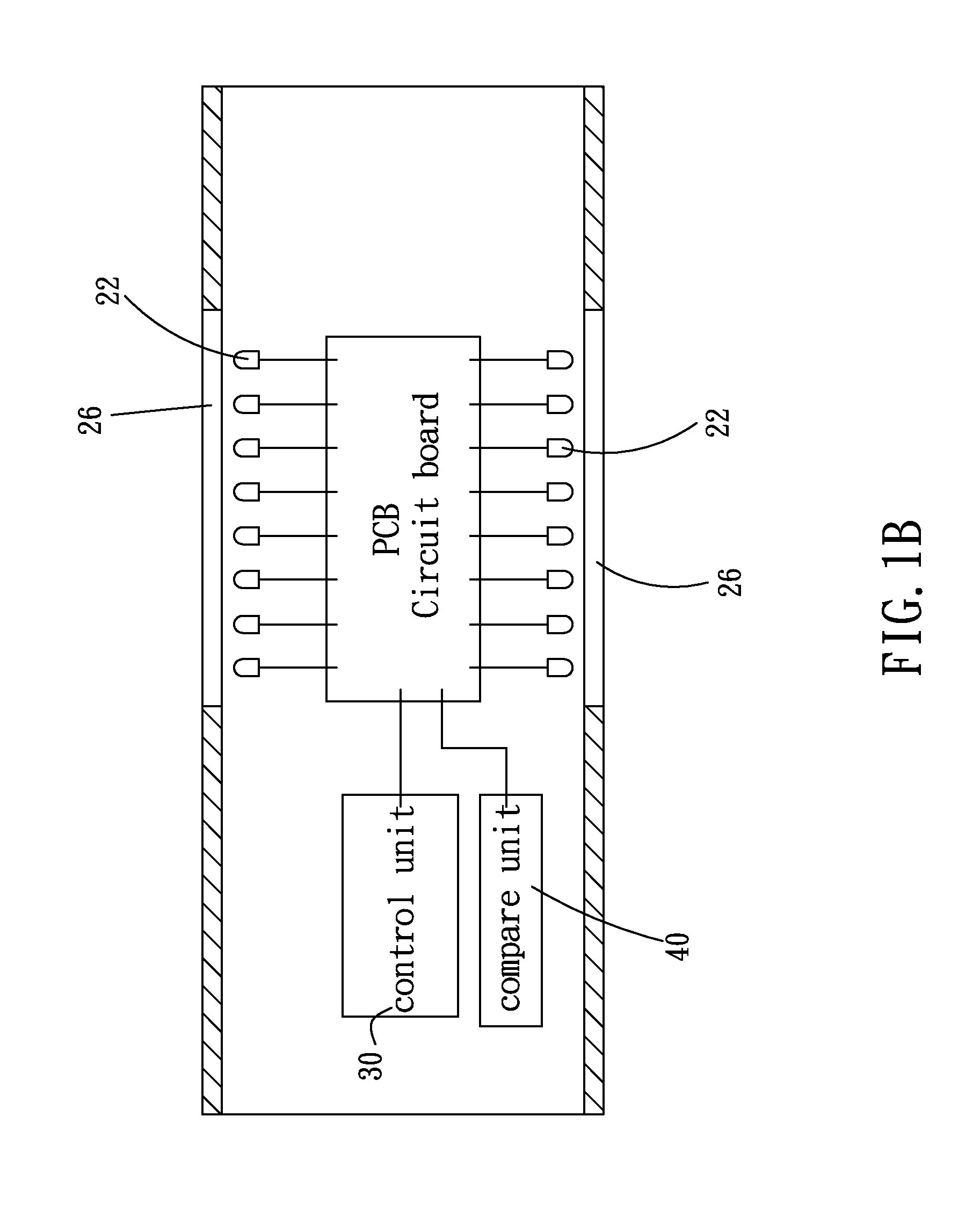

Digital tool with a light display

ActiveUS7874694B2Small light display areaEliminate the effects ofLighting support devicesLighting elementsDisplay deviceEngineering

A digital tool with a light display comprises at least one light display assembly. The light display assembly includes four or more light-emitting elements to cooperate with a light-transmitting element. The light display assembly can be the whole or a part of a handle sleeve. Therefore, by cooperating with a compare unit and a control unit, under the predetermined condition, the light-emitting elements can emit light through the light-emitting area synchronously or alternately.

Owner:ECLAT TORQ TECH

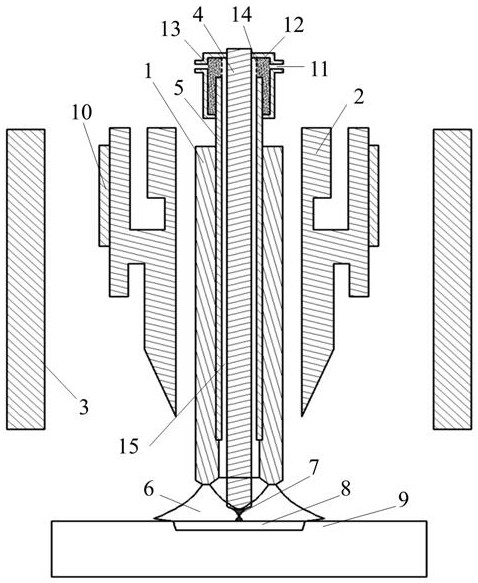

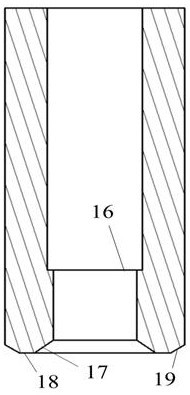

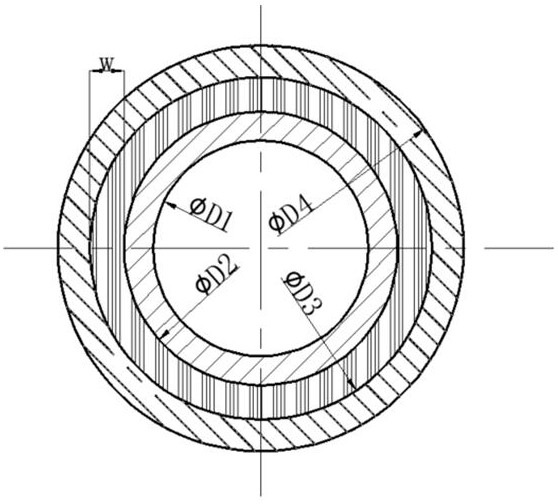

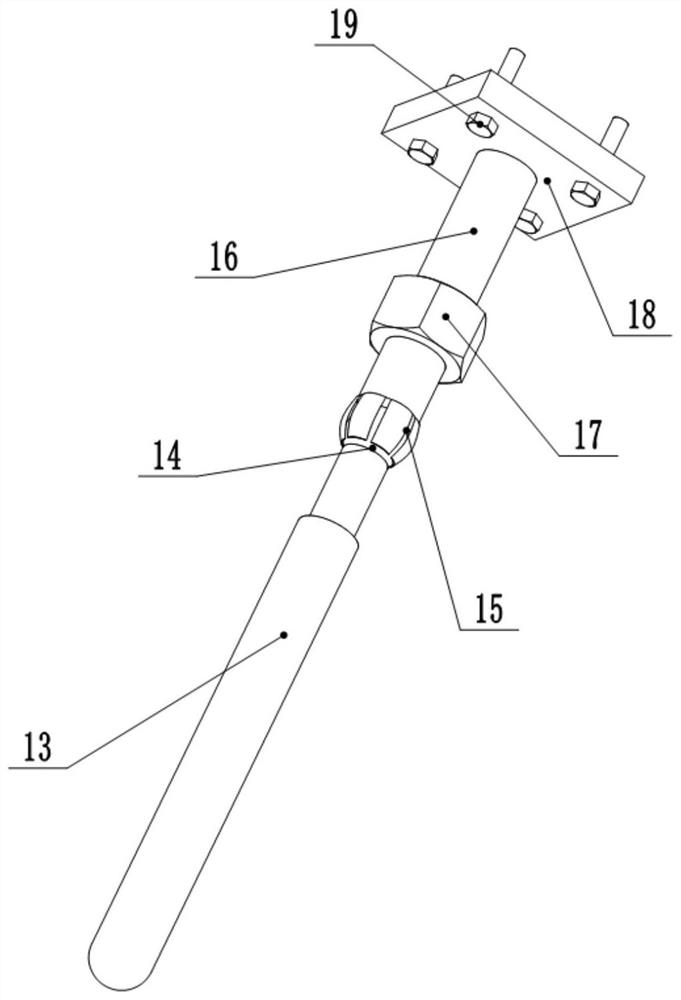

Hollow tungsten electrode coaxial wire filling welding device and regulating and welding method

