Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Easy to segregate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-toughness and low-yield-ratio quenched and tempered steel plate used in low-temperature environment and manufacturing method of high-toughness and low-yield-ratio quenched and tempered steel plate

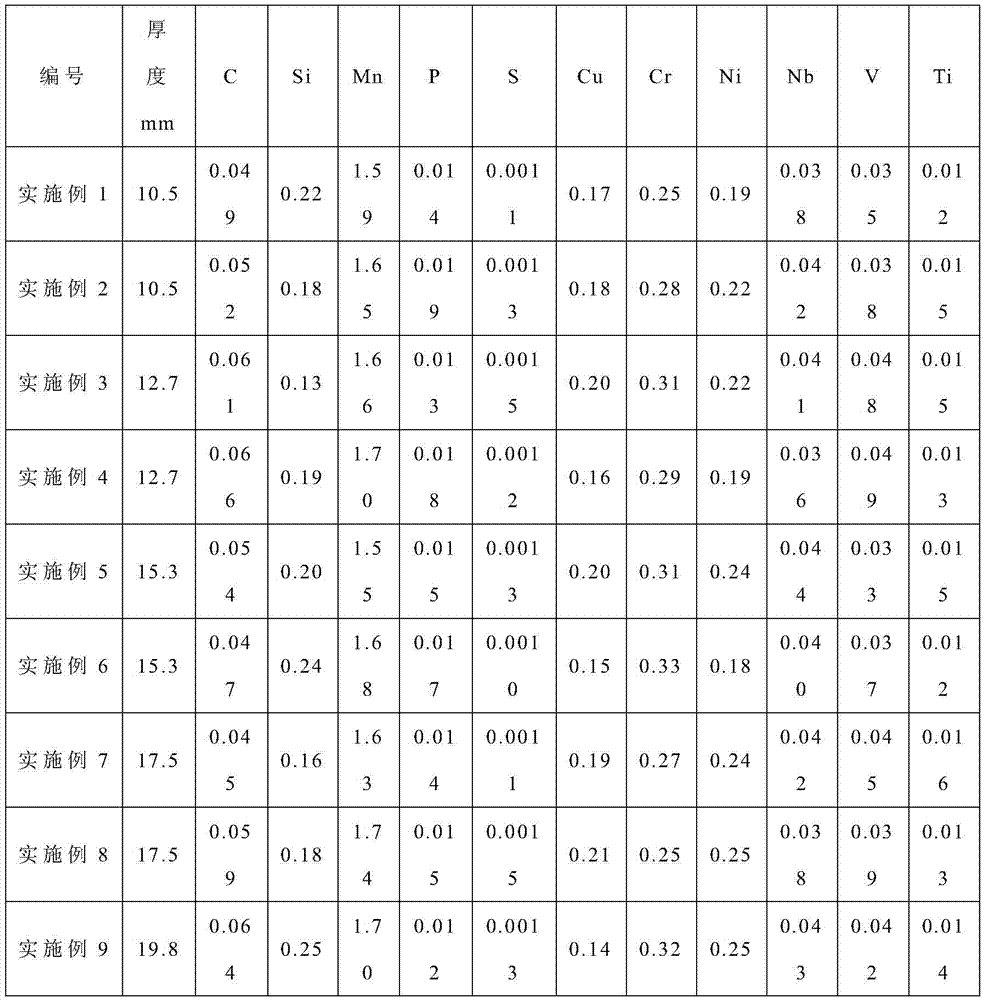

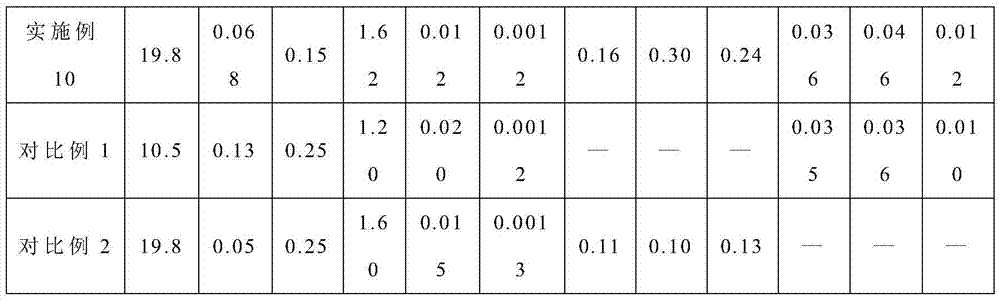

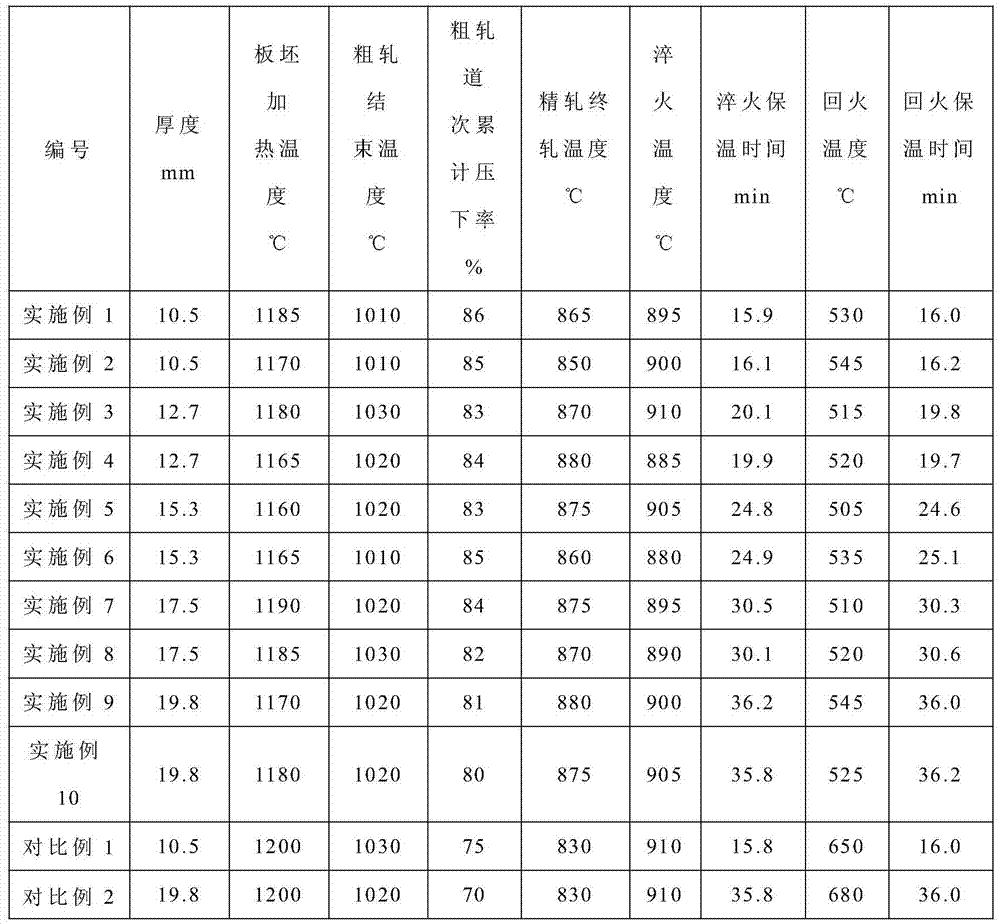

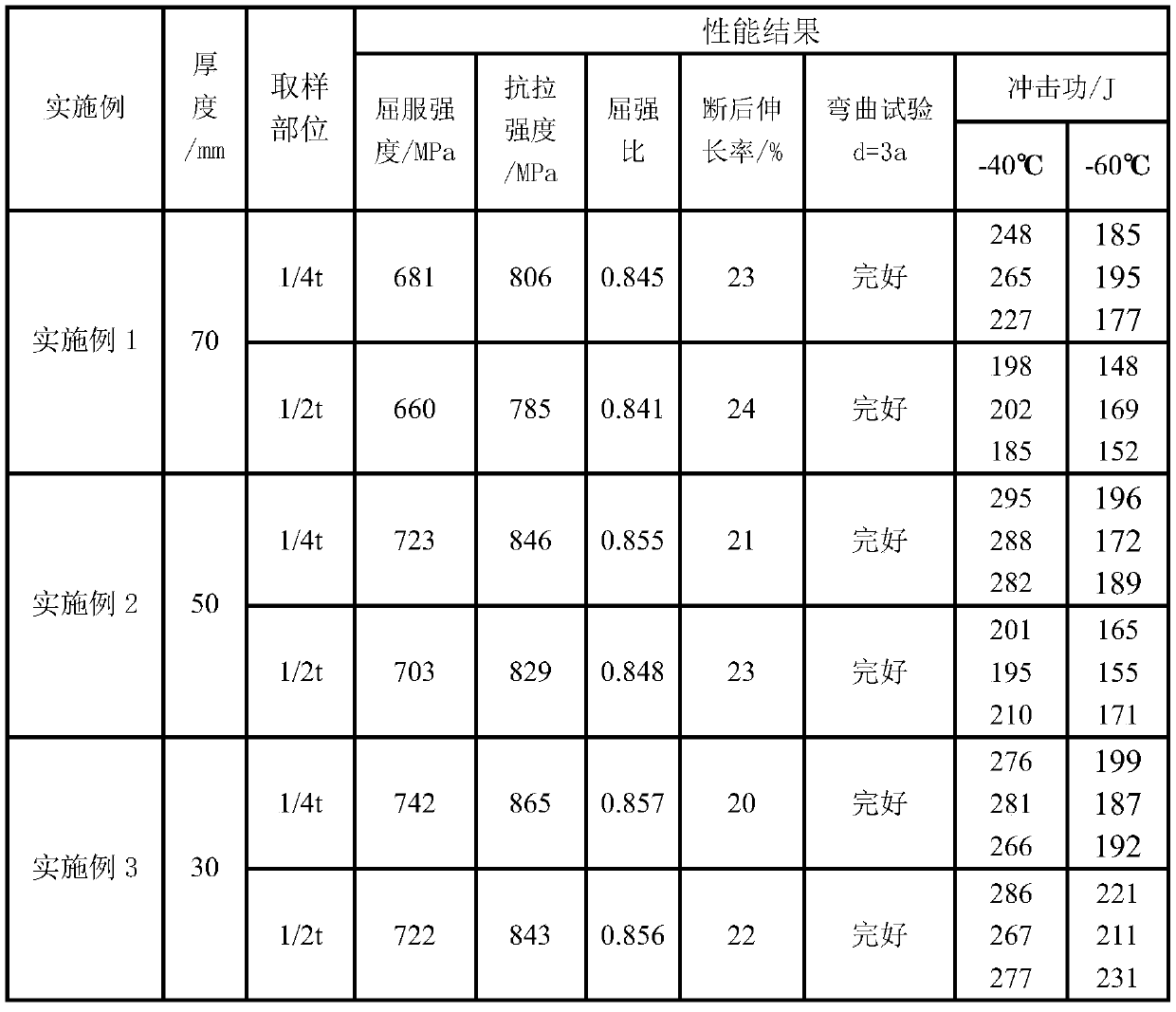

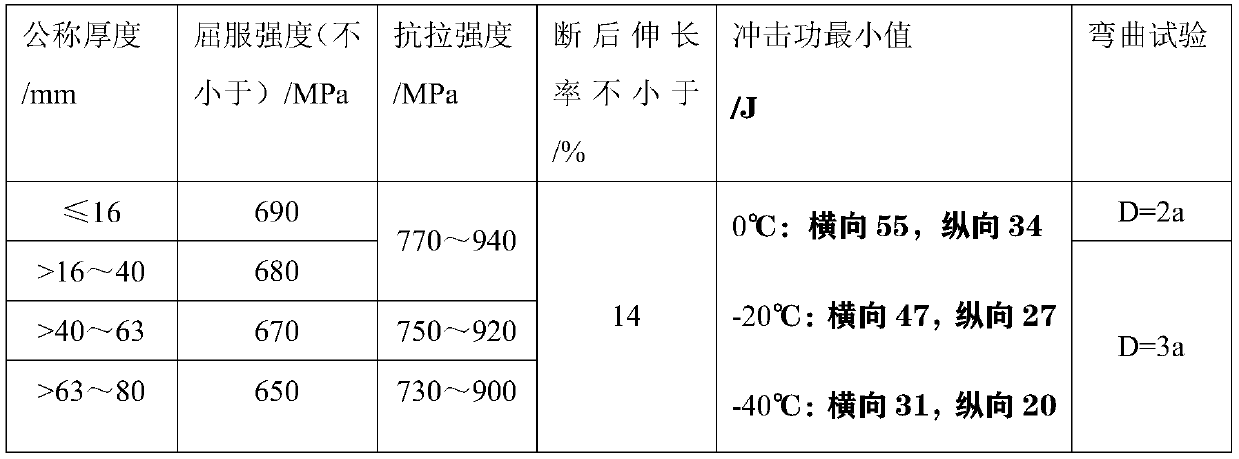

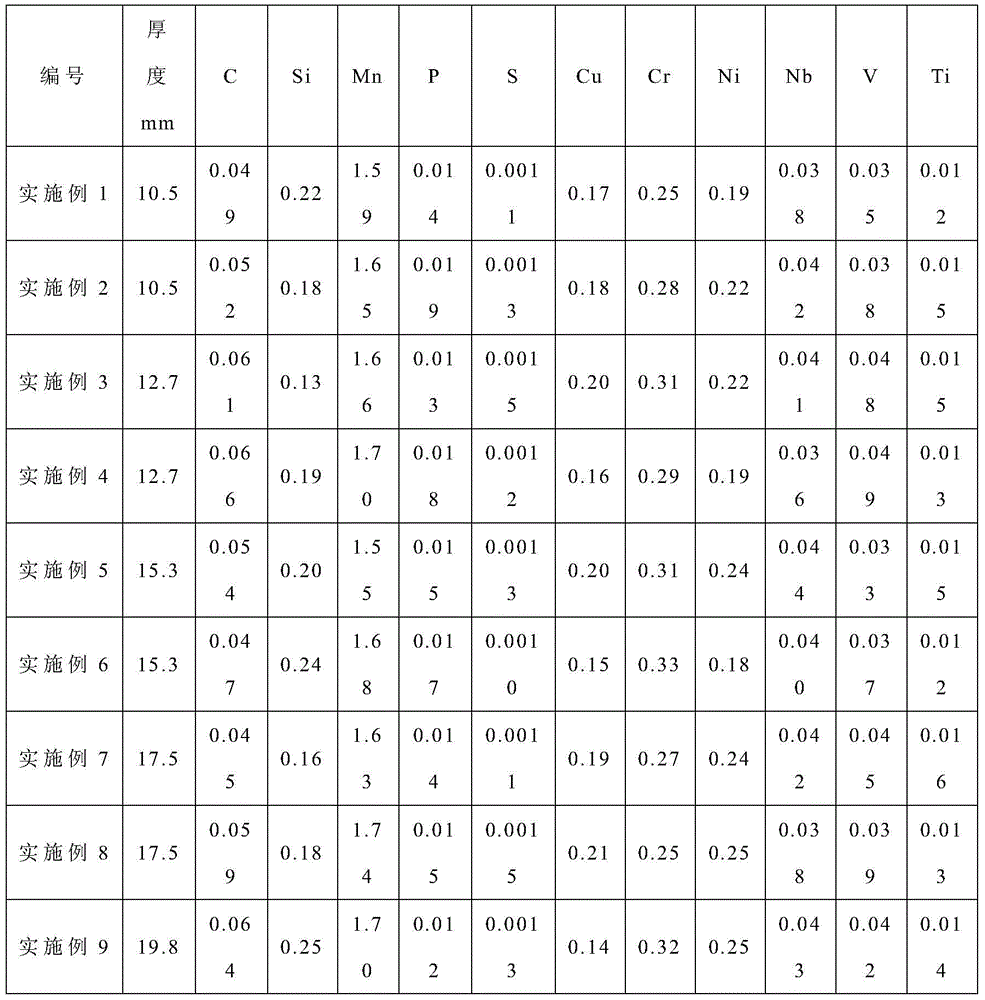

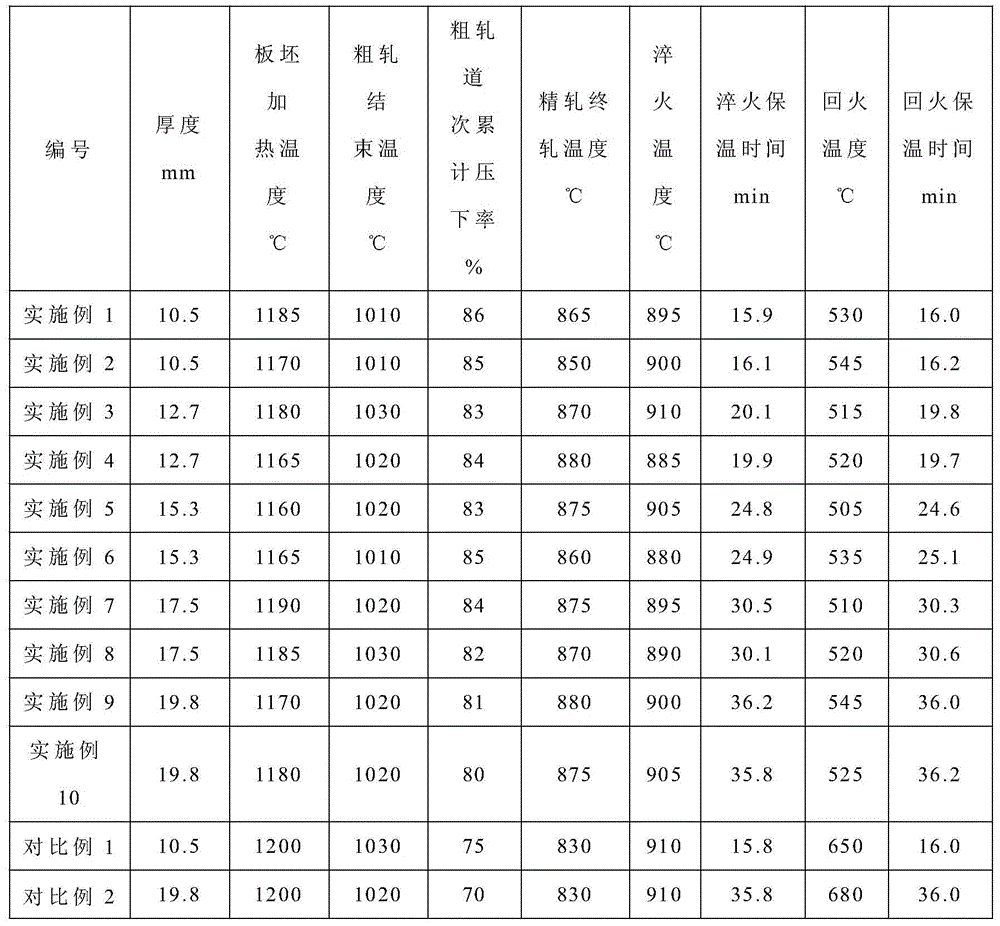

The invention discloses a high-toughness and low-yield-ratio quenched and tempered steel plate used in a low-temperature environment. The high-toughness and low-yield-ratio quenched and tempered steel plate comprises, by weight, 0.045-0.068% of C, 0.13-0.25% of Si, 1.55-1.74% of Mn, smaller than or equal to 0.020% of P, smaller than or equal to 0.0015% of S, 0.25-0.33% of Cr, 0.14-0.21% of Cu, 0.18-0.25% of Ni, 0.035-0.044% of Nb, 0.033-0.049% of V, 0.010-0.016% of Ti and the balance Fe and inevitable impurities. The invention further discloses a manufacturing method of the high-toughness and low-yield-ratio quenched and tempered steel plate used in the low-temperature environment. A proper number of alloy elements such as Cu, Cr and Ni are added to the steel plate on the basis of a low-C and high-Mn system, and Nb, V and Ti are adopted for microalloying. Due to a pass reduction schedule and an offline heat treatment regime in the hot rolling process are optimized, quenched and tempered type pipeline steel which is high in low-temperature-environment toughness and low in yield ratio and is used for a straight seam welded pipe is finally obtained.

