Medium plate made of duplex stainless steel with excellent low-temperature toughness and manufacturing method for medium plate

A technology of duplex stainless steel and low-temperature toughness, which is applied in the field of duplex stainless steel and its manufacturing, can solve the problems of toughness (impact value drop, etc.), achieve the effect of increasing N solubility, reducing adverse effects, and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

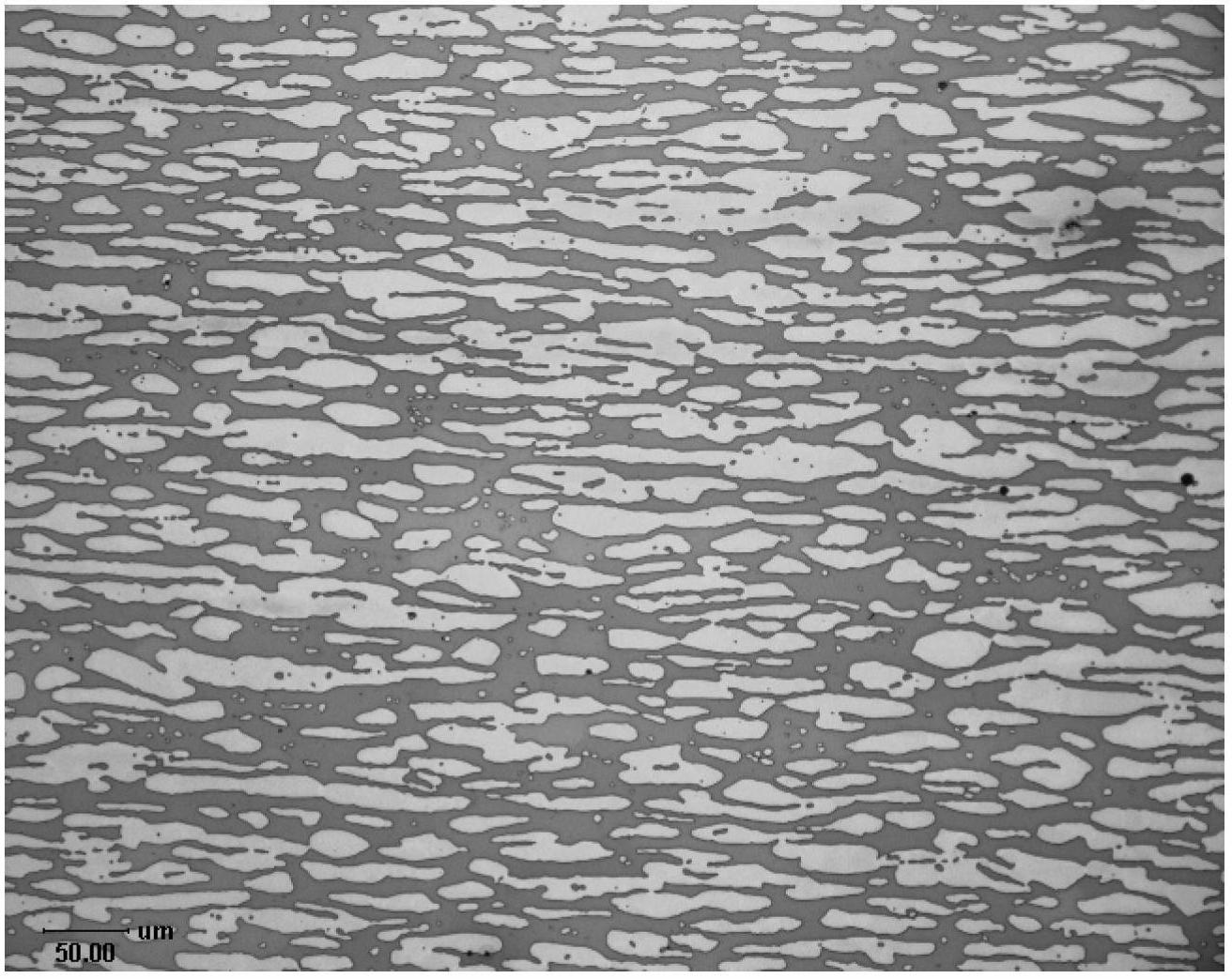

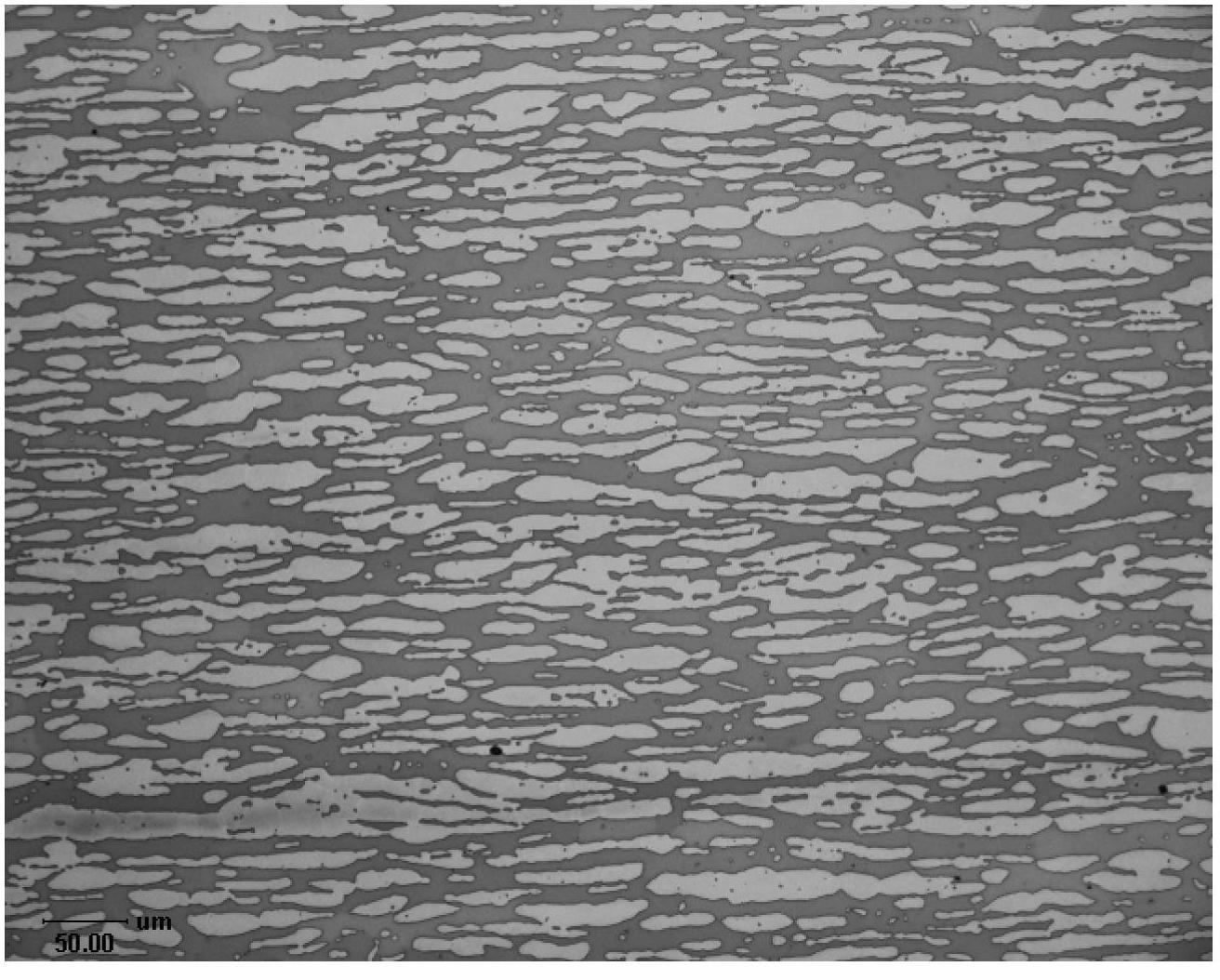