PendingCN112743204ALow heat inputImprove deposition efficiencyWelding accessoriesPorous mediumTungsten electrode

The invention discloses a hollow tungsten electrode coaxial wire filling welding device and a regulating and welding method. An existing hollow tungsten electrode coaxial wire filling welding technology is still low in welding efficiency. The hollow tungsten electrode coaxial wire filling welding device comprises a hollow tungsten electrode (1), tungsten electrode clamps (2), a protective gas hood (3), a welding wire (4), an insulating porcelain tube (5) and a plasma buffering and filtering gas chamber (12); the hollow tungsten electrode is clamped by the symmetrically-arranged tungsten electrode clamps; the protective gas hood is located on the outer sides of the tungsten electrode clamps; and the plasma buffering and filtering gas chamber is fixed to the upper end of the hollow tungsten electrode; a step is arranged in the hollow tungsten electrode; the insulating porcelain tube is inserted into the step in the hollow tungsten electrode; a welding wire is inserted into the insulating porcelain tube; a gap between the welding wire and the hollow tungsten electrode forms an ion gas channel (15); an ion gas filter screen (14) is fixed in the plasma buffering and filtering gas chamber; and a porous medium material (13) is filled in a closed space formed by the ion gas filter screen and the plasma buffering and filtering gas chamber. The method is used for core tungsten electrode coaxial wire filling regulation and welding.