Owner:武汉钢铁有限公司

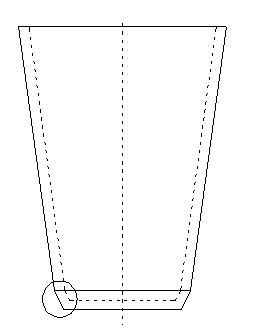

Wet process for building 3t intermediate frequency electric furnace

The invention relates to a wet process for building a 3t intermediate frequency electric furnace. By the process, 3t of materials can be melted, and the service life is prolonged. The process comprises the following steps of: (1) manufacturing a steel crucible die which has a shape of a truncated hollow cone; (2) paving an insulation layer and a thermal insulation layer by using two layers of asbestos cloth; (3) paving a furnace bottom, namely paving two layers of asbestos cloth at the furnace bottom in a staggered mode; (4) paving a furnace wall, namely paving two layers of asbestos cloth next to the inner wall of an induction coil from top to bottom, ensuring that each layer is flat and does not have any wrinkle, adhering longitudinal joints for lapping by using water glass, staggering joints of two adjacent layers, and adhering the asbestos cloth which stretches out of the upper plane to a fireproof brick plane at an upper opening of the furnace by using the water glass; (5) preparing a furnace lining material from refined quartz sand; (6) manually knotting a furnace lining, brushing a layer of water glass before filling, and tamping a filler; and (7) baking the furnace and sintering, namely baking only by using firewood after the furnace is built by the wet process, adding 50 to 60kg of firewood into a hearth for several times, and completely combusting to bake the furnace lining.

Owner:HANGZHOU ZHONGQIANG ROLLER

Laser smelting furnace with water cooled copper mould and method for smelting ingot