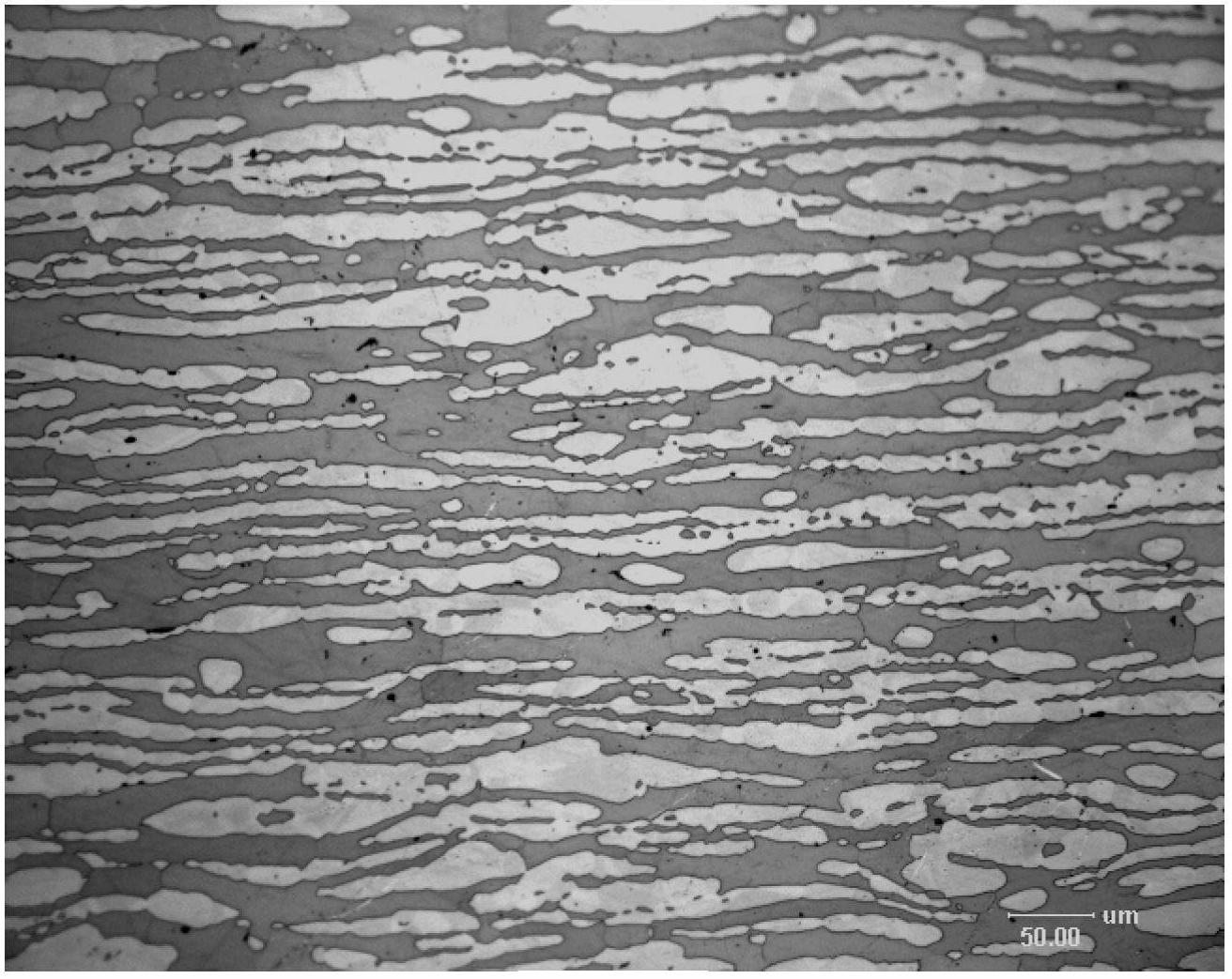

[0045] The metallographic diagram of the alloy of embodiment 1 along the rolling direction (also known as the longitudinal direction) is as follows figure 1 As shown (the austenite phase accounts for about 58%), the alloy metallographic diagram of the alloy in Example 1 perpendicular to the rolling direction (also known as the transverse direction) is as follows figure 2 As shown, the metallographic diagram of the alloy of Comparative Example 2 along the rolling direction is as follows image 3 shown. Table 1 also shows the mechanical properties and corrosion resistance of the steel of the present invention and the comparative steel types, especially the impact toughness at -40°C and -80°C. Among them, the metallographic sample of duplex stainless steel is electrolytically corroded, and the etchant is 40gKOH+100mlH 2 O, corrosion current 0.3~0.8A / cm 2 The mechanical properties are all taken from the hot-rolled annealed sheet, and the impact properties are in accordance wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com