Owner:HARBIN WELDING INST LTD

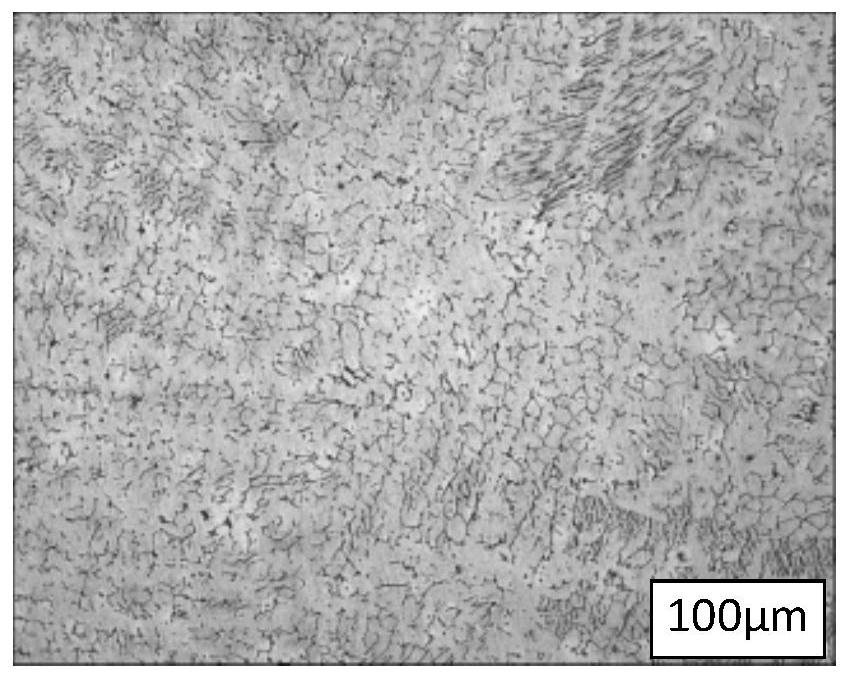

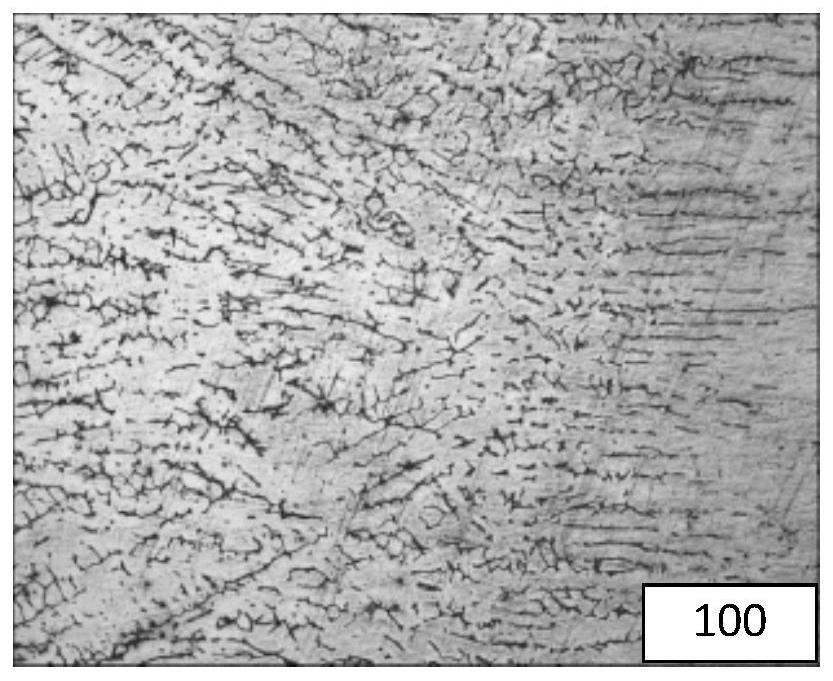

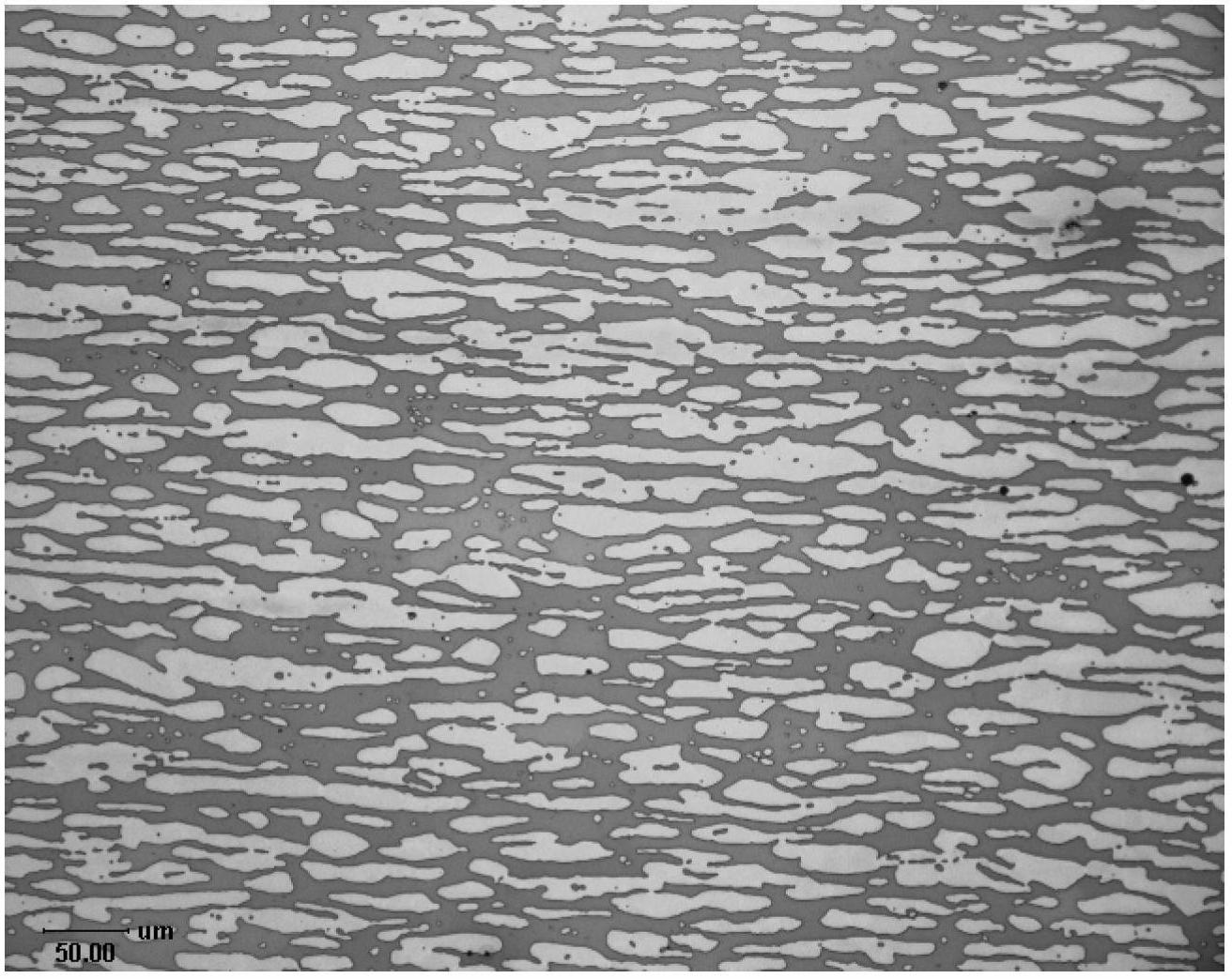

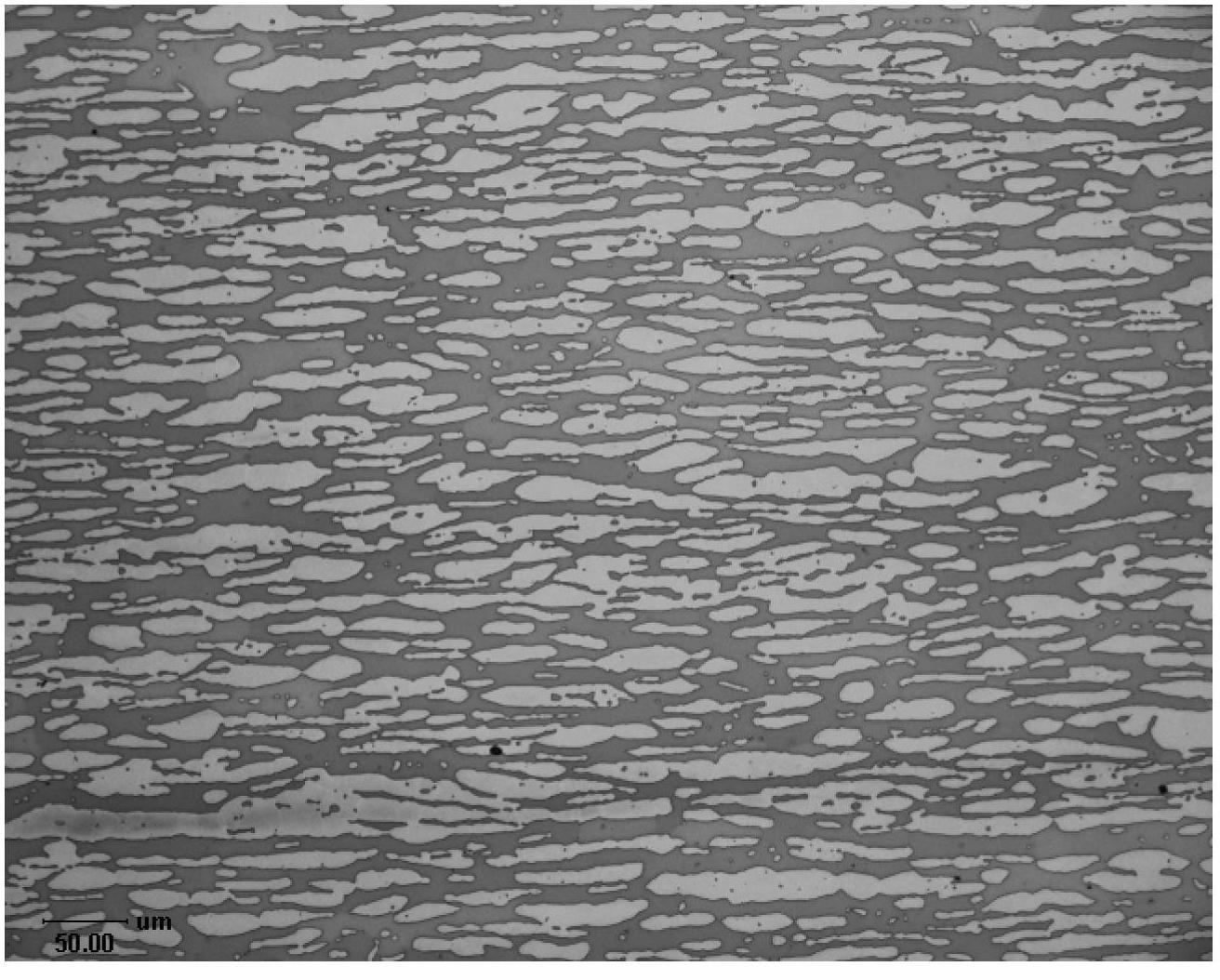

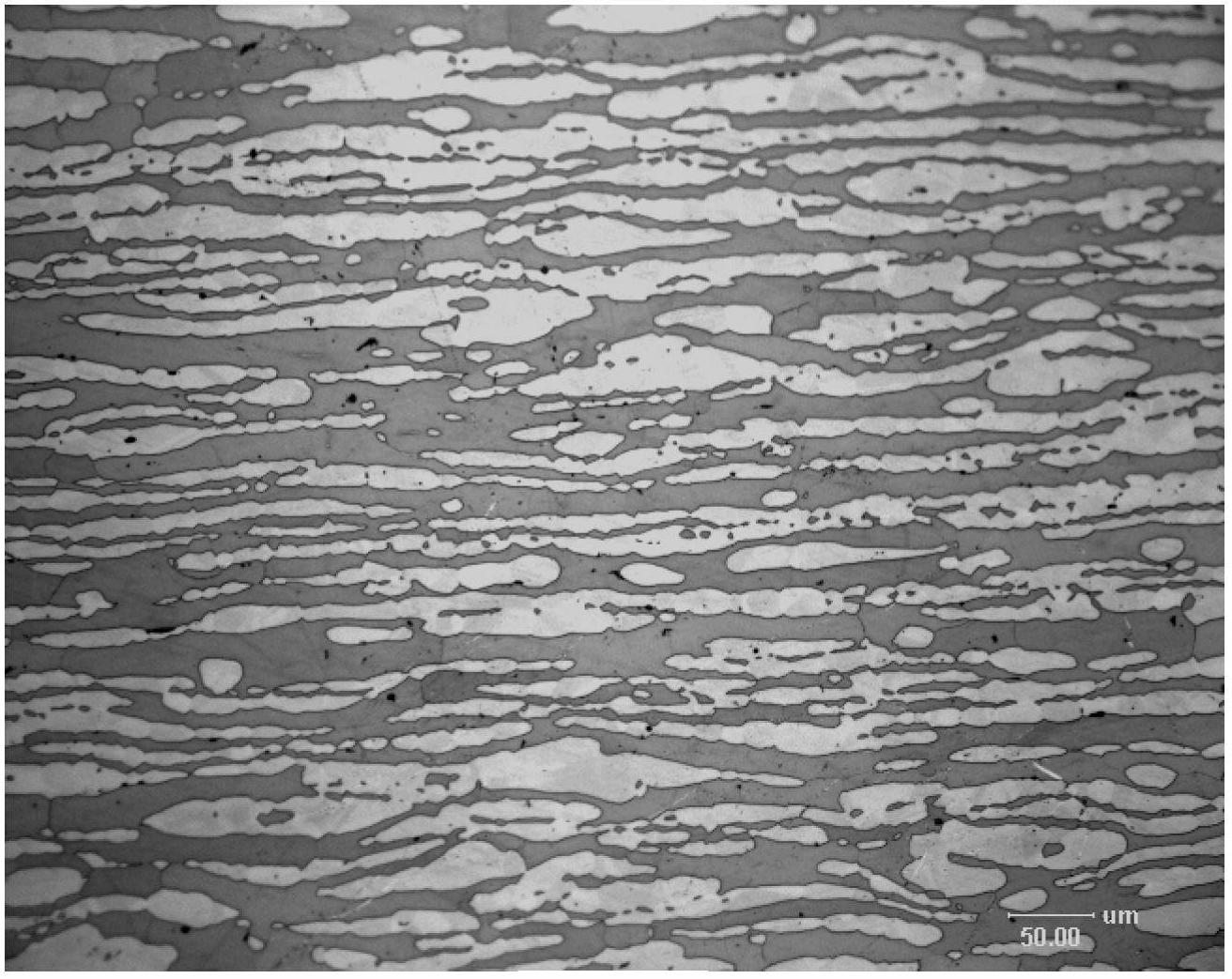

Medium plate made of duplex stainless steel with excellent low-temperature toughness and manufacturing method for medium plate

The invention discloses a medium plate made of duplex stainless steel with excellent low-temperature toughness and a manufacturing method for the medium plate. The duplex stainless steel comprises the following chemical components in weight percentage: 0.01-0.10 percent of C, 0.2-1.0 percent of Si, 2.0-3.5 percent of Mn, 20.0-21.5 percent of Cr, 3.0-3.5 percent of Ni, 0.08-0.15 percent of N, 0.5-1.0 percent of W, 0.01-0.5 percent of Cu, 0.001-0.005 percent of B, 0.05-0.25 percent of V and the balance Fe and unavoidable impurities. The stainless steel is proper in phase proportion and excellent in low-temperature toughness through controlling component proportion. Meanwhile, the length-width ratio of the austenite phase of the stainless steel along the rolling direction is enabled to be less than 3 through a special rolling process, and thus, the stainless steel is prevented from being excessively lengthened along the rolling direction. The duplex stainless steel is excellent in low-temperature toughness along the longitudinal direction and the lateral direction. The longitudinal impact value and the lateral impact value are greater than 220J at the temperature of -40 DEG C, and the longitudinal impact value and the lateral impact value are greater than 200J at the temperature of -80 DEG C. The duplex stainless steel can be widely applied to the field of coasting buildings and petrochemical engineering under the cold condition.