Owner:BEIHANG UNIV

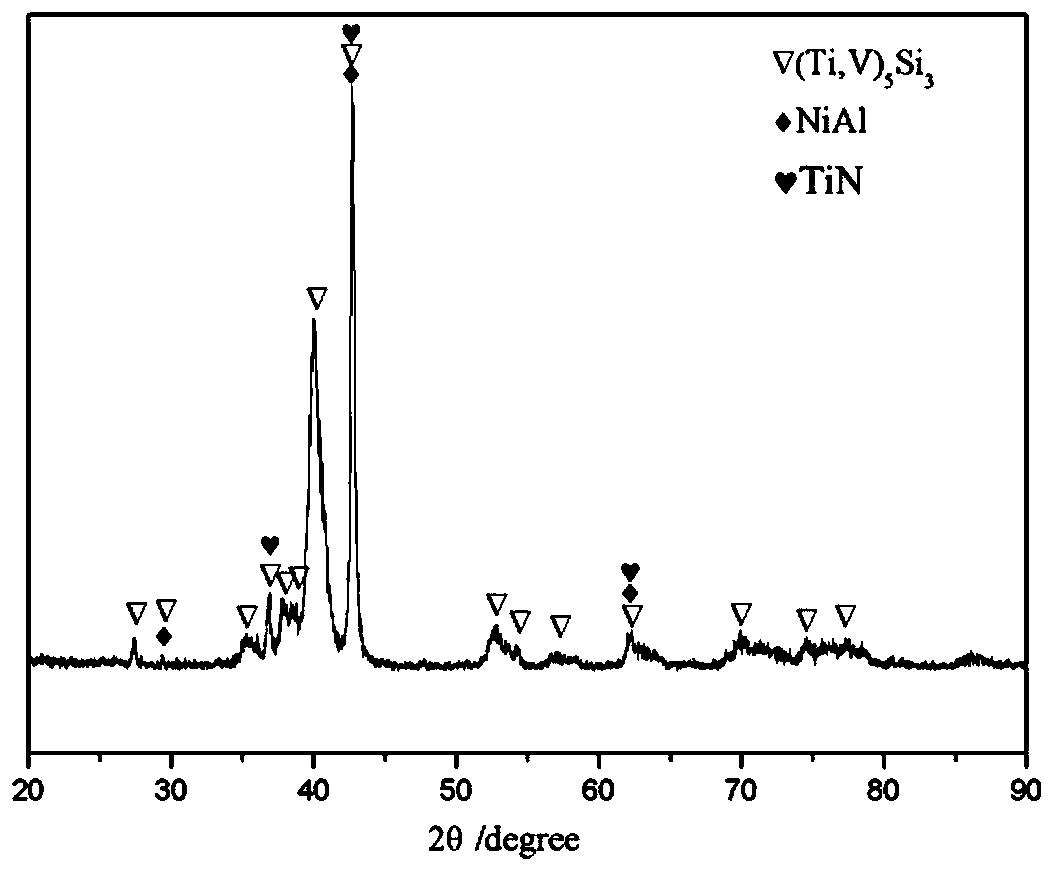

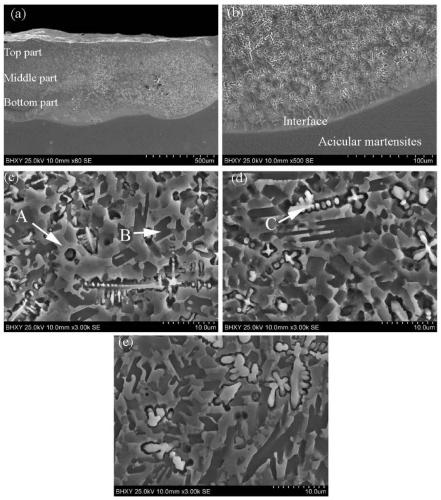

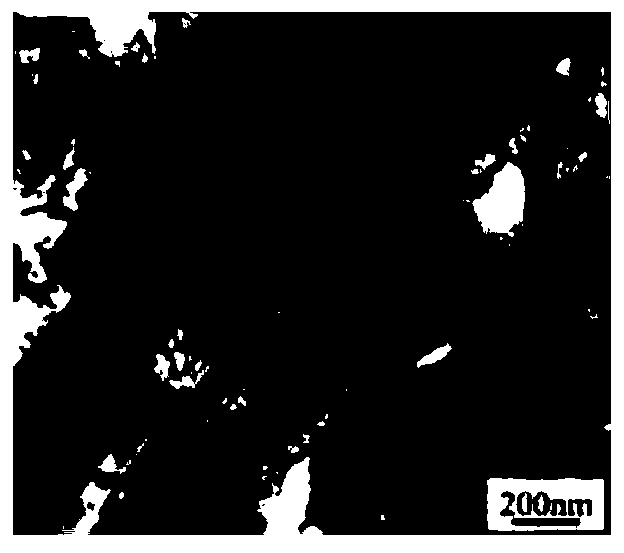

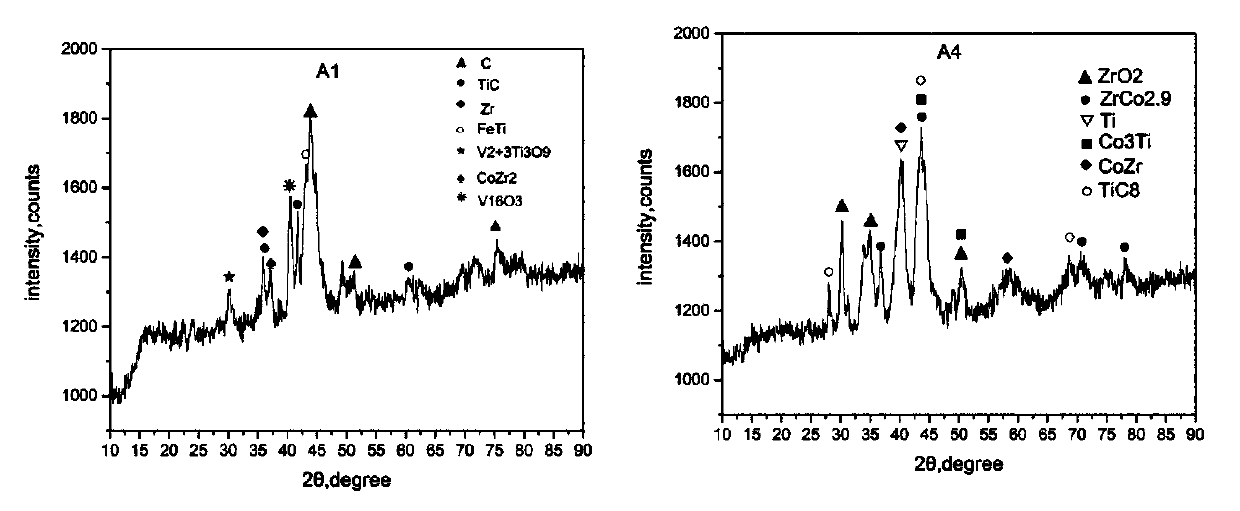

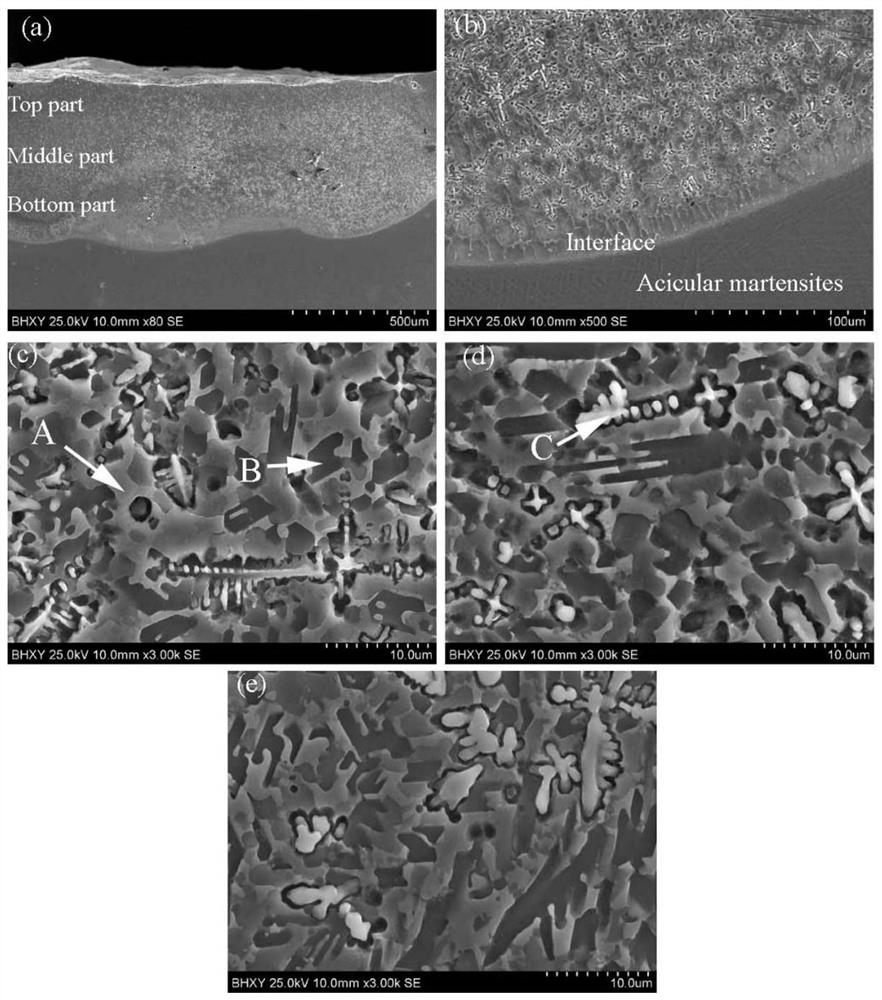

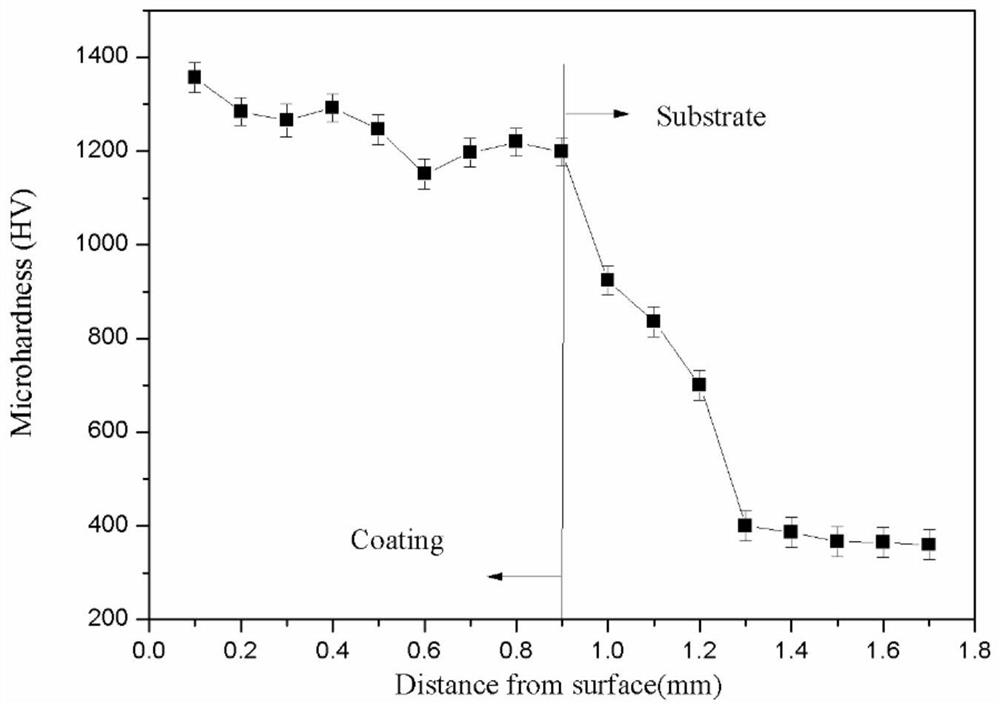

High-entropy alloy coating resistant to high-temperature abrasion and preparation process and application thereof

ActiveCN109763125AHigh hardnessImprove wear resistanceMetallic material coating processesHigh entropy alloysRare earth

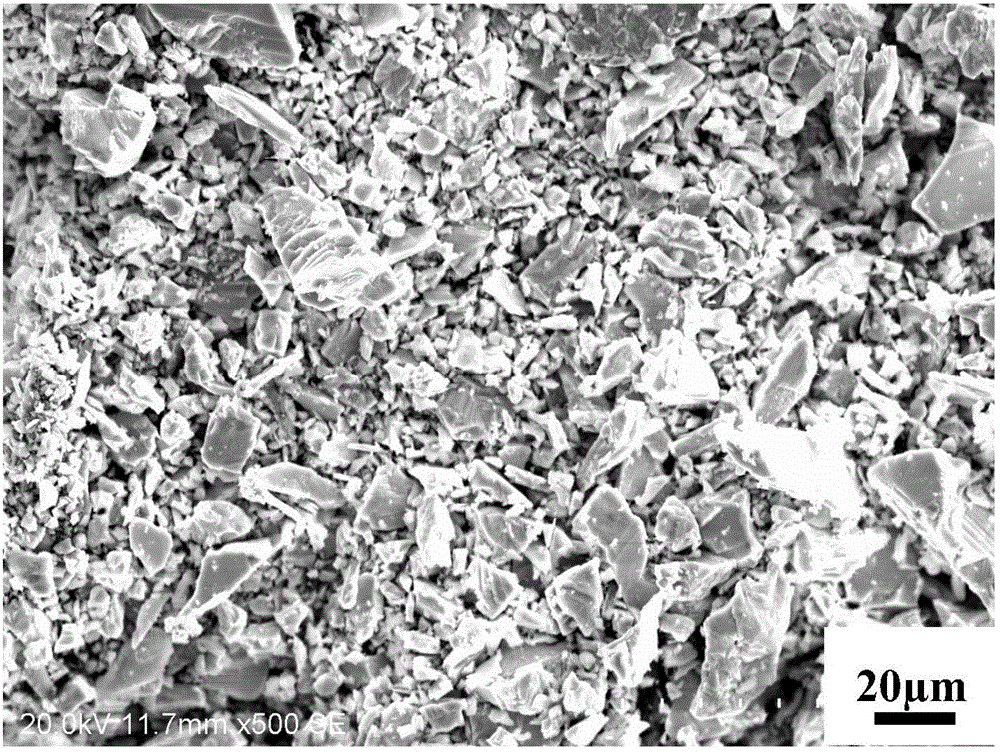

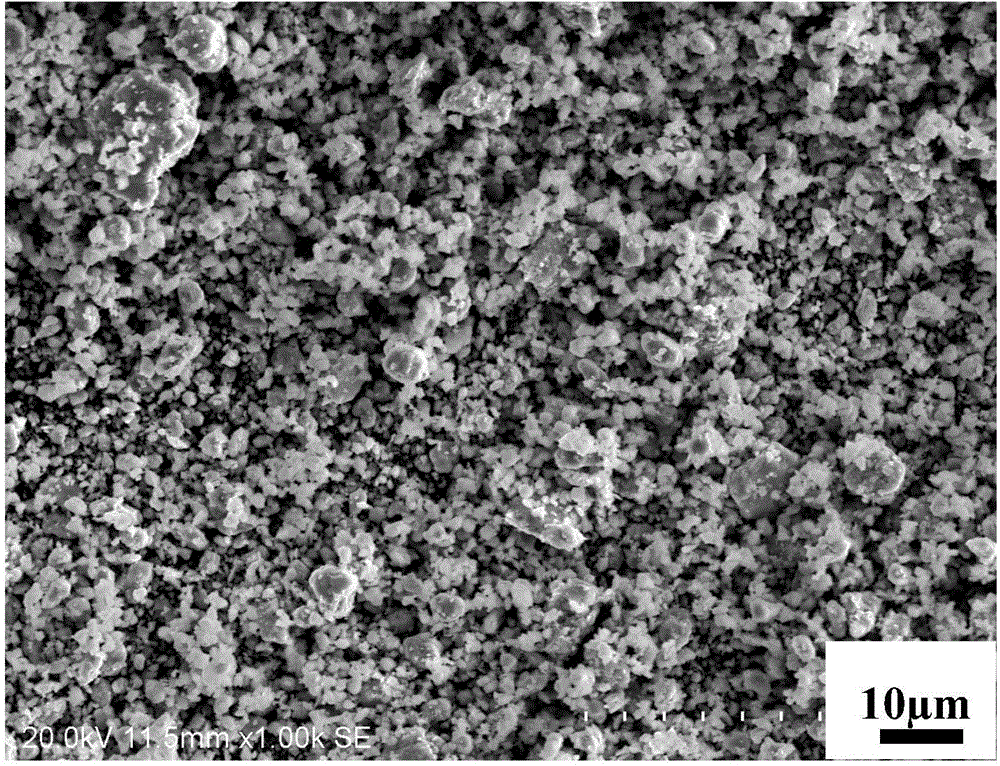

The invention relates to a high-entropy alloy coating resistant to high-temperature abrasion and a preparation process and application thereof. The preparation process comprises the following steps: (1) the surface of a titanium alloy sample is polished and washed; (2) metal powder, a ceramic hard phase and rare earth oxide are evenly mixed, and cladding material powder is formed to be flatly laidon the washed surface of a titanium alloy; and (3) the titanium alloy coating is prepared through laser cladding, wherein the metal powder includes Ti, Ni, Al, Si and V, a ceramic phase material is B4C or TiC or TiN, and the rare earth oxide is Y2O3. According to the high-entropy alloy coating, the hardness of a titanium alloy part can be remarkably improved, abrasion resistance of the titanium alloy part is improved, and the using range of the titanium alloy part is enlarged.

