An iron-based alloy powder for laser cladding on the outer surface of a hydraulic support live column

A technology of laser cladding and hydraulic support, applied in metal material coating process, coating and other directions, can solve the problem that the cladding layer cannot eliminate the aging phenomenon, the working cycle of the hydraulic support movable column is short, the cladding layer is uneven and not dense, etc. problems, to achieve the effect of reducing porosity and pores, uniform and dense organization, and reducing the tendency of intergranular corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

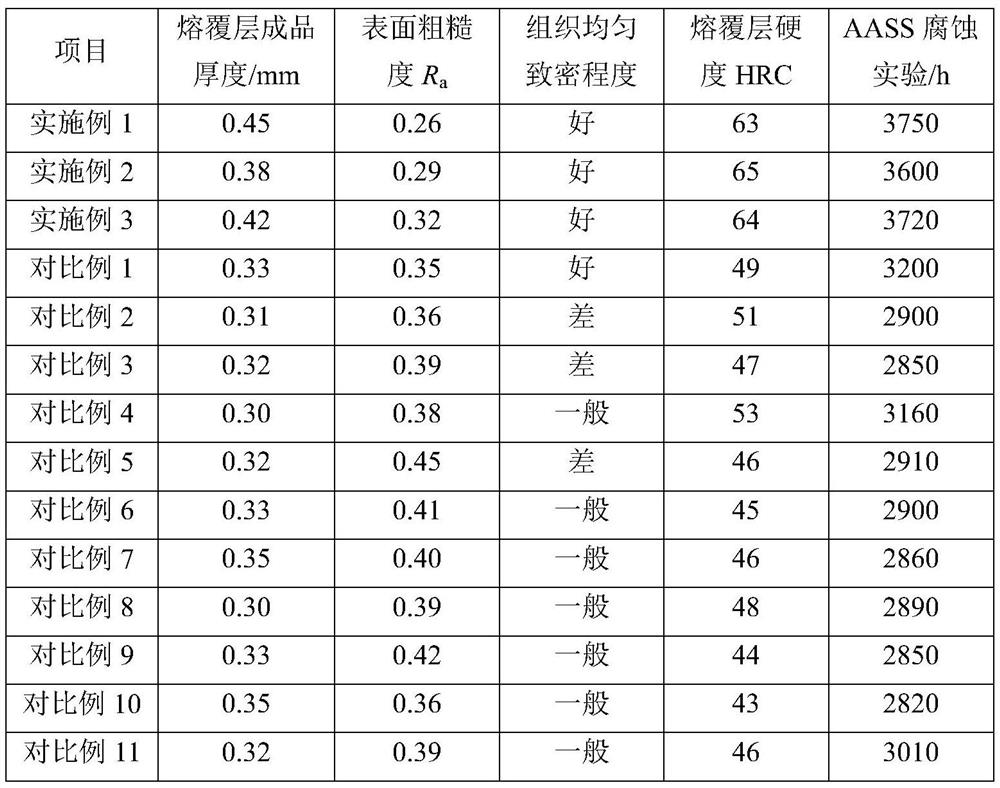

Examples

Embodiment 1

[0021] An iron-based alloy powder for laser cladding on the outer surface of a hydraulic support live column, the chemical composition and mass percentage are: 3.0% beryllium, 2.0% neodymium, 0.08% nitrogen, 1.5% cobalt, 18.0% chromium, 0.05% carbon, and 0.16% molybdenum %, boron 1.8%, yttrium 1.0%, nickel 2.8%, silicon 0.1%-0.3%, niobium 1.2%, titanium 1.6%, and the balance is iron.

[0022] The particle size of the alloy powder is 80 μm-120 μm.

Embodiment 2

[0024] An iron-based alloy powder for laser cladding on the outer surface of a hydraulic support live column, the chemical composition and mass percentage are: beryllium 6.0%, neodymium 4.0%, nitrogen 0.12%, cobalt 3.5%, chromium 22.0%, carbon 0.09%, molybdenum 0.30% %, boron 3.2%, yttrium 2.2%, nickel 4.0%, silicon 0.3%, niobium 2.6%, titanium 2.2%, and the balance is iron.

[0025] The particle size of the alloy powder is 80 μm-120 μm.

Embodiment 3

[0027] An iron-based alloy powder for laser cladding on the outer surface of a hydraulic support live column, the chemical composition and mass percentage are: beryllium 4.5%, neodymium 3.0%, nitrogen 0.10%, cobalt 2.5%, chromium 20.0%, carbon 0.07%, molybdenum 0.23% %, boron 2.5%, yttrium 1.6%, nickel 3.4%, silicon 0.2%, niobium 1.9%, titanium 1.9%, and the balance is iron.

[0028]The particle size of the alloy powder is 80 μm-120 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com