Owner:BAOSHAN IRON & STEEL CO LTD

Aluminum alloy welding wire special for high-speed train and preparation method thereof

InactiveCN106238953AGood dispersionGood emulsificationWelding/cutting media/materialsSoldering mediaImpurityMaterials science

The invention discloses an aluminum alloy welding wire special for a high-speed train and a preparation method thereof. The welding wire comprises, by weight, 5%-6% of Mg, 0.1%-0.18% of Ti, 0.15%-0.28% of Cr, 0.08%-0.15% of Mn, 0.01%-0.05% of La, 0.1%-0.18% of Te, 0.01%-0.05% of Bi, 0.1%-0.2% of Er, 0.05%-0.18% of Yb, 0.2%-0.4% of Zr, 0.1%-0.25% of Ag, 0.5%-1.8% of Sn, 0.5%-2% of Mo, 1%-2.5% of W, 0.5%-1.5% of V, less than or equal to 0.3% of Fe and Si, less than or equal to 0.2% of Zn, less than or equal to 0.05% of the single content of other impurity elements, less than or equal to 0.15% of the total content of the other impurity elements and the balance Al.

Owner:安徽飞弧焊业股份有限公司

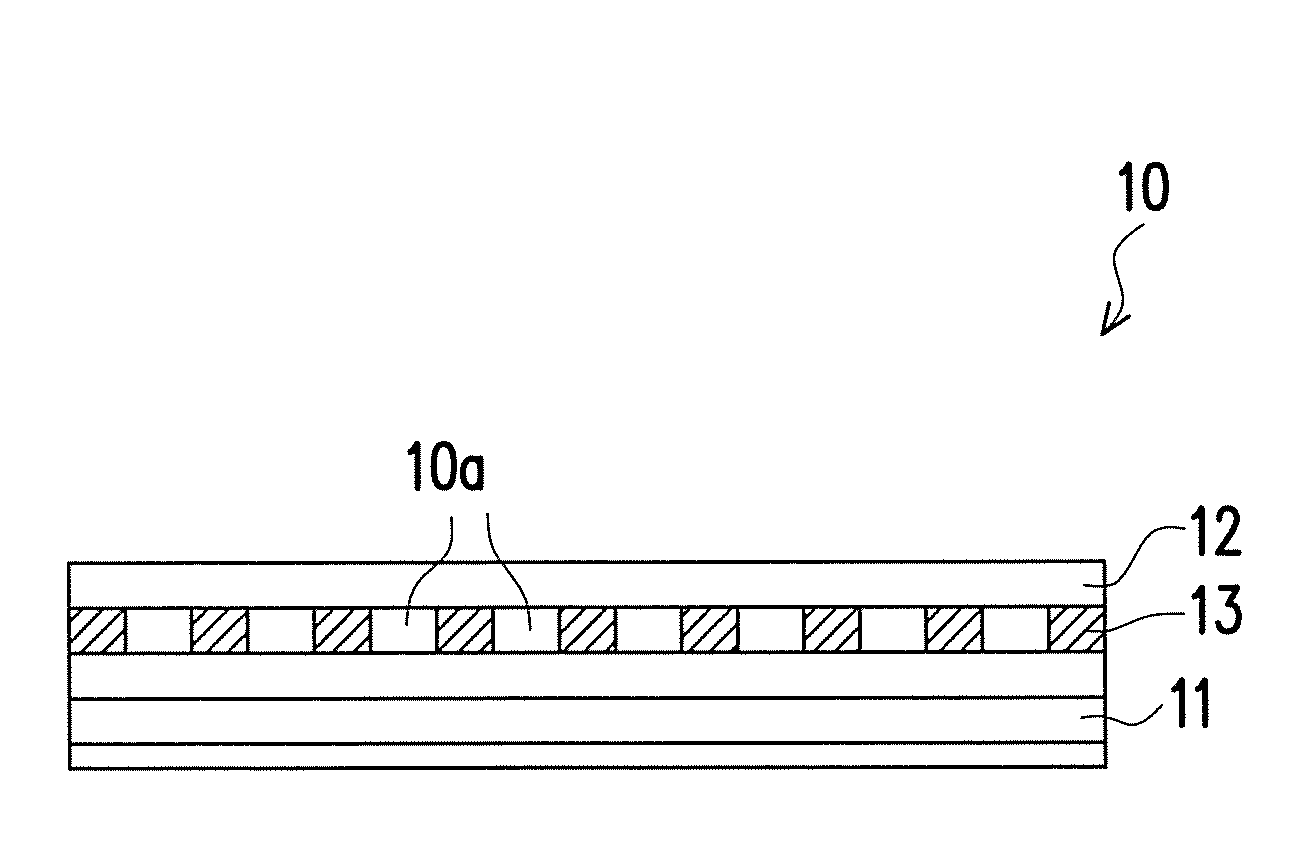

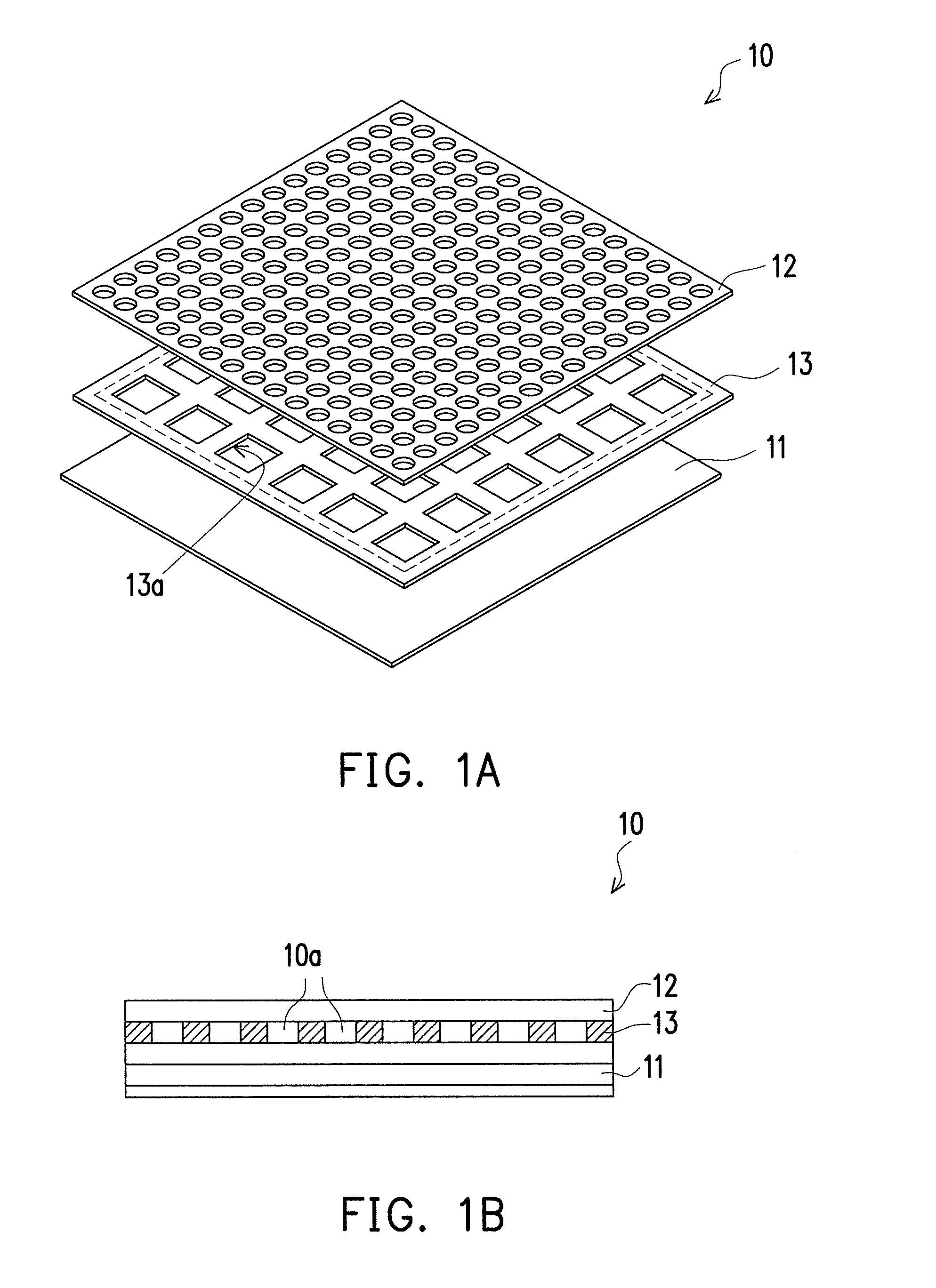

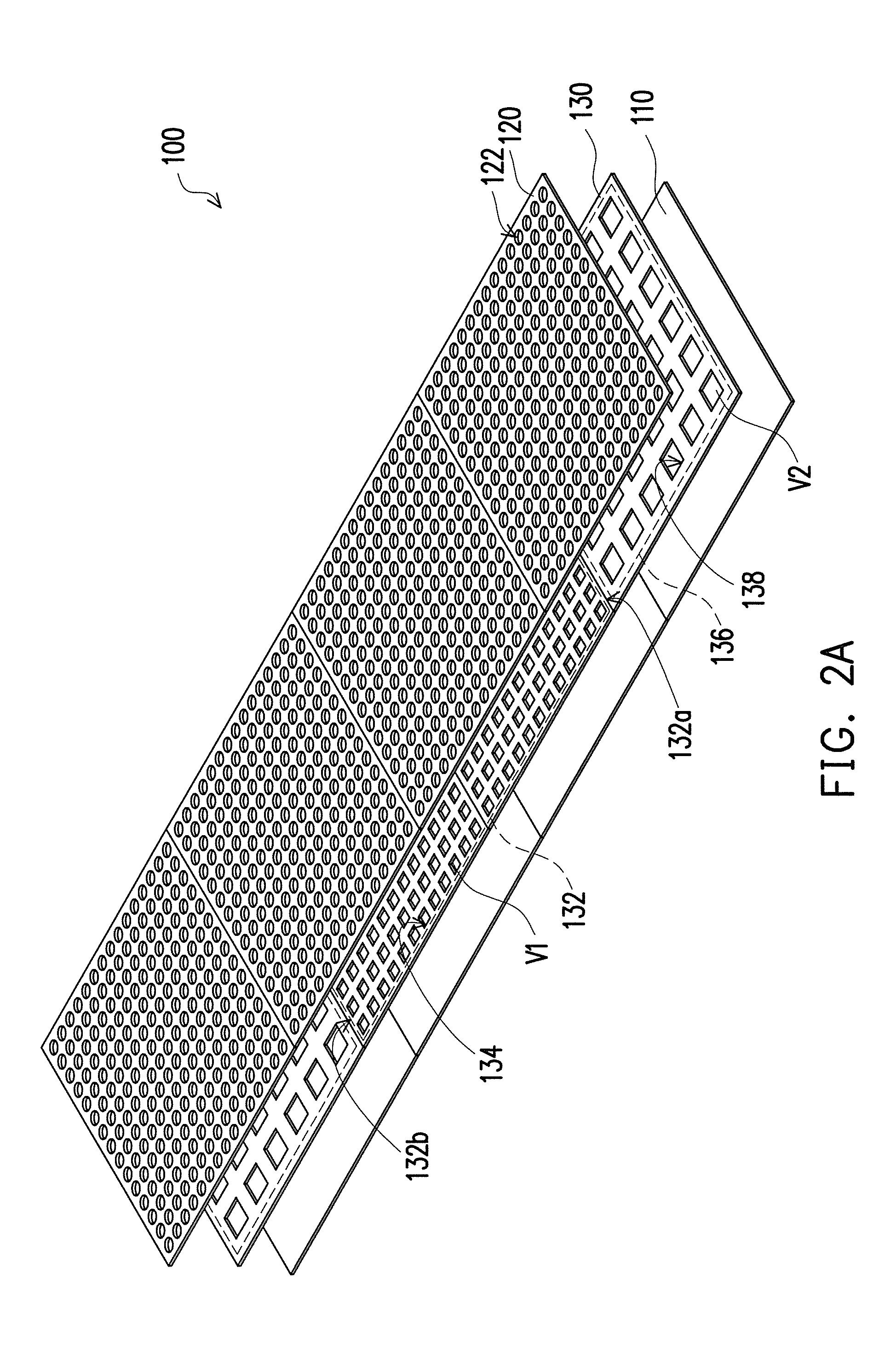

Electret loudspeaker device

ActiveUS20130044905A1Eliminate DirectionalitySuitable for useElectrostatic transducer loudspeakersDeaf-aid setsElectretLoudspeaker

An electret loudspeaker device including a diaphragm, a first perforated electrode and a first spacer is provided. The diaphragm has an electret layer and an electrode layer. The first perforated electrode is stacked on a side of the diaphragm near the electret layer, and has multiple holes. The first spacer is stacked between the diaphragm and the first perforated electrode, and includes a first distribution area and plural second distribution areas. The first distribution area has first openings penetrating through the first spacer, and each first opening has a first opening space volume between the diaphragm and the first perforated electrode. Each second distribution area has second openings penetrating through the first spacer, and each second opening has a second opening space volume between the diaphragm and the first perforated electrode. A difference between the first and the second opening space volumes is greater than 10%.