Owner:QINGDAO BINHAI UNIV

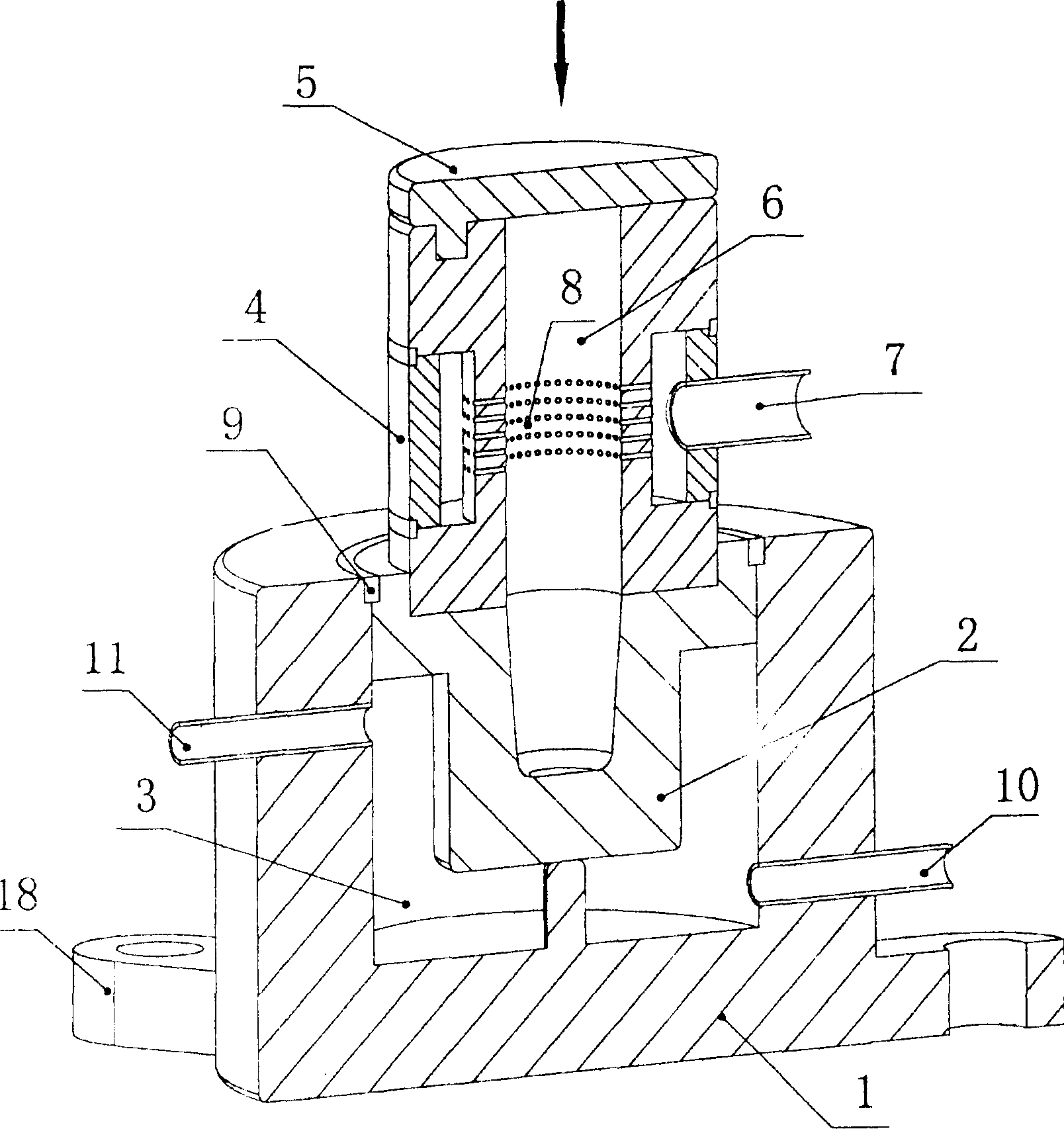

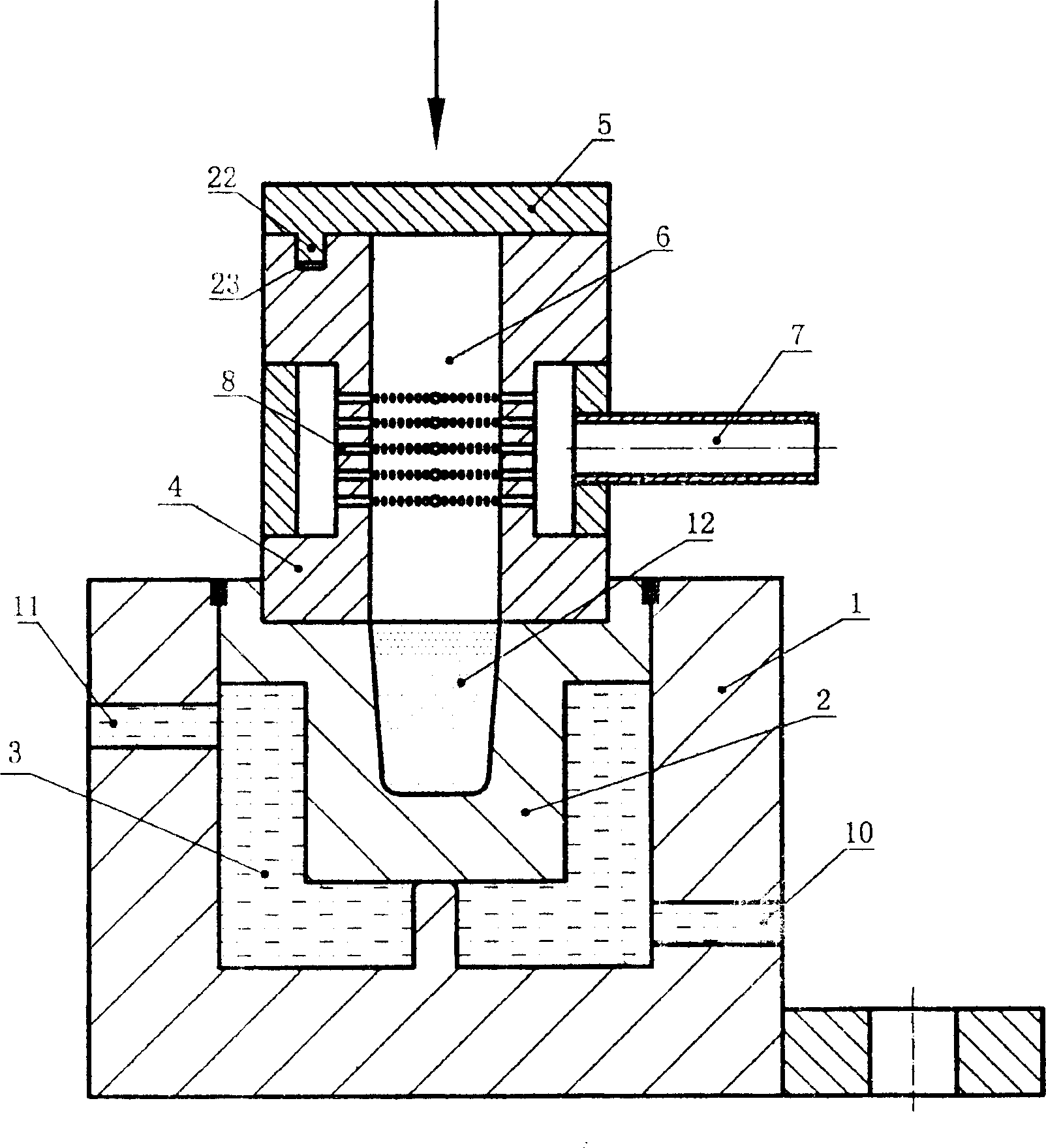

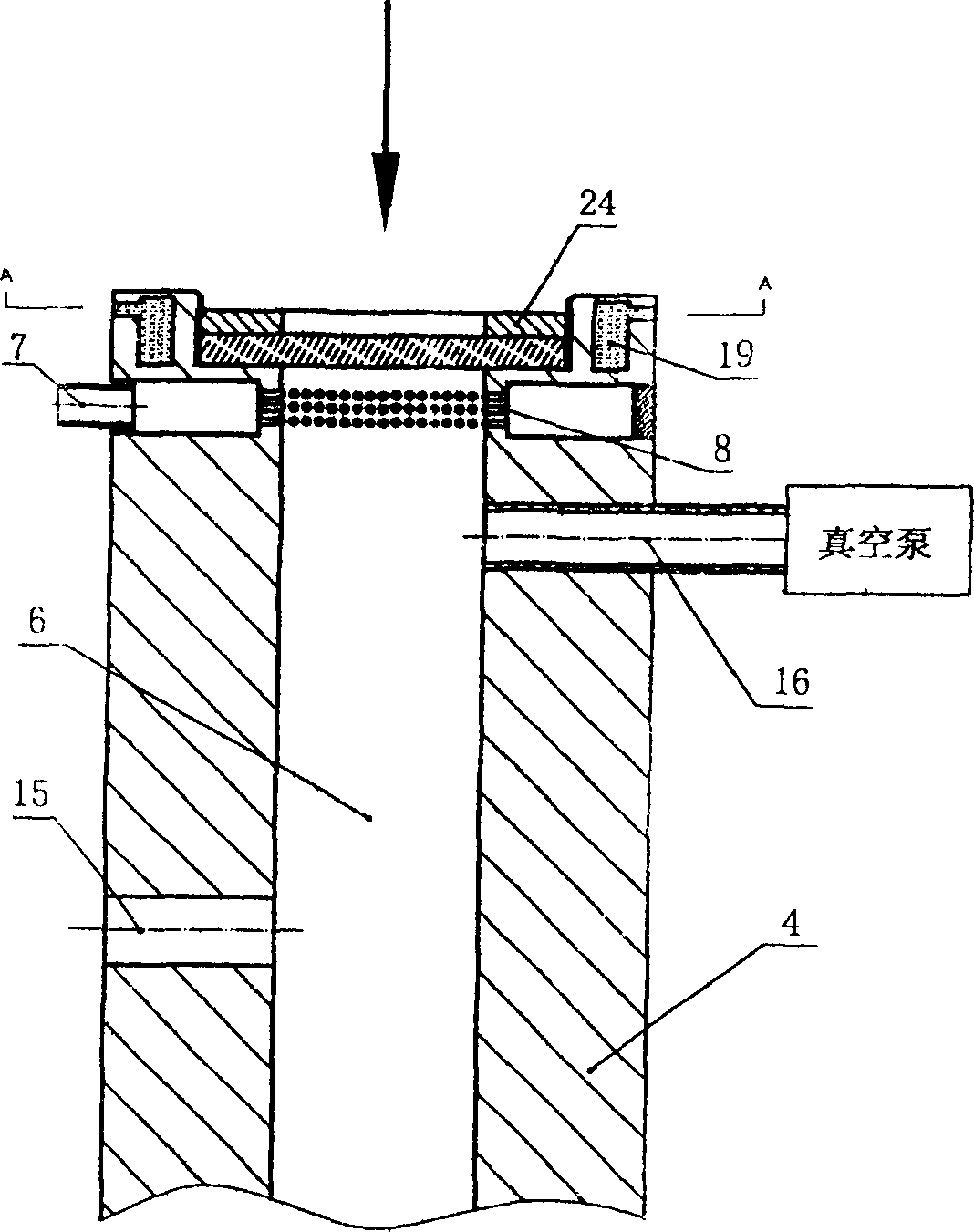

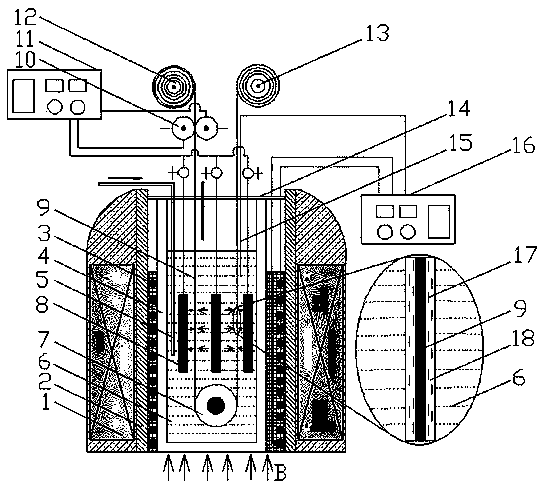

Method and device for preparing high-strength and high-conductivity copper-carbon nano-tube composite material under magnetic field

ActiveCN105696059ASave energyReliable production processElectrolytic coatingsMagnetohydrodynamicsContact resistance

The invention discloses a method and device for preparing a high-strength and high-conductivity copper-carbon nano-tube composite material under a magnetic field. A dispersing agent is added to enable a bilayer structure to be formed on a carbon nano-tube particle surface, an outer-layer dispersing agent polar end and a plating solution have the higher affinity, the wetting degree of carbon nano-tube particles by the plating solution is improved, and uniform dispersion distribution of the particles is facilitated; in the plating process, the exerted magnetic field and an electric field interact to generate the magnetohydrodynamic effect caused by Lorentz force, so that the mass transfer effect of the planting solution is enhanced, and the uniformity of the plating solution is improved; the nano-tube particles are stretched in the axial direction under the effect of the Lorentz force, and are orderly arranged in an orientation manner under the effect of the magnetic field; meanwhile, adhesive force between the composite electrodeposition nano-tube particles and a metal belt base plate is increased due to the effect of the magnetic field, and compactness and stability of a copper-carbon nano-tube composite plating layer are improved; and due to the fact that the phenomenon that copper ions are wrapped with a nano-tube exists, the contact resistance between the nano-tube and a metal base plate is reduced, and therefore the conductivity of the copper-carbon nano-tube composite material is effectively improved.

Owner:SHANGHAI UNIV

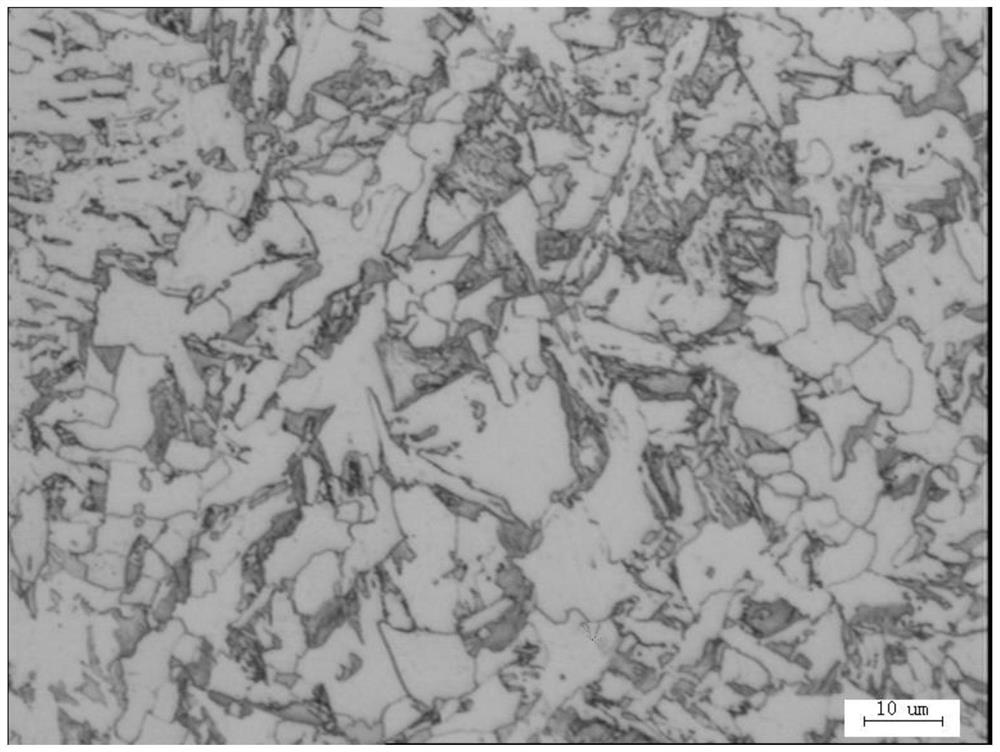

690 MPa grade high-strength low-yield-ratio medium-manganese steel medium-thickness steel and manufacturing method

The invention discloses 690 MPa grade high-strength low-yield-ratio medium-manganese steel medium-thickness steel and a manufacturing method, and relates to the technical field of steel smelting. Thesteel comprises the following chemical components of, in percentage by mass, 0.05%-0.10% of C, 4.1%-4.7% of Mn, 0.15%-0.4% of Si, less than or equal to 0.010% of P, less than or equal to 0.003% of S,0.01%-0.05% of Ti, less than or equal to 0.6% of Ni + Cr + Mo, and the balance Fe and inevitable impurities. The requirements of ultra-high strength steel safety performance and construction cost in acomplex environment in the field of engineering machinery can be met.

