Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Eliminate bending deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

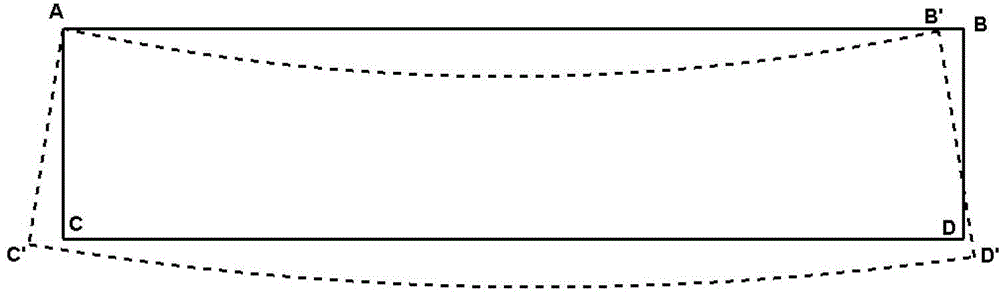

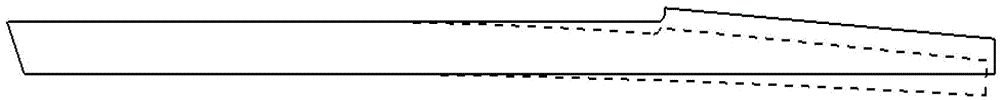

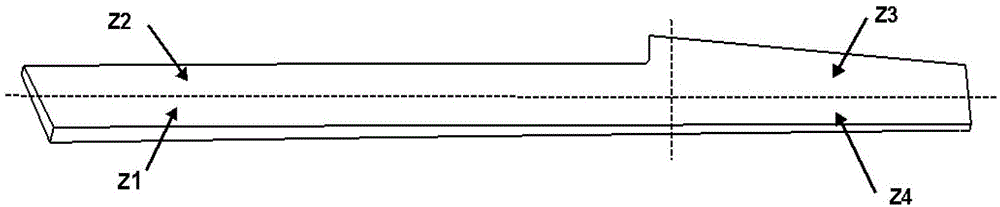

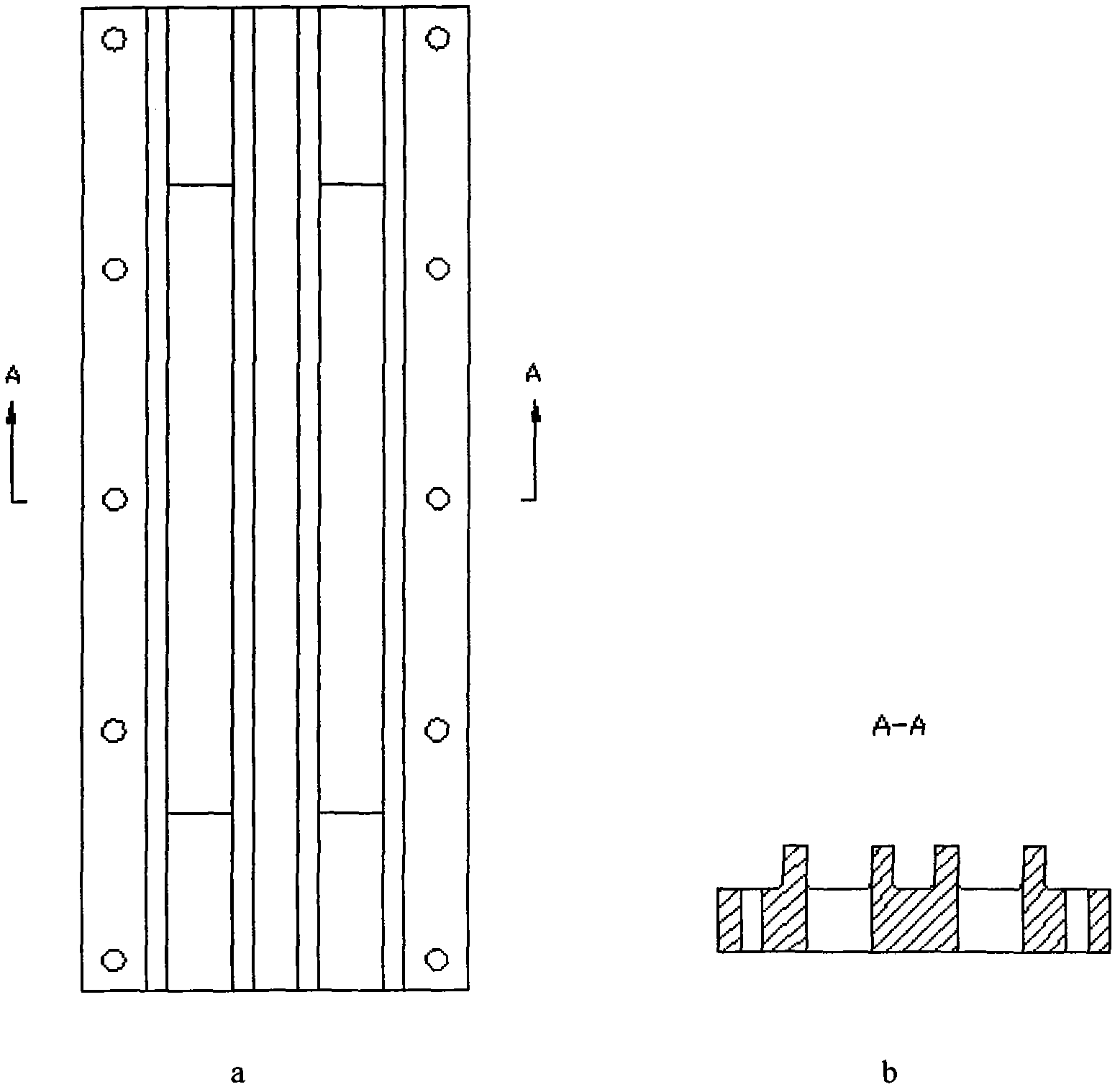

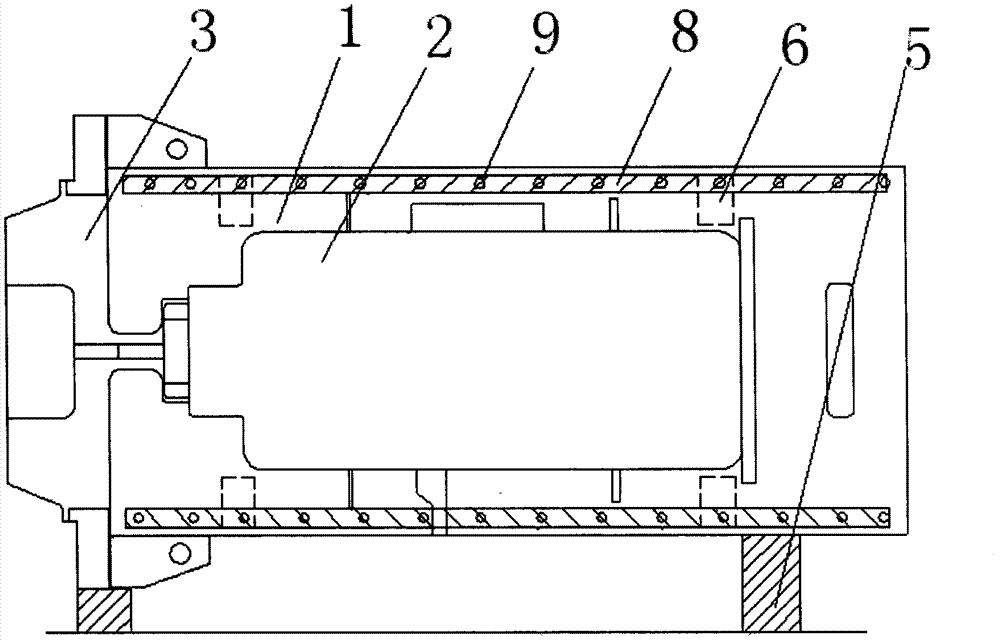

Shape maintenance shot peening strengthening and calibration method for preventing in-plane bending of wall panel

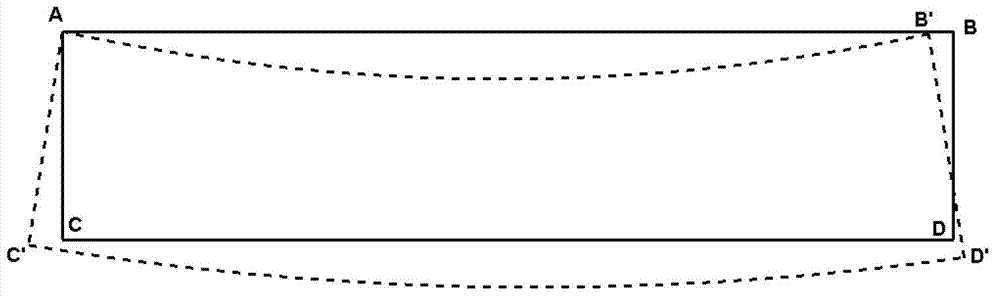

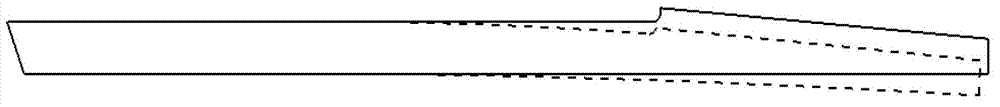

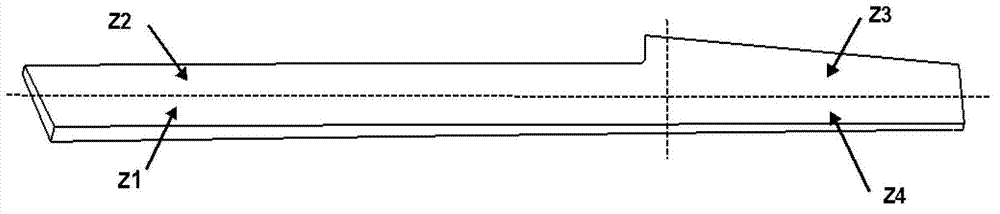

The invention belongs to the forming technique of aerospace wall panels, relating to a shape maintenance shot peening strengthening and calibration method for preventing the in-plane bending of a wall panel. The method comprises the following steps of: firstly carrying out regional division on the spare parts of the wall panel, then inputting data in a shot peening device, and finally carrying out shot peening strengthening in a double opposite spraying manner; when in-plane bending occurs for the shot peening, calibrating thin-gauge skins, firstly choosing a calibration region, and then inputting the data into the shot peening device; and carrying out double opposite spraying on the inner and the outer thin-gauge skins in the deformed region with in-plane bending. According to the invention, aiming at the complicated structural shape, shot peening strengthening is carried out on the wall panel under the condition of guaranteeing that the space shapes of the spare parts are not changed after deformation, and the calibration method for forming the in-plane bending after the shot peening strengthening reduces the rejection rate of the spare parts, avoids severe economic lost and has good technological and economic benefits.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

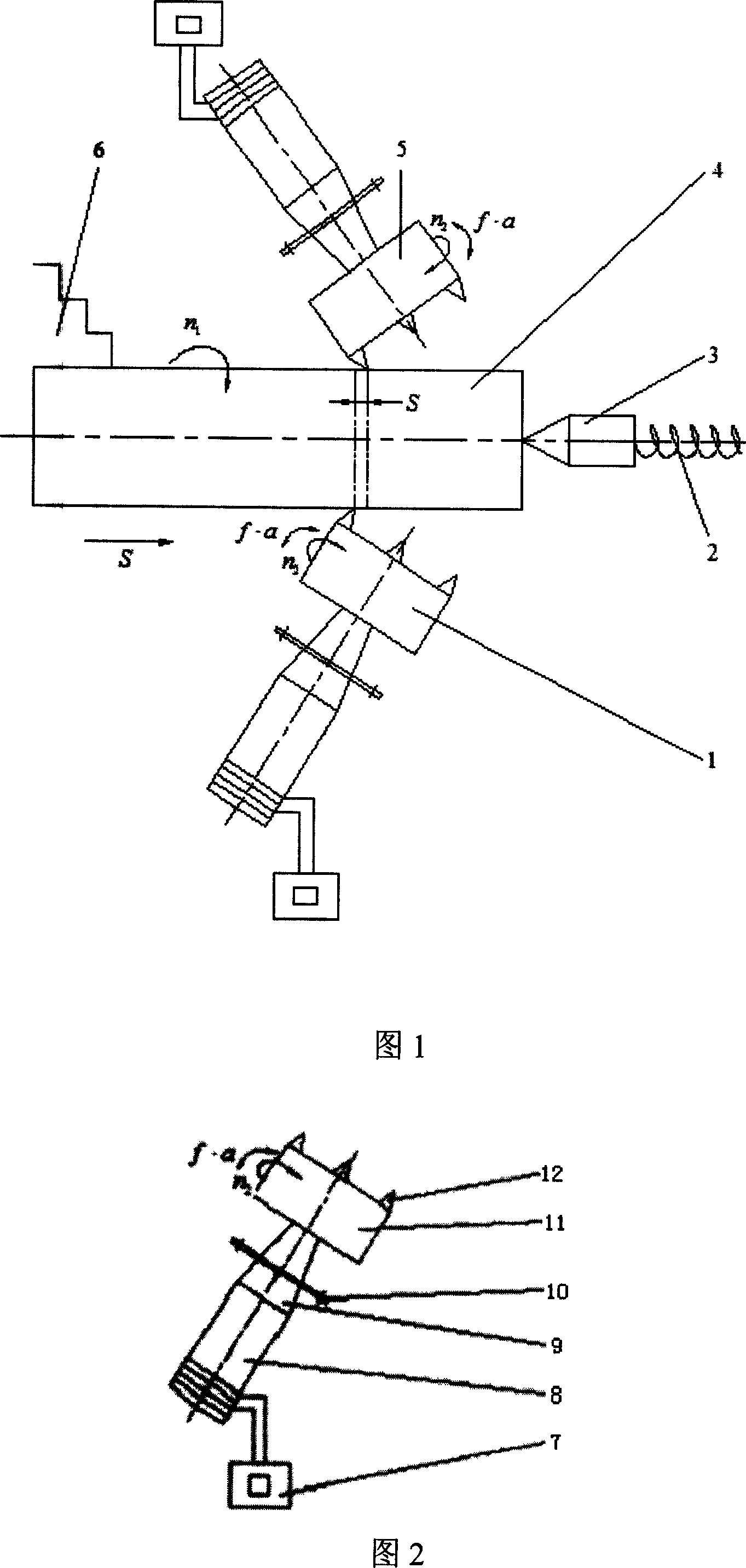

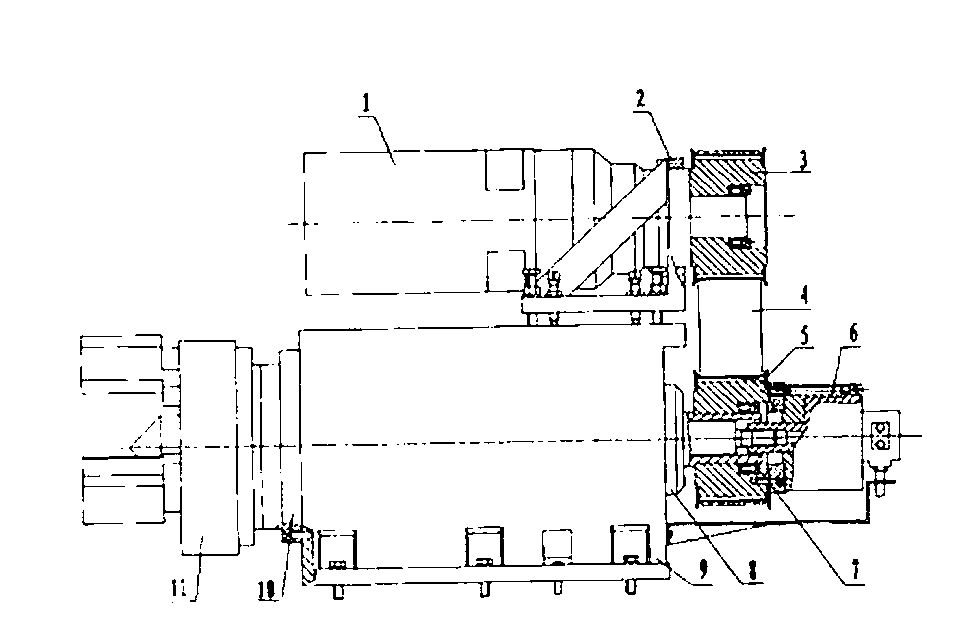

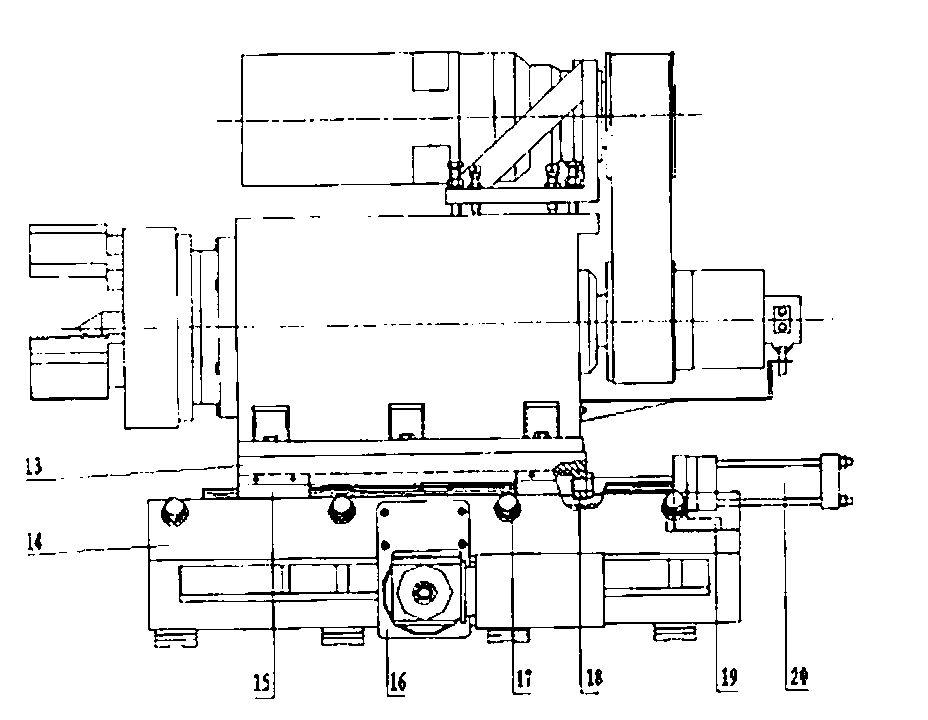

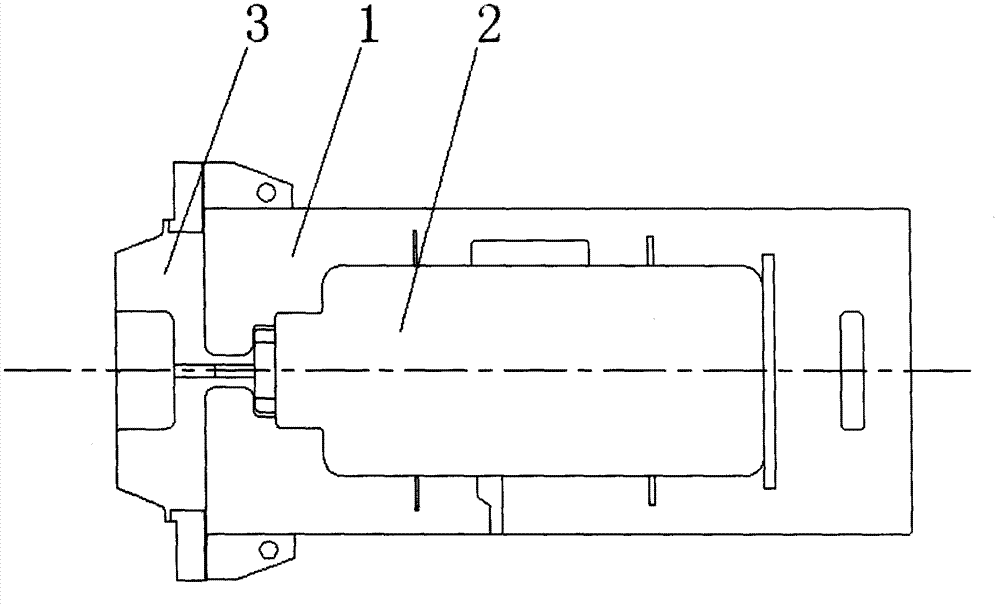

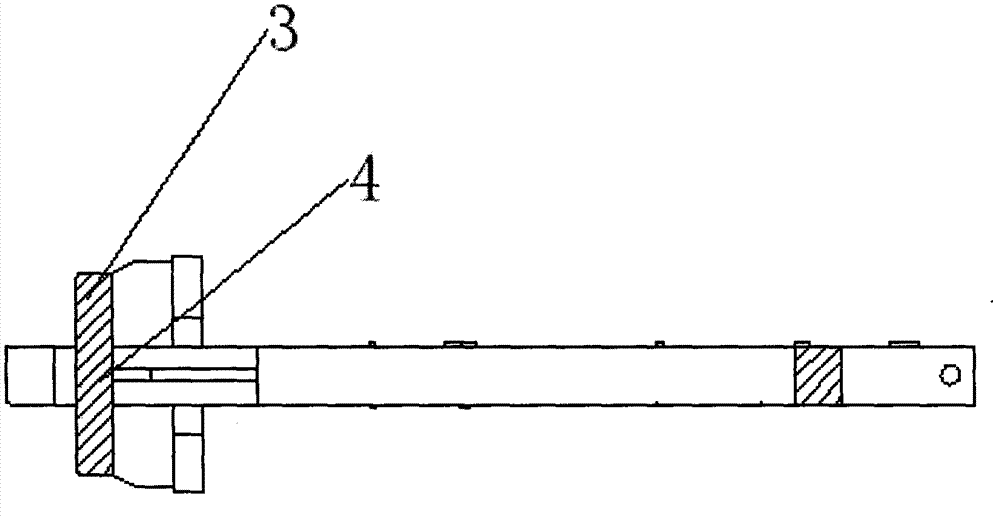

Ultrasonic torsional vibration turning-milling system and method with oppositely fed double cutter

InactiveCN101020244AEliminate bending deformationEliminate pressure instabilityMilling equipment detailsDriving apparatusMilling cutterEngineering

The present invention discloses one kind of ultrasonic torsional vibration turning-milling system and method. In the turning-milling process, the resultant motion of the rotation of the milling cutter, the rotation of the workpiece, the axial feeding of the milling cutter shaft, the radial feeding of the milling cutter and the ultrasonic torsional vibration of the milling cutter is adopted to complete the cutting of the workpiece. The ultrasonic torsional vibration of the milling cutter is generated with two sets of ultrasonic torsional vibration devices arranged radially along the workpiece. The present invention has the advantages of eliminating the bending deformation the radial force generates, eliminating the bending deformation caused by elongation of slender shaft, high machining precision, etc.