Owner:NAT TAIWAN UNIV

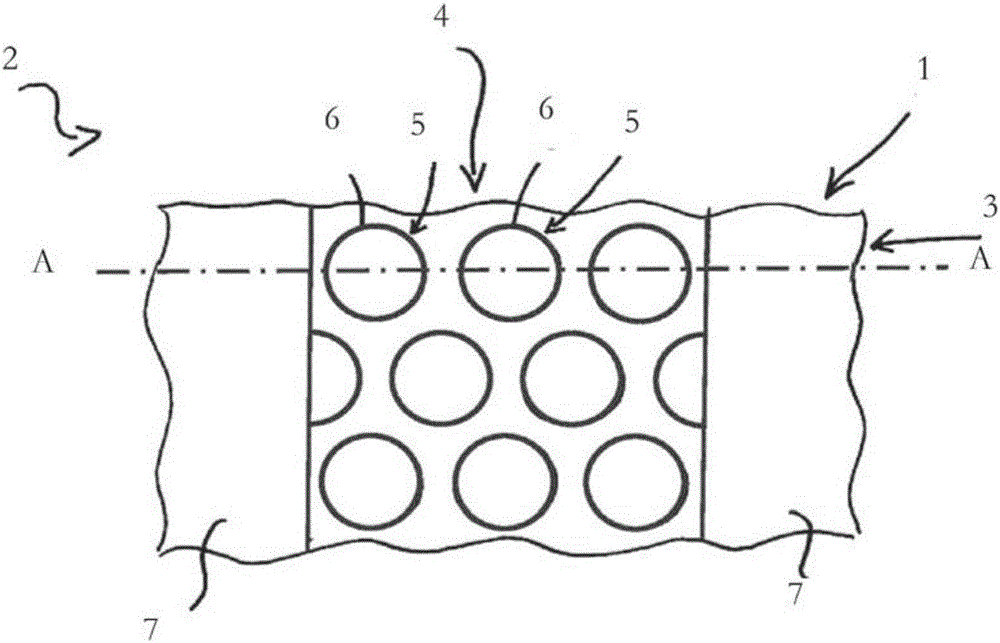

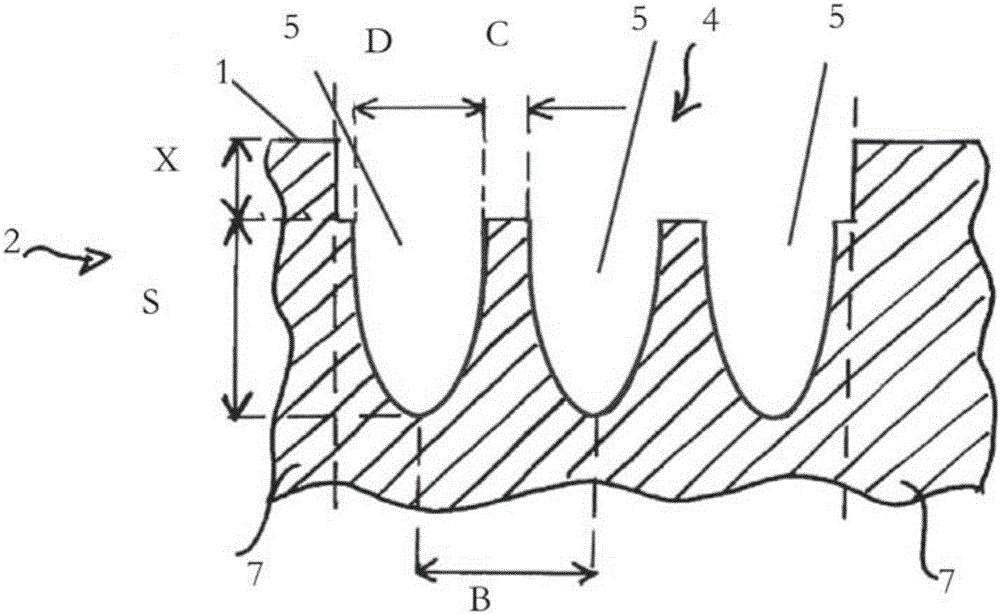

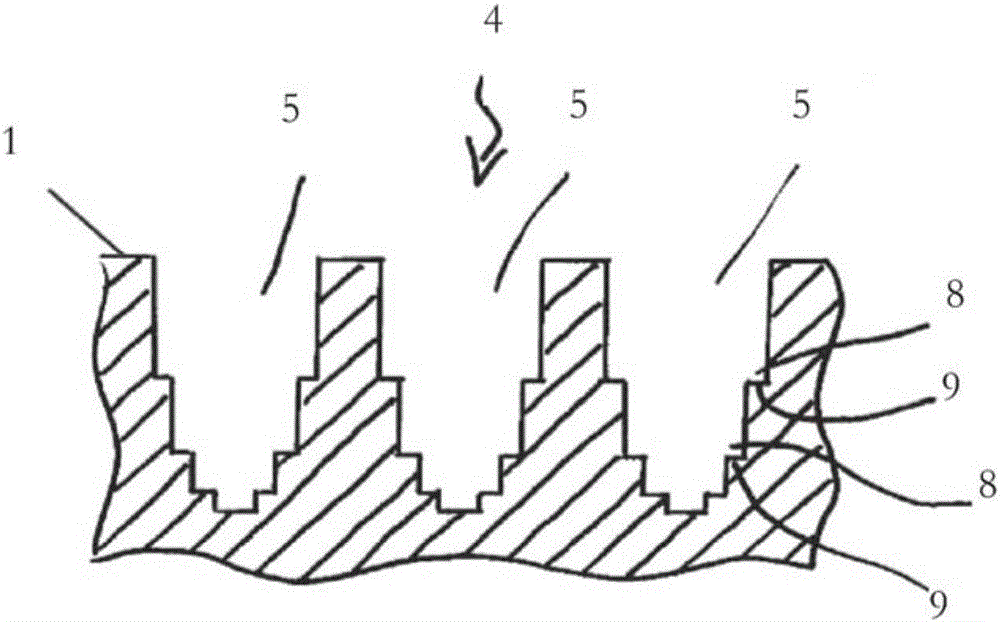

Polymer product, preferably vehicle tyre

ActiveCN106573508ASmall reflective propertiesEliminate DirectionalityTyre sidewallsEngineeringPolymer

The invention relates to a polymer product (2), preferably a vehicle tyre (10), with two sidewalls (11), wherein on the outer surface (1) of the polymer product (2) there is disposed at least one representation (3), which has a two-dimensional area (4) that is covered by a pattern. The invention is based on the object of providing by simple means a polymer product that has on its outer surface at least one two-dimensional area with a pattern, by means of which a higher-contrast representation with a directionally independent contrast can be achieved, and which can also be produced more reliably. The object is achieved by the pattern being a two-dimensional dot pattern, in that each dot is a three-dimensional element (5), which is formed as an elevation or depression of the surface (1), in that each element (5) has a base area (6) and a peak height (S), in that the pattern has elements (5) with a peak height (S) of 0.10 mm to 0.4 mm, preferably of 0.20 mm to 0.30 mm, and in that the pattern has elements (5) that are at a distance (B) from the respectively nearest neighbour of 0.10 mm to 0.50 mm, preferably 0.15 mm to 0.25 mm, wherein the distances (B) are measured between the geometric centroids of the base areas (6) of the elements (5).

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

Laminated composite wooden material and method of manufacturing material

InactiveUS7338701B2Light weightPowerfulNatural patternsThree-dimensional effectsFlexural strengthComposite lumber

A seven-layered laminated composite lumber 1 is constructed by stacking veneers 2, whose oven-dry specific gravity is 0.6 or larger, alternately with veneers 3, whose oven-dry specific gravity is 0.4 or less, and by bonding them together. The invention can thus provide a laminated composite lumber that is light in weight, is substantially resistant to warping and distortion, and yet retains the desired bending strength and nail holding power, and a method of producing such a laminated composite lumber.