Owner:NANJING IRON & STEEL CO LTD

Novel Cr-Y-O nanocluster oxide dispersion strengthening reduced activation steel

ActiveCN105239010AImprove high temperature mechanical properties and high temperature structure stabilityReduce oxygen contentOxideNeutron irradiation

The invention aims to provide novel Cr-Y-O nanocluster oxide dispersion strengthening reduced activation steel applicable to a fusion reactor. According to the composition proportion of the oxide dispersion strengthening reduced activation steel, Fe serves as a substrate; C is larger than or equal to 0.04% and smaller than or equal to 0.14%; Cr is larger than or equal to 10.0% and smaller than or equal to 14.0%; W is larger than or equal to 1.1% and smaller than or equal to 1.50%; V is larger than or equal to 0.15% and smaller than or equal to 0.35%; Ta is larger than or equal to 0.03% and smaller than or equal to 0.19%; Mn is larger than or equal to 0.2% and smaller than or equal to 0.6%; Si is larger than or equal to 0.05% and smaller than or equal to 0.15%; Y is larger than or equal to 0.20% and smaller than or equal to 0.75%; a small quantity of impurities are unavoidably mixed in the manufacturing process. The contents of impurity elements and easily activating elements which can generate radionuclides after neutron irradiation are strictly controlled, wherein N is smaller than 0.010%; Al is smaller than 0.010%; Ni is smaller than 0.005%; Mo is smaller than 0.005%; Nb is smaller than 0.010%; Cu is smaller than 0.010%; P is smaller than 0.005%; S is smaller than 0.005%. The oxide dispersion strengthening reduced activation steel is uniform in structure, oxide nanocluster is in dispersion distribution, the excellent mechanical properties are achieved, and moreover the low activation property and the good irradiation swelling resistance are also achieved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

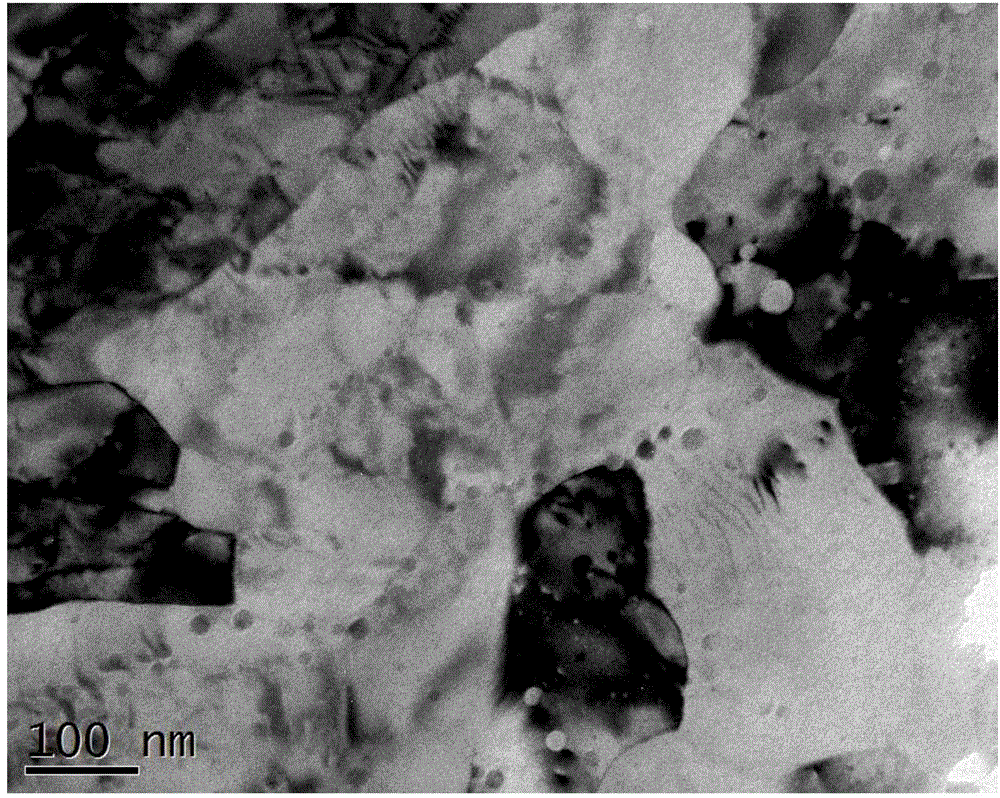

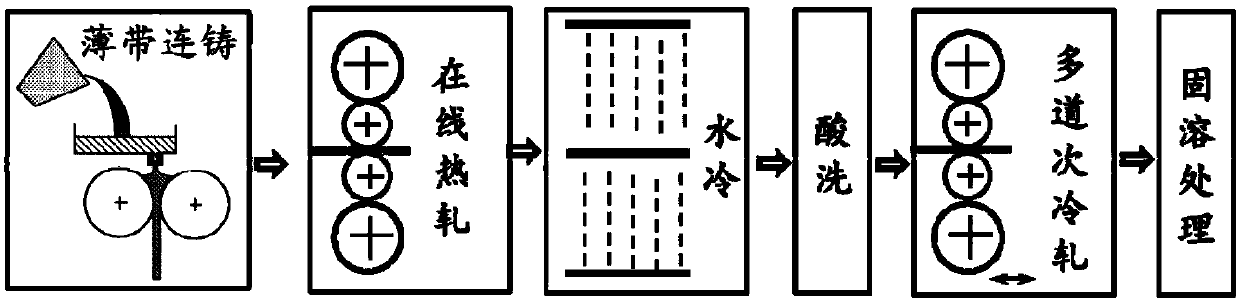

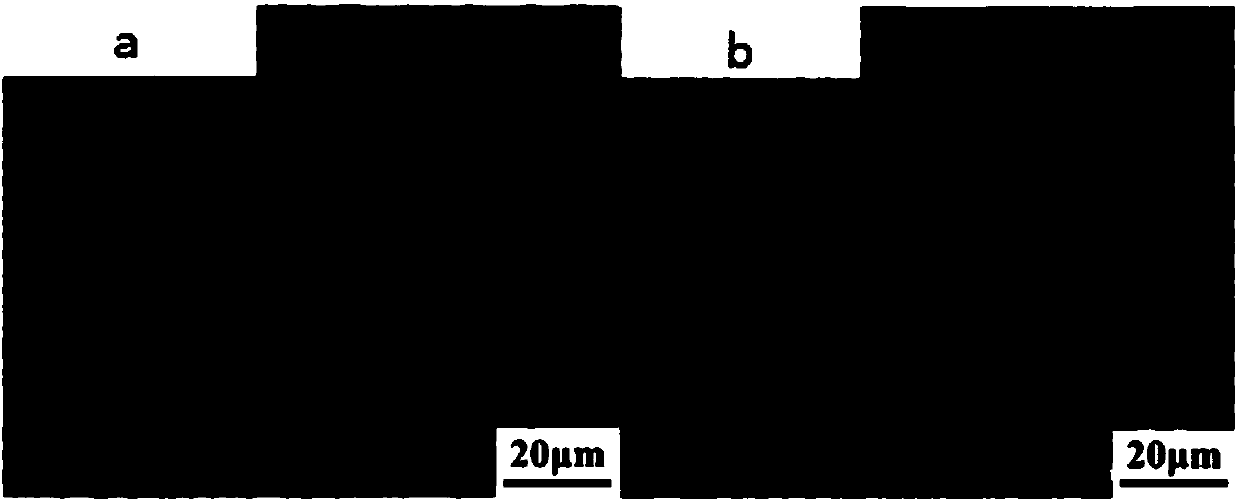

Near-net shaping preparation method of super double-phased stainless steel thin strip

The invention discloses a near-net shaping preparation method of a super double-phased stainless steel thin strip. The super double-phased stainless steel thin strip is composed of, by mass, 0-0.03% of C, 24-32% of Cr, 0.5-2.5% of Mn, 0.3-0.5% of N, 2-6% of Mo, 4-8% of Ni, and the balance Fe and other inevitable impurities. The preparation method comprises the following steps that (1) a thin stripbillet is obtained through smelting and thin strip continuous casting, and the smelting temperature is 1530-1570 DEG C; (2) online hot rolling is conducted, and the hot rolling rate is 20-30%; (3) acid pickling is conducted; (4) cold rolling is conducted and the cold rolling overall reduction is 60-85%; and (5) solution treatment is conducted. The obtained thin strip has the good mechanical performance and excellent corrosion resistance, and compared with a conventional process, the yield is greatly improved, and energy consumption is greatly reduced.

Owner:NORTHEASTERN UNIV

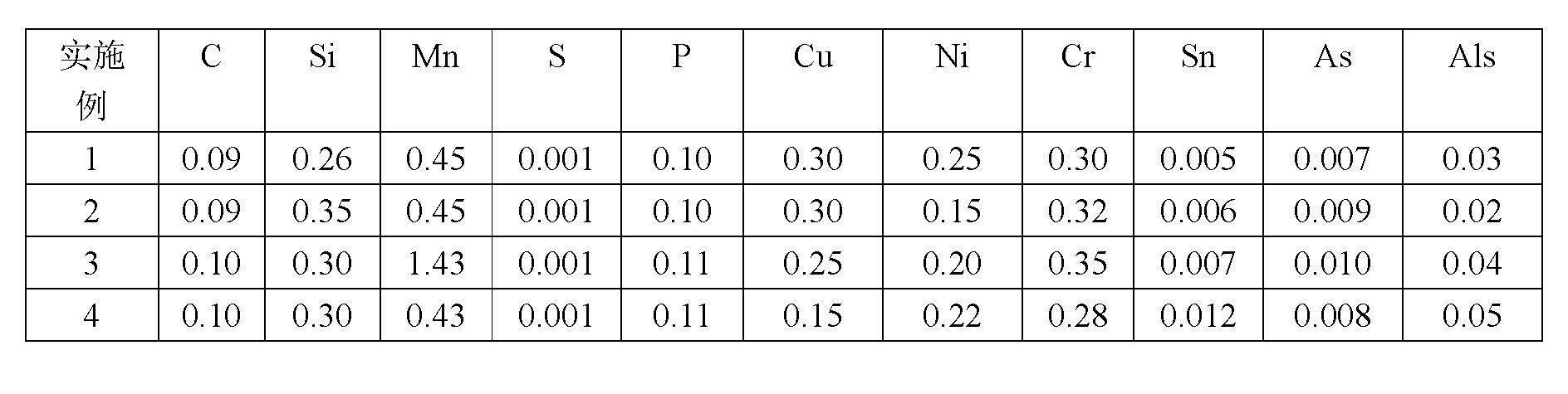

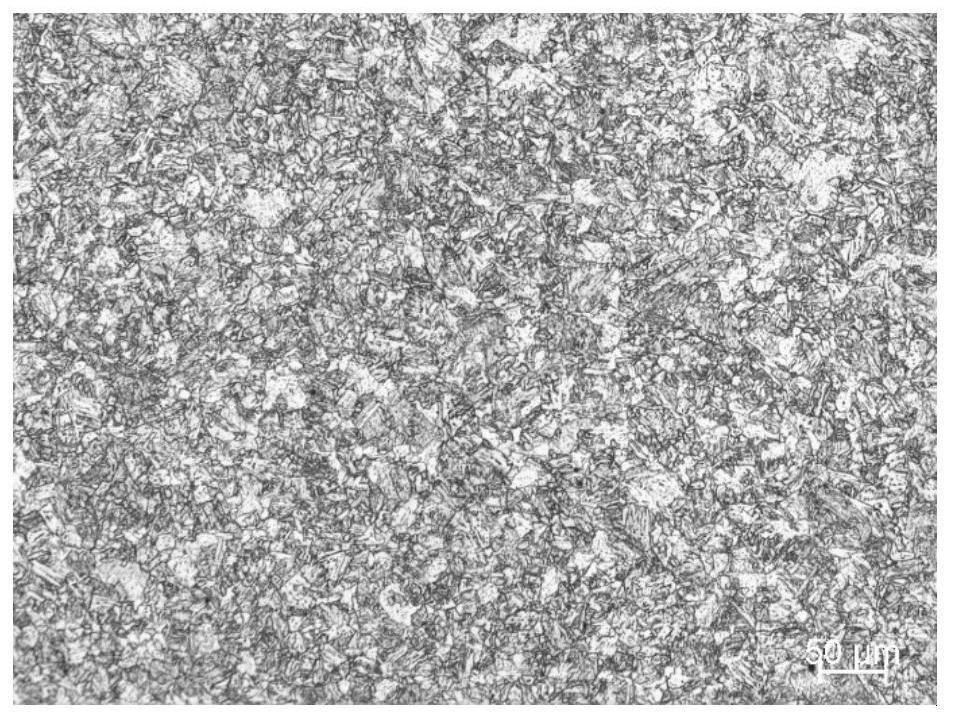

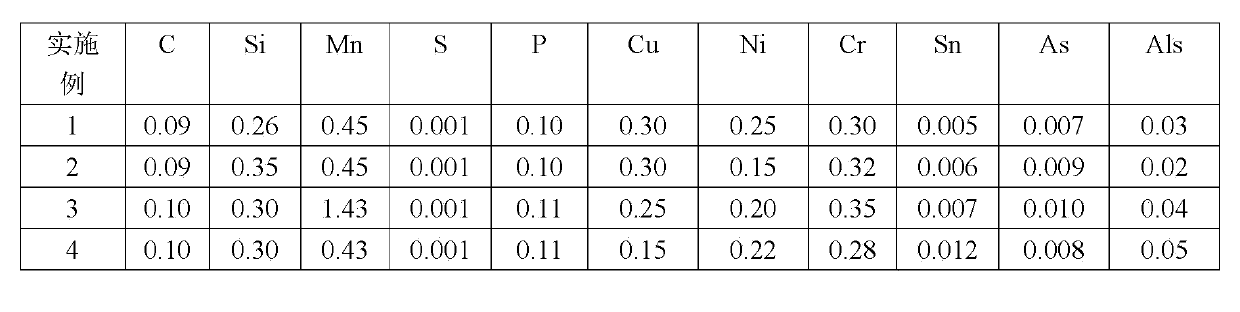

Hot rolling container steel without punctiform surface defect and manufacturing method thereof