Owner:HANGZHOU DIANZI UNIV

Method for producing overturning plate valve cover by resin sand

InactiveCN102773403AHigh strengthReduce thermal stressFoundry mouldsFoundry coresCementiteRaw material

The invention provides a method for producing an overturning plate valve cover by resin sand, aiming at effectively reducing the cementite tissue in a casting piece, and improving the yield. The method comprises the following steps of: firstly manufacturing a mould and a sand box, wherein the mould is of an integrated structure, and the sand box is wholly cast by nodular iron; evenly mixing raw sand and curing agent, and adding furan resin in proportion, and evenly mixing; filling the resin sand into the sand box till the sand box is filled and struck off, and putting on a plain jolter to be mechanically rammed; preparing coating material, and coating the coating material on the surface of formed resin sand, wherein the coating method adopts a pouring and coating method; after the coating material is dried, baking the surface of the resin sand coated with the coating material by a blast burner; hoisting the sand box to a pouring platform for mould assembling; adding raw materials into an intermediate frequency furnace to be smelted according to the normal nodular iron proportion, and balling according to a normal method; transporting the balled molten iron to the pouring platform, pouring under the temperature condition of 1450 DEG C, releasing a box clamp after pouring for 1 hour, and keeping the temperature for 2 hours; falling the sand after cooling to be less than 200 DEG C; and cleaning the casting piece.

Owner:SHANXI YUQING ENVIRONMENTAL PROTECTION

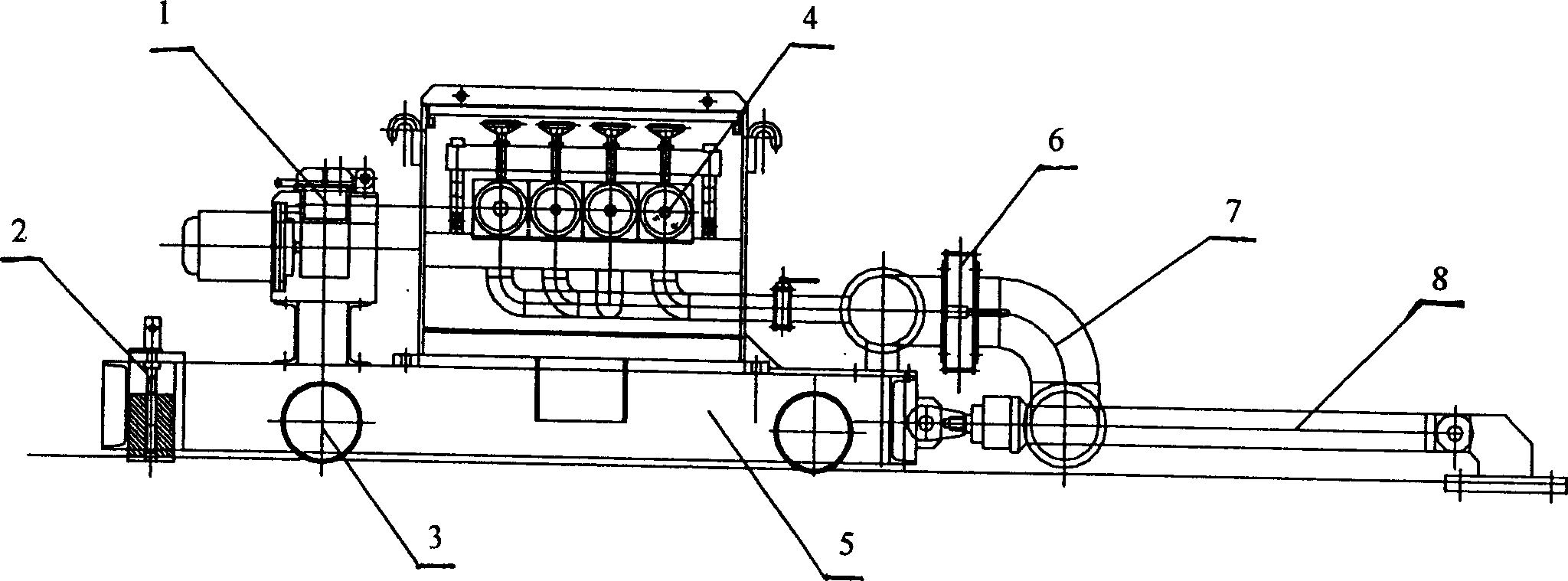

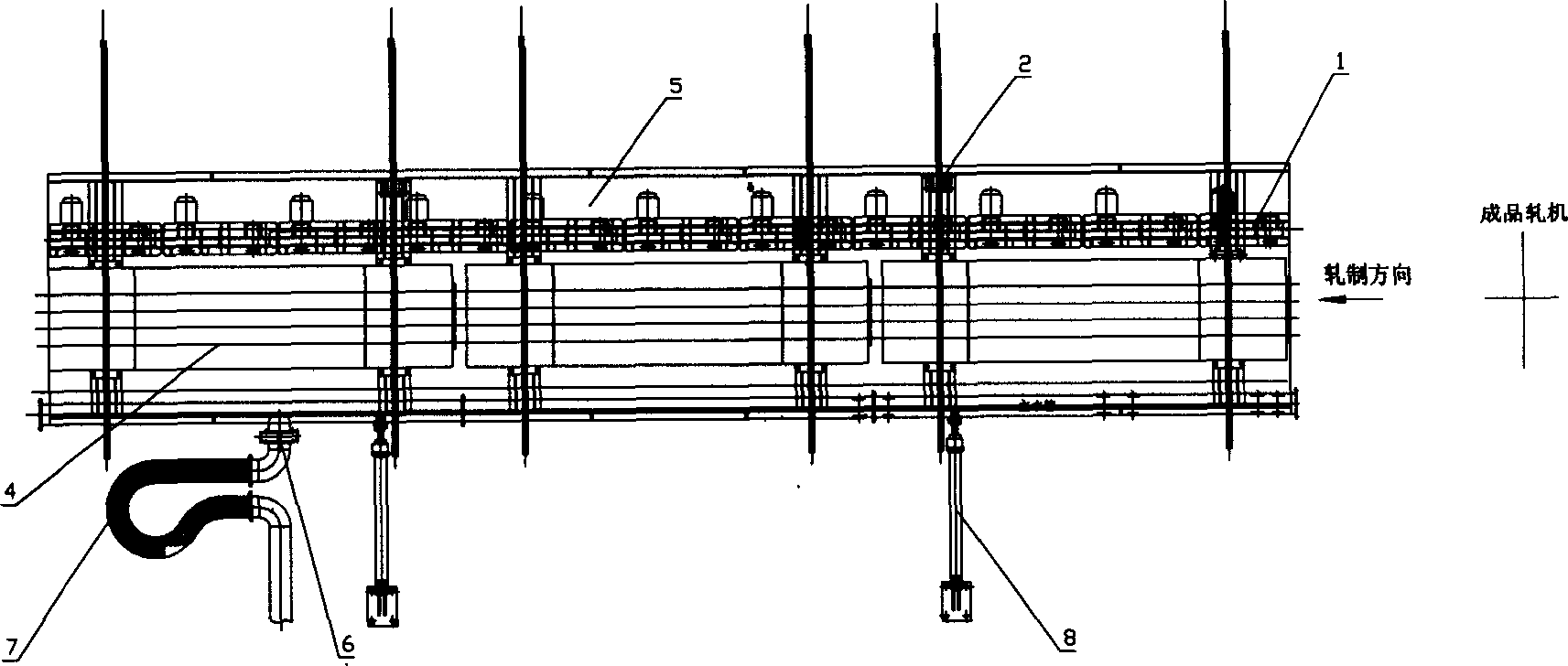

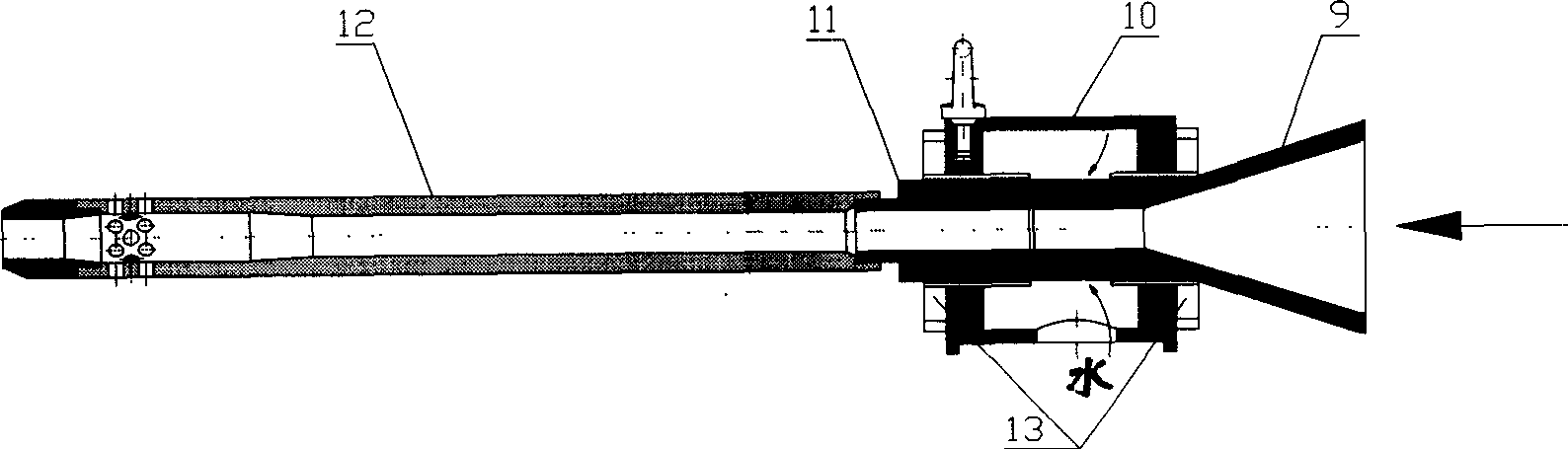

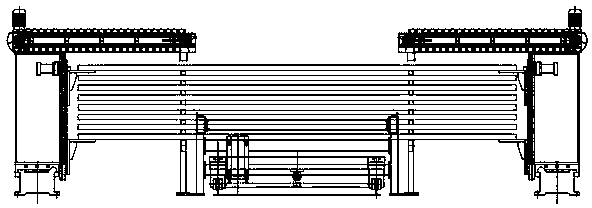

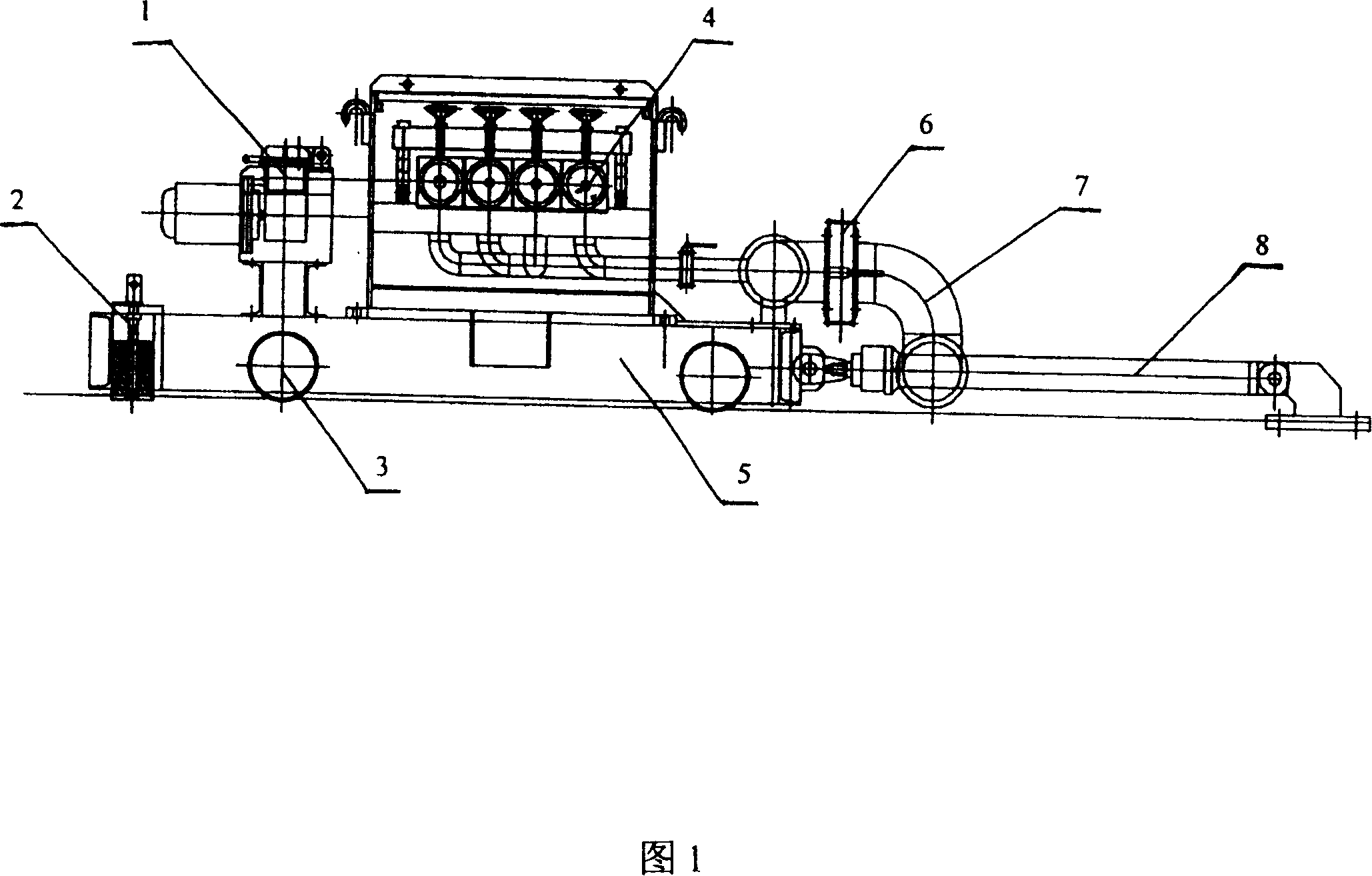

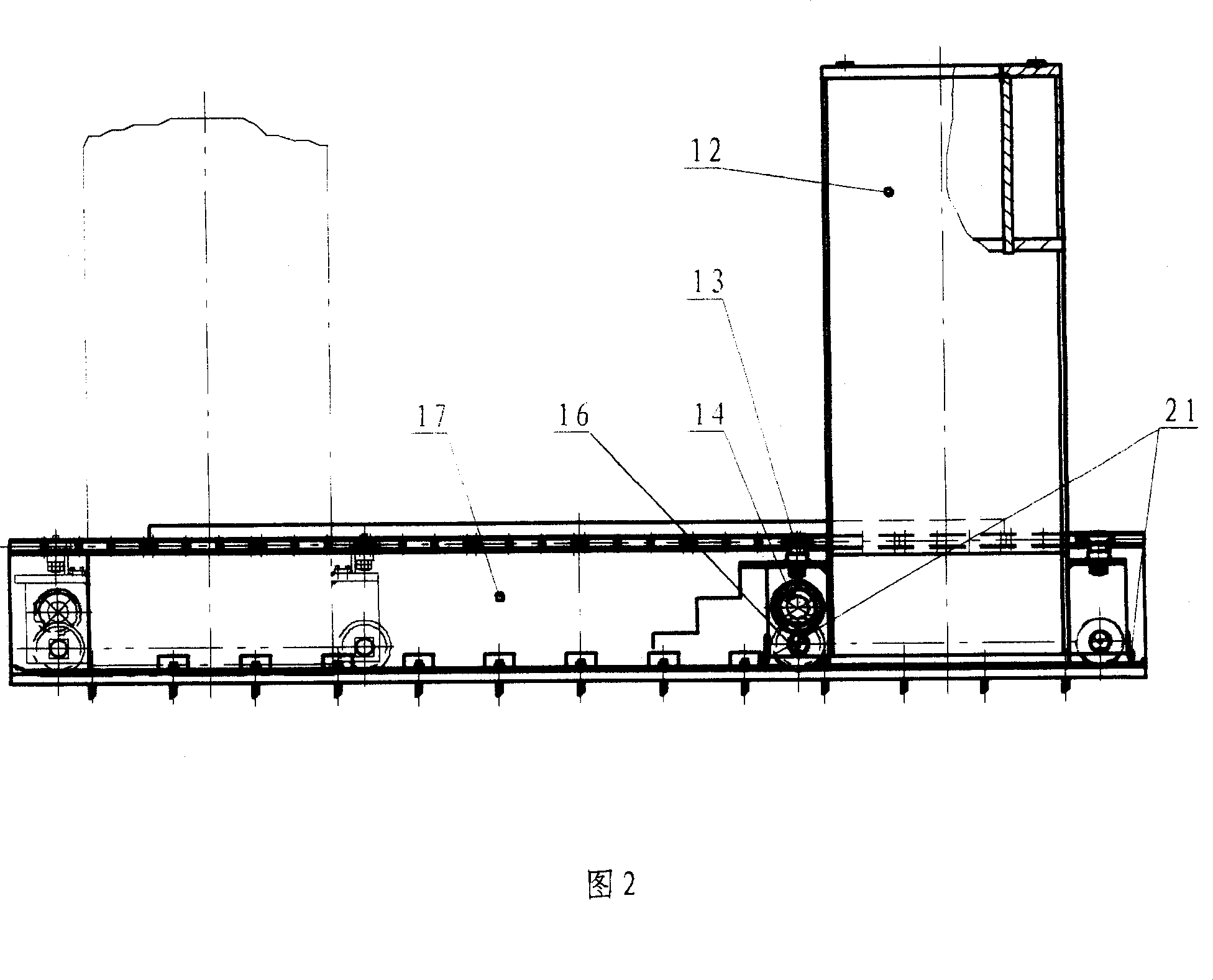

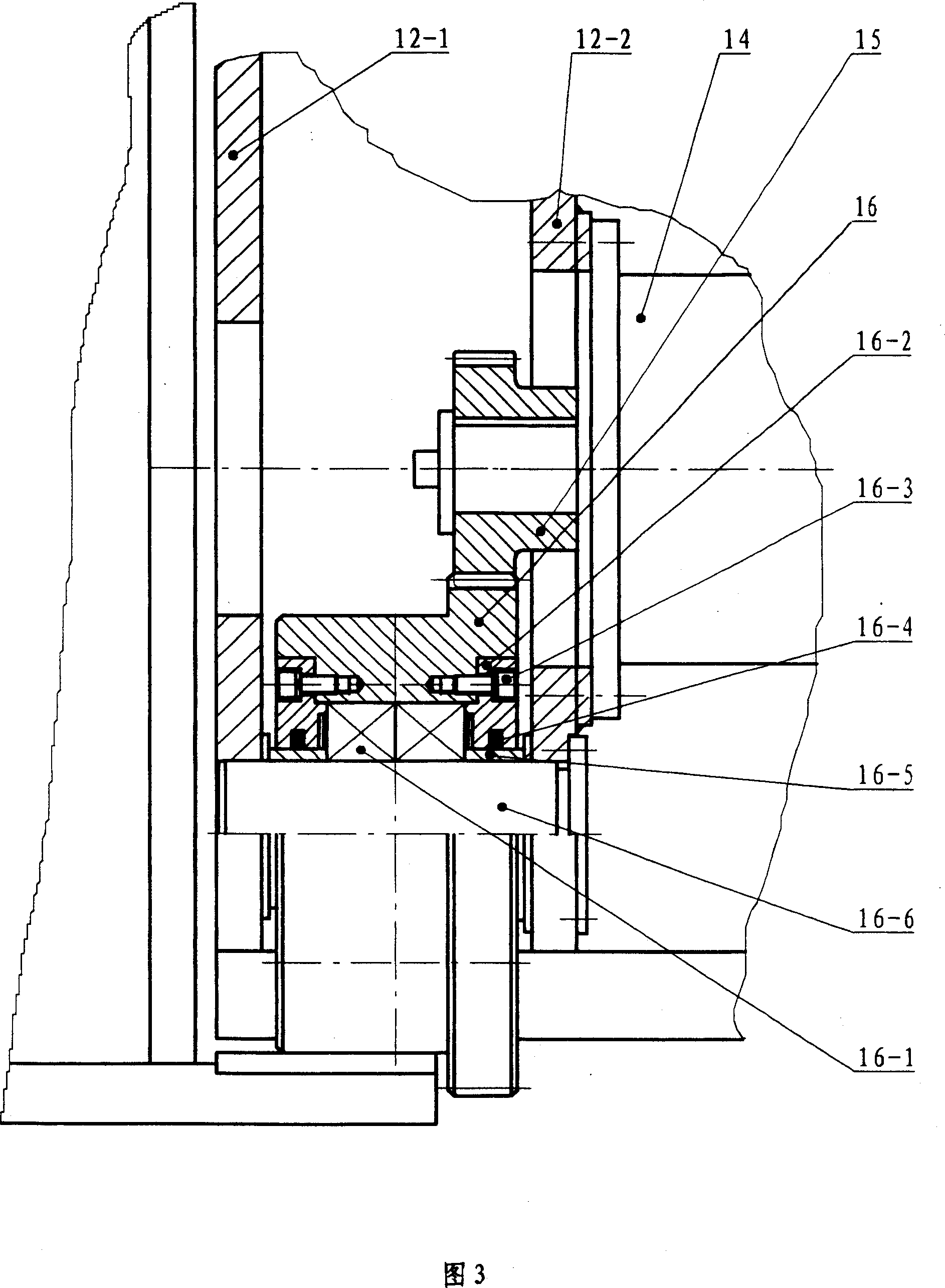

Ultrafast cooling device for wire and rod hot rolling production line

An ultrahigh-speed cooling system for the hot-rolling line of wire and rod materials is composed of at least one cooler consisting of main body, inlet horn pipe, outlet guide pipe and the sleeve pipe of guide pipe, at least one main valve, at least one water trunk, high-pressure water pump, the bench with at least one pair of castors, casing of cooler, and reverse water barrier for preventing the splashing of high-pressure water.