Owner:UNI WOOD CORP

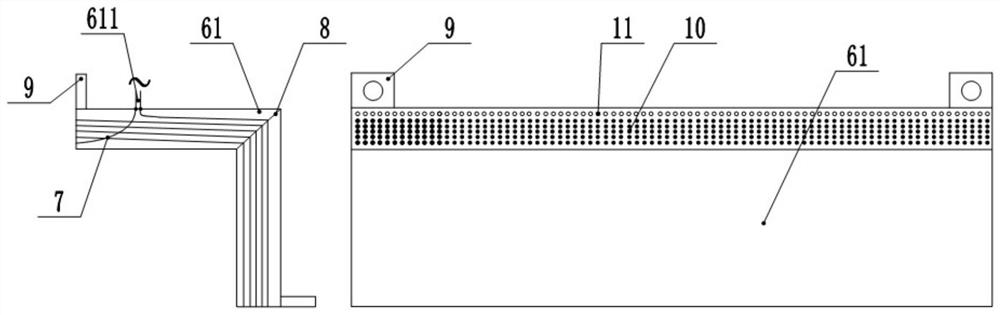

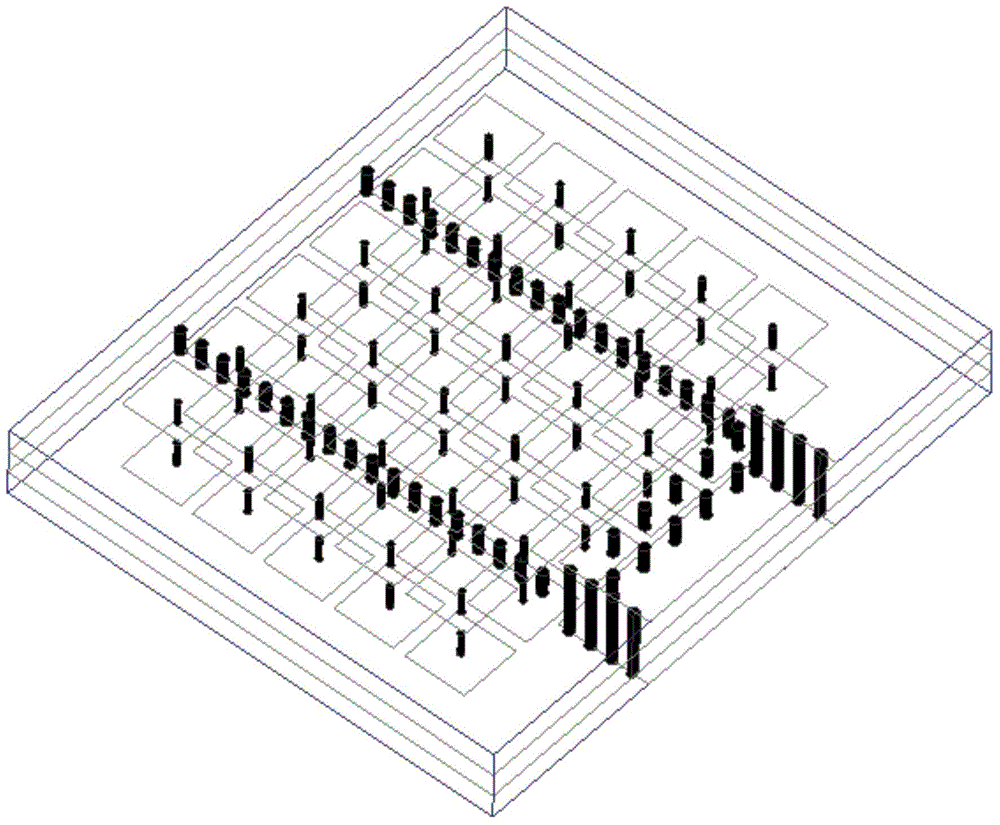

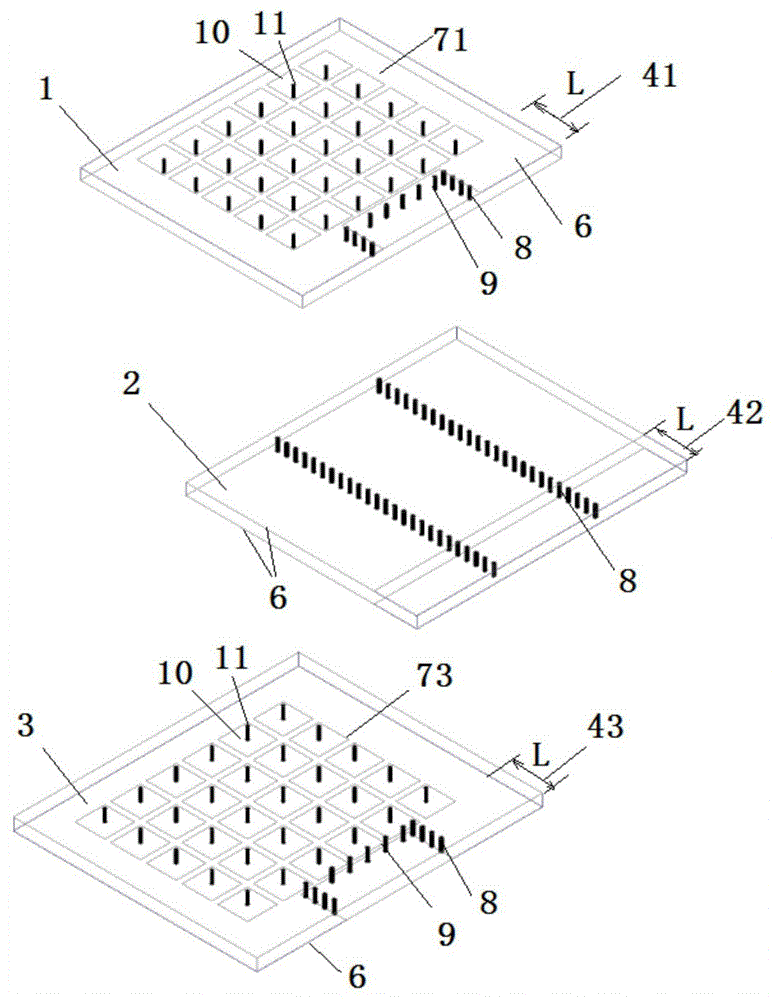

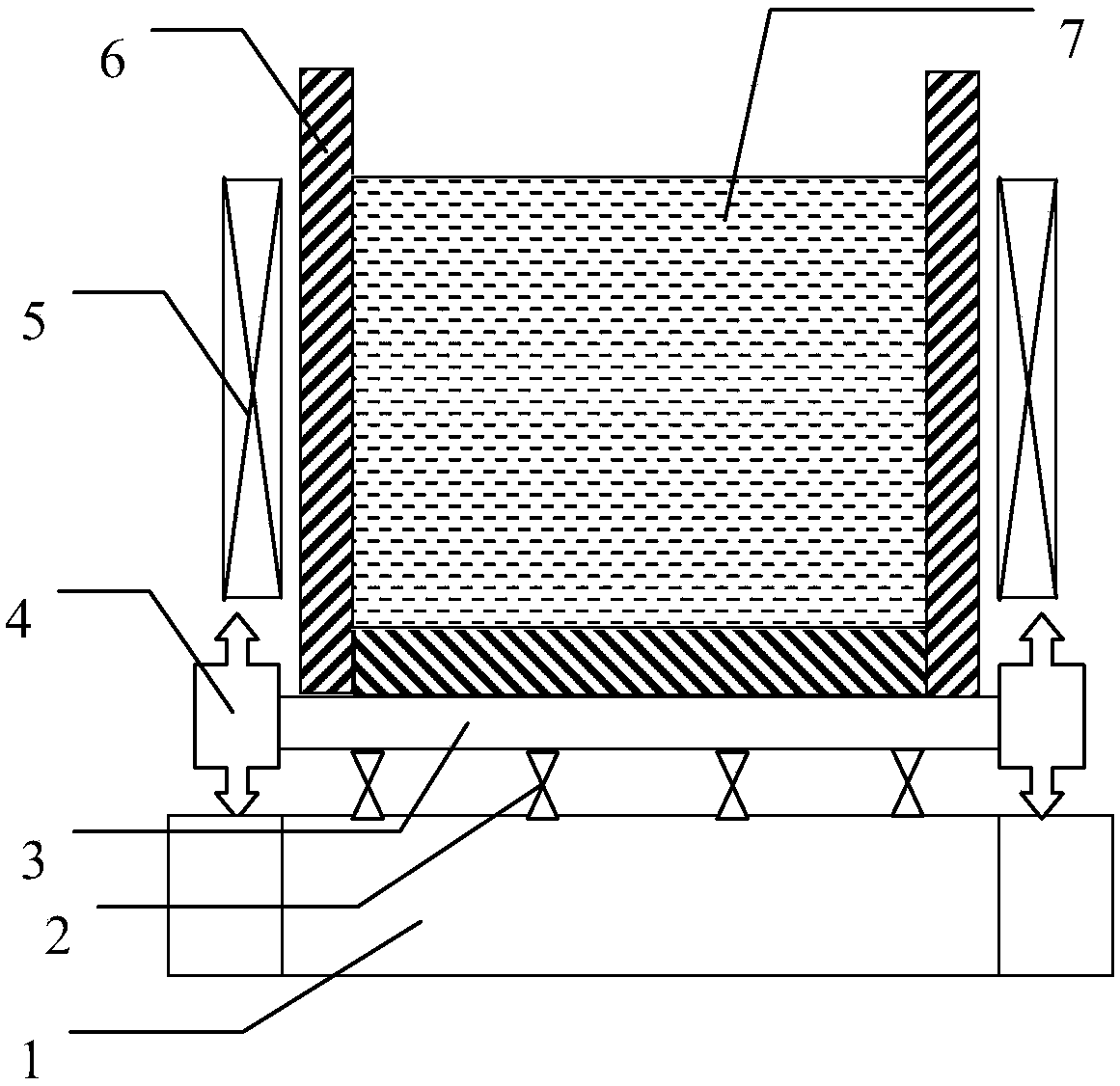

Preparation device and preparation method of directional steel fiber reinforced concrete prefabricated component

ActiveCN112025924AEliminate bending resistanceEliminate DirectionalityCeramic shaping apparatusFiber-reinforced concreteSteel fibre

The invention relates to the field of prefabricated type concrete structures, and particularly discloses a preparation device of a directional steel fiber reinforced concrete prefabricated component.The preparation device comprises a bottom supporting frame, the supporting frame is a rectangular metal frame, two first sliding rails in the horizontal direction are arranged on the upper surface ofthe supporting frame, and the two first sliding rails are symmetrically arranged; a coil is arranged on the first sliding rails, pulleys are fixed to the bottom of the coil, and the coil is slidably connected to the first sliding rails through the pulleys; two symmetrically-arranged steel supports are placed at the bottom of the supporting frame, the upper surfaces of the steel supports are located in the internal space of the coil, the steel supports are located between the two first sliding rails, a non-metal formwork is placed on the steel supports and penetrates through the coil, and vibrating rods are arranged on the coil; and a current exchanger is further arranged beside the supporting frame and electrically connected with the coil. The preparation device aims to solve the problem that tensile strength of a concrete matrix is insufficient due to steel fiber random distribution and low unidirectional reinforcement efficiency in an existing steel fiber concrete component.