The invention discloses hot rolling container steel without a punctiform surface defect, which is characterized in that the hot rolling container steel is manufactured from the following elements in percentage by weight: 0.05-0.20 of C, 0.05-1.00 of Si, 0.2-2.0 of Mn, 0.05-0.20 of P, 0.05-0.60 of Cu, 0.20-0.80 of Cr, 0-0.60 of Ni, no more than 0.010 of S, 0.015-0.060 of Als, no more than 0.020 percent of Sn, no more than 0.020 percent of As, and the remaining is iron and non-avoidable residue. The manufacturing method of the hot rolling container steel is as following: firstly, the raw material steel plate base of the hot rolling container steel is obtained by desulfurization, converting and blowing, and continuous casting of molten iron, and then heating, rough rolling after scaling, primary rolling, refine rolling, laminar flow cooling and coil treating are carried out on the raw material steel plate base. The problems that container steel generates punctiform and salix-leaf-shaped defects on the surface after being heated in a heating furnace for 180 minutes or after being heated in a normal heating condition for 60-180 minutes are solved by the manufacturing method disclosed by the invention.

Owner:武汉钢铁有限公司

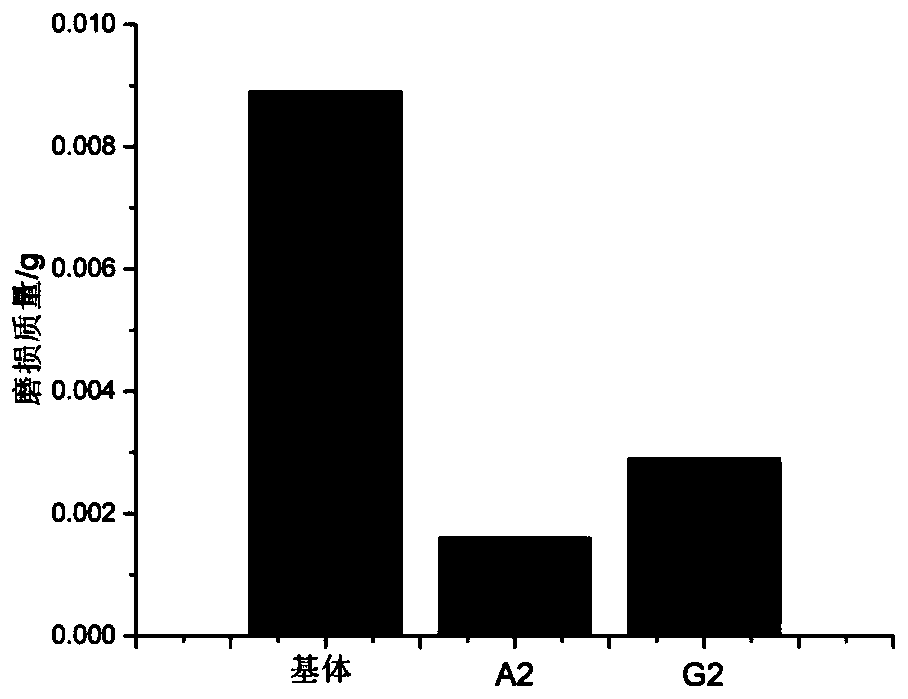

Ceramic-reinforced cobalt-based cladding material, cobalt-based cladding coating and preparation method thereof

PendingCN110846651AImprove wear resistanceHigh hardnessMetallic material coating processesBorideWear resistance

The invention discloses a cobalt-based cladding material, a cobalt-based cladding coating and a preparation method thereof. The cobalt-based cladding material is formed by mixing cobalt-based powder and ceramic material powder or cobalt-based powder, ceramic material powder and yttrium oxide powder, wherein the content of the ceramic material powder is 5%-45%, the content of the yttrium oxide powder is 0.5%-1.5%, the balance is the cobalt-based powder, and the ceramic material is zirconium nitride, zirconium carbide or zirconium boride. A matrix material is subjected to surface modification ina laser cladding mode, the hard phase in the ceramic powder is uniformly distributed, dispersion strengthening is formed, the hardness of the coating is improved, the wear resistance of the coating is improved, and the wear resistance can be improved to 5.56 times of the matrix. When the Y2O3 zirconium nitride, the zirconium carbide or the zirconium boride is matched for use, a cladding layer isfurther refined, the cladding layer is thickened, the homogenization degree is increased, the hardness is greatly improved, and the wear resistance of the surface of the cladding layer can be improvedto 8.09 times of the matrix.

Owner:SHANDONG AGRI & ENG UNIV +2

Acicular ferrite type high-strength steel bar and preparation method thereof

PendingCN114015848AStrong precipitation strengtheningReduce toughnessProcess efficiency improvementEarthquake resistanceReinforced concrete

The invention belongs to the technical field of hot-rolled ribbed steel bars for reinforced concrete structures, and particularly relates to an acicular ferrite type high-strength steel bar and a preparation method thereof. Steel in the steel bar comprises the following chemical components in percentage by weight: 0.25 to 0.35 percent of C, 0.40 to 0.80 percent of Si, 1.40 to 1.80 percent of Mn, less than or equal to 0.030 percent of P, less than or equal to 0.030 percent of S, 0.02 to 0.04 percent of Nb, 0.09 to 0.15 percent of V, 0.15 to 0.45 percent of Cr, 0.010 to 0.019 percent of N and the balance of Fe and inevitable impurity elements. Under the condition of existing process equipment of a production plant, the acicular ferrite type high-strength steel bar is prepared by adopting a high C, Si and Mn component design and a V and Nb combined microalloying mode and combining a rolling self-tempering process, the 700MPa-grade reinforcing steel bar with excellent comprehensive performance is produced on the premise of keeping material ductility, the yield strength of the 700MPa-grade reinforcing steel bar is greater than or equal to 700MPa, the tensile strength is greater than or equal to 830MPa, the percentage elongation after fracture is greater than or equal to 14%, the total elongation under the maximum force is greater than or equal to 9%, the anti-seismic performance is good, and the requirements of high-rise and large-span anti-seismic structures are met.

Owner:安徽吾兴新材料有限公司

High-strength container plate with excellent low-temperature toughness and manufacturing method

The invention discloses a high-strength container plate with excellent low-temperature toughness and a manufacturing method, and relates to the technical field of iron and steel production. The high-strength container plate is prepared from the chemical composition in percentage by mass: 0.07% to 0.11% of C, 0.10% to 0.30% of Si, 1.30% to 1.60% of Mn, 0.40% to 0.80% of Ni, 0.05% to 0.12% of Mo, 0.02% to 0.05% of V, 0.02% to 0.05% of Alt, less than or equal to 0.008% of P, less than or equal to 0.002% of S and the balance of Fe and avoidable impurities. The material strength is upgraded by adding a small amount of alloy, the alloy cost is low, accurate control is easily achieved, the use temperature is lower, the strength is further significantly improved, and the material consumption of tank construction can be reduced.

Owner:NANJING IRON & STEEL CO LTD

Bismuth-containing free-cutting pre-hardened plastic die steel and preparation method thereof

ActiveCN112030073AShorten the production cycleReduce processing costsMetal-working apparatusChemical compositionIngot

The invention discloses bismuth-containing free-cutting pre-hardened plastic die steel and a preparation method thereof. The die steel comprises the following chemical components of, in percentage bymass, 0.32%-0.40% of C, 0.15%-0.30% of Si, 1.50%-1.70% of Mn, 1.70%-2.00% of Cr, 0.85%-1.15% of Ni, 0.25%-0.40% of Mo, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.05%-0.10%of V, 0.05%-0.15% of Bi, and the balance Fe. The preparation method comprises the following steps that smelting and casting are performed into a cast ingot according to set chemical components, the cast ingot is subjected to high-temperature homogenization treatment into a forging stock, normalizing treatment is performed offline after forging to refine grains, and finally, quenched-tempered heattreatment is performed to obtain a uniform structure with the hardness of 32-48HRC. According to the bismuth-containing free-cutting pre-hardened plastic die steel, through reasonable chemical component design, the bismuth element is added to replace traditional free-cutting elements including sulfur and lead, and due to the fact that a sulfur content is controlled, reasonable forging and heat treatment processes are matched, the hot brittleness phenomenon and anisotropy caused by the sulfur element are avoided, meanwhile, the problems that the lead is harmful to human bodies and pollutes anenvironment are solved.

Owner:NORTHEASTERN UNIV

Welding wire for Al-Cu-Si-Mg alloy welding, and preparation method thereof

ActiveCN108788514AGood melting and casting performanceGood resistance to welding cracksWelding/cutting media/materialsSoldering mediaCrack resistanceAlloy

The invention relates to a welding wire for Al-Cu-Si-Mg alloy welding, and a preparation method thereof, and belongs to the technical field of metal connection. The welding wire provided by the invention has excellent casting wire performance, and is applicable for large-scale industrial production, and used for fusion welding of 2Al4 alloy; the welding crack resistance is high, and the normal temperature performance of a welding head is superior to the normal temperature performance of BJ-380A; the low-temperature performance is equivalent to the low-temperature performance of BJ-380, and theproblems of BJ-380A and BJ-380 welding wires are solved completely.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Wheel with high contact fatigue performance and production method thereof

InactiveCN113403538AEasy to segregateStrong dragRail-engaging wheelsFurnace typesContact fatigueHeat treating

The invention provides a wheel with high contact fatigue performance and a production method thereof. The wheel comprises the following components of 0.55%-0.65% of C, 0.15%-0.30% of Si, 0.40%-1.2% of Mn, 0.10%-0.25% of Cr, 0.02%-0.03% of Al, less than or equal to 0.010% of P, 0.020%-0.035% of S, 0.10%-0.20% of V, less than or equal to 10 ppm of T.O, less than or equal to 1.5 ppm of [H], 80-120 ppm of [N] and the balance Fe and inevitable impurity elements. Compared with the prior art, steel for the wheel with the high contact fatigue performance is produced by using specific components and a reasonable preparation method, and through a certain heat treatment process, it is ensured that the surface contact fatigue resistance of the prepared wheel is obviously improved.

Owner:MAANSHAN MAGANG JINXI RAIL TRANSPORT EQUIP

Hot delivery and hot charging production method of micro-alloyed steel

The invention provides a hot delivery and hot charging production method of micro-alloyed steel. The micro-alloyed steel comprises the component of Fe, and further comprises C, Si, Mn, P, S, Al, Nb, Ti, Cr, Mo, Ni, Cu, B, N, O, and unavoidable impurity elements, wherein O is less than or equal to 0.002%, Nb is less than or equal to 0.11%, Ti is 0.08%-0.020%, and Ti / N is greater than or equal to 3.4, B is 0.001%-0.004%. The hot delivery and hot charging technology comprises the following steps that (1)when a continuous casting slab is subjected to straightening, surface temperature is 850-950 DEG C, and when hot delivery and hot charging are carried out, the surface temperature is 500-850 DEG C; a casting blank is preferentially and directly sent and delivered by using a roller way, or after number spraying is carried out, the casting blank is lifted off a line, but not stacked, and then delivered onto a furnace after natural cooling; (2)and during the heating process, the temperature of a preheating section hearth is greater than the surface temperature of the casting blank when the casting blank is subjected to hot delivery and hot charging. The hot delivery and hot charging production method of the micro-alloyed steel effectively avoids the star shake of steel plate surface caused by hot delivery and hot charging at two phase regions of micro-alloyed steel continuous castingslab, so that the industrial production of the micro-alloyed steel by hot delivery and hot delivery is possible, the production cost is reduced, and the hot delivery and hot charging technology is simple.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Hot-rolled steel plate for submarine conveying pipe and preparation method thereof

ActiveCN111534748AHigh strengthLow yield ratioFurnace typesHeat treatment furnacesSubmarineMicrostructure

The invention relates to the technical field of metal material processing, in particular to a hot-rolled steel plate for a submarine conveying pipe and a preparation method thereof. The chemical components of the hot-rolled steel plate include 0.03-0.05% of C, 0.15-0.25% of Si, 1.40-1.60% of Mn, 0.02-0.04% of Al, 0.02-0.04% of Nb, 0.010-0.020% of Ti, 0.40-0.50% of Ni, 0.15-0.25% of Cr, 0.10-0.20%of Mo, 0.008% or less of P, 0.001% or less of S and the balance Fe and inevitable impurity elements. By innovating the chemical composition, the production process and the microstructure, the preparedhot-rolled steel plate has excellent mechanical properties and good welding performance, reduces the risk of deformation and fracture failure of the submarine conveying pipe under the influence of ocean waves, ocean currents, submarine earthquakes, faults and seabed collapse, and has good application prospects.

