Testing device and manufacturing method for radial stiffness of scroll plate spring of linear compressor

A linear compressor and radial stiffness technology, applied in the field of leaf spring detection, can solve problems such as difficulties, increased radial stiffness measurement, and rare radial stiffness of spiral leaf springs, achieving positive development and eliminating leaf springs. Effects of Force Bias and Bending Deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

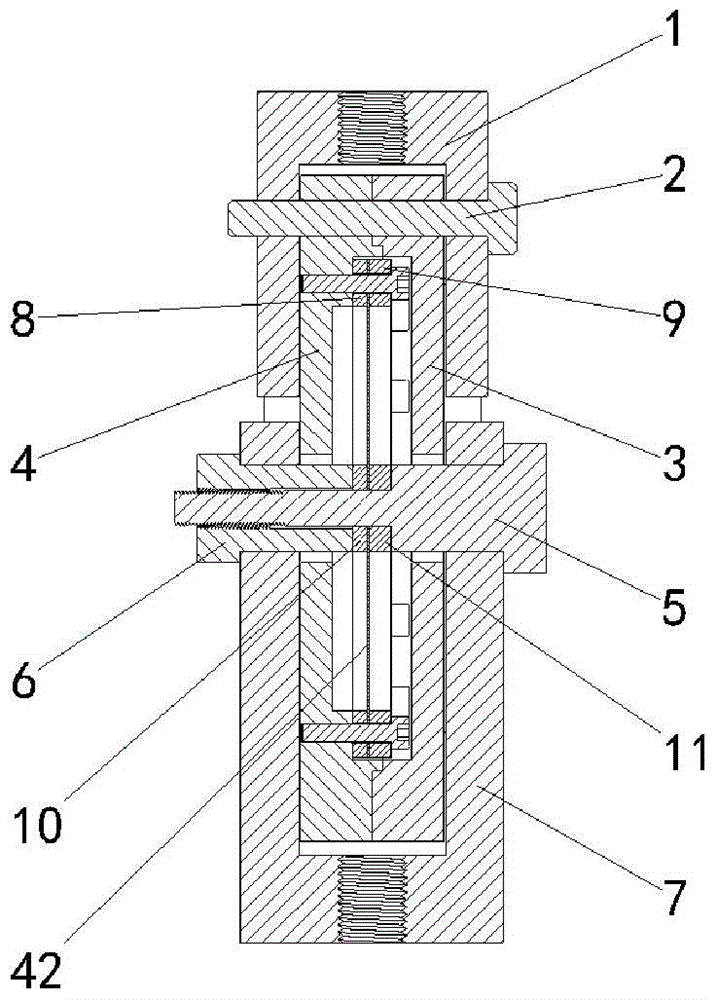

[0040] Below in conjunction with accompanying drawing and embodiment the specific embodiment of the present invention is described in further detail:

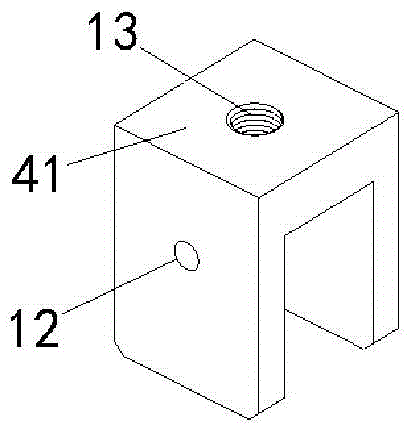

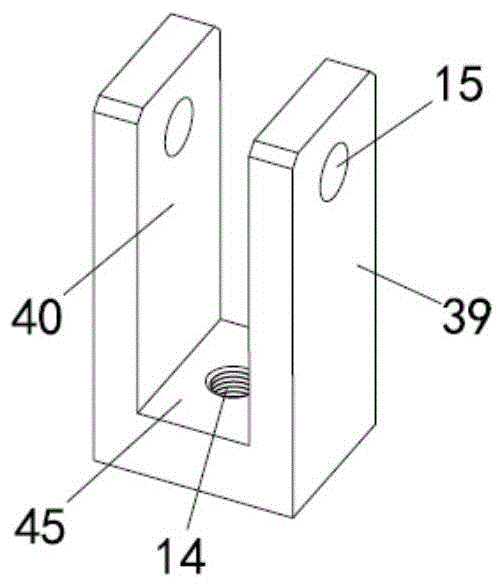

[0041] The invented test device for the radial stiffness of the spiral plate spring of a linear compressor consists of an upper lifting lug 1, a positioning pin 2, a cover plate 3, a base 4, a fixing screw 5, a fixing nut 6, a lower lifting lug 7, an inner washer 8, an outer Composed of a washer 9, an inner gasket 10 and an outer gasket 11, it is characterized in that the upper part of the upper lifting lug 1 is processed with an upper lifting lug threaded hole 13 perpendicular to the upper end surface 41 of the upper lifting lug, and the upper hanging lug 1 is horizontally processed with a hanging hole through the upper lifting lug 1. Ear positioning pin holes 12; one side of the cover plate 3 is processed with a cover plate positioning ring 20, the other side is processed with a cover plate guide groove 18, the center has a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com