Owner:TAIZHOU UNIV

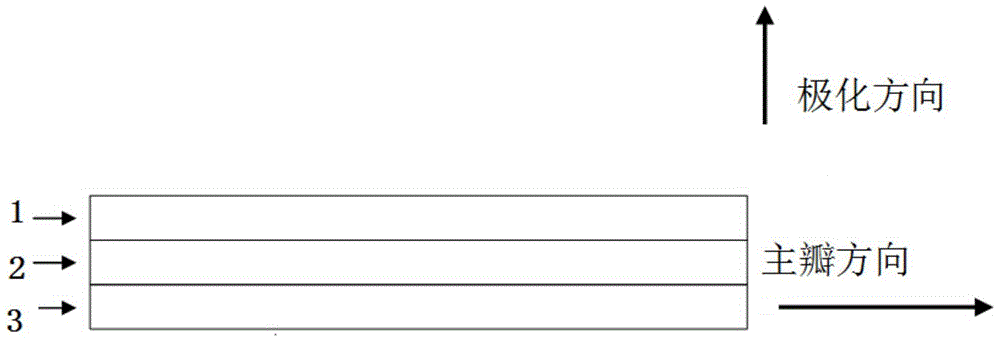

Vertically polarized antenna

InactiveCN105119056AImprove antenna standing waveImprove directionalityWaveguide mouthsStanding wavePhysics

The present invention provides a vertically polarized antenna which comprises three layers of the dielectric plates which are a first layer, a second layer and a third layer. The right end of each layer of dielectric plate has a section of L area extending leftward from the right boundary of the dielectric plate, a stepped substrate integrated waveguide structure whose L area height is higher than that of the left side of the L area is formed by the whole second layer, a first layer L area and a third layer L area together. The length of the L area is L. The vertically polarized antenna comprises the stepped substrate integrated waveguide structure, through using the step transition technology is employed at an E plane, for E plane discontinuities, the transition of the E plane is carried out directly, the antenna standing wave is greatly improved, the efficiency is high, the size is only changed for several millimeters, according to the E plane transition structure, the antenna E plane directivity can be improved, at the same time through laying electromagnetic band gap structures at upper and lower surfaces, in the condition of not enlarging the antenna size, the backward radiation is greatly inhibited, and the antenna E plane directivity is further improved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

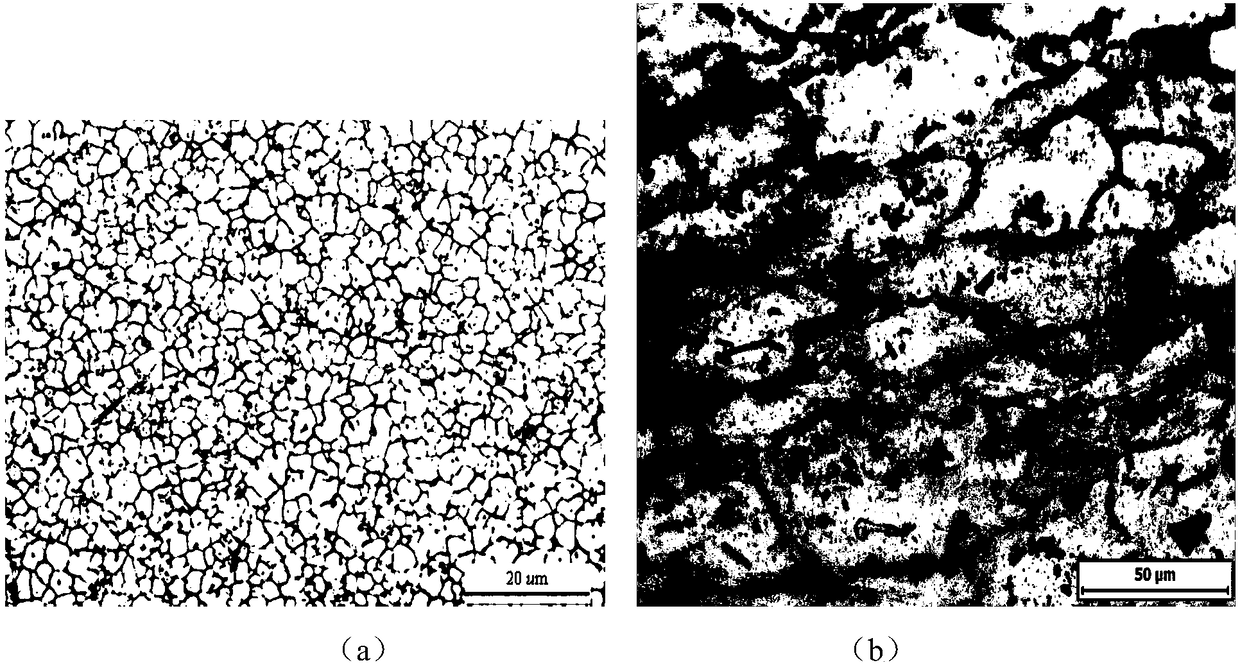

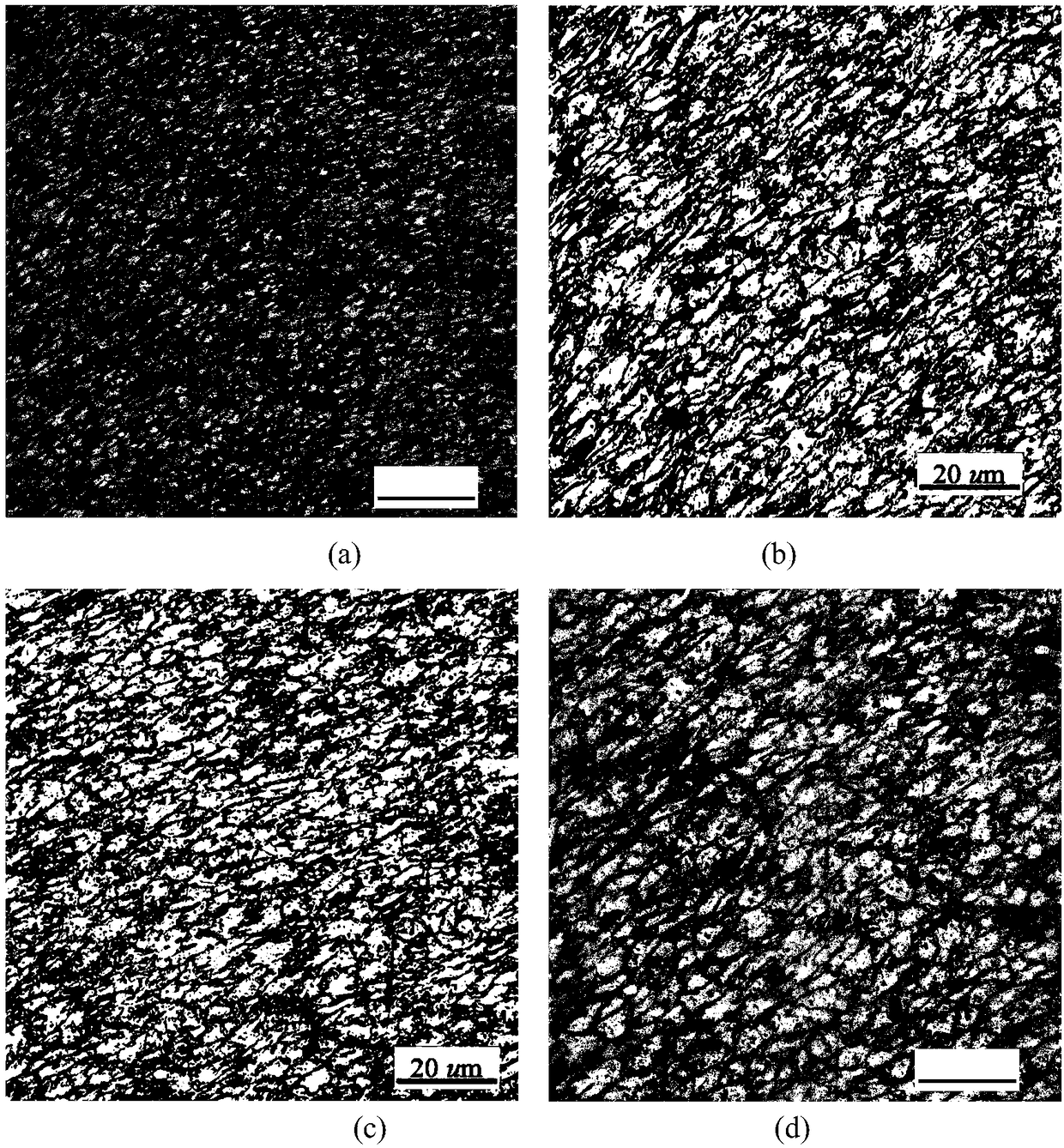

Method for refining metal solidification structure through combination effect of magnetic field and vibration

The invention provides a method for refining a metal solidification structure through the combination effect of a magnetic field and vibration, and belongs to the technical field of metal solidification control. During a metal melt solidification process, a metal liquid and a casting mould generate high frequency micro-amplitude vibration; meanwhile, the magnetic field is applied to the metal meltand the metal melt is electromagnetically stirred; the metal solidification structure including particles and a precipitated phase is refined through the combination effect of high-frequency vibration and electromagnetic stirring; and the comprehensive property of a metal casting is favorably improved. The method has the obvious advantages that the metal refining effect is more obvious compared with single electromagnetic stirring or single vibration; besides, metals are not polluted; and the method is applicable to solidification structure refining of various metal melts.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com