Owner:NORTHEASTERN UNIV

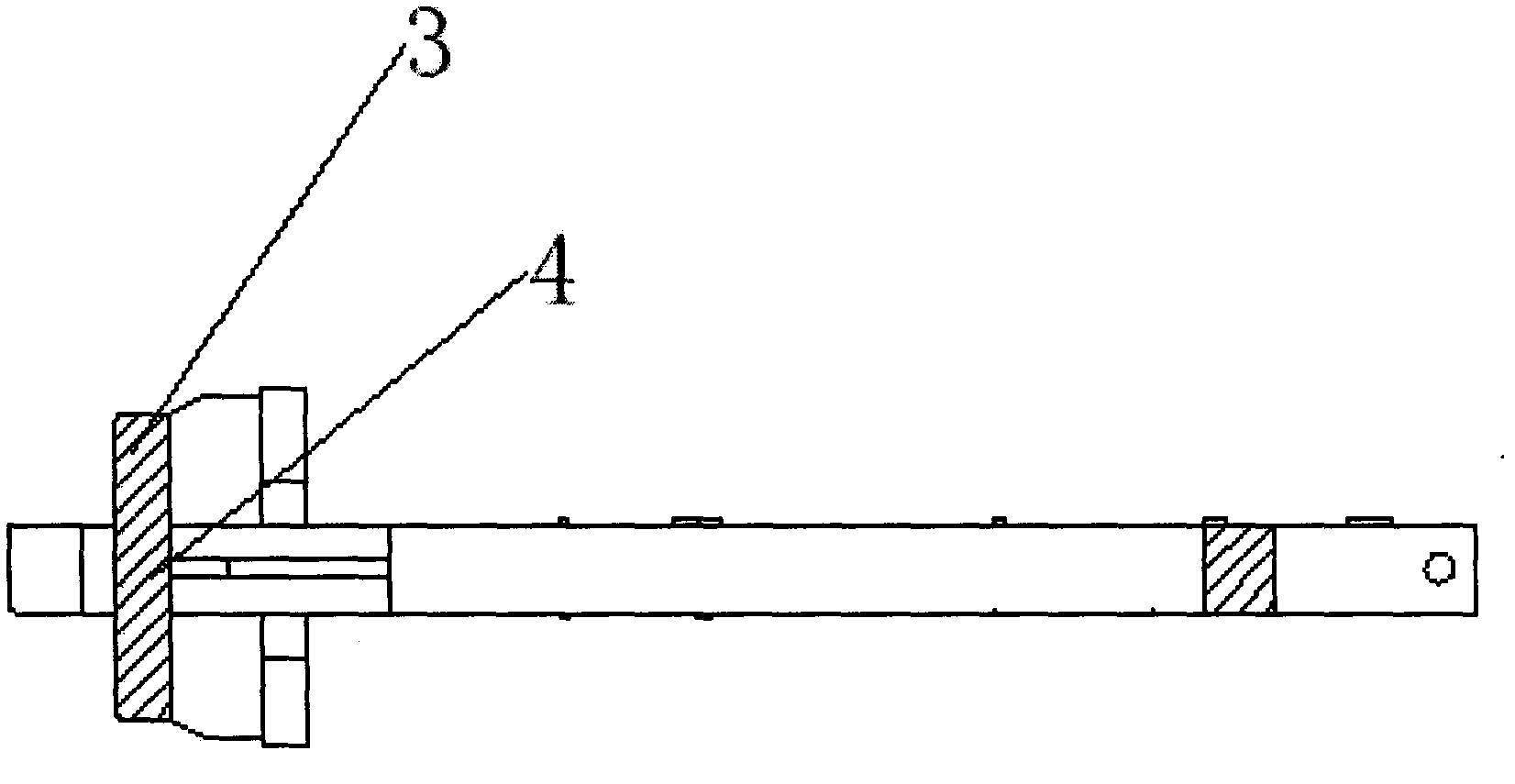

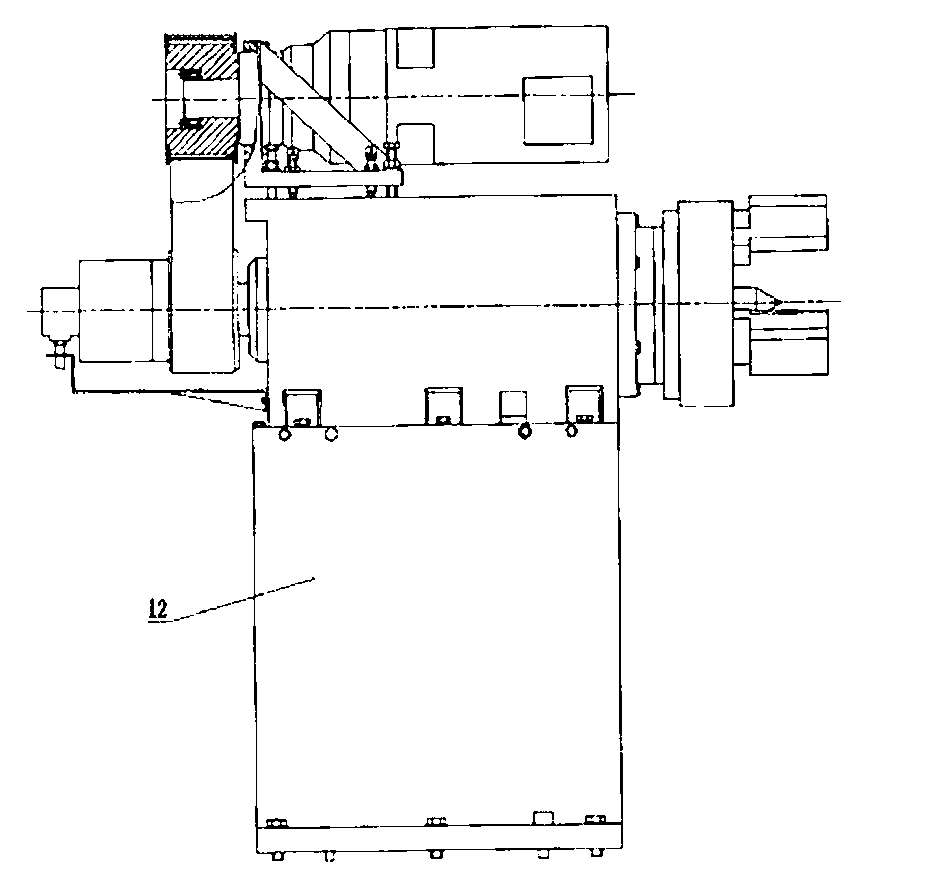

Method for eliminating bending deformation of rolling mill-type heavy part

ActiveCN102416496AQuality improvementExtended service lifeMilling equipment detailsEngineeringProcessing accuracy

The invention discloses a method for eliminating bending deformation of a rolling mill-type heavy part. Design idea of the invention is as below: when a workpiece is in an edge-on state, bending deformation caused by deadweight is little, so processing a flatwise cushion block holding surface and a measure reference surface under the state can gain high precision. A plurality of measure referencepoints are transversely arranged on a measure reference surface, and a flatness of each measure reference point position is measured and recorded. When a workpiece is disposed horizontally, bending deformation will be occurred near a middle part of the workpiece, due to deadweight effect; under this circumstance, only a height of a cushion block under the workpiece needs to be adjusted, so that the flatness of the workpiece at each measure reference point corresponds with the data recorded in the edge-on state of the workpiece, thereby eliminating bending deformation of the workpiece. The method for eliminating bending deformation of the rolling mill-type heavy part of the invention can eliminate bending deformation of the heavy part before processing and increase processing precision of the workpiece.

Owner:CHANGZHOU BAOLING HEAVY IND MACHINERY

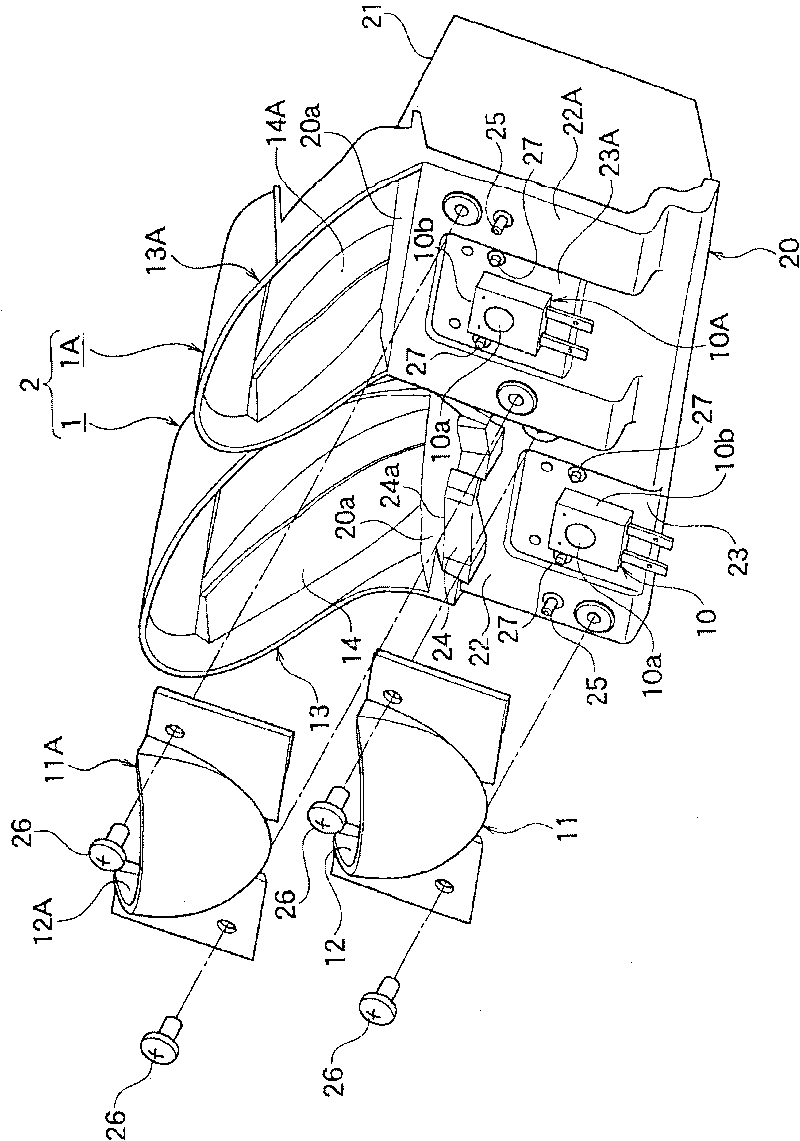

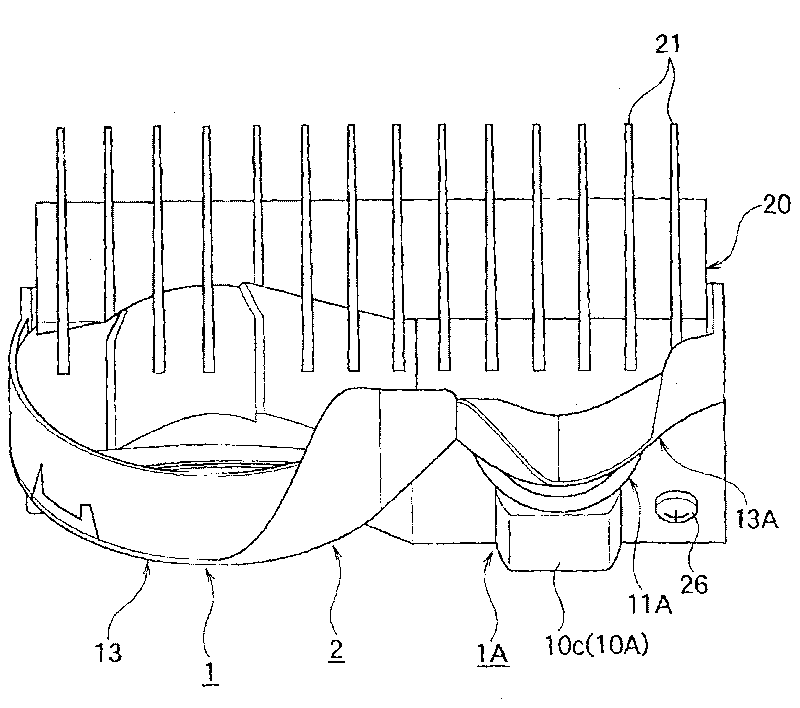

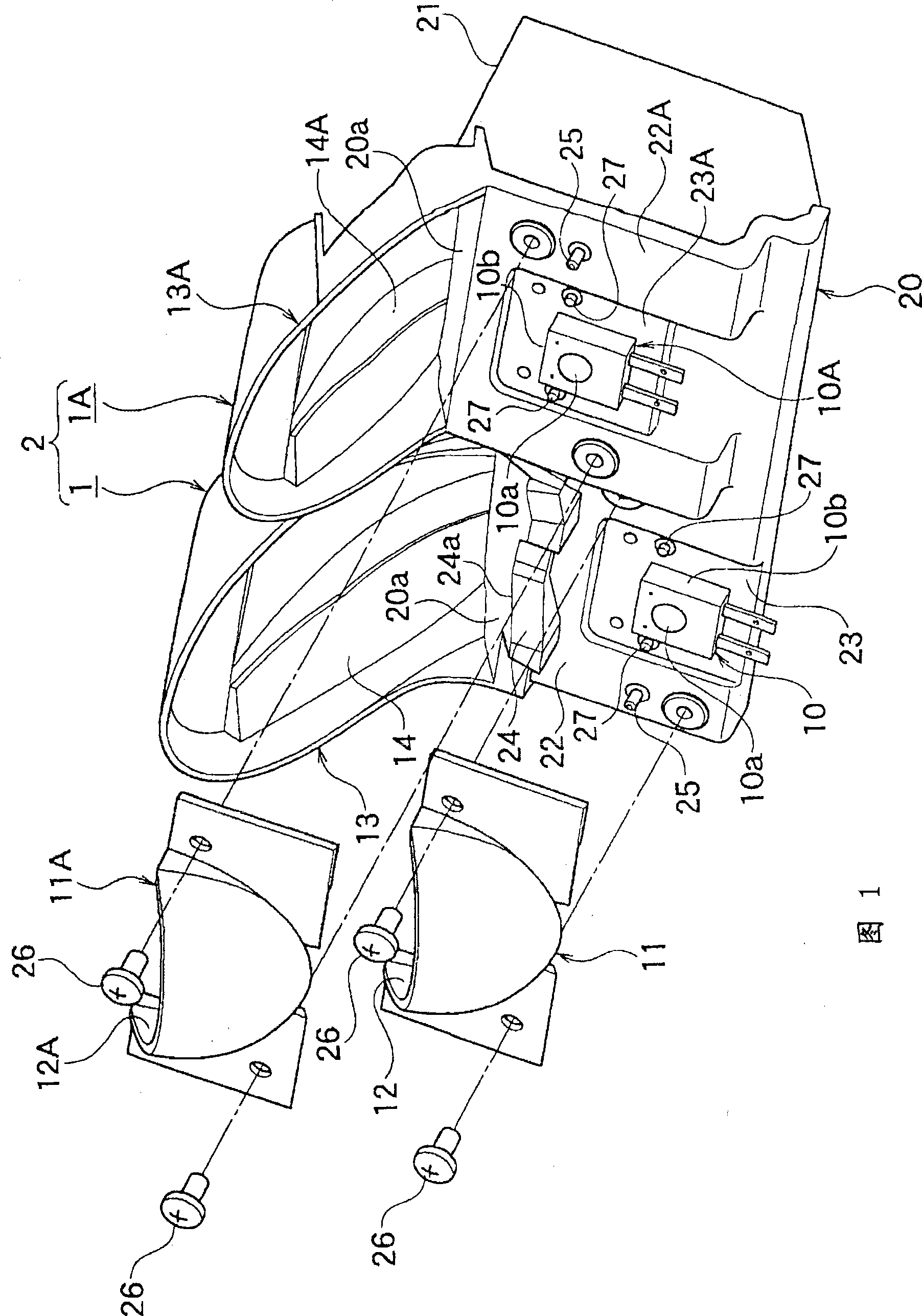

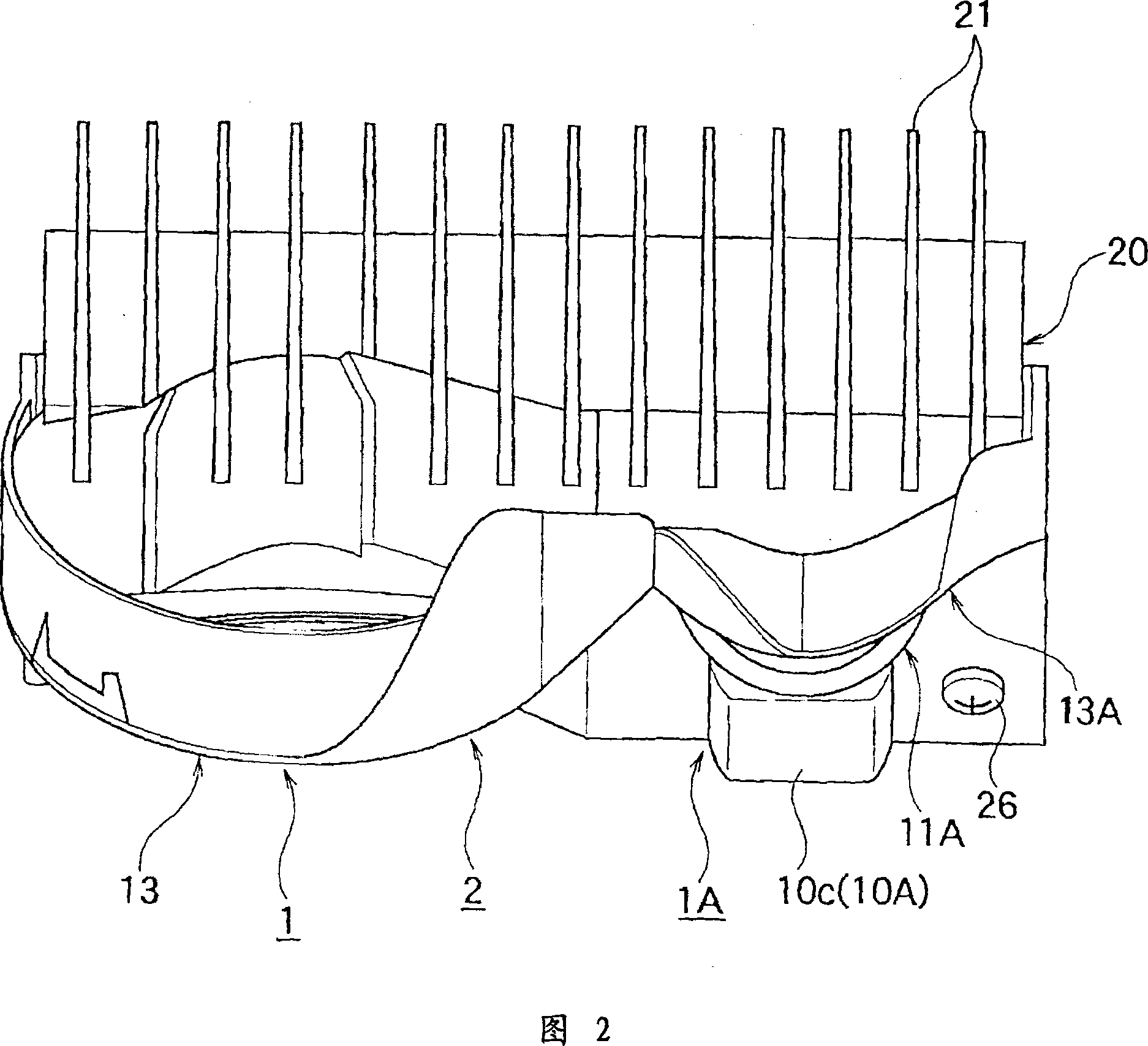

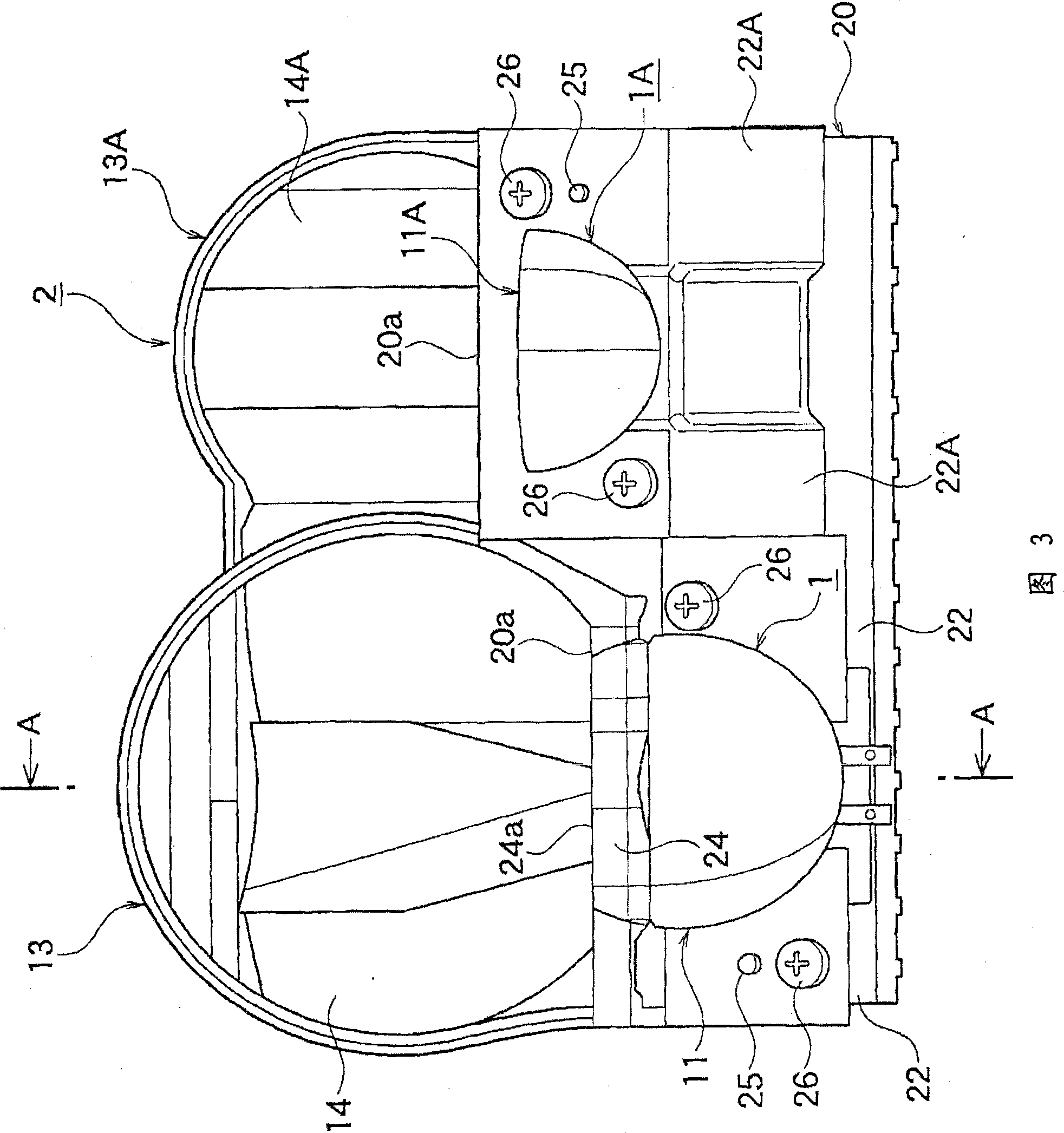

Vehicular lamp

InactiveCN101749616AWith cooling functionImprove cooling effectPoint-like light sourceLighting heating/cooling arrangementsThermal deformationOptoelectronics

The invention provides a vehicular lamp with excellent photometric performance instead of the deteriorated photometric performance caused by the thermal deformation of reflectors or the assembly errors of the reflectors. The vehicular lamp is provided with a semiconductor-type light source, a first reflector, a second reflector and a radiating rib, wherein the first reflector covers the semiconductor-type light source and reflects light emitted from the semiconductor-type light source to a preset direction; the second reflector reflects the reflecting light from the first reflector to the front of the lamp; and the radiating rib intensely arranges the semiconductor-type light source, the first reflector and the second reflector. The vehicular lamp is characterized in that at least the second reflector and the radiating rib are integrally formed.

