Hollow tungsten electrode coaxial wire filling welding device and regulating and welding method

A technology of welding device and tungsten electrode, which is applied in hollow tungsten electrode coaxial filler wire welding device and control and welding fields, can solve the problems of welding process stability and process controllability cannot be guaranteed, assembly problems and conductive uniformity problems cannot be solved. It is solved, without considering the uniformity of gas feeding, etc., to achieve the effect of improving deposition efficiency, eliminating directional problems, and improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

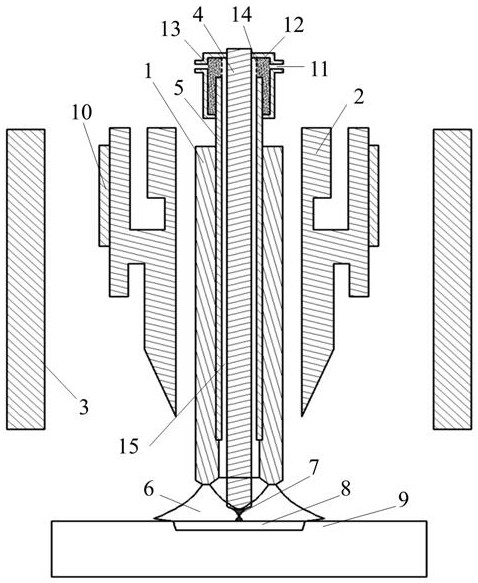

[0055] A hollow tungsten pole coaxial wire filling welding device, the hollow tungsten pole coaxial wire filling welding device comprises a hollow tungsten pole 1, a tungsten pole clamp 2, a protective gas cover 3, a welding wire 4, an insulating porcelain tube 5, and an ion buffer filter Air chamber 12;

[0056] The hollow tungsten electrode is clamped by symmetrically arranged tungsten electrode holders, the protective gas cover is located outside the tungsten electrode holder, and the plasma buffer and filter air chamber is fixed on the upper end of the hollow tungsten electrode;

[0057] There is a step in the hollow tungsten pole, the insulating porcelain tube is inserted into the step in the hollow tungsten pole, the welding wire is inserted in the insulating porcelain tube, and the welding wire and the The gap between the hollow tungsten electrodes forms an ion gas channel 15;

[0058] The gas passes through the ion gas channel and passes through the porous material in...

Embodiment 2

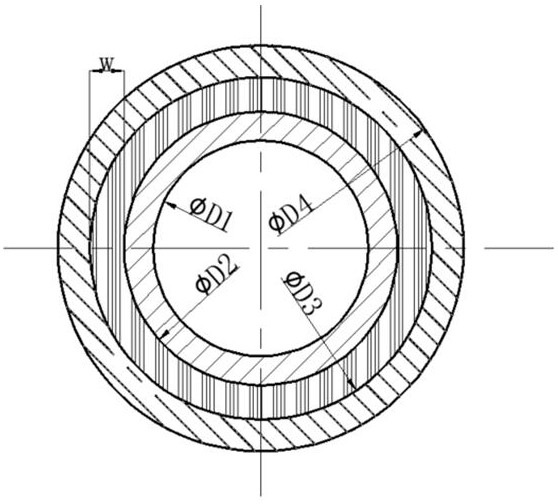

[0064] According to the hollow tungsten pole coaxial wire-filled welding device described in Embodiment 1, the bottom of the hollow tungsten pole is a bell mouth, and the end face is circular, cut along the radial direction, and divided into multiple arc emission points. Hollow tungsten pole with stepped petals.

[0065] The shape of the hollow tungsten electrode electron emission end includes three parts: ①The inner hole of the hollow tungsten electrode electron emission end with an outer diameter of D1 and an inner hole diameter of D4 is processed into a bell mouth shape with a certain angle. The inner surface of the bell mouth is called the inner wall. The diameter of the inner wall is D2; ②A bevel with a certain chamfer is processed on the outer diameter of the hollow tungsten electron emission end, and the torus formed by the inclination is called the outer wall; ③The unprocessed end face of the electron emission end is used for emission Electrons, the end face is called ...

Embodiment 3

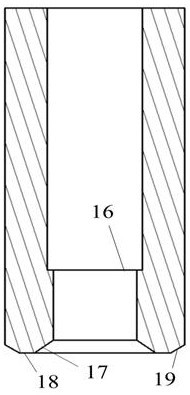

[0068] According to the hollow tungsten electrode coaxial wire-filling welding device described in embodiment 1 or 2, the step of the inner step hole processing of the stepped petal hollow tungsten electrode is located 10-20 mm above the end of the hollow tungsten electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com