Owner:SHOUGANG CORPORATION

Hot rolling container steel without punctiform surface defect and manufacturing method thereof

The invention discloses hot rolling container steel without a punctiform surface defect, which is characterized in that the hot rolling container steel is manufactured from the following elements in percentage by weight: 0.05-0.20 of C, 0.05-1.00 of Si, 0.2-2.0 of Mn, 0.05-0.20 of P, 0.05-0.60 of Cu, 0.20-0.80 of Cr, 0-0.60 of Ni, no more than 0.010 of S, 0.015-0.060 of Als, no more than 0.020 percent of Sn, no more than 0.020 percent of As, and the remaining is iron and non-avoidable residue. The manufacturing method of the hot rolling container steel is as following: firstly, the raw material steel plate base of the hot rolling container steel is obtained by desulfurization, converting and blowing, and continuous casting of molten iron, and then heating, rough rolling after scaling, primary rolling, refine rolling, laminar flow cooling and coil treating are carried out on the raw material steel plate base. The problems that container steel generates punctiform and salix-leaf-shaped defects on the surface after being heated in a heating furnace for 180 minutes or after being heated in a normal heating condition for 60-180 minutes are solved by the manufacturing method disclosed by the invention.

Owner:武汉钢铁有限公司

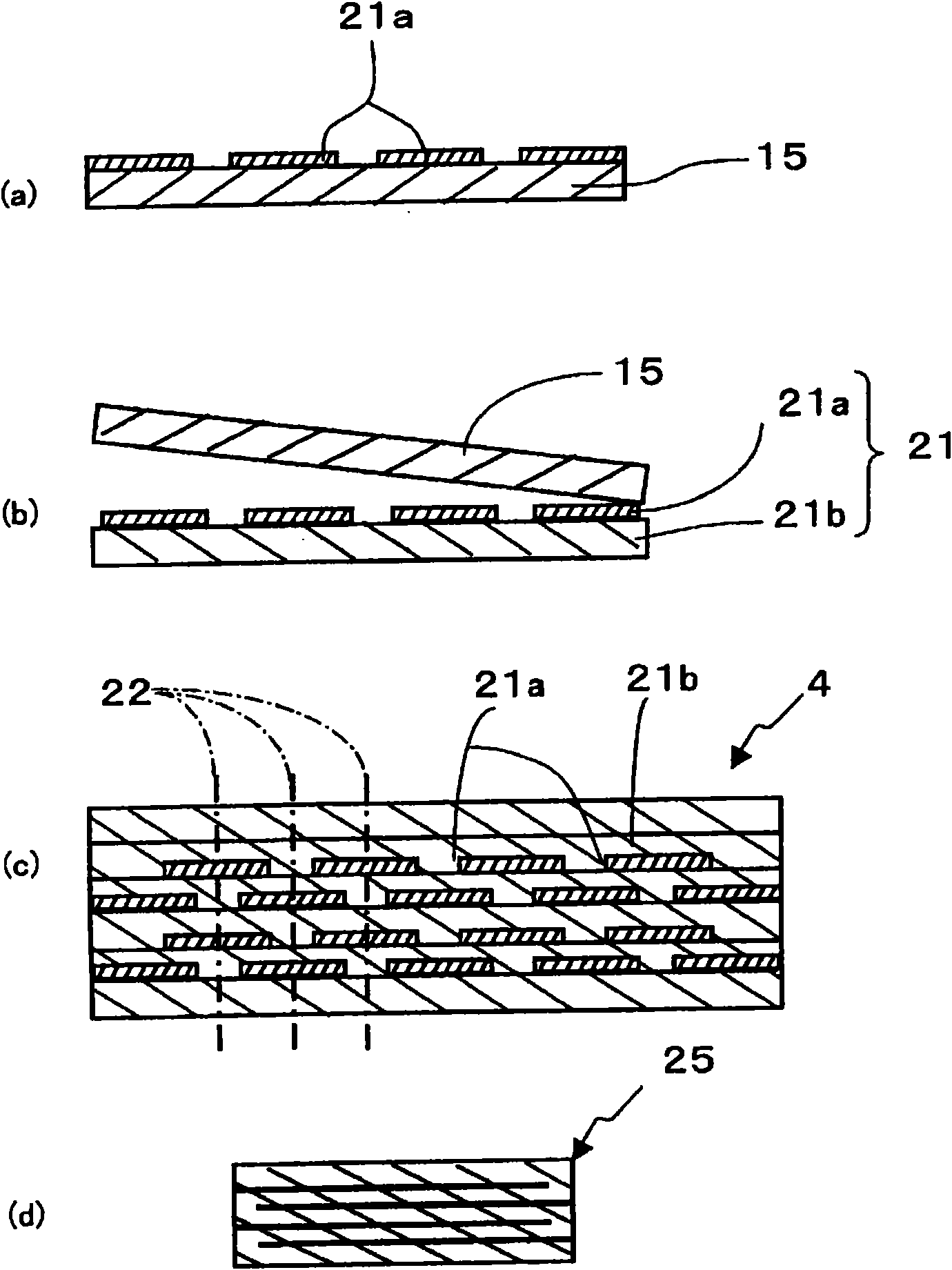

Metal films, methods for production thereof, methods for production of laminated electronic components, and laminated electronic components

InactiveCN101688321AHigh melting pointInhibition of contractionFixed capacitor electrodesFixed capacitor dielectricElectrical conductorElectronic component

A metal film containing Ni as a main component and Mn and at least one element selected from the group consisting of the elements of Groups 3A, to 6A of the periodic table includes a central part anda peripheral part in which Mn and the element selected from the group consisting of the elements of Groups 3A to 6A of the periodic table are present in a concentration higher in the peripheral part than that in the central part. The metal film used as a conductor layer can have an increased melting point at the peripheral part and thus can be prevented from shrinking during heating. The metal film used as a conductor layer in electronic components and the like can be prevented from plastically deforming or shrinking during heating so that the conductor layer can have a large effective area and high adhesion to ceramic layers.

Owner:KYOCERA CORP

A high-entropy alloy coating resistant to high temperature wear and its preparation process and application

ActiveCN109763125BHigh hardnessImprove wear resistanceMetallic material coating processesHigh entropy alloysAlloy coating

Owner:QINGDAO BINHAI UNIV

Engineering steel material with excellent core low-temperature impact toughness and lamellar tearing resisting performance and production method thereof

ActiveCN102268615BImprove toughnessGood lamellar tear resistanceProcess efficiency improvementManganeseOxygen

The invention relates to a production method of an engineering steel material with excellent core low-temperature impact toughness and lamellar tearing resisting performance. The engineering steel material comprises the following main components in percentage by weight: 0.030-0.010 percent of carbon, 1.20-1.60 percent of manganese, 0.10-0.35 percent of silicon, 0.015-0.03 percent of niobium, 0.005-0.020 percent of titanium, 0.020-0.040 percent of total aluminum, and not less than 0.10 percent of calcium / total aluminum; the engineering steel material also comprises the following residual components in percentage by weight: not more than 0.006 percent of nitrogen, not more than 0.004 percent of oxygen, not more than 0.015 of phosphorus, not more than 0.006 percent of sulfur, not more than 0.04 percent of arsenic, not more than 0.03 percent of stannum and not more than 0.02 percent of antimony; and except the main components and the residual components, the balance is ferrum. According to the engineering steel material and the production method provided by the invention, without adding nickel, vanadium and other expensive alloying elements and without adopting offline quenching and tempering treatment and other expensive equipment, the steel material with the yield strength of not less than 420 Megapascal and the excellent core toughness and lamellar tearing resisting performance can be obtained by only adopting a niobium and titanium micro-alloyed low carbon-manganese-niobium-titanium component system and fitting with an online quenching and tempering process.

Owner:SHAOGUAN IRON & STEEL GROUP CORP GUANGDONG PROV +1

Preparation method and device of high-strength and high-conductivity copper-carbon nanotube composite material under magnetic field

ActiveCN105696059BSave energyReliable production processElectrolytic coatingsCarbon nanotubeContact resistance

The invention discloses a method and device for preparing a high-strength and high-conductivity copper-carbon nano-tube composite material under a magnetic field. A dispersing agent is added to enable a bilayer structure to be formed on a carbon nano-tube particle surface, an outer-layer dispersing agent polar end and a plating solution have the higher affinity, the wetting degree of carbon nano-tube particles by the plating solution is improved, and uniform dispersion distribution of the particles is facilitated; in the plating process, the exerted magnetic field and an electric field interact to generate the magnetohydrodynamic effect caused by Lorentz force, so that the mass transfer effect of the planting solution is enhanced, and the uniformity of the plating solution is improved; the nano-tube particles are stretched in the axial direction under the effect of the Lorentz force, and are orderly arranged in an orientation manner under the effect of the magnetic field; meanwhile, adhesive force between the composite electrodeposition nano-tube particles and a metal belt base plate is increased due to the effect of the magnetic field, and compactness and stability of a copper-carbon nano-tube composite plating layer are improved; and due to the fact that the phenomenon that copper ions are wrapped with a nano-tube exists, the contact resistance between the nano-tube and a metal base plate is reduced, and therefore the conductivity of the copper-carbon nano-tube composite material is effectively improved.

Owner:SHANGHAI UNIV

A kind of welding wire for al-cu-si-mg alloy welding and preparation method thereof

ActiveCN108788514BGood melting and casting performanceGood resistance to welding cracksWelding/cutting media/materialsSoldering mediaAlloyFusion welding

The invention relates to a welding wire used for Al-Cu-Si-Mg alloy welding and a preparation method thereof, belonging to the technical field of metal connection. The welding wire of the present invention has good melting and casting performance, is suitable for large-scale industrial production, is used for fusion welding of 2A14 alloy, and has good resistance to welding cracks. Quite completely solved the problems of BJ‑380A and BJ‑380 welding wire.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

A kind of production method of micro-alloyed steel that can be hot-transported and hot-charged

The invention provides a hot delivery and hot charging production method of micro-alloyed steel. The micro-alloyed steel comprises the component of Fe, and further comprises C, Si, Mn, P, S, Al, Nb, Ti, Cr, Mo, Ni, Cu, B, N, O, and unavoidable impurity elements, wherein O is less than or equal to 0.002%, Nb is less than or equal to 0.11%, Ti is 0.08%-0.020%, and Ti / N is greater than or equal to 3.4, B is 0.001%-0.004%. The hot delivery and hot charging technology comprises the following steps that (1)when a continuous casting slab is subjected to straightening, surface temperature is 850-950 DEG C, and when hot delivery and hot charging are carried out, the surface temperature is 500-850 DEG C; a casting blank is preferentially and directly sent and delivered by using a roller way, or after number spraying is carried out, the casting blank is lifted off a line, but not stacked, and then delivered onto a furnace after natural cooling; (2)and during the heating process, the temperature of a preheating section hearth is greater than the surface temperature of the casting blank when the casting blank is subjected to hot delivery and hot charging. The hot delivery and hot charging production method of the micro-alloyed steel effectively avoids the star shake of steel plate surface caused by hot delivery and hot charging at two phase regions of micro-alloyed steel continuous castingslab, so that the industrial production of the micro-alloyed steel by hot delivery and hot delivery is possible, the production cost is reduced, and the hot delivery and hot charging technology is simple.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

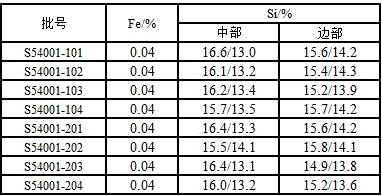

A kind of high-purity alsi14a alloy and its preparation process

The invention discloses a preparation technique of high-purity AlSi14A alloy. Raw materials are composed of 4N pure aluminum ingots, 4N pure aluminum liquid and industrial silicon. The preparation technique comprises the steps that firstly, 60% of the 4N pure aluminum ingots are added in proportion, heated and melted; then the industrial silicon is laid on the surface of aluminum melt; after the silicon is completely melted, 40% of the 4N pure aluminum liquid is laid on the surface of the industrial silicon, and the effect that the industrial silicon is sufficiently melted is guaranteed; then sufficient stirring is conducted; after sufficient stirring is conducted, a refining agent is added, refining is conducted when the temperature is controlled to be 710-730 DEG C, after refining is finished, molten slag on the surface is cleaned away, and standing is conducted; and refining alloy liquid is cast. By the adoption of the preparation technique, a traditional raw material adding mode is changed, a part of the 4N pure aluminum ingots are firstly added, heated and melted in the raw material adding process, and after the temperature of the melt reaches 800 DEG C, the industrial silicon is laid on the surface of aluminum melt; then another part of the 4N pure aluminum liquid is laid on the surface of the industrial silicon, the effect that the industrial silicon is sufficiently melted is guaranteed, and the uniformity of Si is guaranteed.

Owner:石河子众和新材料有限公司

High-purity AlSi14A alloy and preparation technique thereof

The invention discloses a preparation technique of high-purity AlSi14A alloy. Raw materials are composed of 4N pure aluminum ingots, 4N pure aluminum liquid and industrial silicon. The preparation technique comprises the steps that firstly, 60% of the 4N pure aluminum ingots are added in proportion, heated and melted; then the industrial silicon is laid on the surface of aluminum melt; after the silicon is completely melted, 40% of the 4N pure aluminum liquid is laid on the surface of the industrial silicon, and the effect that the industrial silicon is sufficiently melted is guaranteed; then sufficient stirring is conducted; after sufficient stirring is conducted, a refining agent is added, refining is conducted when the temperature is controlled to be 710-730 DEG C, after refining is finished, molten slag on the surface is cleaned away, and standing is conducted; and refining alloy liquid is cast. By the adoption of the preparation technique, a traditional raw material adding mode is changed, a part of the 4N pure aluminum ingots are firstly added, heated and melted in the raw material adding process, and after the temperature of the melt reaches 800 DEG C, the industrial silicon is laid on the surface of aluminum melt; then another part of the 4N pure aluminum liquid is laid on the surface of the industrial silicon, the effect that the industrial silicon is sufficiently melted is guaranteed, and the uniformity of Si is guaranteed.