Owner:ICHIKOH IND LTD

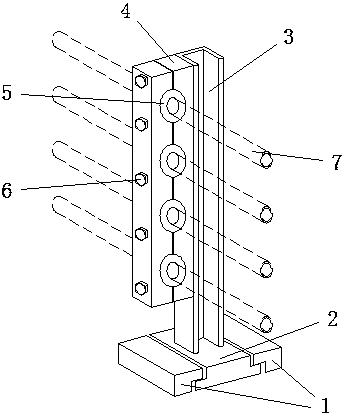

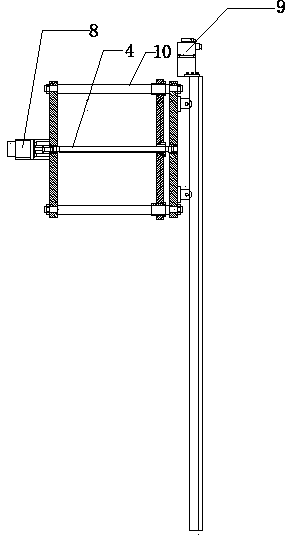

Fire resistant oil pipeline sliding support for steam turbine

InactiveCN104048110ASafe and stable operationEliminate bending deformationPipe supportsEngineeringThermal expansion

The invention provides a fire resistant oil pipeline sliding support for a steam turbine. The fire resistant oil pipeline sliding support comprises a vertical support vertical column, wherein fixed bases with sliding rails are laid below the support vertical column, the bottom of the support vertical column is connected with a sliding base matched with the sliding rails of the fixed bases, the side face of the support vertical column is connected with a pipe clamp in parallel, a plurality of pipeline through holes are formed in the pipe clamp vertically side by side, and the pipeline through holes are parallel to the sliding rails. The fire resistant oil pipeline sliding support has the advantages that stress generated due to thermal expansion of equipment connected with a fire resistant oil pipeline can be fully released, pipeline bending deformation caused by thermal expansion is completely eliminated, vibration of the fire resistant oil pipeline is effectively avoided, looseness of a connector for connecting the tail end of the pipeline with a hydraulic servo-motor or a pipeline welded junction tension fracture is avoided, and safe and stable operation of a steam turbine generator unit is guaranteed.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

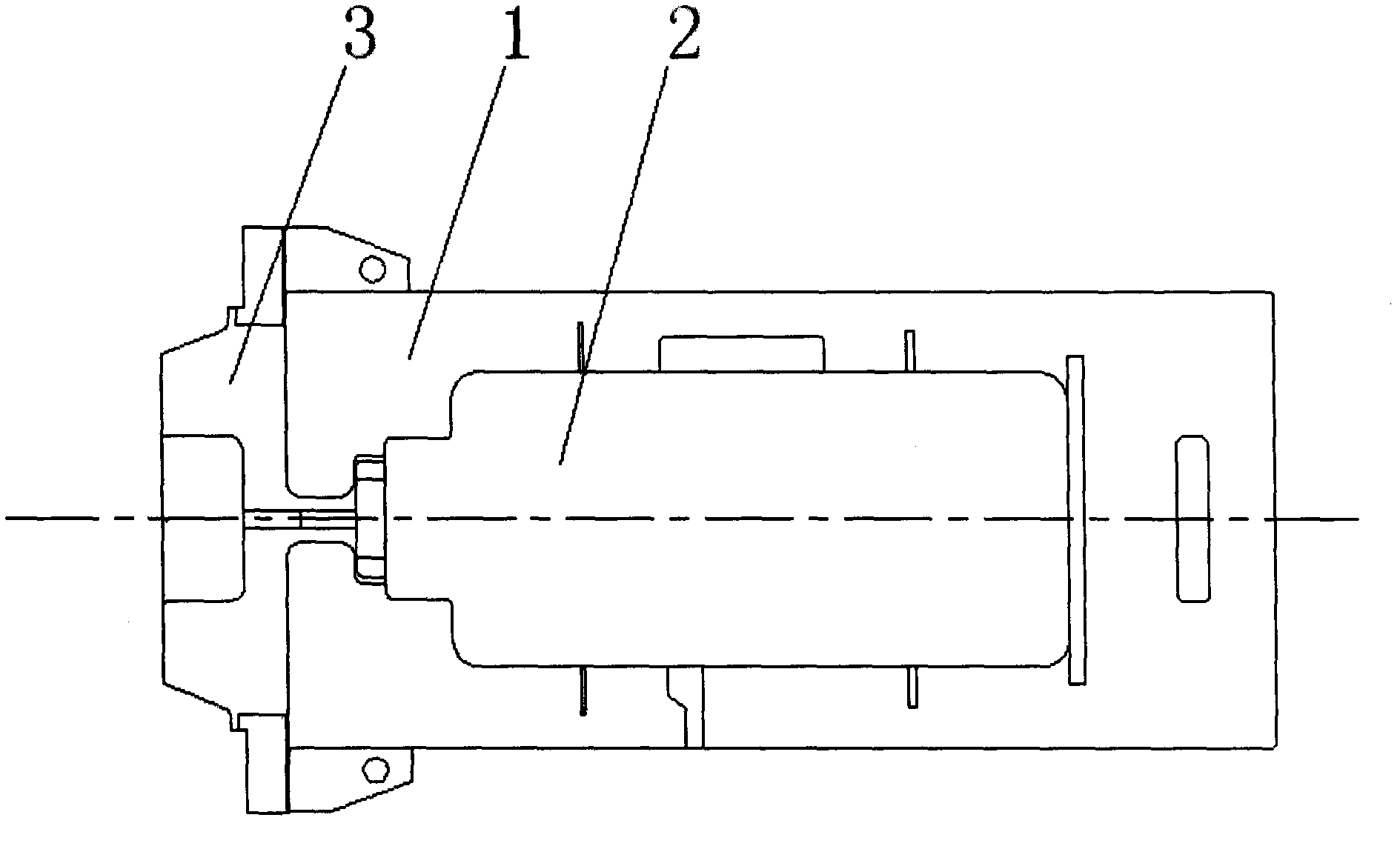

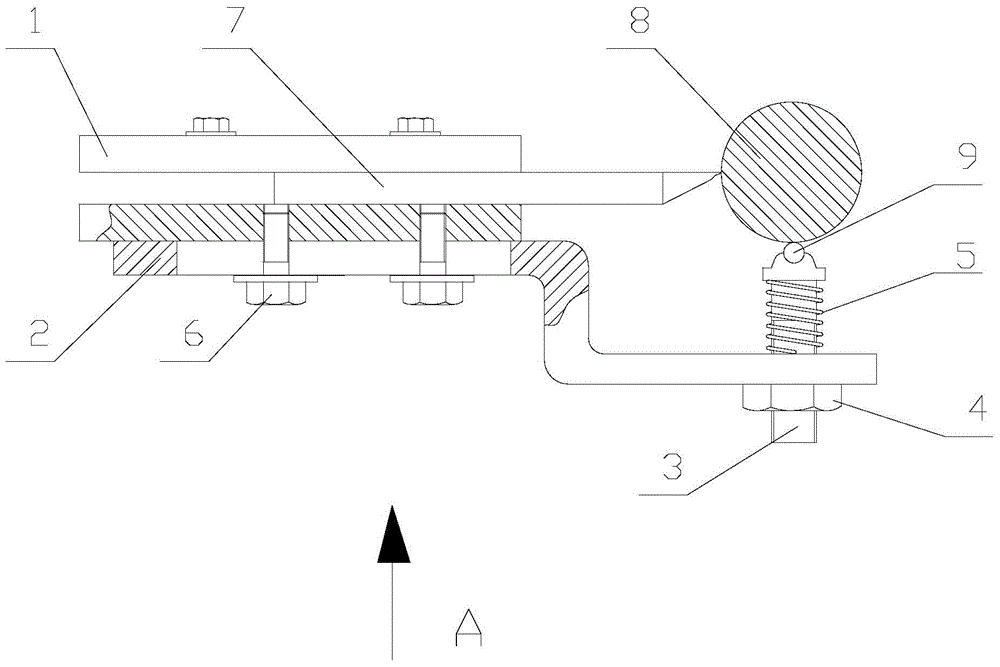

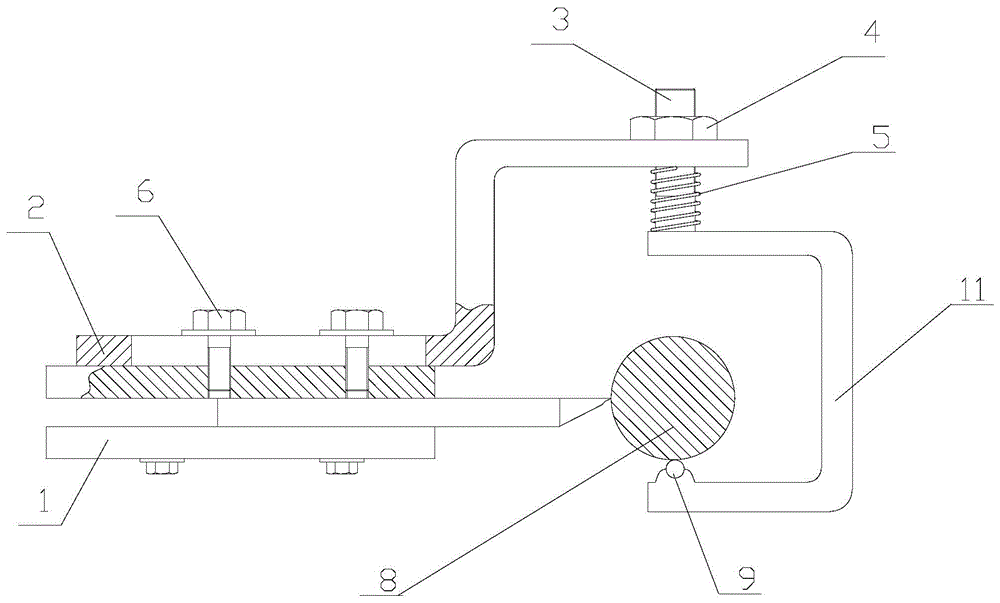

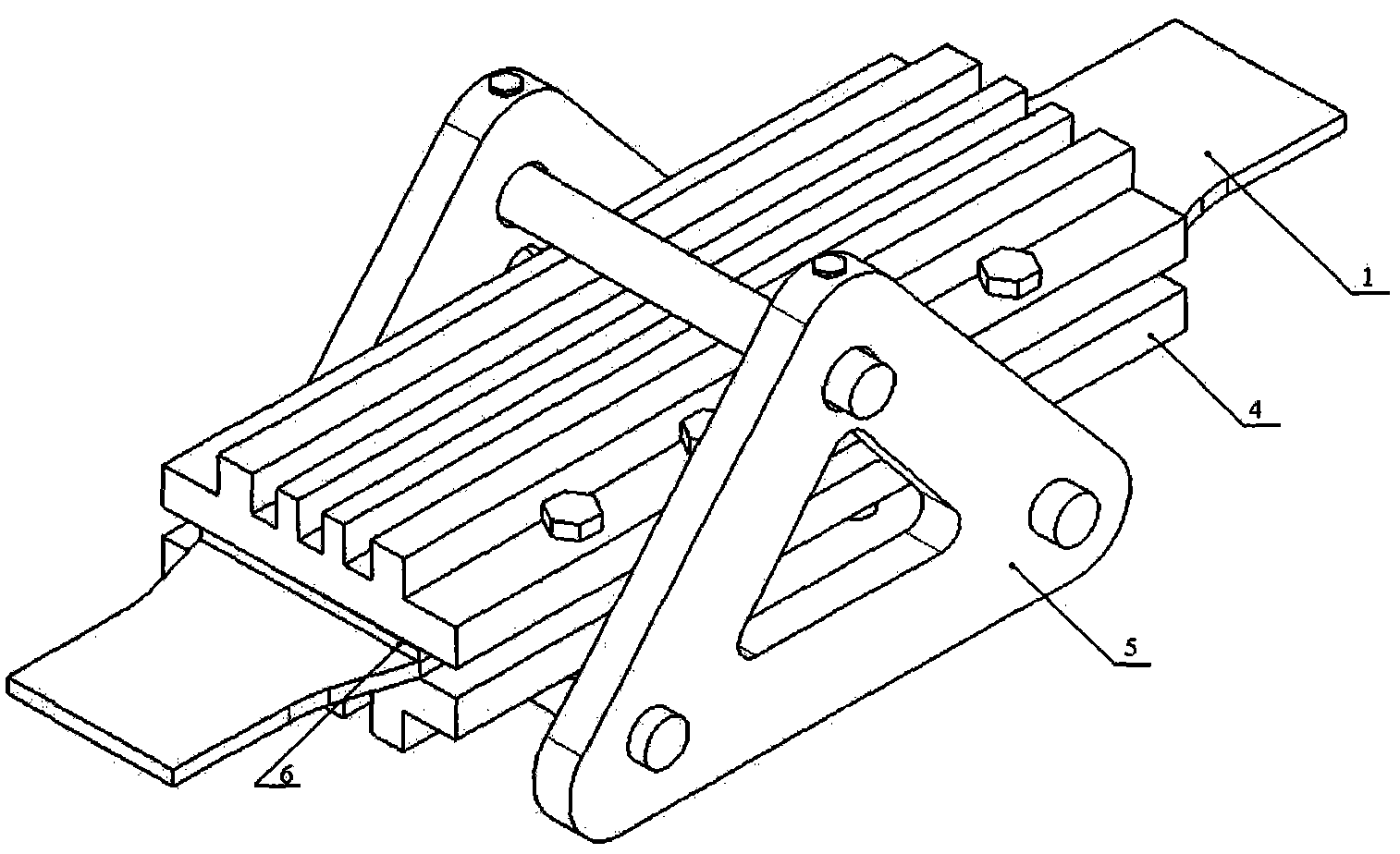

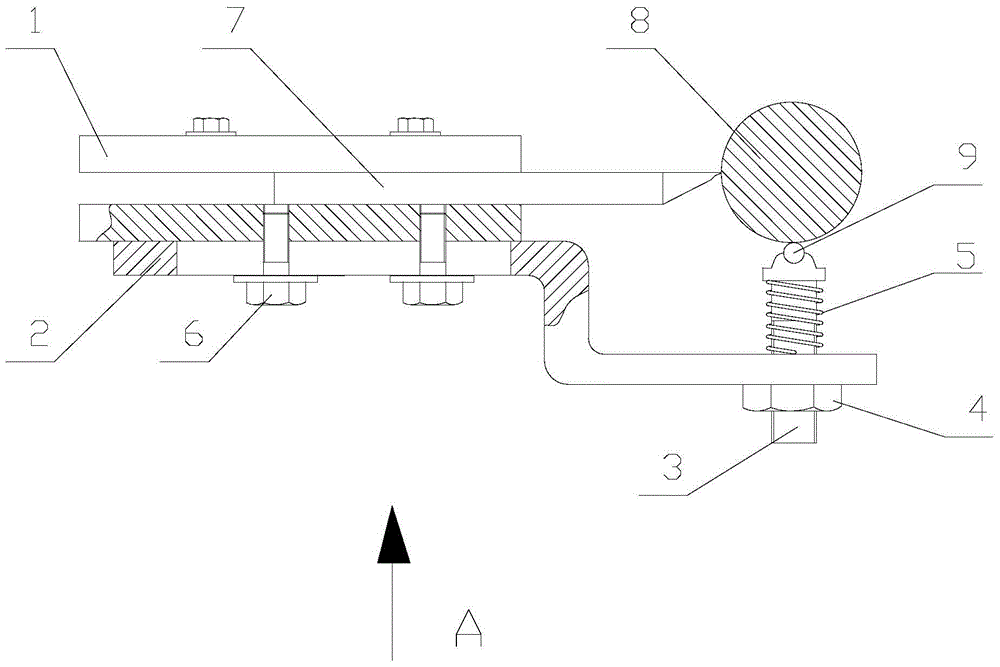

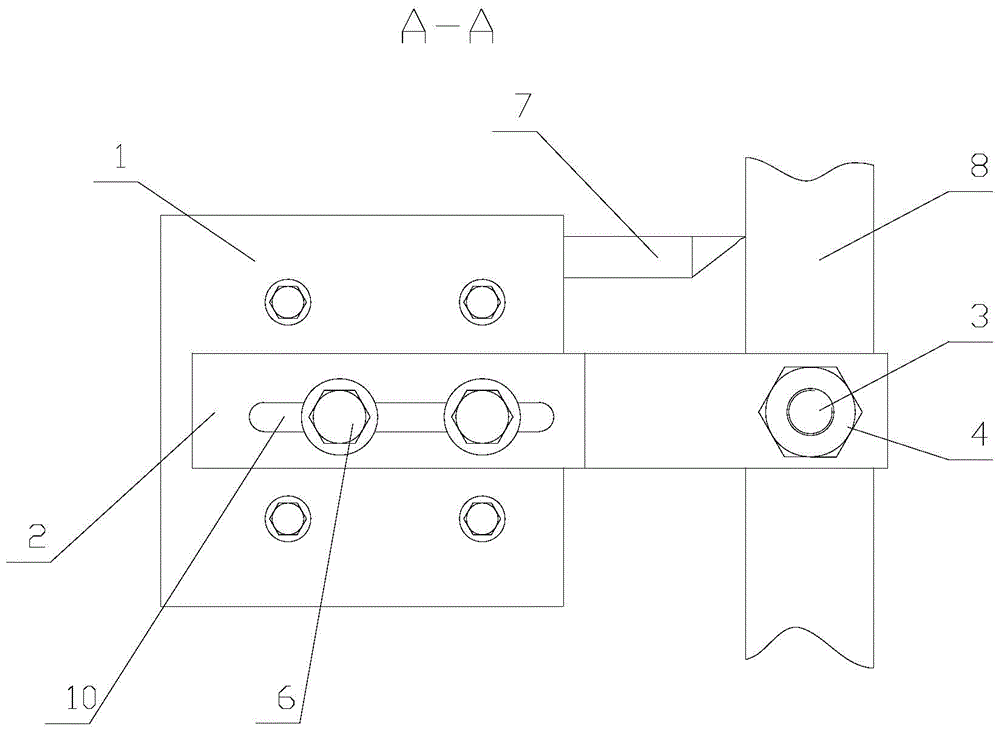

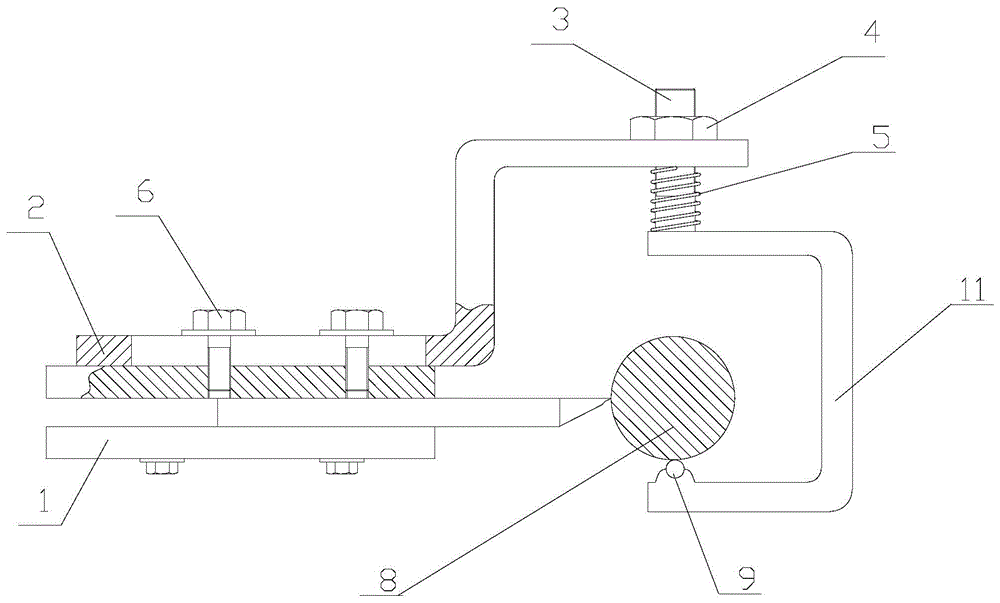

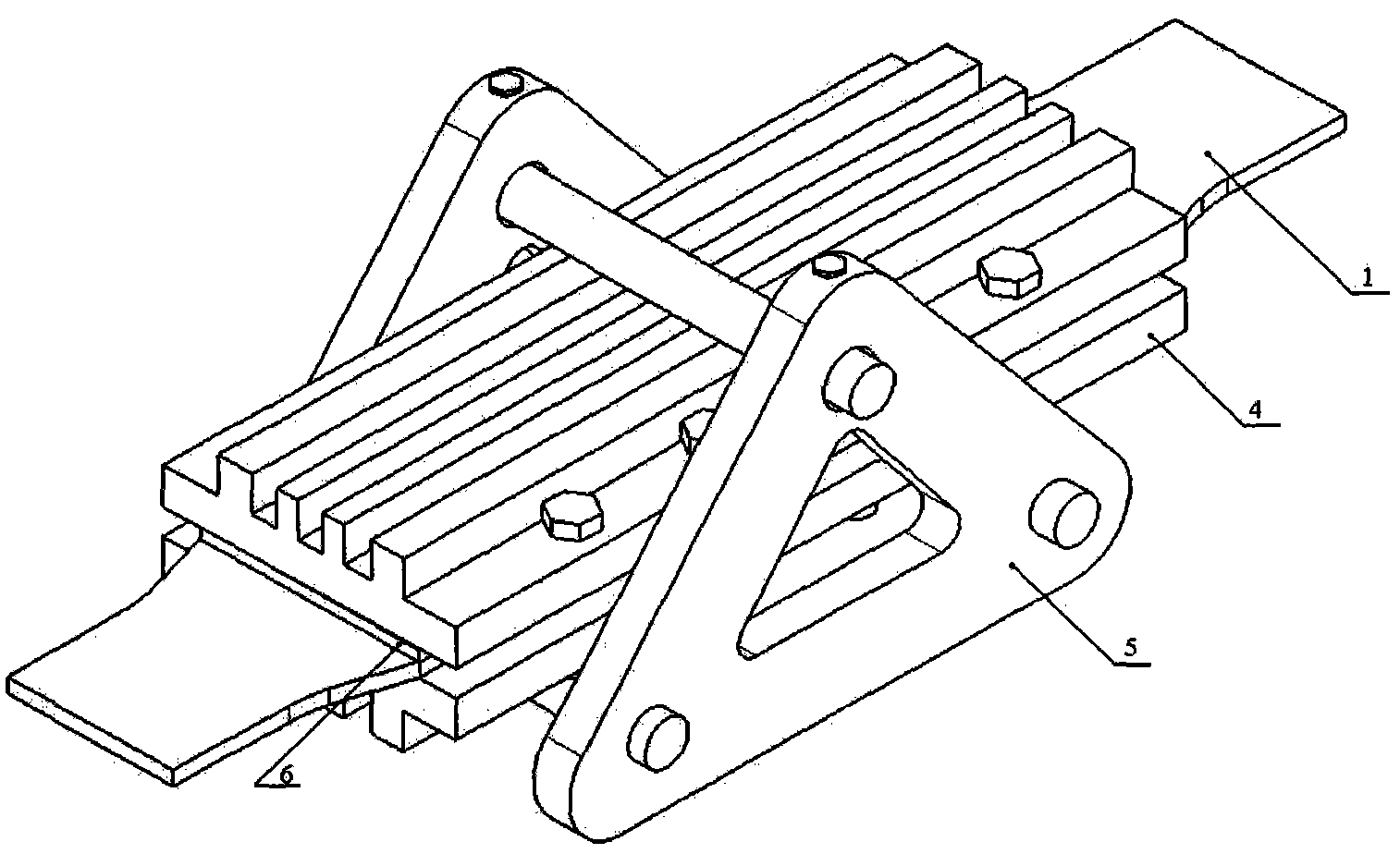

Knife rest

ActiveCN104057109AEliminate bending deformationGuarantee processing qualityLarge fixed membersEngineeringTorsion spring

The invention relates to a knife rest. The knife rest comprises a knife handle seat, a support arm, a regulating dowel, a regulating nut, a compression spring and a fastening bolt, wherein a turning tool is arranged on the knife handle seat, the support arm is fixed on the lower part of the knife handle seat through the fastening bolt, the front end of the support arm extends to the lower part of a slender shaft to be processed, the regulating dowel penetrates through a through hole in the support arm, the lower part of the support arm is provided with the regulating nut matched with the regulating dowel, the upper part of the support arm is provided with the compression spring, one end of the compression spring presses the upper surface of the support arm, the other end of the compression spring presses a step arranged on the regulating dowel, and the top end of the regulating dowel is provided with a round ball which can rotate freely. According to the knife rest, before processing, each component is regulated, and then processing operation can be carried out; no regulation is needed halfway, the use is convenient, the efficiency is high, and the processing effect is good.

