A kind of v-n-cr microalloyed q550 grade hot-rolled strip steel and its preparation method

A hot-rolled strip steel and micro-alloying technology, which is applied in the field of hot-rolled strip steel manufacturing, can solve the problems of large amount of alloy and large fluctuations in structure and properties, and achieve short process flow, high uniformity of structure and properties, and simple operation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The V-N-Cr microalloy hot-rolled steel strip whose thickness is 20.0mm is prepared, and the process steps are as follows:

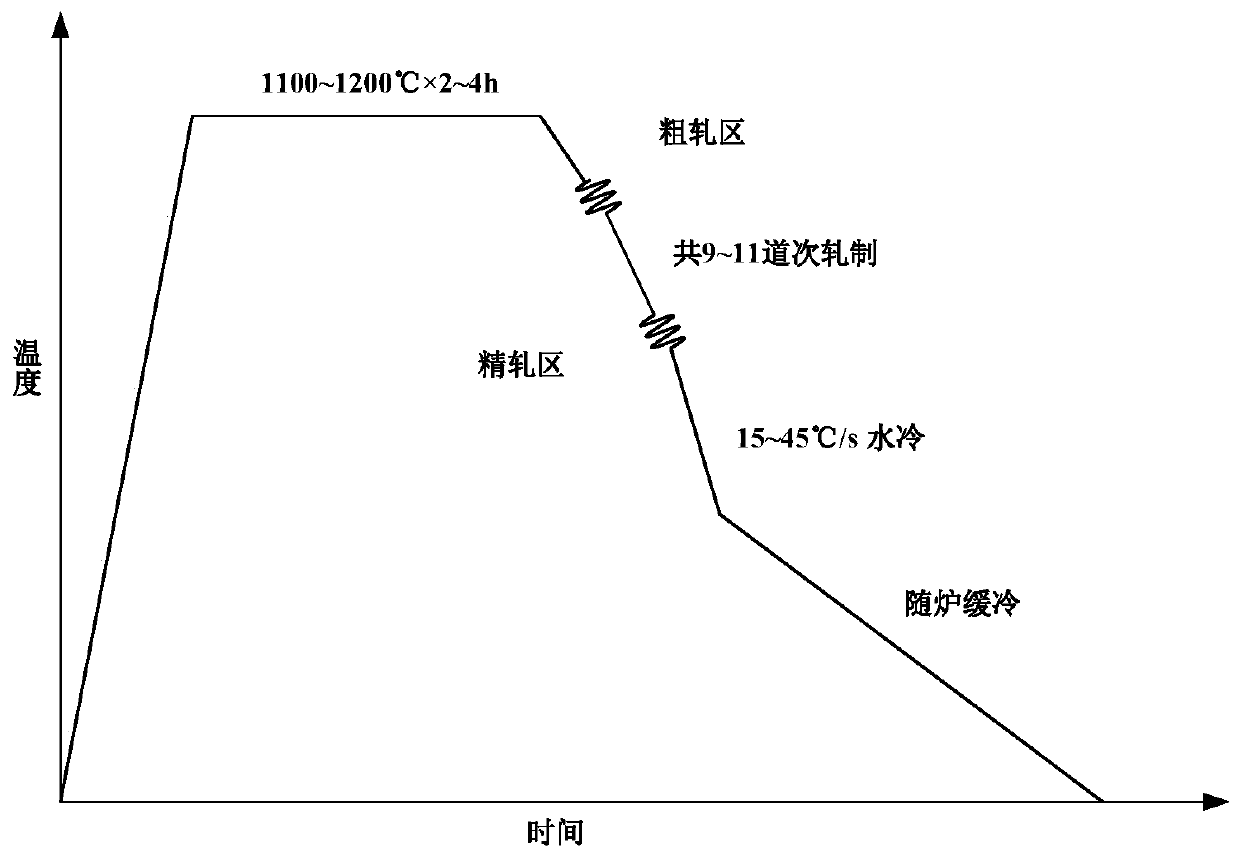

[0033]Heat the alloy billet with a thickness of 140mm to 1200°C with the furnace and keep it warm for 4 hours. Its chemical composition is as follows: C: 0.05%, Mn: 2.0%, Si: 0.50%, S: 0.002%, P: 0.010%, Al : 0.05%, V: 0.15%, N: 0.020%, Cr: 0.30%, the balance is Fe and other unavoidable impurities; followed by 11 passes of hot rolling into a 20.0mm thick hot rolled sheet. The starting and finishing temperatures of the rough rolling stage are 1160°C and 1100°C respectively, the rough rolling is carried out in 5 passes to 56mm, and the pass reduction rate is 14-18%; the starting and finishing temperatures of the finish rolling stage are respectively At 955°C and 890°C, finish rolling to 20.0mm in 6 passes, and the reduction rate of each pass is 14-17%. After hot rolling, water cooling to 585°C at a cooling rate of 15°C / s, such as figure 1 shown;

...

Embodiment 2

[0036] The V-N-Cr microalloy hot-rolled steel strip whose thickness is 10.0mm is prepared, and the process steps are as follows:

[0037] Heat the alloy billet with a thickness of 80mm to 1150°C with the furnace and keep it warm for 3 hours. Its chemical composition is: C: 0.11%, Mn: 1.8%, Si: 0.30%, S: 0.003%, P: 0.005%, Al : 0.01%, V: 0.10%, N: 0.013%, Cr: 0.20%, the balance is Fe and other unavoidable impurities; followed by 9 passes of hot rolling into a 10.0mm thick hot rolled sheet. The starting and finishing temperatures of the rough rolling stage were 1100°C and 1060°C, respectively, and the rough rolling was carried out in 3 passes to 40mm, and the reduction rate of each pass was 19-23%. The starting and finishing temperatures of the finish rolling stage were respectively At 915°C and 850°C, finish rolling to 10.0mm in 6 passes, and the reduction rate of each pass is 18-23%. After hot rolling, water cooling to 566°C at a cooling rate of 32°C / s, such as figure 1 show...

Embodiment 3

[0040] The V-N-Cr microalloy hot-rolled steel strip whose thickness is 2.5mm is prepared, and the process steps are as follows:

[0041] Heat the alloy billet with a thickness of 50mm to 1100°C with the furnace and hold it for 2 hours. Its chemical composition is as follows: C: 0.15%, Mn: 1.5%, Si: 0.10%, S: 0.005%, P: 0.015%, Al : 0.04%, V: 0.06%, N: 0.008%, Cr: 0.10%, the balance is Fe and other unavoidable impurities; followed by 9 passes of hot rolling into a 2.5mm thick hot rolled sheet. The starting and finishing temperatures of the rough rolling stage were 1060°C and 980°C, respectively, and the rough rolling was carried out in 3 passes to 18mm, and the pass reduction rate was 28-30%. The starting and finishing temperatures of the finish rolling stage were respectively At 870°C and 805°C, finish rolling to 2.5mm in 6 passes, and the reduction rate of each pass is 28-30%. After hot rolling, water cooling to 520°C at a cooling rate of 45°C / s, such as figure 1 shown.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com