Guide rail automatic stacking machine

A stacker and automatic technology, which is applied in the direction of object stacking, metal processing equipment, feeding devices, etc., can solve the problems of guide rail surface collision, bruise, straightness bending, and increase the cost of driving maintenance, so as to eliminate collisions injury, reduce labor costs, reduce the frequency of use and the effect of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

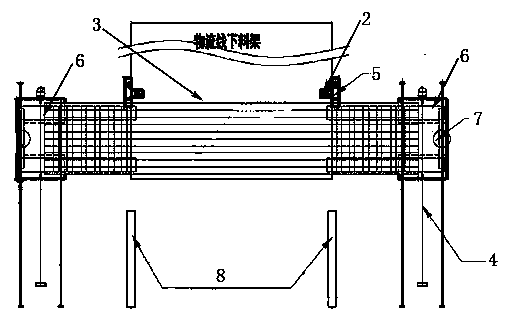

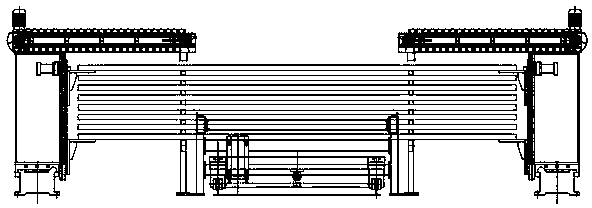

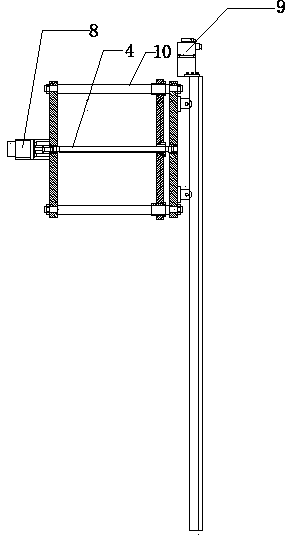

[0020] The present invention relates to a guide rail automatic stacker, which includes a driving control device, a transmission device and a special stacking frame 8 .

[0021] Such as figure 1 , The transmission device includes a counting device and two sets of completely symmetrical moving devices.

[0022] The mobile device is provided with several servo motors, and the servo motors are used to control the operation and movement of each component on the mobile device. The servo motors are all controlled by the drive control device. The operation route of the drive control device is set in advance by the staff, or it can also be controlled by a pre-programmed PLC program.

[0023] The mobi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com