Owner:HARBIN DONGAN ENGINE GRP

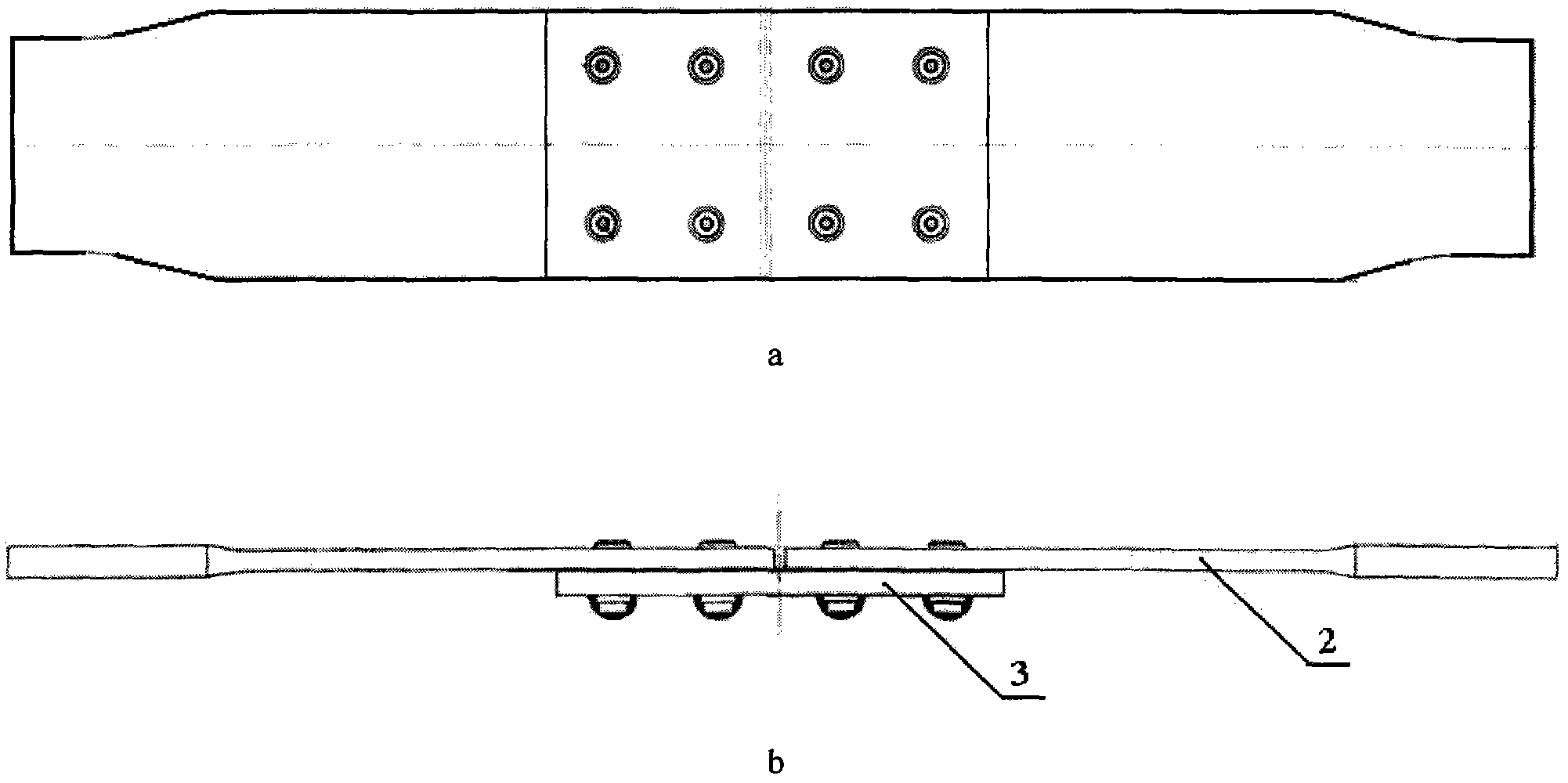

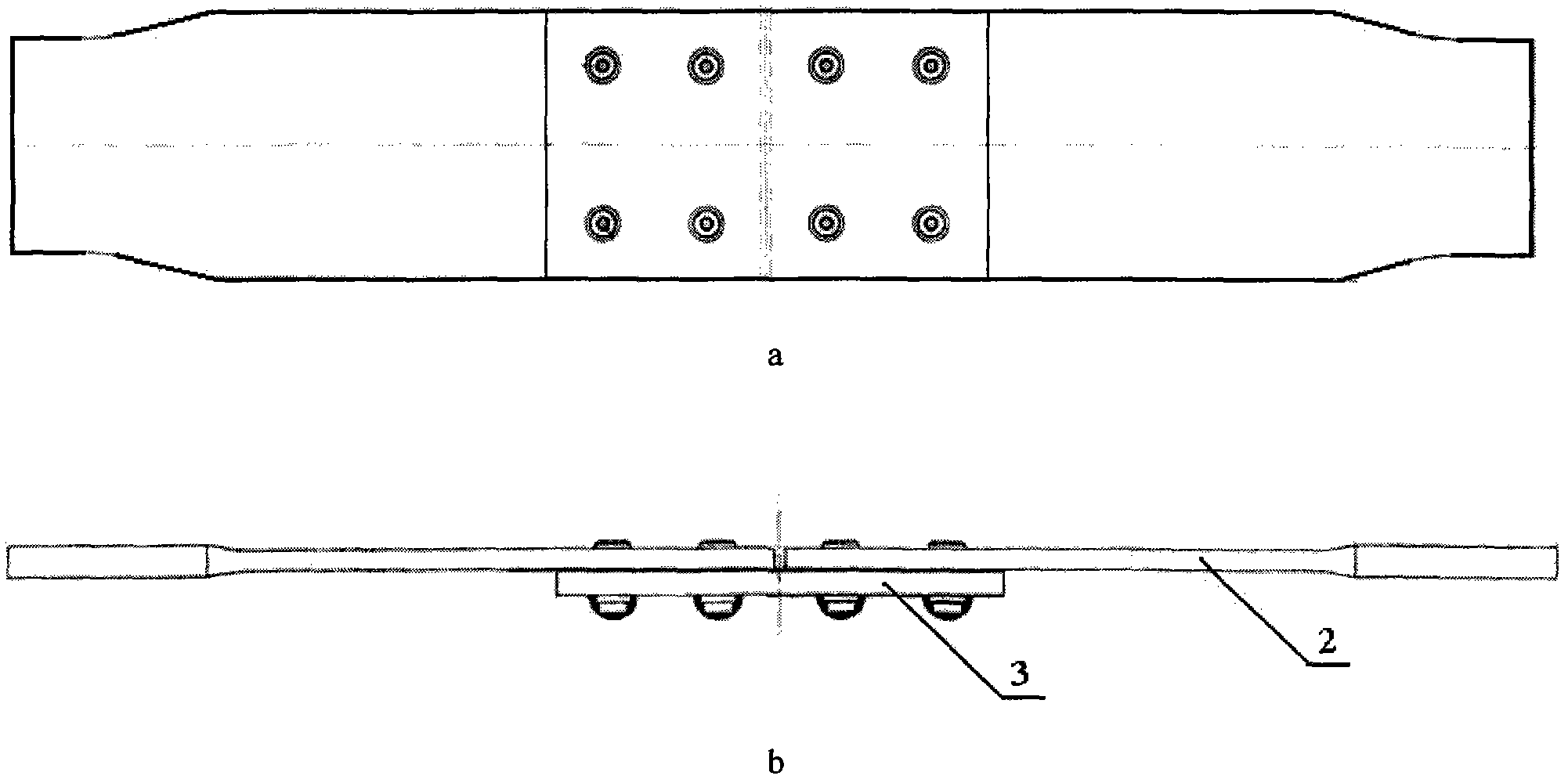

Fatigue property test method for wallboard lap joint structure

InactiveCN102323050AGuaranteed validityThe test effect is goodMachine part testingLoad cycleEngineering

The invention relates to a fatigue property test method for a wallboard lap joint structure. The fatigue property test method is characterized by comprising the following steps of: installing a test piece in a triaxial bending-limitation clamp; clamping two ends of the test piece by using an upper chuck and a lower chuck of a tester, wherein the centering line of the two chucks is overlapped with the central line of the two ends of the test piece; then prestretching a connection piece twice; continuing to load a sine waveform with a frequency of 5 Hz, wherein the peak value of the load is 0.3[P]n; and reducing the frequency by 1 Hz every 1,000-3,000 times so as to acquire the length a of a crack at each time and a corresponding load cycle number N. The fatigue property test method has the beneficial effects that a fatigue crack extension test for the wallboard lap joint structure with longitudinal load can be carried out; a good test effect is achieved during actual use; and furthermore, any obvious vibration or deformation can be avoided, bending deformation can be eliminated effectively, axial load transmission and deformation cannot be influenced and the effectiveness of test data is guaranteed.

Owner:AIR FORCE UNIV PLA

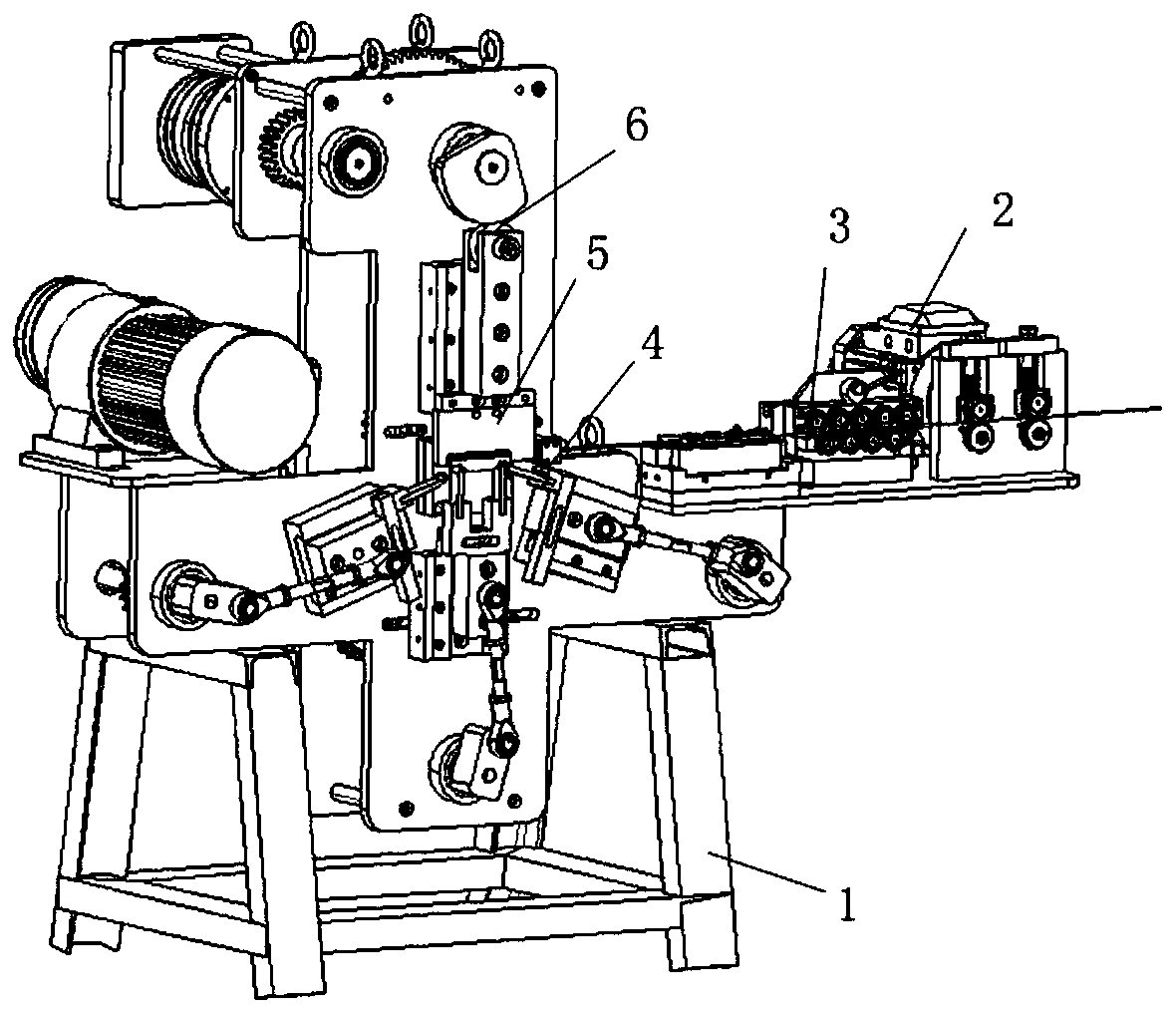

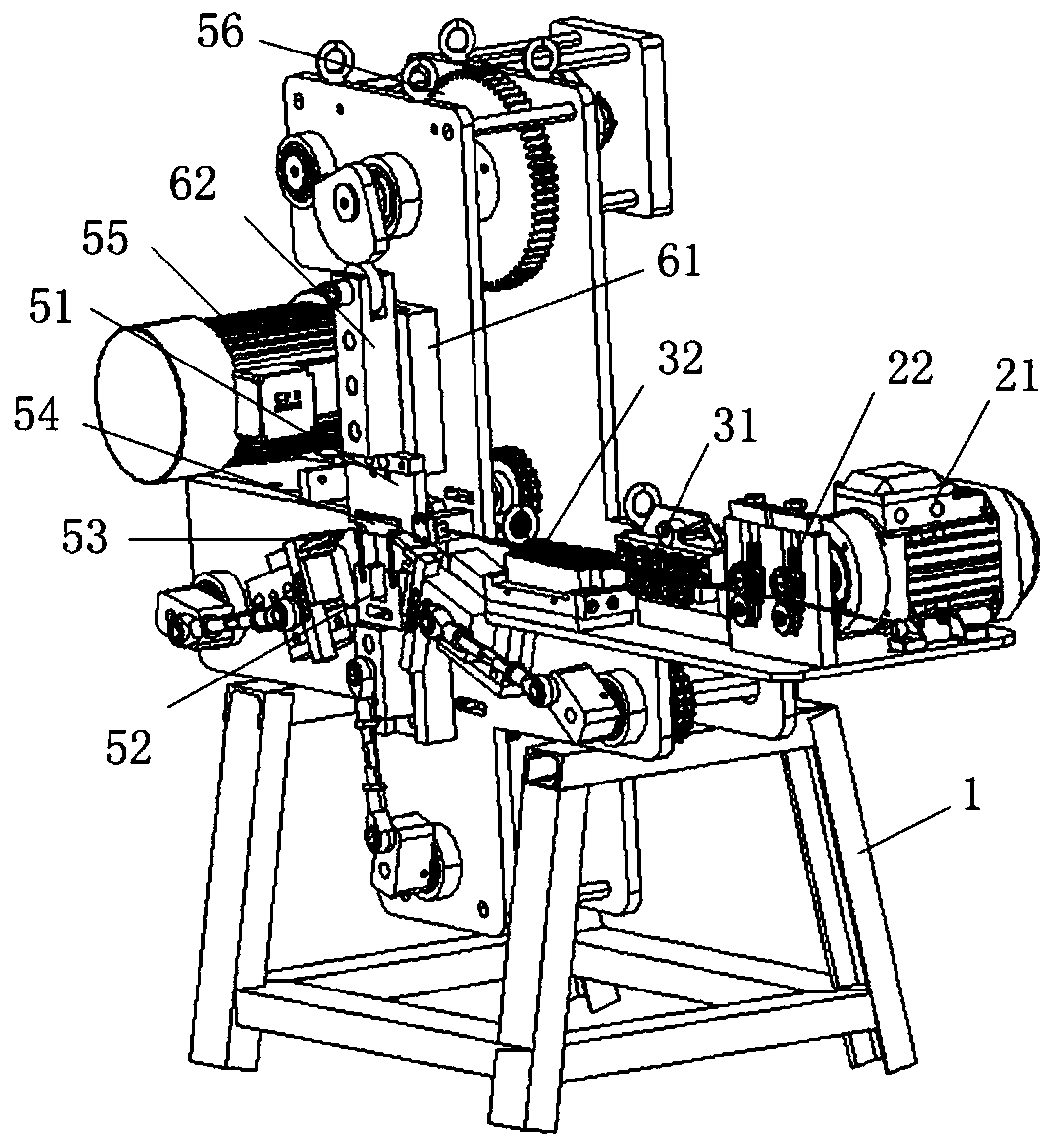

Flattening feeding device

InactiveCN107649608AImprove production efficiencyEliminate bending deformationMetal-working feeding devicesPositioning devicesStamping pressSheet material

The invention discloses a flattening type feeding device, which comprises a feeding track, and a plurality of conveying rollers for conveying plates are arranged in the feeding track, and the conveying rollers include rollers respectively arranged on the upper and lower end surfaces of the plates. The upper conveying roller and the lower conveying roller, the upper conveying roller and the lower conveying roller are arranged in a dislocation in the feeding track, the plate is limited between the upper conveying roller and the lower conveying roller and is driven to the punching machine for stamping, and A transmission device is included, the transmission device is arranged under the feeding track, and the transmission device drives the transmission roller to rotate. The invention has simple structure and convenient operation, can avoid defects caused by material jams, thereby improving the production efficiency of the enterprise.

