Preparation device and preparation method of directional steel fiber reinforced concrete prefabricated component

A technology for reinforcing concrete and prefabricated components, applied in manufacturing tools, ceramic molding machines, etc., can solve the problems of insufficient tensile strength of concrete matrix and low efficiency of one-way reinforcement, and achieve the effect of flexible cross-sectional form of components and improvement of structural mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 Shown:

[0036]A preparation device for directional steel fiber reinforced concrete prefabricated components, comprising a support frame 1 at the bottom, the support frame 1 is a rectangular metal frame, and the upper surface of the support frame 1 is provided with two first slide rails 2 in the horizontal direction, and two second sliding rails 2 A slide rail 2 is arranged symmetrically; the first slide rail 2 is provided with a coil 6, and the bottom of the coil 6 is fixed with a pulley 12, and the coil 6 is slidably connected to the first slide rail 2 through the pulley 12, and the support frame 1 is fixed with a second The slide rail 3, the second slide rail 3 is perpendicular to the first slide rail 2, and the first slide rail 2 is slidably connected to the second slide rail 3; two symmetrically arranged steel supports 4 are placed...

specific Embodiment approach

[0037] A method for preparing a directional steel fiber reinforced concrete prefabricated component, using the above-mentioned directional steel fiber reinforced concrete prefabricated component preparation device, comprising the following steps:

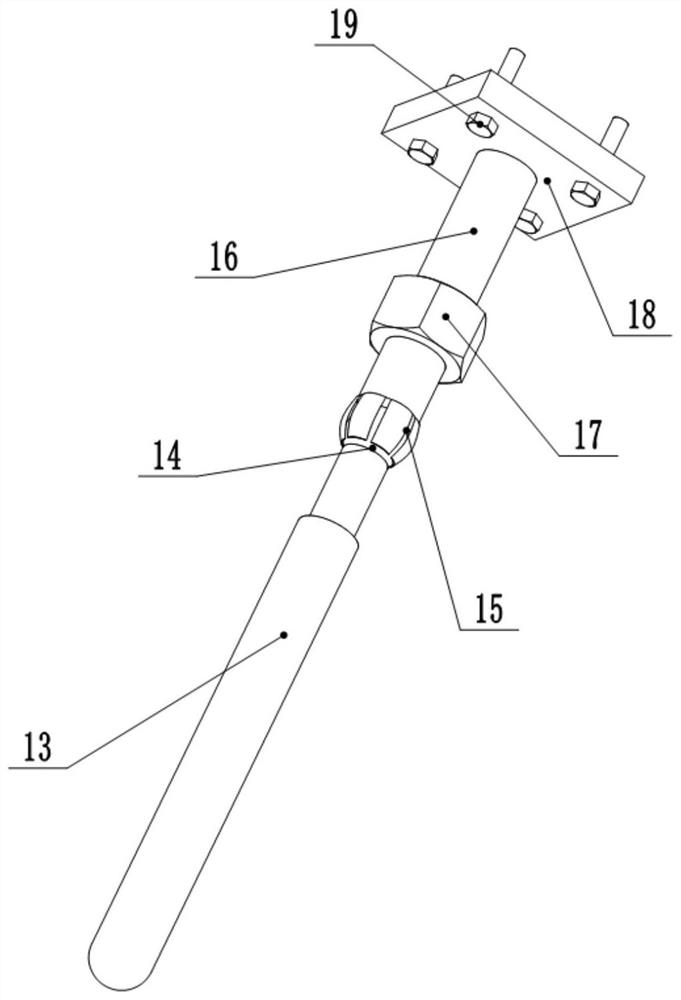

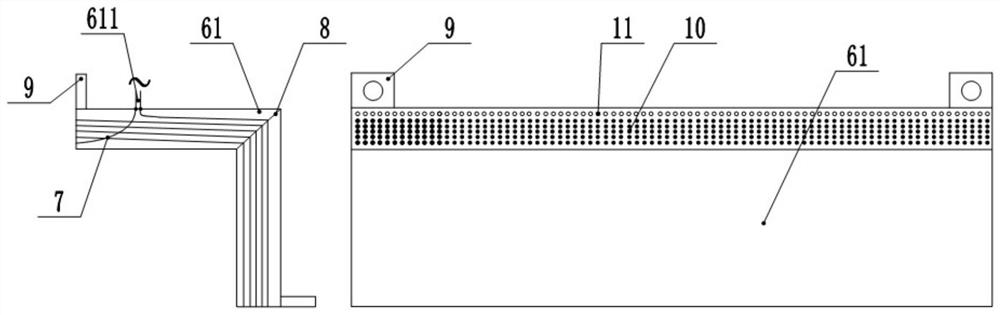

[0038] The first step: install the coil 6; according to the size of the non-metal template 5, adjust the number of the air inlet module 64, the air outlet module 65 and the flat module 63, and assemble the coil 6 through the bolt 19 and the splicing plate 9; The vibrating rod 13 is installed on the lower surface of the air intake module 64. After the vibrating rod 13 is rotated to the required angle, the nut 17 is rotated downward, and the nut 17 presses the shrapnel 15, and the shrapnel 15 fixes the vibrating rod 13; slide The first slide rail 2, make the first slide rail 2 face the pulley 12 respectively, then place the coil 6 on the first slide rail 2, connect the port with the current exchanger 20, and complete the installation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com