A kind of preparation method of silver tin oxide electrical contact material

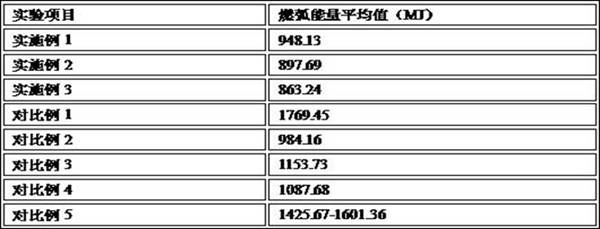

An electrical contact material, silver tin oxide technology, used in contacts, circuits, electrical switches, etc., can solve the problems of high arc energy, inability to meet the requirements of AC contactors and relays, short electrical life, etc. Arc energy, the effect of promoting the reaction of silver, and improving the wetting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

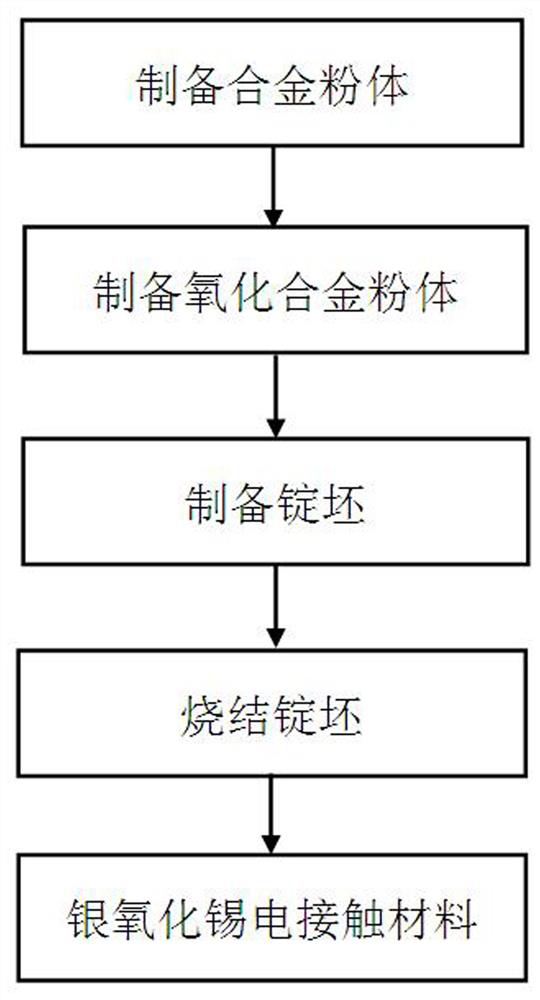

[0030] In an embodiment, the preparation method of the silver tin oxide electrical contact material comprises the following steps:

[0031] S1: In parts by weight, it includes the following raw materials: 63-72 parts of silver powder, 16-28 parts of tin powder, 1-2 parts of graphite powder, 0.3-0.5 parts of europium powder, 2-4 parts of rubidium carbonate powder, copper powder 6-8 parts of bismuth powder, 3-5 parts of bismuth powder, and 2.7-5.6 parts of molybdenum carbide powder are put into a smelting furnace for smelting, and the alloy powder is obtained after water atomization;

[0032] The particle size of the silver powder is 0.2-13.3 μm;

[0033] The particle size of the tin powder is 0.5-11.8 μm;

[0034] The particle size of the graphite powder is 1.2-10.3 μm;

[0035] The particle size of the europium powder is 1.2-3.4 μm;

[0036] The particle size of the rubidium carbonate powder is 0.7-5.2 μm;

[0037] The particle size of the copper powder is 0.9-8.5 μm;

[...

Embodiment 1

[0046] A preparation method of silver tin oxide electrical contact material, comprising the following steps:

[0047] S1: in parts by weight, it includes the following raw materials: 65 parts of silver powder, 17 parts of tin powder, 1 part of graphite powder, 0.3 part of europium powder, 2 parts of rubidium carbonate powder, 6 parts of copper powder, 3 parts of bismuth powder, molybdenum carbide 2.8 parts of powder are put into the melting furnace and smelted, and the alloy powder is obtained after water atomization;

[0048] The particle size of the silver powder is 0.5-13.1 μm;

[0049] The particle size of the tin powder is 0.9-10.2 μm;

[0050] The particle size of the graphite powder is 1.6-10.2 μm;

[0051] The particle size of the europium powder is 1.7-3.2 μm;

[0052] The particle size of the rubidium carbonate powder is 0.8-4.5 μm;

[0053] The particle size of the copper powder is 1.1-8.3 μm;

[0054] The particle size of the bismuth powder is 0.5-7.2 μm;

[...

Embodiment 2

[0061] A preparation method of silver tin oxide electrical contact material, comprising the following steps:

[0062] S1: In parts by weight, it includes the following raw materials: 70 parts of silver powder, 26 parts of tin powder, 2 parts of graphite powder, 0.5 part of europium powder, 3.7 parts of rubidium carbonate powder, 8 parts of copper powder, 5 parts of bismuth powder, molybdenum carbide 5.4 parts of powder were put into a melting furnace for smelting, and the alloy powder was obtained after water atomization;

[0063] The particle size of the silver powder is 1-11 μm;

[0064] The particle size of the tin powder is 0.7-10.1 μm;

[0065] The particle size of the graphite powder is 1.4-9.8 μm;

[0066] The particle size of the europium powder is 1.7-3.1 μm;

[0067] The particle size of the rubidium carbonate powder is 0.9-5 μm;

[0068] The particle size of the copper powder is 0.9-6.4 μm;

[0069] The particle size of the bismuth powder is 0.6-5.9 μm;

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com