Owner:江门市睿智隽永科技有限公司

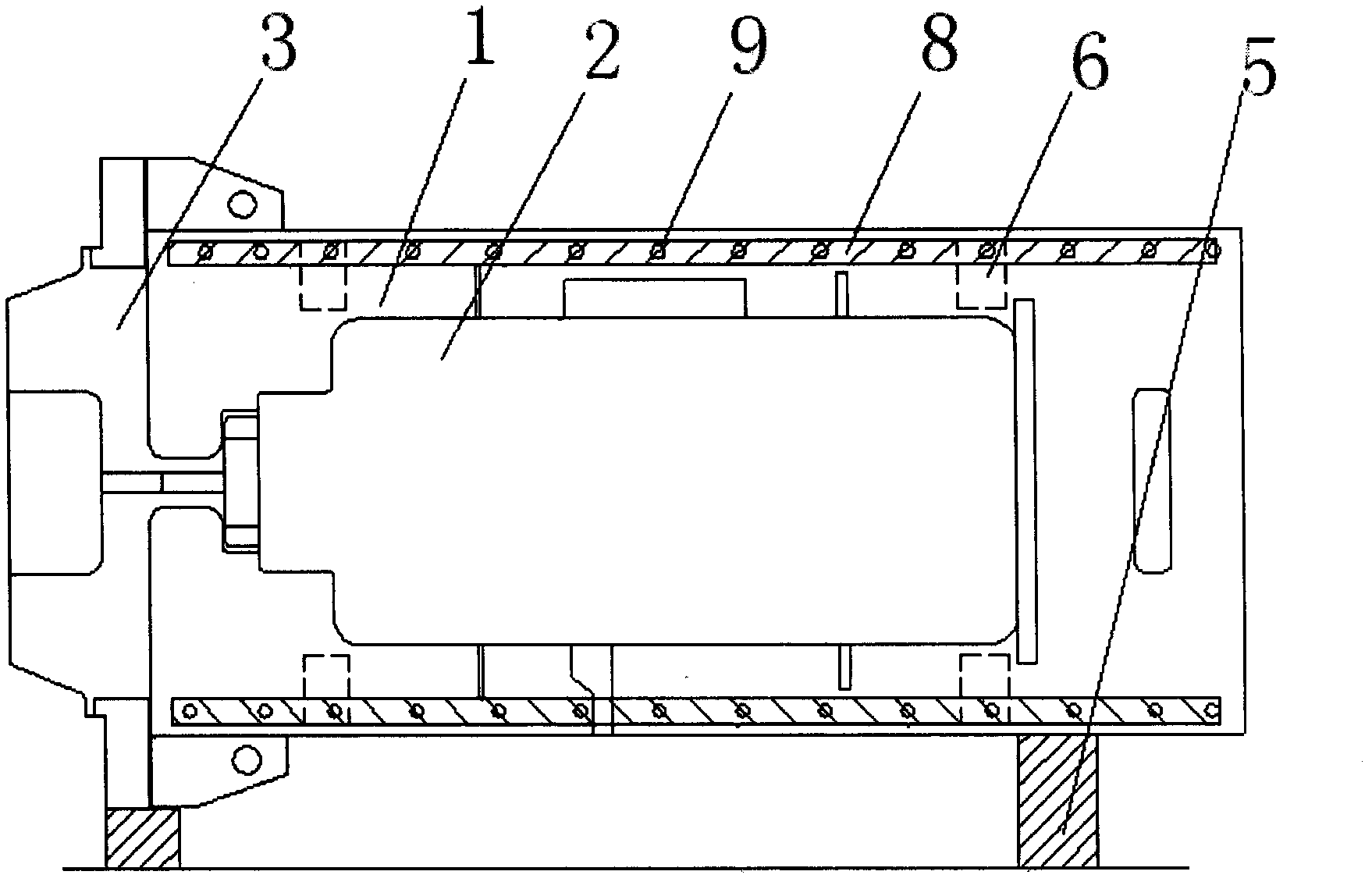

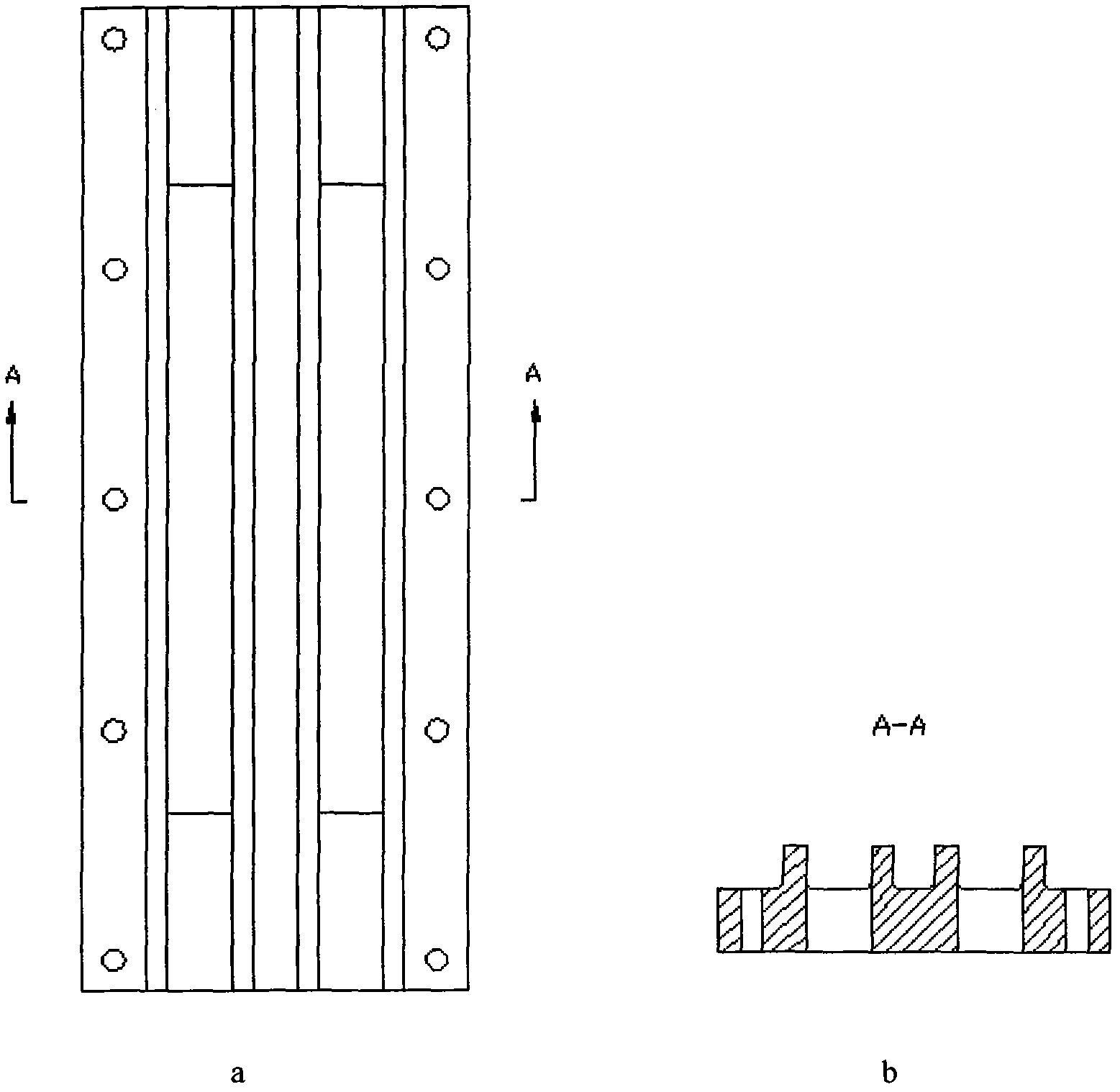

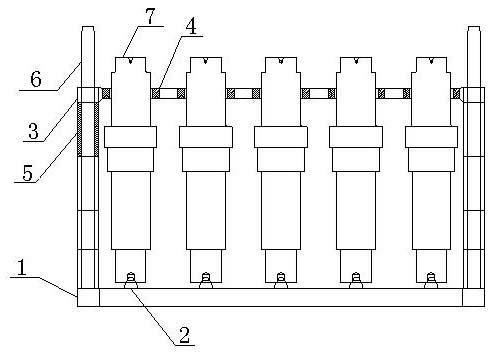

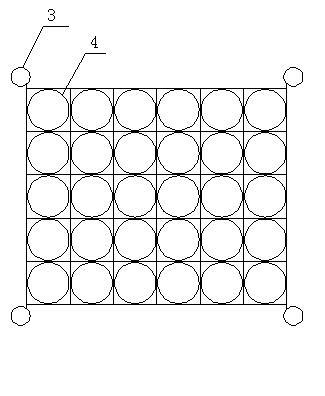

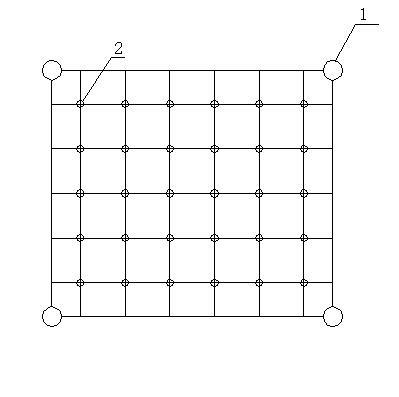

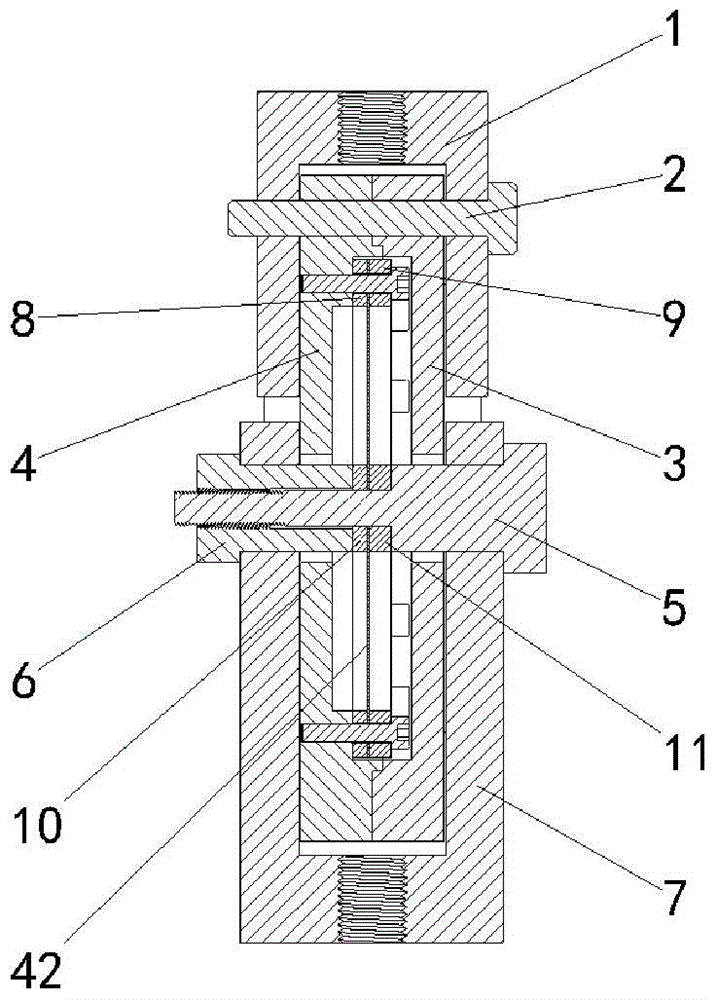

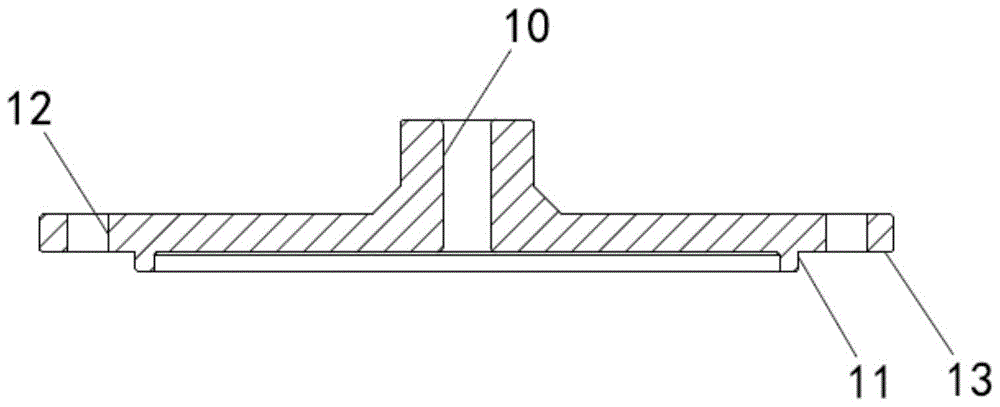

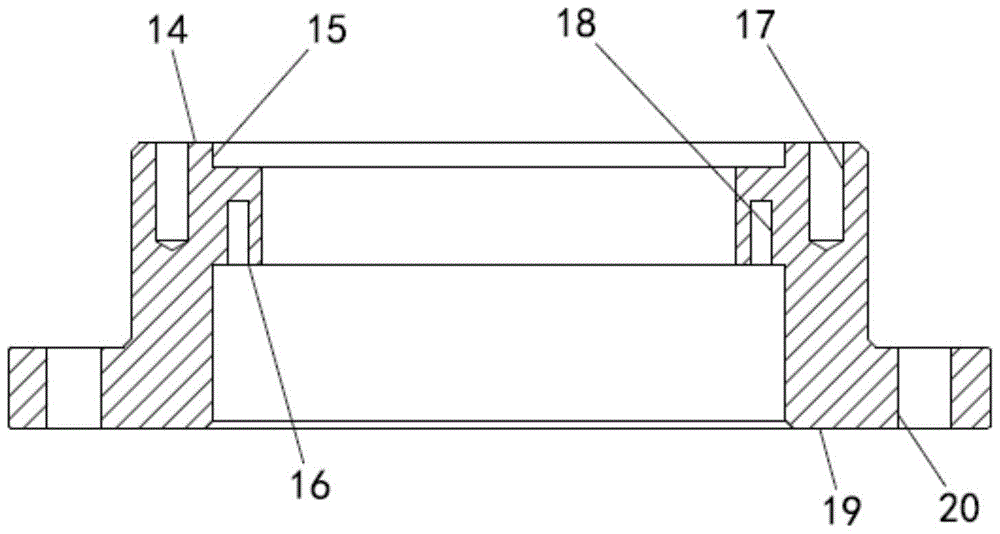

Gear shaft quenching work fixture

InactiveCN102605151AGuaranteed to stand vertically at all timesSame distanceFurnace typesHeat treatment furnacesGear wheelEngineering

The invention discloses a gear shaft quenching work fixture, which comprises a discharging disc positioning sleeve (1) and a feeding disc positioning sleeve (3). The discharging disc positioning sleeve (1) and the feeding disc positioning sleeve (3) are arranged on a vertical rod group (6) in parallel, one or more discharging disc positioning ejector pins (2) is arranged on the discharging disc positioning sleeve (1), one or more workpiece positioning holes (4) corresponding to the discharging disc positioning ejector pins (2) is arranged on the feeding disc positioning sleeve (3), a shaft workpiece (7) is fixed between each discharging disc positioning ejector pin (2) and the corresponding workpiece positioning hole (4), the bottom of each shaft workpiece (7) is fixed on the corresponding discharging disc positioning ejector pin (2), and the top of each shaft workpiece (7) is fixed in the corresponding workpiece positioning hole (4). The gear shaft quenching work fixture has the advantages that the gear shaft quenching work fixture is convenient in installation, reduces deformation, and improves quenching quality and production efficiency.

Owner:江国辉

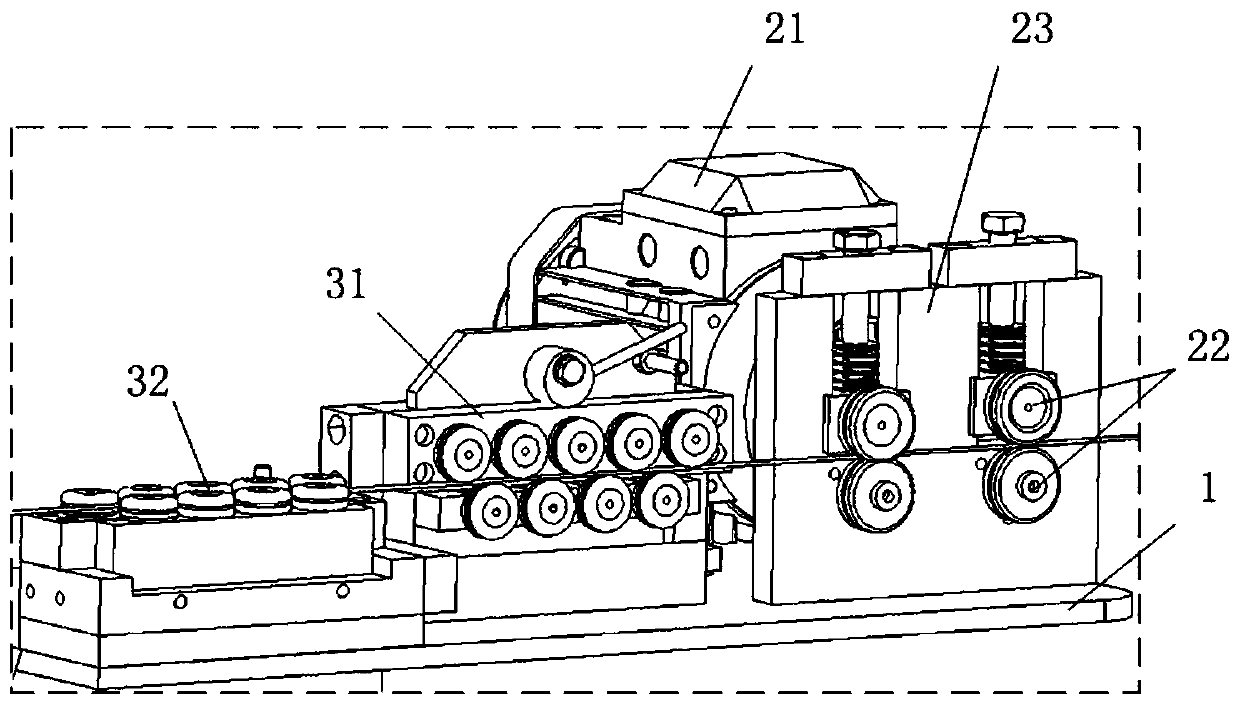

Bending machine for sleeper production

PendingCN110238331AEliminate bending deformationAvoid deflectionWire articlesEngineeringMechanical engineering

The invention provides a bending machine for sleeper production. The bending machine comprises a supporting frame, a conveying device, a straightening device, a cutting device and a bending device, in practical application, a conveying wheel is driven by a conveying motor in the conveying device to rotate and convey the fine steel wires to be machined; and then the fine steel wires are extruded through a plurality of straight wheels in the straightening device, so that the thin steel wire is maintained on the flat straight line, the bending deformation on the fine steel wire is ensured, the flat thin steel wire is cut into a preset length through the cutting device, and finally, a concave die, a male die and a thrust rod in the bending device are jointly bent to form a bent hook shape. According to the bending machine, the bending deformation on the thin steel wire to be machined can be eliminated through the straightening device, so that the influence of bending deformation on the finished product can be eliminated. By means of a plurality of bending modules on the bending device, deflection of the fine steel wires in the bending process is avoided, and the qualified rate of finished products is improved.

Owner:北京好运达智创科技有限公司

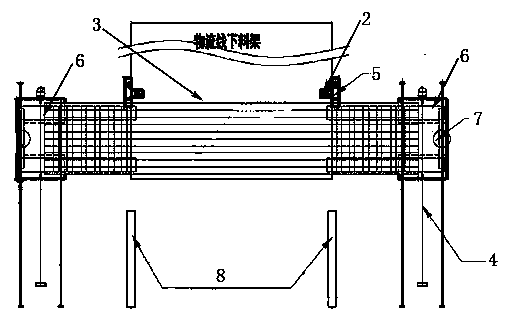

Guide rail automatic stacking machine

InactiveCN104370117AEliminate collision damageEliminate bending deformationMetal-working feeding devicesStacking articlesEngineeringAutomation

The invention discloses a guide rail automatic stacking machine. The guide rail automatic stacking machine is characterized by comprising a drive control device and a transmission device; the transmission device comprises a counting device and two completely-symmetric moving devices; each moving device comprises an automatic transverse moving and stacking frame with a conveying belt, a blocking and feeding trolley and a transverse moving trolley, wherein the blocking and feeding trolley and the transverse moving trolley are both arranged on the automatic transverse moving and stacking frame; the counting device comprises a photoelectric switch and counters. The guide rail automatic stacking machine has the advantages that the movable trolleys are adopted to replace manual hoisting, so that automation in the whole operating process is achieved, the labor cost of products is lowered, collision and damage are eliminated, and the use frequency and maintenance cost of a crane are reduced.

Owner:CHANGJIANG RUNFA MACHINERY

Ultrafast cooling device for wire and rod hot rolling production line

InactiveCN100376336CImprove mechanical propertiesEasy to controlWork treatment devicesMetal rolling arrangementsProduction lineWire rod

An ultrahigh-speed cooling system for the hot-rolling line of wire and rod materials is composed of at least one cooler consisting of main body, inlet horn pipe, outlet guide pipe and the sleeve pipe of guide pipe, at least one main valve, at least one water trunk, high-pressure water pump, the bench with at least one pair of castors, casing of cooler, and reverse water barrier for preventing the splashing of high-pressure water.

Owner:NORTHEASTERN UNIV LIAONING

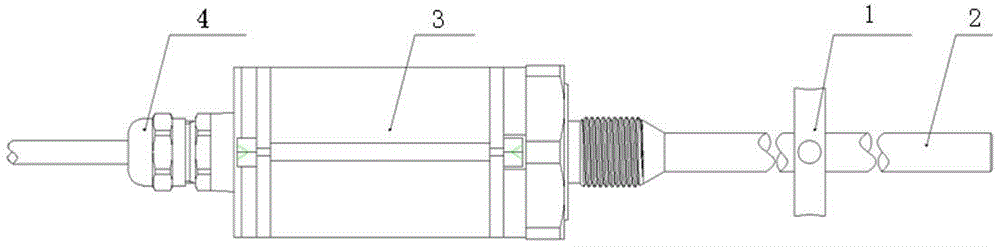

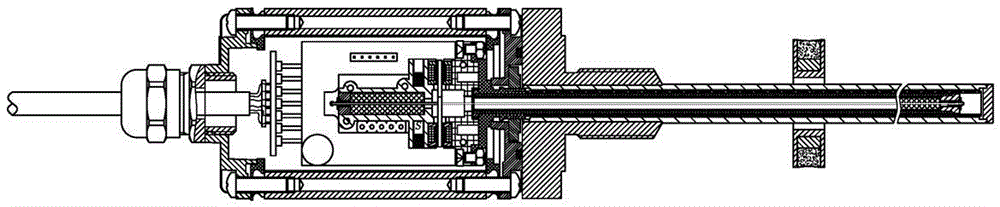

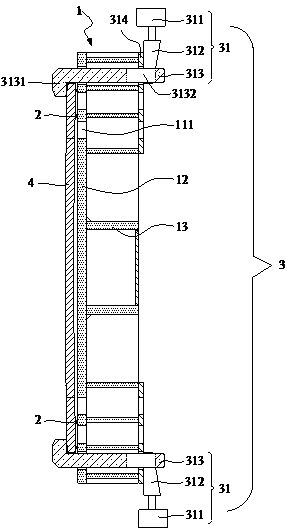

A tensioning installation method of a magnetostrictive displacement sensor and its waveguide wire

ActiveCN103486958BReduce curvatureEliminate bending deformationUsing electrical meansGlass fiberUltrasound attenuation

The invention provides a magnetostrictive displacement sensor and a tensioning mounting method of a waveguide wire thereof. The sensor comprises a position magnetic ring, a measuring rod, a wire outlet connector and an electronic bin, wherein the measuring rod comprises an outer sleeve pipe end face sealing cover, an outer sleeve pipe and a plastic insulation sleeve, the rear end of a waveguide pipe is arranged in the plastic insulation sleeve, the outer sleeve pipe is arranged outside the plastic insulation sleeve, the outer sleeve pipe end face sealing cover is arranged on the end portion of the waveguide pipe and the end portion of the outer sleeve pipe, the waveguide pipe comprises a waveguide wire which is arranged in a glass fiber pipe, a high-temperature lead is arranged outside the glass fiber pipe, the glass fiber pipe and the high-temperature lead are arranged in an inner sleeve pipe, the waveguide wire and the high-temperature lead are fixed at a rear end hollow rivet, and the front end of the waveguide wire is fixed on a front end hollow rivet. The invention further provides the tensioning mounting method of the waveguide wire. The waveguide wire in the waveguide pipe is in a tensioned state all the time, the bending degree is small, the straight degree is high, a clamping ring does not need to be supported by an external device, attenuation of torsional stress wave strength is small, product debugging time is short, measuring precision is high, and work is reliable.

Owner:FIRSTRATE SENSOR

knife holder

ActiveCN104057109BEliminate bending deformationGuarantee processing qualityLarge fixed membersEngineeringTorsion spring

The invention relates to a knife rest. The knife rest comprises a knife handle seat, a support arm, a regulating dowel, a regulating nut, a compression spring and a fastening bolt, wherein a turning tool is arranged on the knife handle seat, the support arm is fixed on the lower part of the knife handle seat through the fastening bolt, the front end of the support arm extends to the lower part of a slender shaft to be processed, the regulating dowel penetrates through a through hole in the support arm, the lower part of the support arm is provided with the regulating nut matched with the regulating dowel, the upper part of the support arm is provided with the compression spring, one end of the compression spring presses the upper surface of the support arm, the other end of the compression spring presses a step arranged on the regulating dowel, and the top end of the regulating dowel is provided with a round ball which can rotate freely. According to the knife rest, before processing, each component is regulated, and then processing operation can be carried out; no regulation is needed halfway, the use is convenient, the efficiency is high, and the processing effect is good.

Owner:HARBIN DONGAN ENGINE GRP

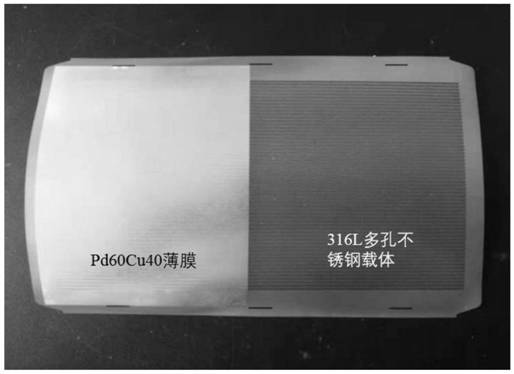

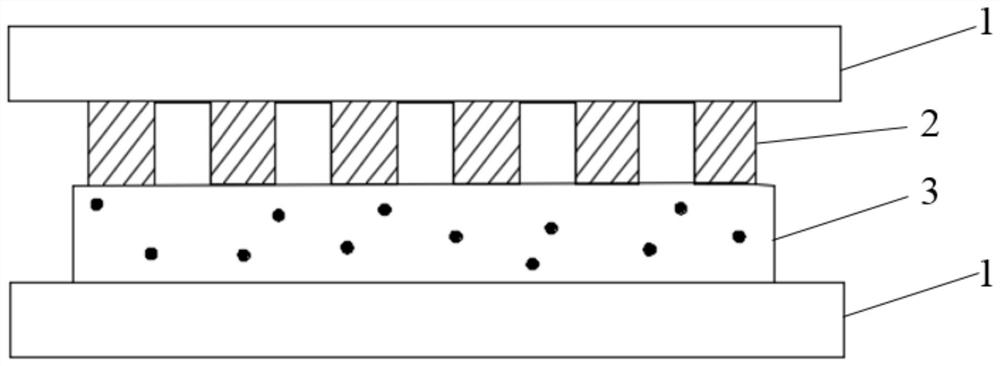

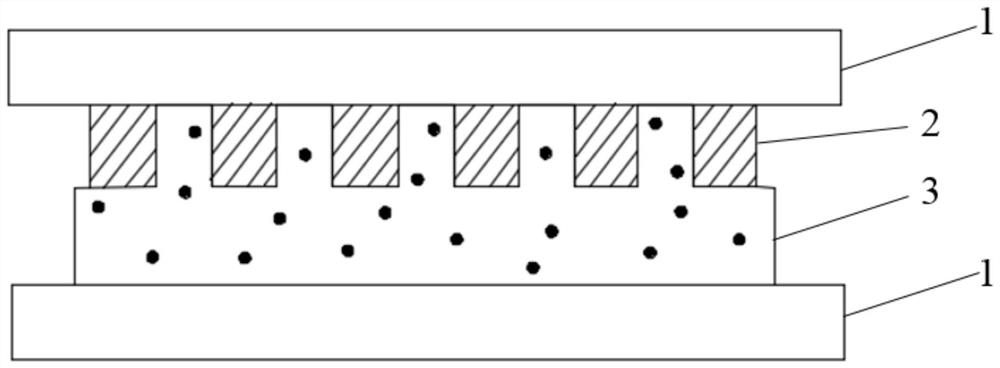

A kind of connection method of palladium-based alloy thin film and porous stainless steel carrier

ActiveCN113560708BThickness is easy to controlGood size controlWelding/soldering/cutting articlesNon-electric welding apparatusFiberAluminum silicate

The invention discloses a method for connecting a palladium-based alloy film and a porous stainless steel carrier, comprising the following steps: 1. Sintering aluminum silicate fiber paper to obtain a pressure transmission material; 2. Putting the pressure transmission material and the porous stainless steel carrier on the Press molding between the two layers of quartz glass to obtain the assembly; 3. Cover the surface of the porous stainless steel carrier of the assembly with a palladium-based alloy film to obtain the assembly; 4. Place the assembly in a vacuum hot-pressing sintering furnace. Vacuum diffusion welding treatment; 5. Leveling in a creep forming device to obtain a palladium composite film. The invention effectively reduces the gap between the ultra-thin palladium-based alloy film and the porous stainless steel carrier by adopting the pressure transmission material with elastic deformation ability, improves the uniformity of the pressure in the vacuum diffusion welding process, and effectively improves the pressure of the palladium alloy. The combination rate of the membrane and the porous stainless steel carrier makes the prepared palladium composite membrane have better tissue uniformity and higher density, and is suitable for mass production of the palladium composite membrane.