Owner:石河子众和新材料有限公司

A kind of bismuth-containing free-cutting pre-hardened plastic mold steel and its preparation method

ActiveCN112030073BDoes not affect isotropyReduce wearMetal-working apparatusChemical compositionTempering

The invention discloses a bismuth-containing free-cutting pre-hardened plastic mold steel and a preparation method thereof. The chemical composition of the mold steel is as follows according to mass percentage: C: 0.32-0.40%, Si: 0.15-0.30%, Mn: 1.50-1.70 %, Cr: 1.70~2.00%, Ni: 0.85~1.15%, Mo: 0.25~0.40%, P≤0.015%, S≤0.005%, V: 0.05~0.10%, Bi: 0.05~0.15%, and the balance is Fe; its preparation method includes: smelting and casting into ingots according to the set chemical composition, forging the ingots into forging billets after high-temperature homogenization treatment, performing offline normalizing treatment to refine grains after forging, and finally undergoing quenching and tempering heat treatment, A uniform structure with a hardness of 32-48HRC is obtained. The bismuth-containing easy-cutting pre-hardened plastic mold steel of the present invention, through reasonable chemical composition design, adds bismuth element to replace the traditional easy-cutting elements sulfur and lead. It solves the thermal embrittlement phenomenon and the anisotropy caused by sulfur, and at the same time solves the problem that lead is harmful to the human body and pollutes the environment.

Owner:NORTHEASTERN UNIV LIAONING

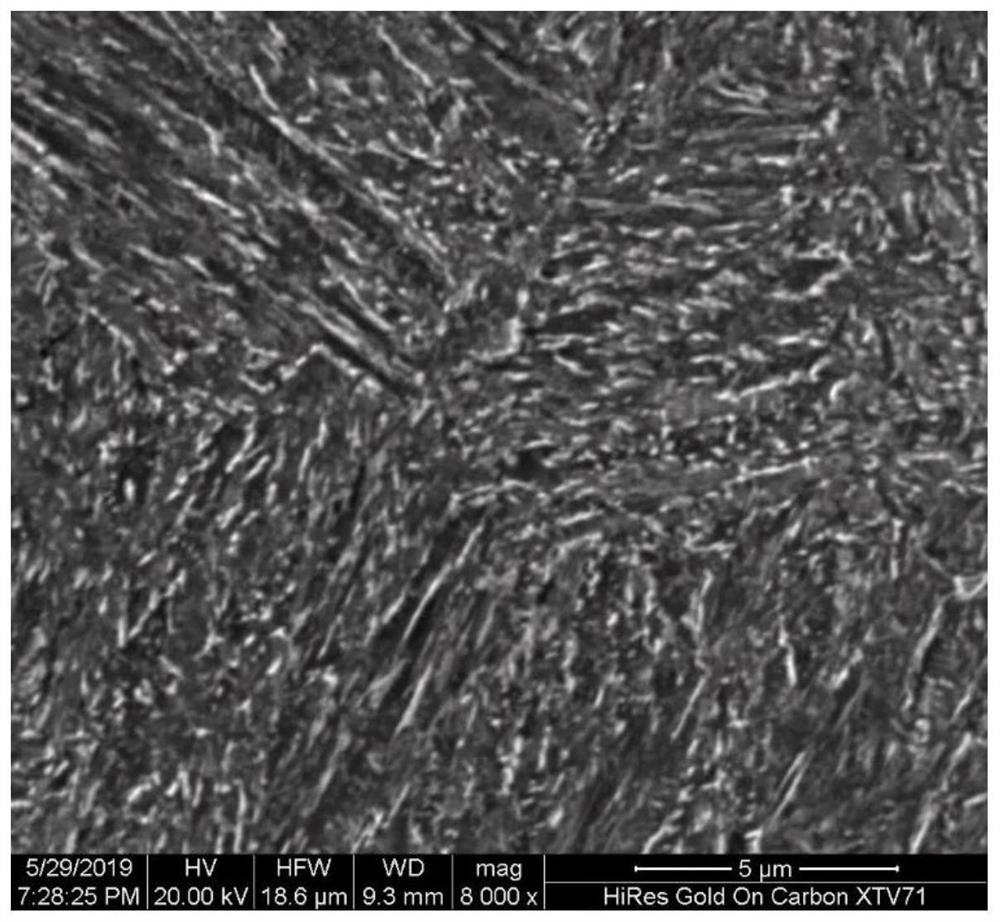

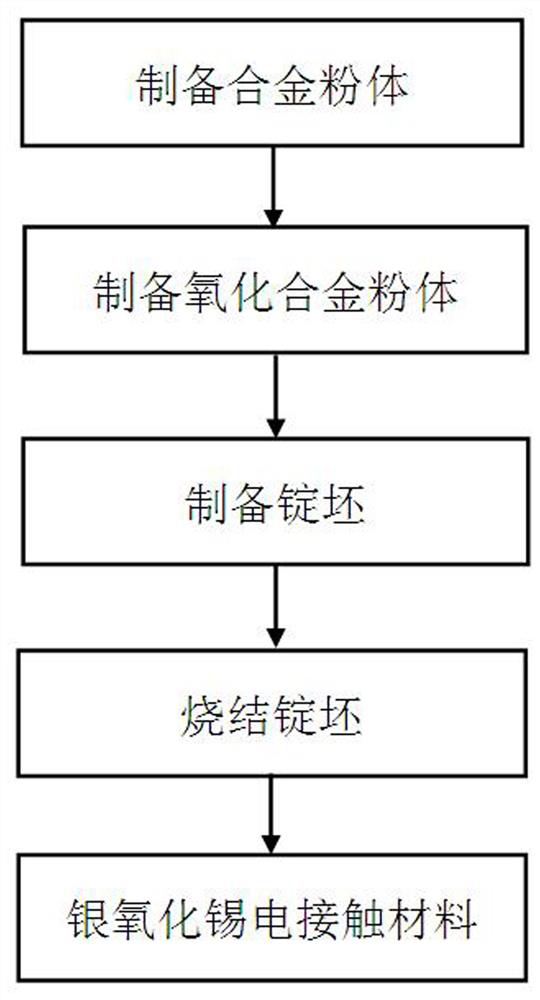

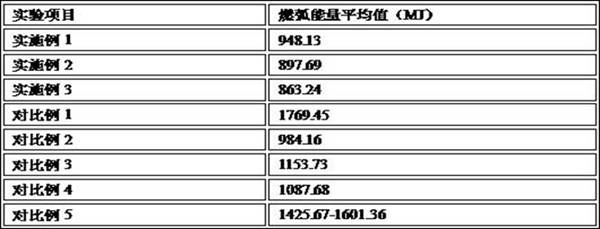

A kind of preparation method of silver tin oxide electrical contact material

ActiveCN111961910BLow arc energyArc energy is smallChemical industryContactsMicrowave ovenMetallurgy

The invention discloses a preparation method of a silver tin oxide electrical contact material, which comprises the following steps: (1) putting raw materials into a smelting furnace for smelting, and atomizing with water to obtain alloy powder; (2) putting the alloy powder into Drying in a microwave oven, and then oxidizing the alloy powder in a microwave oven to obtain an oxidized alloy powder; (3) The oxidized alloy powder is made into an ingot; (4) The ingot is sintered in an oxygen pressure atmosphere to obtain a sintered ingot (5) The sintered ingot is pressed into wire, the wire is used for cold heading rivet contact, the sheet is rolled and punched to produce sheet contact, and silver tin oxide electrical contact material is obtained. The silver tin oxide electrical contact material prepared by the invention has low arc energy, long electrical life, simple designed process route, high material utilization rate and short production cycle, is suitable for large-scale production, and can be vigorously popularized and applied.

Owner:浙江耐迩合金科技有限公司

Belt pressing device of coiling machine

The invention provides a belt pressing device of a coiling machine. The belt pressing device of the coiling machine comprises a mounting base, and a fixed belt pressing rack and a belt coiling mechanism, which are arranged on the mounting base, wherein the fixed belt pressing rack is arranged behind the belt coiling mechanism, a movable belt pressing rack is rotationally arranged at the upper end of the fixed belt pressing rack by a supporting shaft, a counterweight mechanism mounting hole is formed in the front part of the movable belt pressing rack, a width adjustable splitting mechanism is arranged at the front end of the movable belt pressing rack, and the splitting mechanism is positioned above the belt coiling mechanism. The belt pressing device of the coiling machine can be used for solving the problems that a tooling and a micrometer are adopted for adjustment, time and labor are consumed and the adjusting precision is low, and the belt pressing device of the coiling machine can improve the maintaining efficiency. The belt pressing device of the coiling machine has simple structure, the belt material can be pressed and different belt materials can be split and separated conveniently due to the arrangement of the front movable rack and the splitting mechanism, counterweight parts with different quantities can be arranged according to different belt pressing requirements, are used by pressing by self gravities, can be contacted with the belt material in real time, and can ensure the belt pressing effect.

Owner:CHONGQING TIANYU SHAPED PIPE

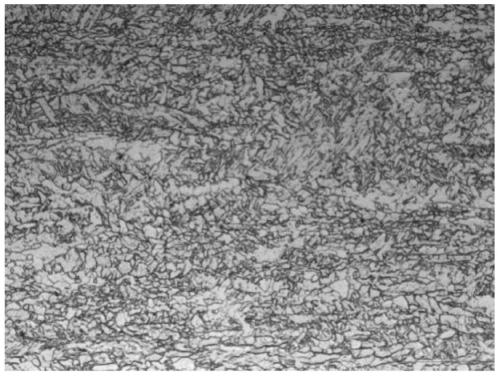

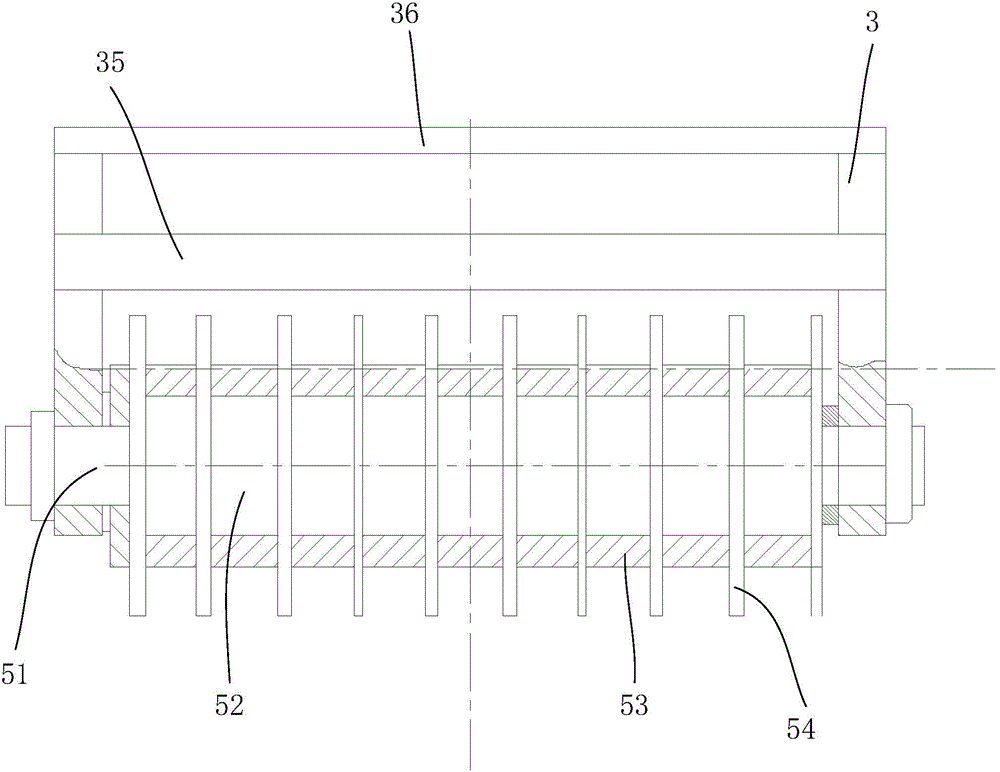

Quenched and tempered steel plate with high strength, toughness and low yield ratio for low temperature environment and preparation method thereof

The invention discloses a high-toughness and low-yield-ratio quenched and tempered steel plate used in a low-temperature environment. The high-toughness and low-yield-ratio quenched and tempered steel plate comprises, by weight, 0.045-0.068% of C, 0.13-0.25% of Si, 1.55-1.74% of Mn, smaller than or equal to 0.020% of P, smaller than or equal to 0.0015% of S, 0.25-0.33% of Cr, 0.14-0.21% of Cu, 0.18-0.25% of Ni, 0.035-0.044% of Nb, 0.033-0.049% of V, 0.010-0.016% of Ti and the balance Fe and inevitable impurities. The invention further discloses a manufacturing method of the high-toughness and low-yield-ratio quenched and tempered steel plate used in the low-temperature environment. A proper number of alloy elements such as Cu, Cr and Ni are added to the steel plate on the basis of a low-C and high-Mn system, and Nb, V and Ti are adopted for microalloying. Due to a pass reduction schedule and an offline heat treatment regime in the hot rolling process are optimized, quenched and tempered type pipeline steel which is high in low-temperature-environment toughness and low in yield ratio and is used for a straight seam welded pipe is finally obtained.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com