Common mode choke coil

A common mode choke coil and coil technology, applied in the direction of transformer/inductor coil/winding/connection, inductor, printed inductor, etc., can solve the problem of reducing the freedom of coil shape design and hindering the small size of common mode choke coil. It can improve the degree of freedom of design, easy adjustment, and reduce the reduction of withstand voltage reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

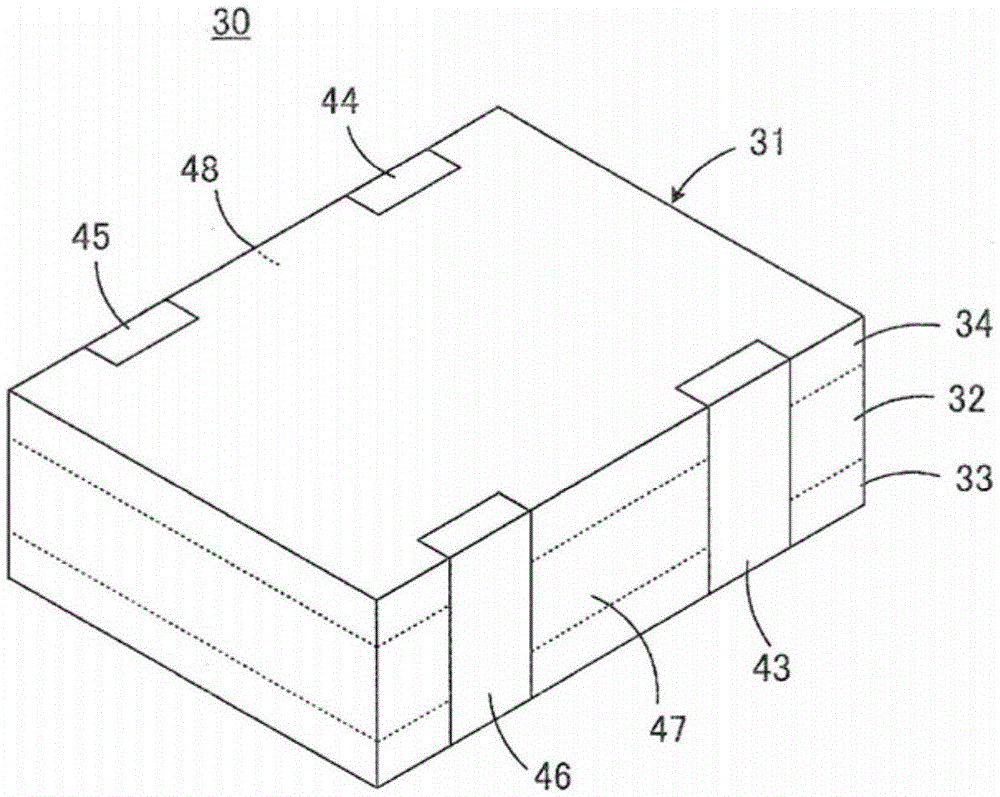

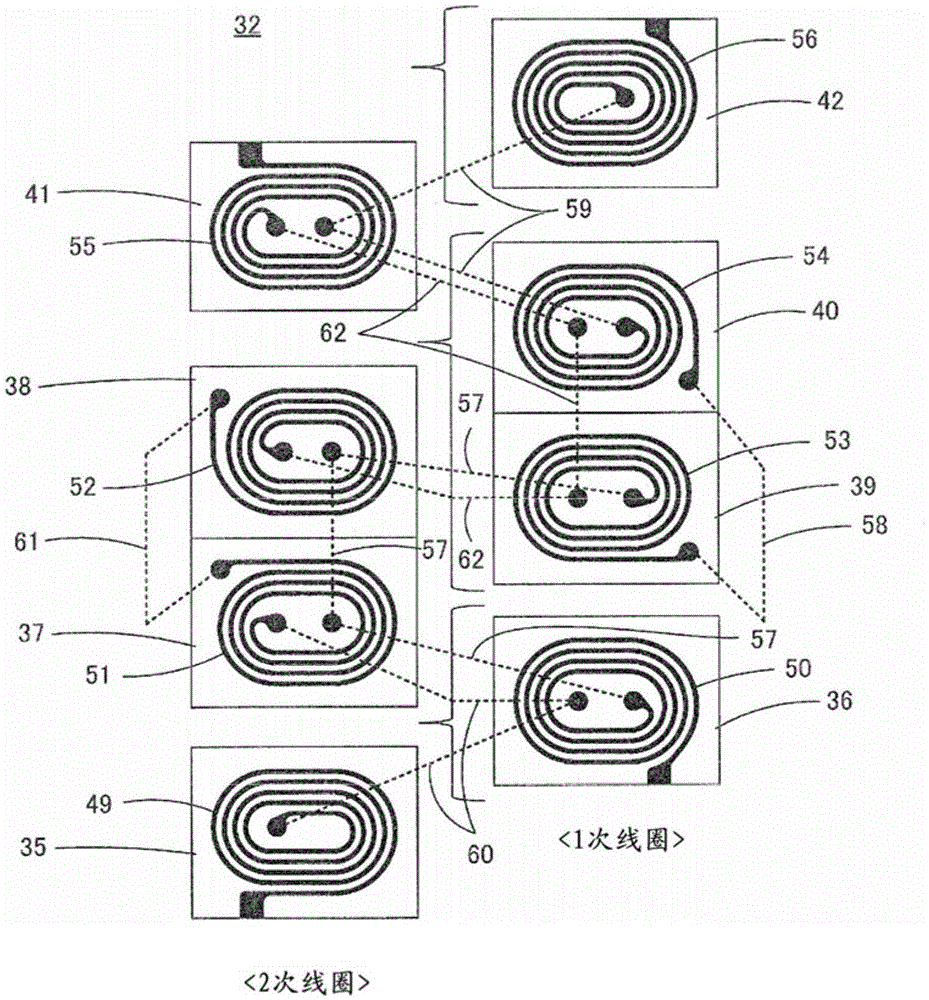

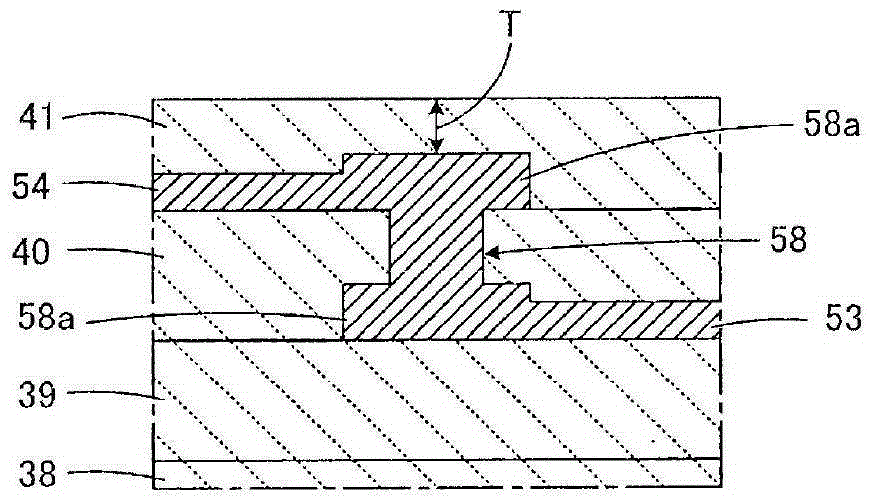

[0047] refer to figure 1 , the common mode choke coil 30 includes a laminated body 31 as a component main body. The laminated body 31 has a structure in which the low magnetic permeability portion 32 is sandwiched between the two magnetic body portions 33 and 34 . The magnetic body portions 33 and 34 are made of, for example, Ni—Cu—Zn-based ferrite, Mn—Zn-based ferrite, hexagonal-based ferrite, or the like. On the other hand, as the material of the low magnetic permeability portion 32, for example, a non-magnetic material such as glass ceramics with a magnetic permeability of almost 1, a Ni-Cu-Zn-based ferrite with a magnetic permeability of about 1 to 10, non-magnetic materials, etc., can be used. Magnetic ferrite, etc. In addition, resins such as polyimide can also be used as the material of the low magnetic permeability portion 32 .

[0048] First to fourth external terminal electrodes 43 to 46 are provided on the outer surface of the laminated body 31 . More specifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com