Owner:XIAN TIANLI CLAD METAL MATERIALS

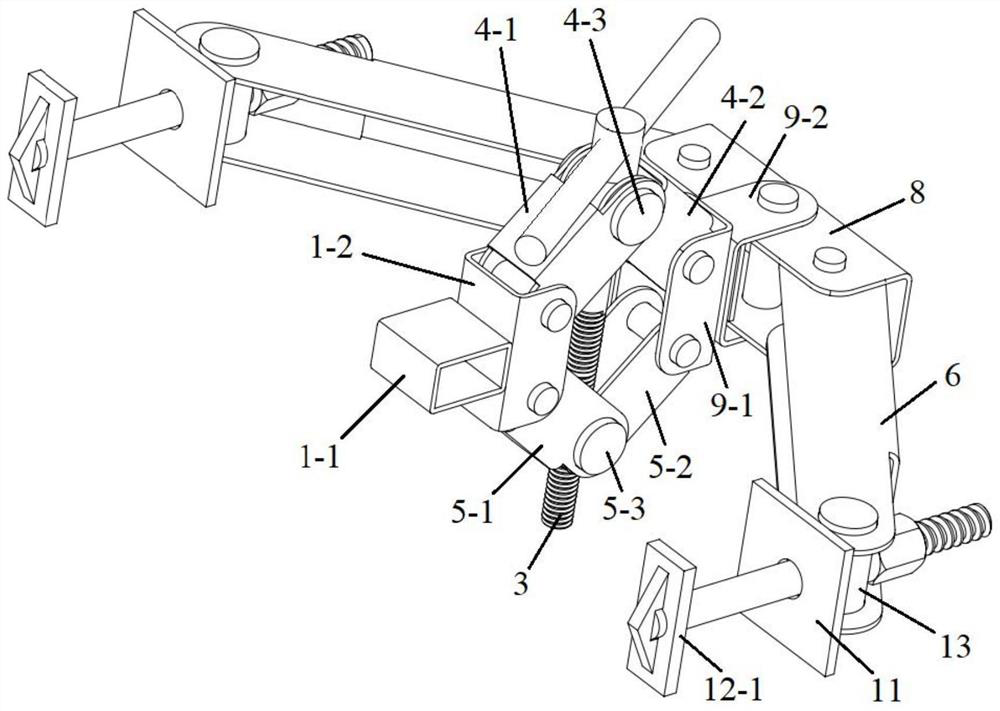

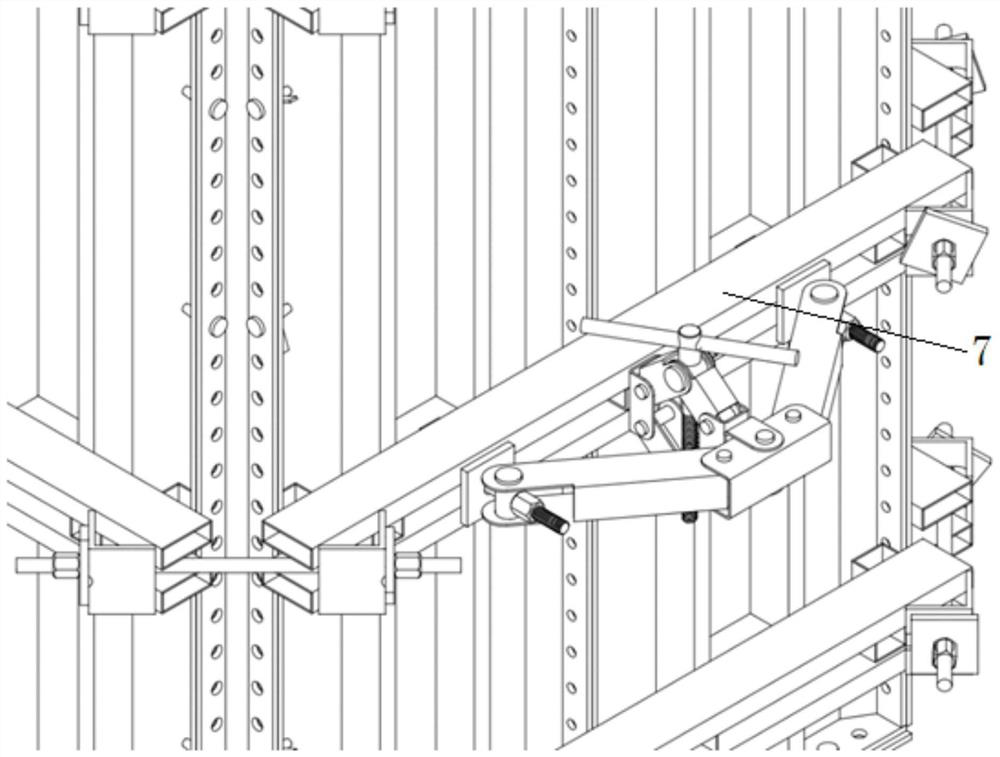

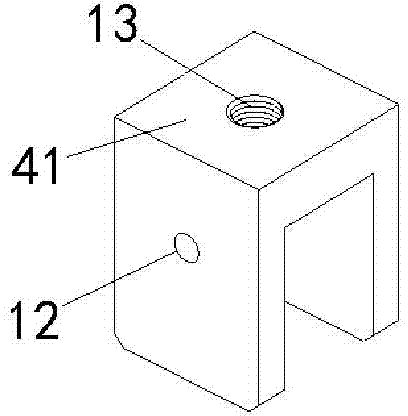

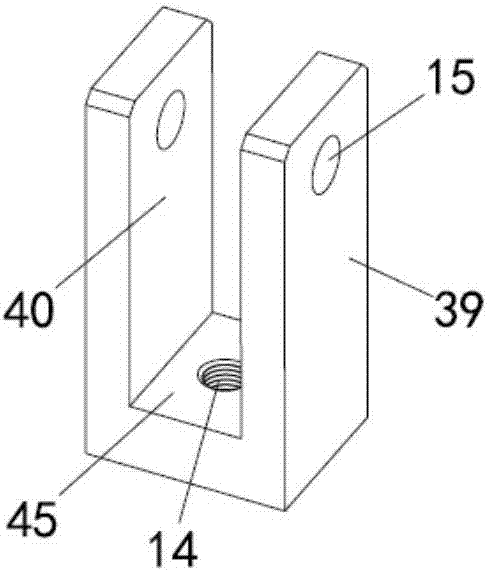

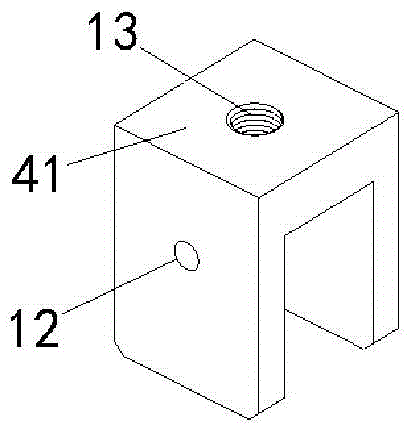

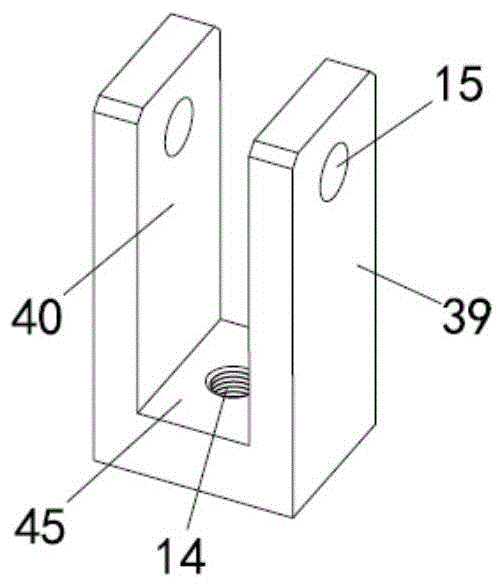

Dorsal bar flexural rigidity reinforcing device

PendingCN111852009ACounteracts bending deformationEliminate bending deformationAuxillary members of forms/shuttering/falseworksEngineeringScrew thread

The invention discloses a dorsal bar flexural rigidity reinforcing device which comprises a positioning block, a screw rod, a first connecting rod, a second connecting rod, a support rod, a U shaped connecting rod, a nut, a T shaped bolt and a pored pin; the first connecting rod comprises a rod A and a rod B hinged to each other and a first pored pin; the second connecting rod comprises a rod C and a rod D hinged to each other and a second pored pin; the screw rod is sequentially arranged in a through hole and an internal threaded hole in a penetrating manner; the screw rod and the second pored pin are in threaded connection; the distance between the first pored pin and the second pored pin can be adjusted through rotating the screw rod; the two ends of the first connecting rod and the second connecting rod are hinged to a positioning block and a U shaped connecting rod; a support rod is hinged to the two ends of the U shaped connecting rod; the first end of the support rod is hinged to the U shaped connecting rod; the second end of the support rod is hinged to a T shaped bolt through the pored pin; the thread end of the T shaped bolt is mounted in the hole of the pored pin in a penetrating manner; and the nut locks a dorsal bar between the nut end of the T shaped bolt and the support rod.

Owner:江苏佳搏实业发展集团有限公司

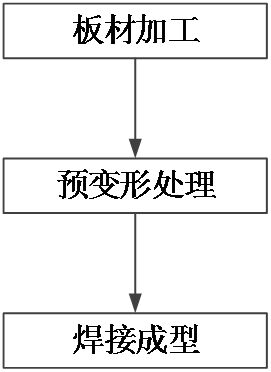

Plate Welding Process for Winch Production

ActiveCN110814564BImprove assembly accuracyImprove product qualityWelding/cutting auxillary devicesAuxillary welding devicesPre deformationMechanical equipment

Owner:JIANGSU SINMA MACHINERY

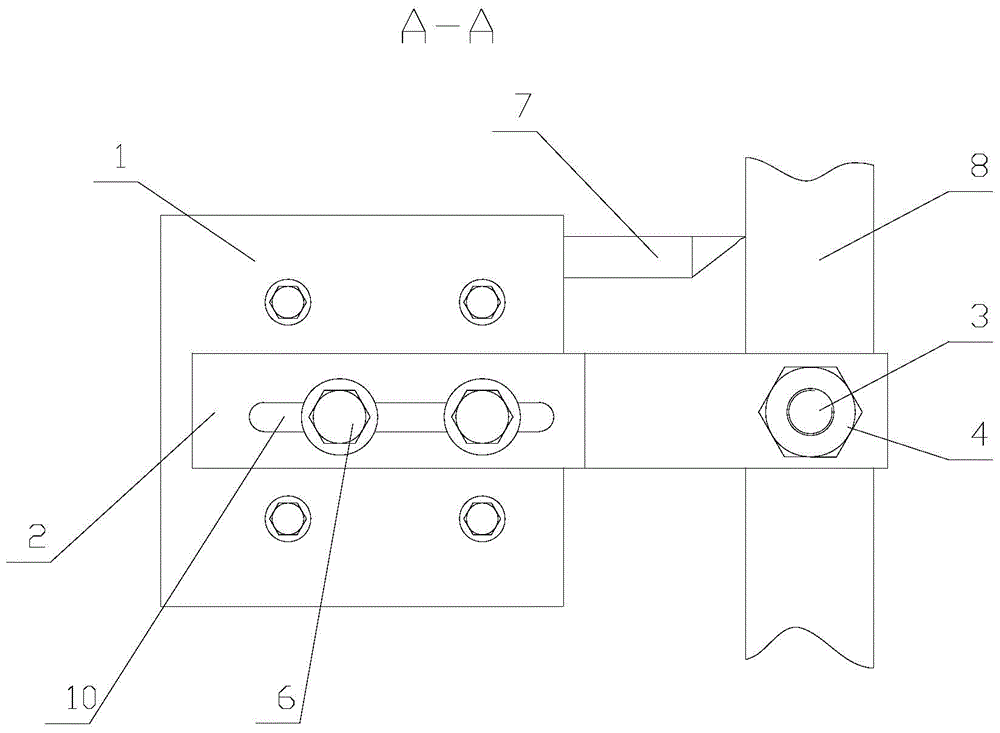

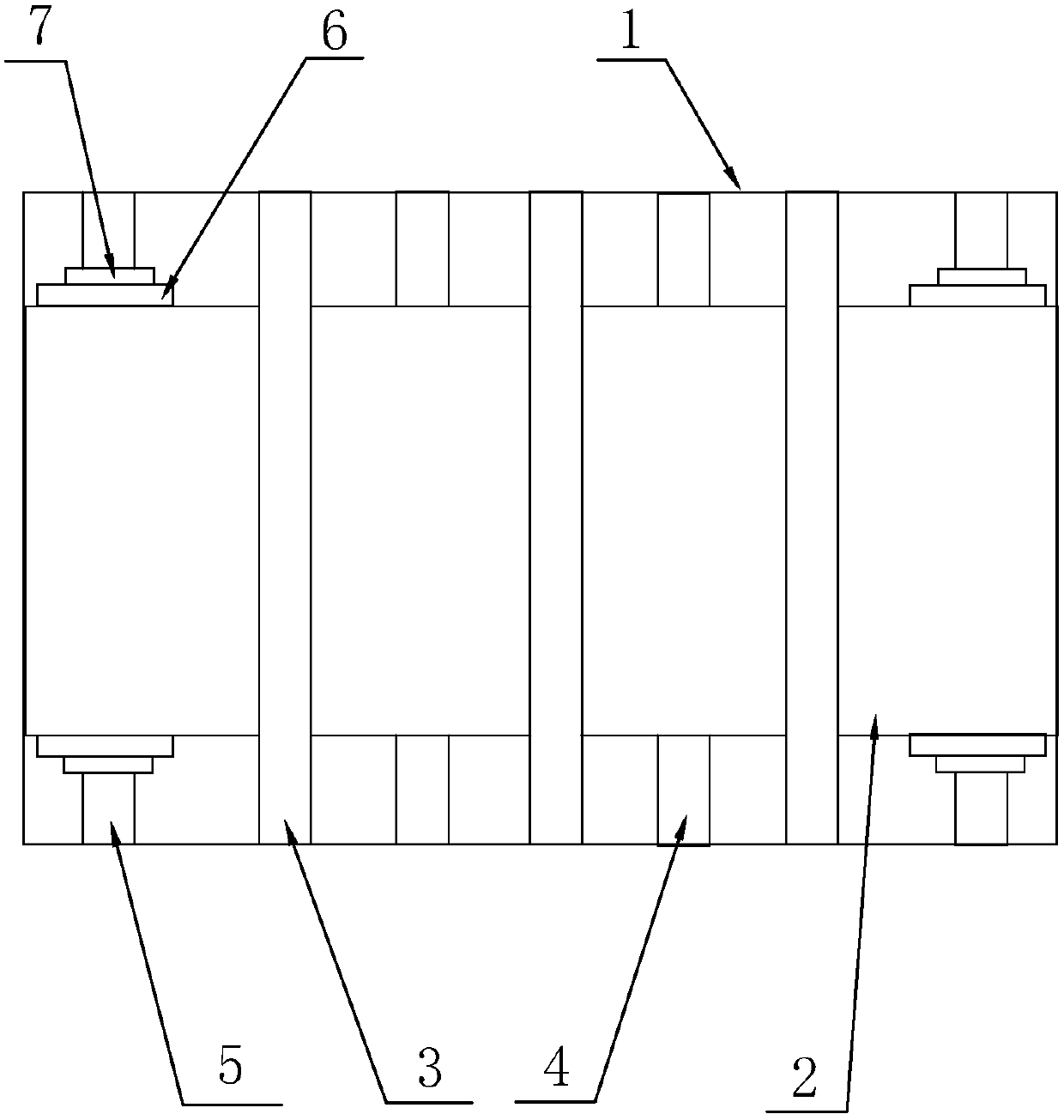

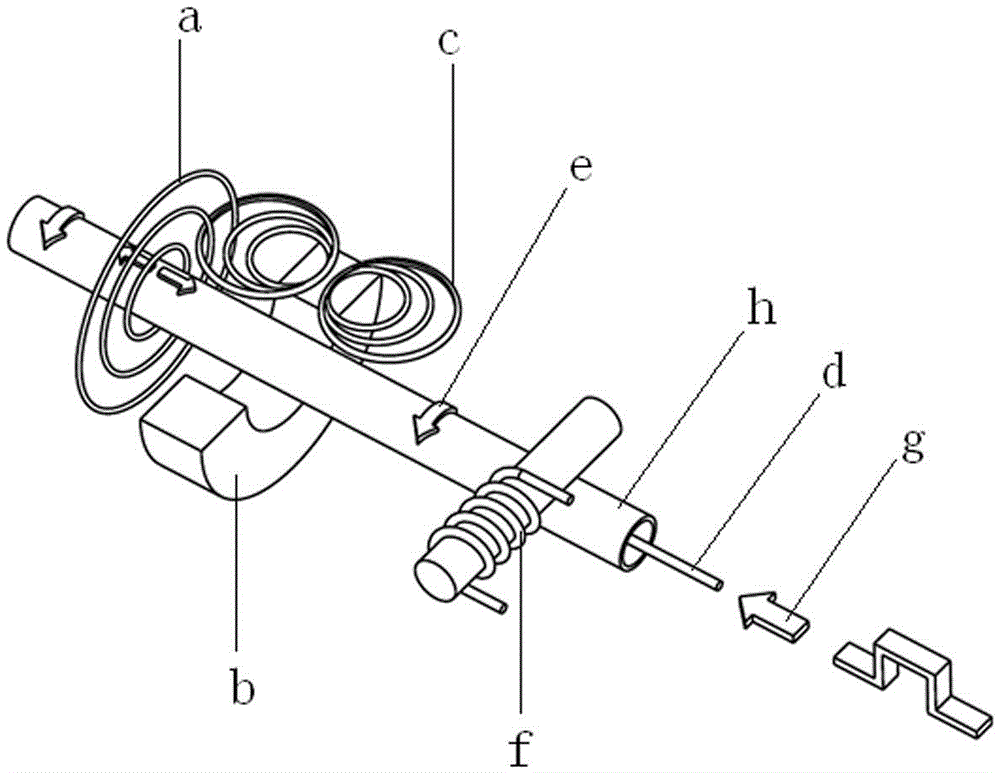

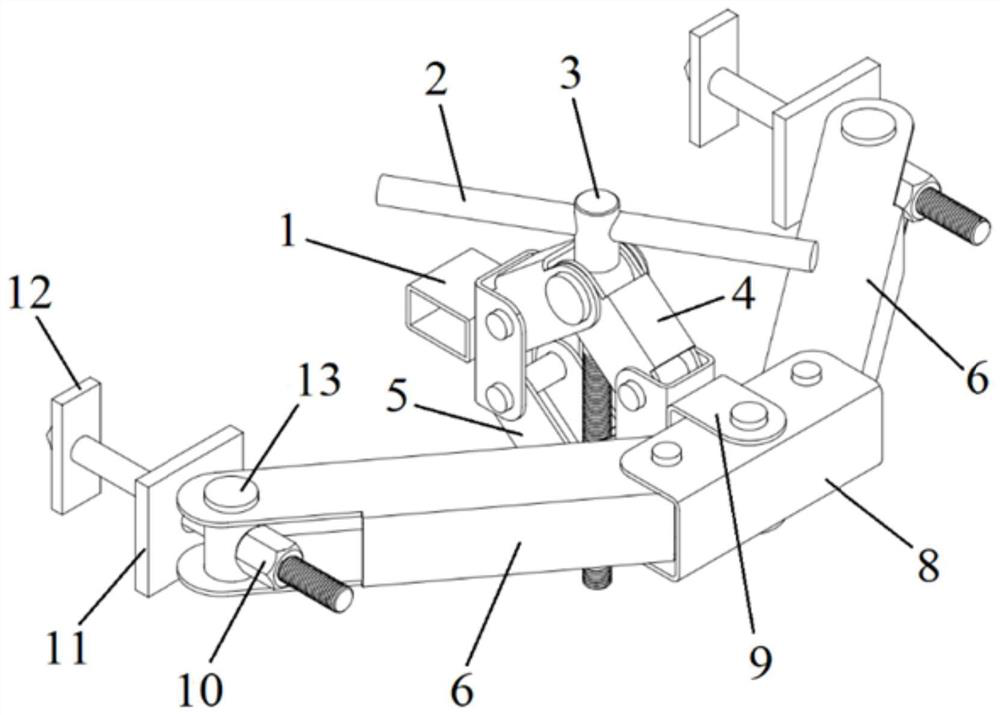

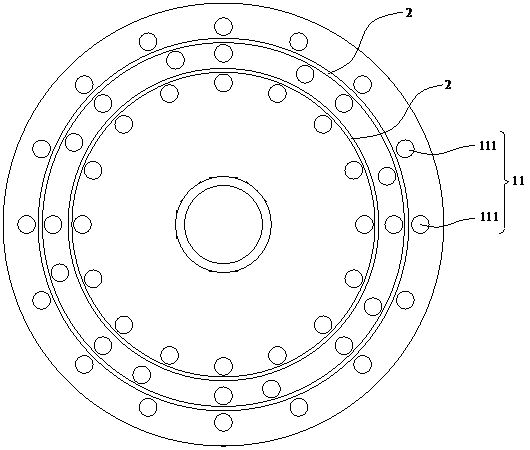

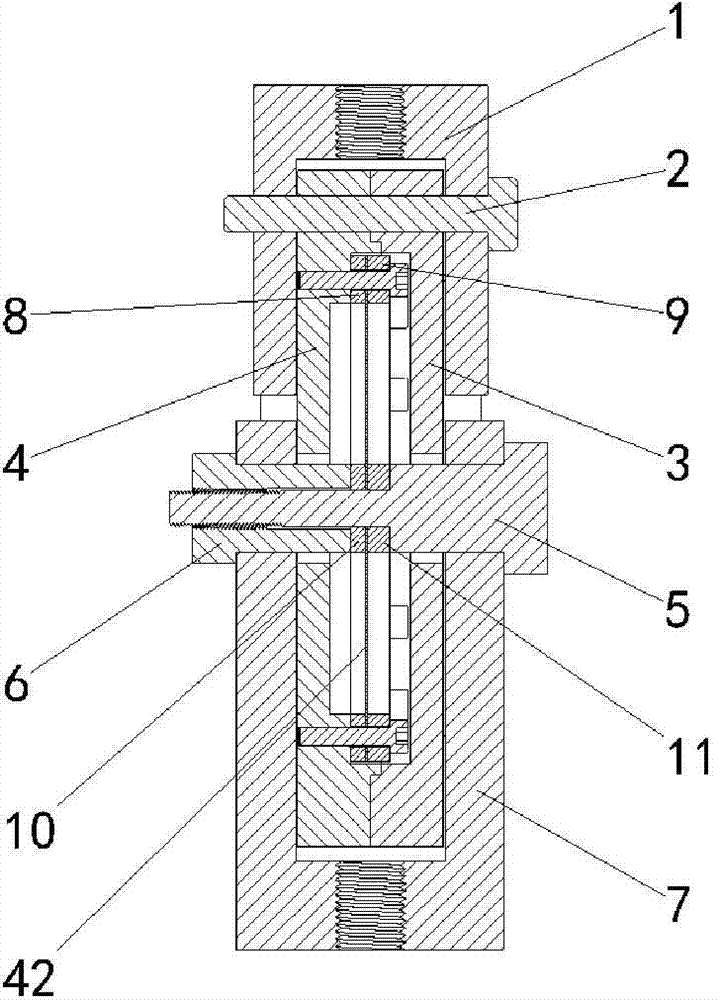

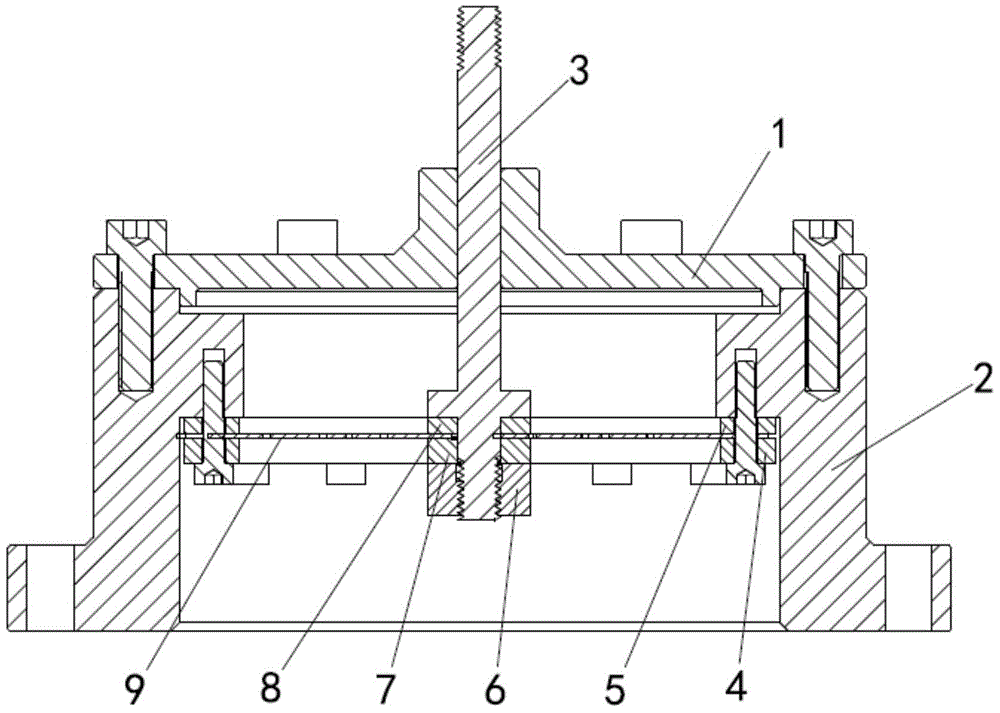

Linear compressor scroll plate spring radial stiffness testing device and manufacturing method thereof

