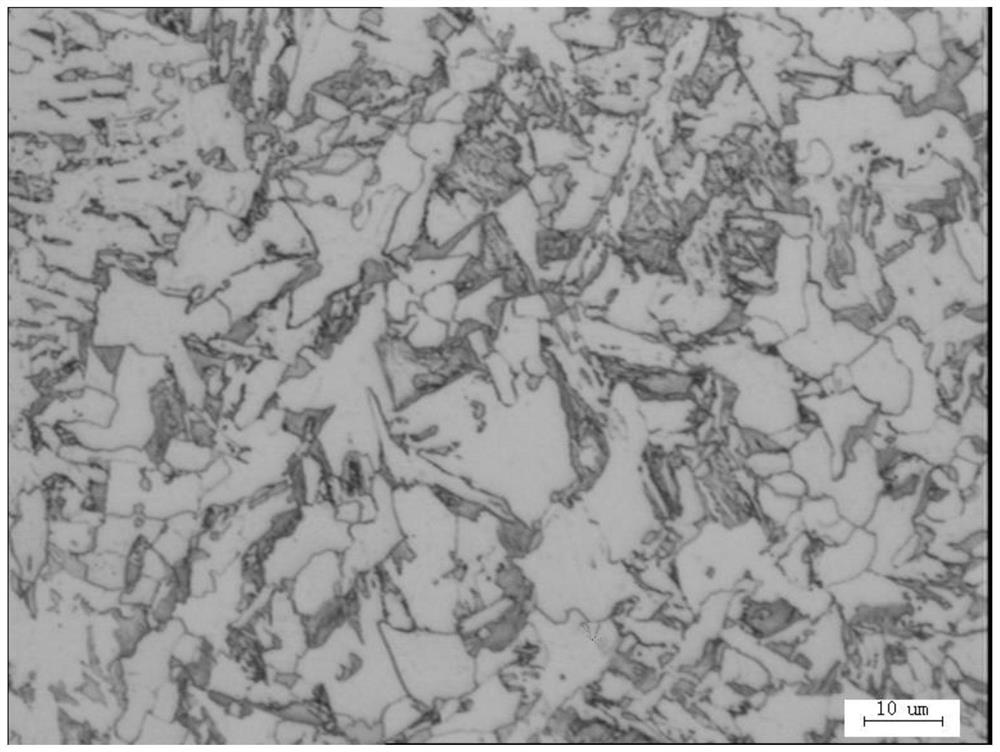

Acicular ferrite type high-strength steel bar and preparation method thereof

A technology of acicular ferrite and high-strength steel bars is applied in the direction of improving process efficiency, which can solve the problems of affecting the plasticity index and time-efficiency performance of steel bars, unfavorable to the promotion of large-scale industrial production, and subcutaneous bubbles of continuous casting billets, and achieves secondary hardening. The effect is obvious, the pearlite structure is refined, and the hardenability is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides an acicular ferrite high-strength steel bar and a preparation method thereof, comprising the following steps:

[0037] S1, 85% molten iron + 15% scrap steel, the composition of the final molten steel, 0.06% C, and the temperature of the final molten steel is 1650°C;

[0038] S2. The time from the ladle entering the LF furnace refining station to the completion of feeding is 7 minutes. The temperature of the molten steel in the ladle is 1550°C. The temperature of the electrode is raised for 15 minutes. Add wollastonite 0kg / t molten steel and lime 6.5kg / t molten steel, and the composition of the molten steel reaches The above target value, the temperature is 1550°C;

[0039] S3. The pouring time of molten steel from the LF furnace refining station to the continuous casting platform is 10 minutes, the ladle is opened and poured for 25 seconds, and the open pouring time is 10 seconds when the tundish is replaced with a sizing nozzle, and the cooling...

Embodiment 2

[0042] This embodiment provides an acicular ferrite high-strength steel bar and a preparation method thereof, comprising the following steps:

[0043] S1, 85% molten iron + 15% scrap steel, the component of molten steel at the end point, 0.07% C, and the temperature of molten steel at the end point is 1665°C;

[0044] S2. The time from the ladle entering the LF furnace refining station to the completion of feeding is 6 minutes. The temperature of molten steel in the ladle is 1560°C, and the heating time is 14 minutes. Add 2.75kg / t of wollastonite and 4.4kg / t of lime to reach the above-mentioned composition Target value, temperature 1560°C;

[0045] S3. The pouring time of molten steel from the LF furnace refining station to the continuous casting platform is 9 minutes, the ladle is opened and poured for 23 seconds, the tundish is replaced with a sizing nozzle and the pouring time is opened for 9 seconds, the cooling water flow rate of the crystallizer: 115m 3 / h, the specific...

Embodiment 3

[0048] This embodiment provides an acicular ferrite high-strength steel bar and a preparation method thereof, comprising the following steps:

[0049] S1, 85% molten iron + 15% scrap steel, final molten steel composition, 0.08% C, final molten steel temperature 1680°C;

[0050] S2. The time from the ladle entering the LF furnace refining station to the completion of feeding is 5 minutes. The temperature of the molten steel in the ladle is 1570°C. For 13 minutes, add wollastonite 5.5kg / t molten steel and lime 2.3kg / t molten steel, and the composition of the molten steel reaches the above target value, temperature 1570℃;

[0051] S3. The pouring time of molten steel from the refining station of the LF furnace to the continuous casting table is 8 minutes, the pouring time of the ladle is 21 seconds, the pouring time of the tundish is 8 seconds when the sizing nozzle is changed, and the cooling water flow rate of the crystallizer: 130m 3 / h, the cooling ratio of water in the seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com