Fire resistant oil pipeline sliding support for steam turbine

A sliding bracket and fuel-resistant technology, which is applied to pipeline brackets, mechanical equipment, pipes/pipe joints/fittings, etc., can solve problems such as loose end joints of pipes, cracking of pipe welds, bending deformation of pipes, etc., to ensure safety and stability The effect of running, eliminating the bending deformation of the pipe, and avoiding the loosening of the joint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention is described in further detail:

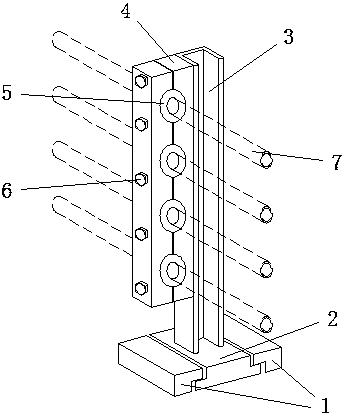

[0012] Such as figure 1 As shown, a steam turbine anti-fuel pipeline 7 sliding support of the present invention includes a vertical support column 3, and a fixed base 1 with slide rails is laid below the support column 3, and the fixed base 1 is fixed on the embedded iron on the ground. The bottom of the support column 3 is connected with a sliding base 2 matched with the slide rail of the fixed base 1 . The cross section of the sliding base 2 is a "convex" shape, and the two sides of the sliding base 2 are pressed under the inner flange of the fixed base 1 and can slide.

[0013] The side of support column 3 is connected with pipe clamp 4 in parallel, and pipe clamp 4 is provided with some pipeline through holes side by side up and down, and pipeline through hole is parallel with slide rail, and anti-fuel oil pipeline 7 penetrates in the pipeline through hole, plays...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com