ActiveCN104330249AAvoid the problem of force biasSimple designMachine part testingRadial stressLinear compressor

The invention discloses a linear compressor scroll plate spring radial stiffness testing device and a manufacturing method thereof. The testing device is formed by an upper lug, a positioning pin, a cover plate, a base, a fixed screw, a fixed nut, a lower lug, an inner washer, an outer washer, an inner gasket and an outer gasket. The inner edge and the outer edge of a scroll plate spring are respectively fixed through the testing device of the invention, thus the stress directions of the inner edge and the outer edge are strict radial directions and are completely overlapped, the stress bias and bending deformation generated in a scroll plate spring radial stiffness test is eliminated to the maximum so as to accurately measure the displacement of the plate spring under radial stress and the corresponding intensity value and changing trend, the comparison and reference of accurate measured data are provided for the design and manufacture of the scroll plate spring, and the device has positive effect for the optimal design of the scroll plate spring and the development of a linear compressor.

Owner:上海铂钺制冷科技有限公司

Testing device and manufacturing method for radial stiffness of scroll plate spring of linear compressor

ActiveCN104330249BAvoid the problem of force biasSimple designMachine part testingRadial stressLinear compressor

The invention discloses a linear compressor scroll plate spring radial stiffness testing device and a manufacturing method thereof. The testing device is formed by an upper lug, a positioning pin, a cover plate, a base, a fixed screw, a fixed nut, a lower lug, an inner washer, an outer washer, an inner gasket and an outer gasket. The inner edge and the outer edge of a scroll plate spring are respectively fixed through the testing device of the invention, thus the stress directions of the inner edge and the outer edge are strict radial directions and are completely overlapped, the stress bias and bending deformation generated in a scroll plate spring radial stiffness test is eliminated to the maximum so as to accurately measure the displacement of the plate spring under radial stress and the corresponding intensity value and changing trend, the comparison and reference of accurate measured data are provided for the design and manufacture of the scroll plate spring, and the device has positive effect for the optimal design of the scroll plate spring and the development of a linear compressor.

Owner:上海铂钺制冷科技有限公司

Shape maintenance shot peening strengthening and calibration method for preventing in-plane bending of wall panel

The invention belongs to the forming technique of aerospace wall panels, relating to a shape maintenance shot peening strengthening and calibration method for preventing the in-plane bending of a wall panel. The method comprises the following steps of: firstly carrying out regional division on the spare parts of the wall panel, then inputting data in a shot peening device, and finally carrying out shot peening strengthening in a double opposite spraying manner; when in-plane bending occurs for the shot peening, calibrating thin-gauge skins, firstly choosing a calibration region, and then inputting the data into the shot peening device; and carrying out double opposite spraying on the inner and the outer thin-gauge skins in the deformed region with in-plane bending. According to the invention, aiming at the complicated structural shape, shot peening strengthening is carried out on the wall panel under the condition of guaranteeing that the space shapes of the spare parts are not changed after deformation, and the calibration method for forming the in-plane bending after the shot peening strengthening reduces the rejection rate of the spare parts, avoids severe economic lost and has good technological and economic benefits.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

Fatigue property test method for wallboard lap joint structure

InactiveCN102323050BGuaranteed validityThe test effect is goodMachine part testingLoad cycleLap joint

The invention relates to a fatigue property test method for a wallboard lap joint structure. The fatigue property test method is characterized by comprising the following steps of: installing a test piece in a triaxial bending-limitation clamp; clamping two ends of the test piece by using an upper chuck and a lower chuck of a tester, wherein the centering line of the two chucks is overlapped with the central line of the two ends of the test piece; then prestretching a connection piece twice; continuing to load a sine waveform with a frequency of 5 Hz, wherein the peak value of the load is 0.3[P]n; and reducing the frequency by 1 Hz every 1,000-3,000 times so as to acquire the length a of a crack at each time and a corresponding load cycle number N. The fatigue property test method has the beneficial effects that a fatigue crack extension test for the wallboard lap joint structure with longitudinal load can be carried out; a good test effect is achieved during actual use; and furthermore, any obvious vibration or deformation can be avoided, bending deformation can be eliminated effectively, axial load transmission and deformation cannot be influenced and the effectiveness of test data is guaranteed.

Owner:AIR FORCE UNIV PLA

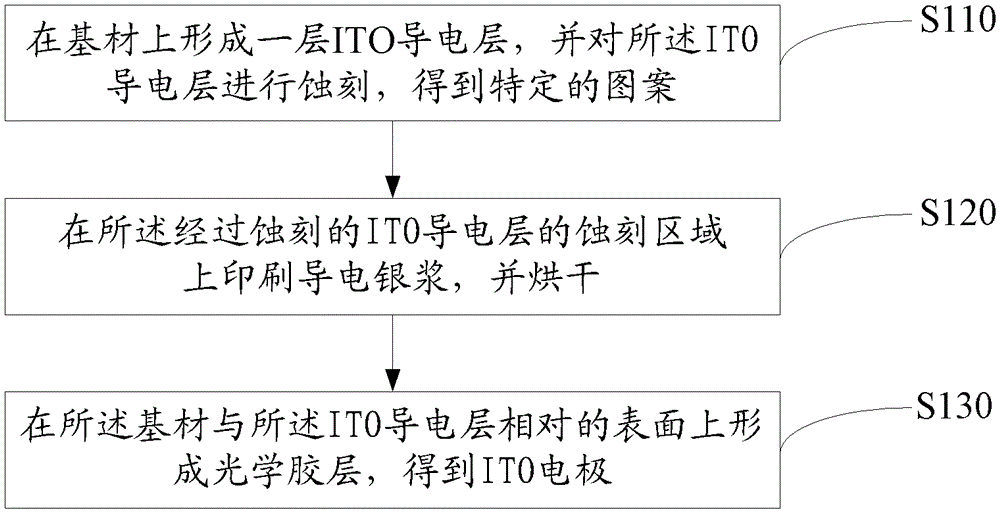

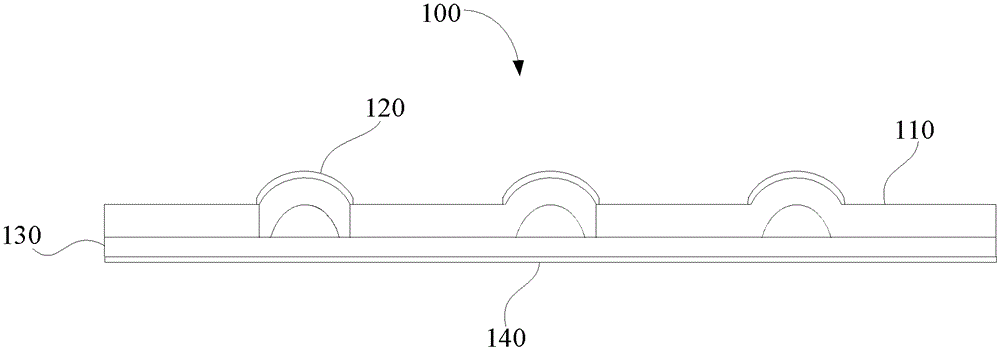

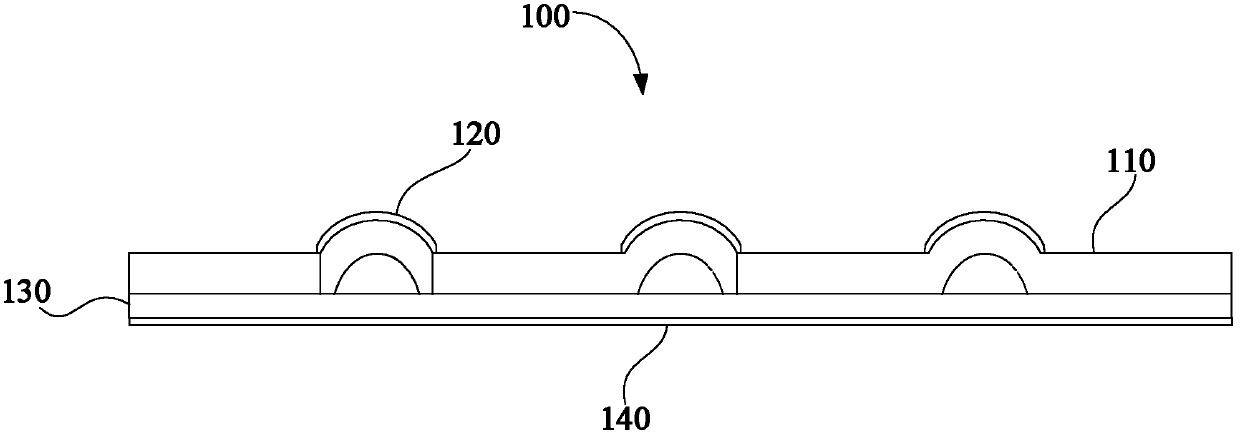

The preparation method of ito electrode and the ito electrode prepared by the method

ActiveCN103310904BAlleviate Surface Deformation VisibilitySoftConductive layers on insulating-supportsCable/conductor manufactureSilver pasteVisibility

Owner:SHENZHEN O FILM TECH

Two-end synchronous driving grinding method and headstock and tailstock special for grinder

InactiveCN102935617AEliminate adverse effects such as bendingEliminate torsional deformationGrinding carriagesGrinding drivesNumerical controlControl system

The invention relates to a two-end synchronous driving grinding method and a headstock and a tailstock special for a grinder, and belongs to the field of machine tools. The technical scheme is that the headstock and the tailstock of the grinder are respectively provided with spindle driving mechanisms which are identical, a reliable numerical-control control system is adopted to control the two spindle driving mechanisms to rotate, each spindle driving mechanism is provided with a servo motor, and a synchronous pulley is arranged at one end of a motor base arranged below each servo motor. A synchronous pulley is also arranged at one end of a spindle box, a spindle unit is arranged in the middle of the spindle box, a compensation claw post-tensioning chuck and a coder are arranged on the spindle unit, a jacking oil cylinder is fixed on an oil cylinder base arranged on the tailstock, and a guide rail pair is arranged between a connection plate and a base of the tailstock. The two-end synchronous driving grinding method and the headstock and the tailstock special for the grinder have the advantages that synchronous driving of two ends of a workpiece is achieved through control and compensation of the control system, and harmful effects caused by torsion deformation, bending deformation and thermal deformation generated by one-end driving are removed. The headstock and the tailstock are novel in design, reasonable in structure, high in positioning accuracy and good in processing reliability.

Owner:ANYANG XINSHENG MACHINE TOOL

Testing device and manufacturing method for axial stiffness of scroll plate spring of linear compressor

ActiveCN104330248BAvoid the problem of force biasGuaranteed deformationMachine part testingLinear compressorUltimate tensile strength

The invention discloses a linear compressor scroll plate spring axial stiffness testing device and a manufacturing method thereof. The testing device is formed by an upper cover, a base, a pull rod, an outer washer, an inner washer, a pressing nut, an outer gasket and an inner gasket. The inner edge and the outer edge of a scroll plate spring are respectively fixed through the testing device of the invention, thus the stress directions of the inner edge and the outer edge are strict axial directions and are parallel to each other in a reverse way, the stress bias and bending deformation generated in a scroll plate spring axial stiffness test is eliminated to the maximum so as to accurately measure the displacement of the plate spring under axial stress and the corresponding intensity value and changing trend, the comparison and reference of accurate measured data are provided for the design and manufacture of the scroll plate spring, and the device has positive effect for the optimal design of the scroll plate spring and the development of a linear compressor.

Owner:上海铂钺制冷科技有限公司

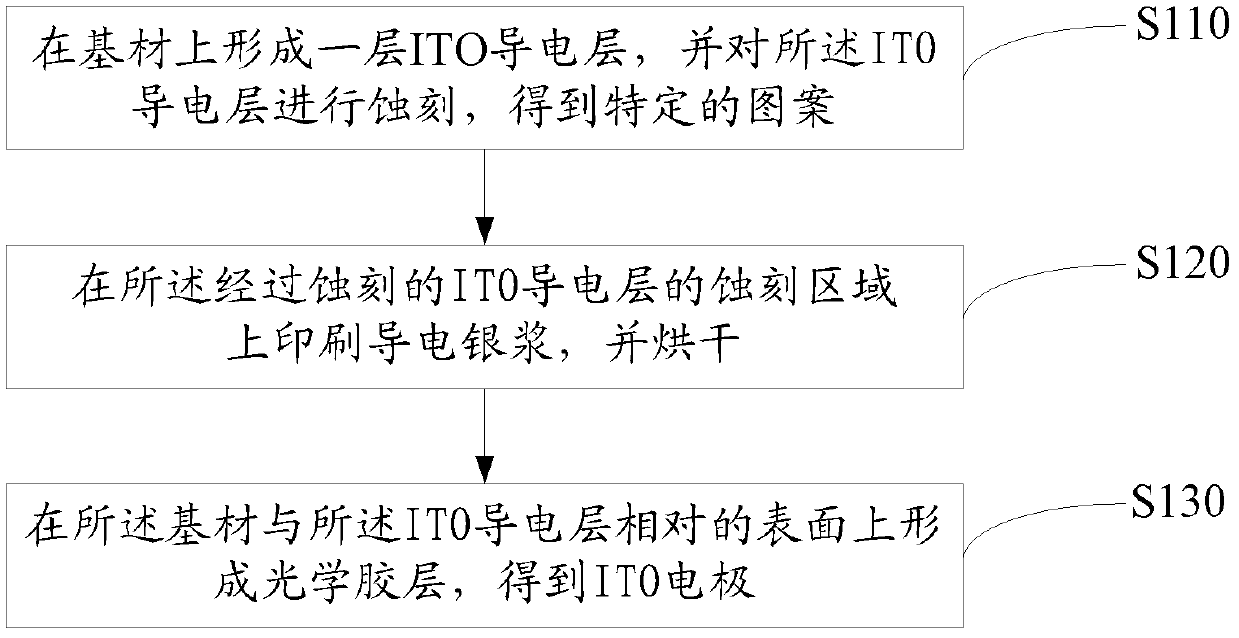

Preparation method for ITO (Indium Tin Oxide) electrode and ITO electrode prepared by adopting method

ActiveCN103310904AAlleviate Surface Deformation VisibilitySoftConductive layers on insulating-supportsCable/conductor manufactureSilver pasteVisibility

The invention relates to a preparation method for an ITO (Indium Tin Oxide) electrode. The method comprises the steps of firstly forming an ITO conductive layer on a substrate, etching the ITO conductive layer to be a preset pattern, then printing conductive silver paste in the etched area of the ITO conductive layer, baking the conductive silver paste and finally forming an optical cement layer on the surface, opposite to the ITO conductive layer, of the substrate. Since optical cement is flexible, the optical cement layer can be attached onto the surface of the substrate, so that bending deformation caused by stress difference can be made up. Moreover, since the optical refractive index of the optical cement is equivalent to the optical refractive index of the substrate, the bending deformation can be eliminated visually and the goal of relieving the visibility of the surface deformation of the ITO electrode can be achieved. Therefore, the ITO electrode prepared by adopting the method has the advantage that the visibility of the surface deformation can be effectively relieved. Besides, the invention additionally provides the ITO electrode.

Owner:SHENZHEN O FILM TECH

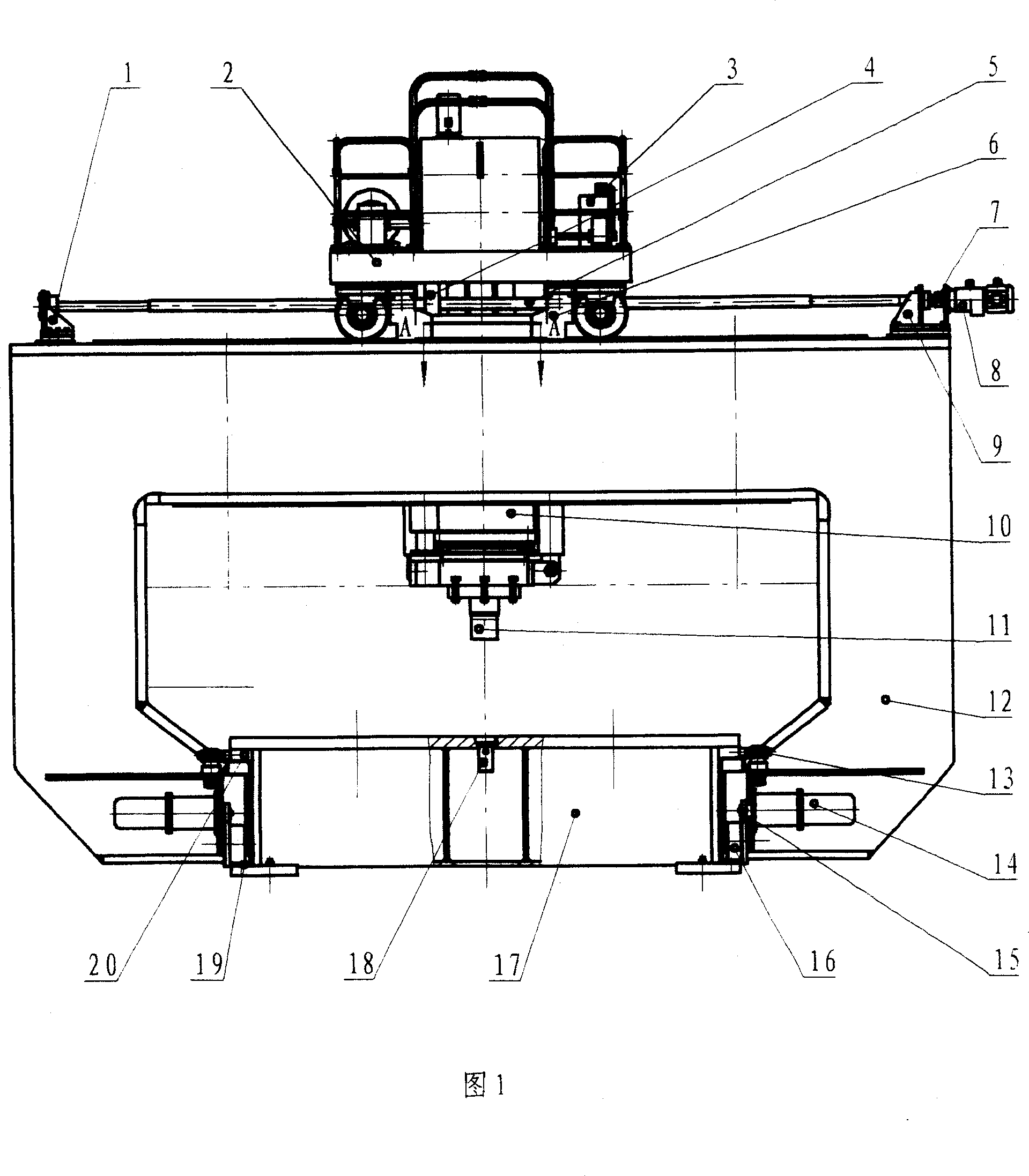

Mobile gantry type digital control massive plate leveling hydraulic press

InactiveCN100348406CImprove carrying capacityEliminate bending deformationPress ramGear wheelMaster cylinder

This invention provides movable portal digital-control heavy-plate leveling hydrostatic machine, which is characterized in that, arranging portal on fixed guide rail, welding support plate on wall side of portal bottom, arranging gear roller on guide and joggled small gear and drive motor; arranging leading screw with one end connected to drive frequency conversion motor and leading screw nut on dolly bottom; arranging two side cylinders on main cylinder sides; arranging dust brush on bearing plate to clear dirty on plant. The invention improves the precision, simplifies structure and increases service life.

Owner:TIANJIN TIANDUAN PRESS CO LTD

Method for eliminating bending deformation of rolling mill-type heavy part

ActiveCN102416496BQuality improvementExtended service lifeMilling equipment detailsControl theorySupport surface

Owner:CHANGZHOU BAOLING HEAVY IND MACHINERY

Vehicular lamp

InactiveCN101749616BWith cooling functionImprove cooling effectPoint-like light sourceLighting heating/cooling arrangementsThermal deformationHeat sink

The invention provides a vehicular lamp with excellent photometric performance instead of the deteriorated photometric performance caused by the thermal deformation of reflectors or the assembly errors of the reflectors. The vehicular lamp is provided with a semiconductor-type light source, a first reflector, a second reflector and a radiating rib, wherein the first reflector covers the semiconductor-type light source and reflects light emitted from the semiconductor-type light source to a preset direction; the second reflector reflects the reflecting light from the first reflector to the front of the lamp; and the radiating rib intensely arranges the semiconductor-type light source, the first reflector and the second reflector. The vehicular lamp is characterized in that at least the second reflector and the radiating rib are integrally formed.

Owner:ICHIKOH IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com