A tensioning installation method of a magnetostrictive displacement sensor and its waveguide wire

A displacement sensor and magnetostrictive technology, which is applied in the direction of instruments, measuring devices, and electrical devices, can solve the problems of high requirements for signal detection circuits, high requirements for software processing, and poor product reliability, so as to shorten debugging time, Improve measurement accuracy and work reliability, and reduce material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

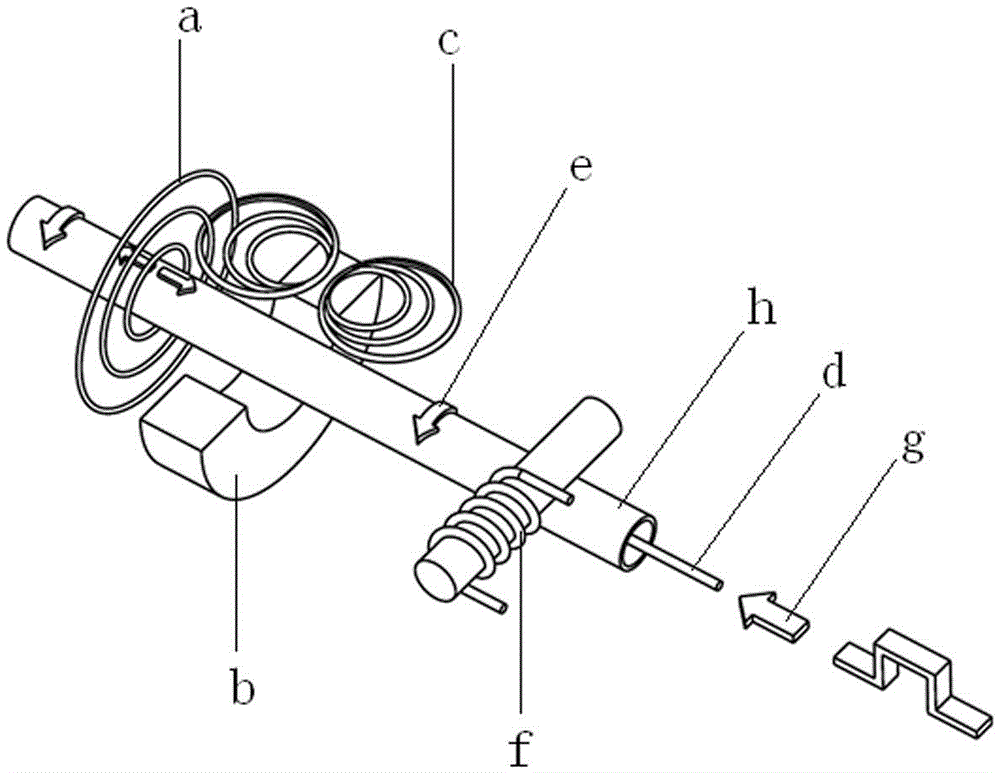

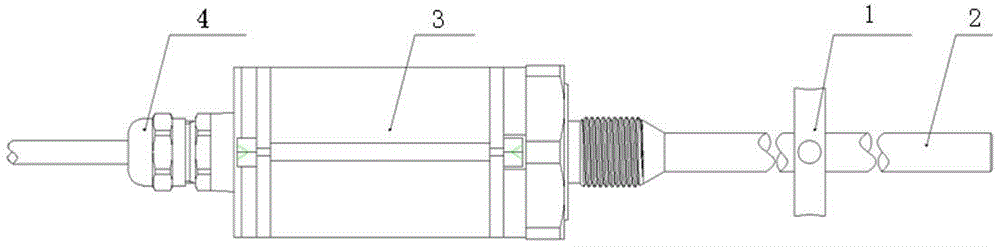

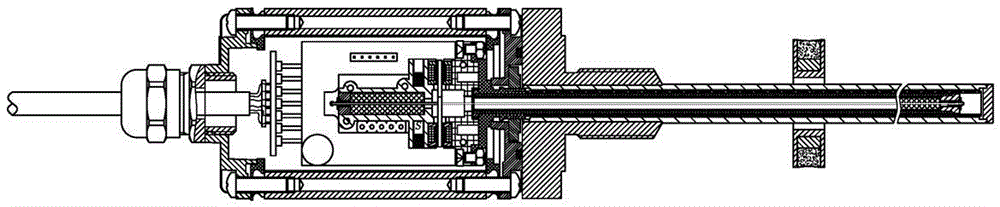

[0023] A magnetostrictive displacement sensor, including a position magnetic ring 1, a measuring rod 2, an electronic chamber 3 and a joint 4 (see figure 2 , image 3 ), the measuring rod 2 includes the outer casing end cover 2-1, the outer casing 2-2 and the plastic insulating sleeve 2-3 (see Figure 4 ), the rear end of the waveguide 2-4 is set inside the plastic insulating sleeve 2-3, the outer sleeve 2-2 is set outside the plastic insulating sleeve 2-3, and the end face cover 2-1 of the outer sleeve is set on the waveguide 2-4 and At the end of the outer casing 2-2, the waveguide 2-4 includes a waveguide wire 2-41, the waveguide wire 2-41 is arranged inside the glass fiber tube 2-45, and the outside of the glass fiber tube 2-45 is provided with a high temperature wire 2-46 , the glass fiber tube 2-45 and the high-temperature wire 2-46 are placed in the inner casing 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com