Novel Cr-Y-O nanocluster oxide dispersion strengthening reduced activation steel

A low-activation steel, dispersion-strengthening technology, applied in the field of anti-irradiation metal materials, can solve the problem that it is easy to be adsorbed on the surface of powder particles, the oxygen content of the oxide dispersion-strengthened low-activation steel matrix cannot be effectively controlled, and the specific surface area of powder particles cannot be effectively controlled. It can achieve low activation performance, good anti-irradiation swelling ability, and the effect of reducing oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The mass percent of the alloying elements of the oxide dispersion strengthened steel is: 0.041%C, 13.88%Cr, 1.35%W, 0.19%V, 0.07%Ta, 0.41%Mn, 0.10%Si, 0.74%Y, 73(ppm ) N, 64 (ppm) Al, 48 (ppm) Ni, 48 (ppm) Mo, 65 (ppm) Nb, Cu<0.010%, P<0.005%, S<0.005%, and the matrix is Fe.

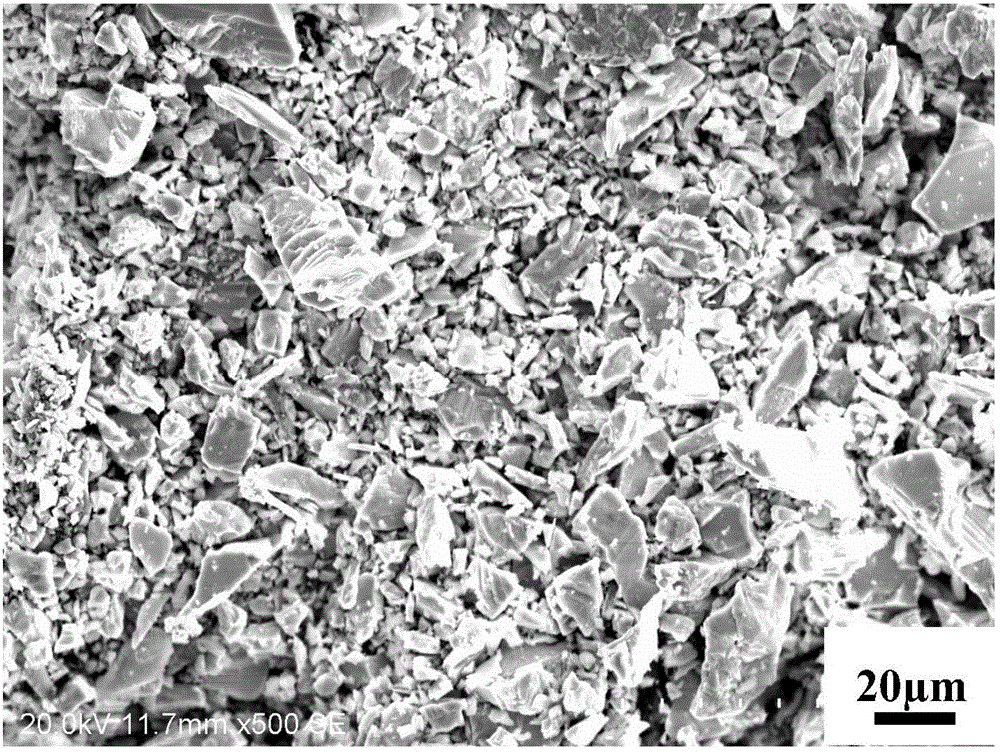

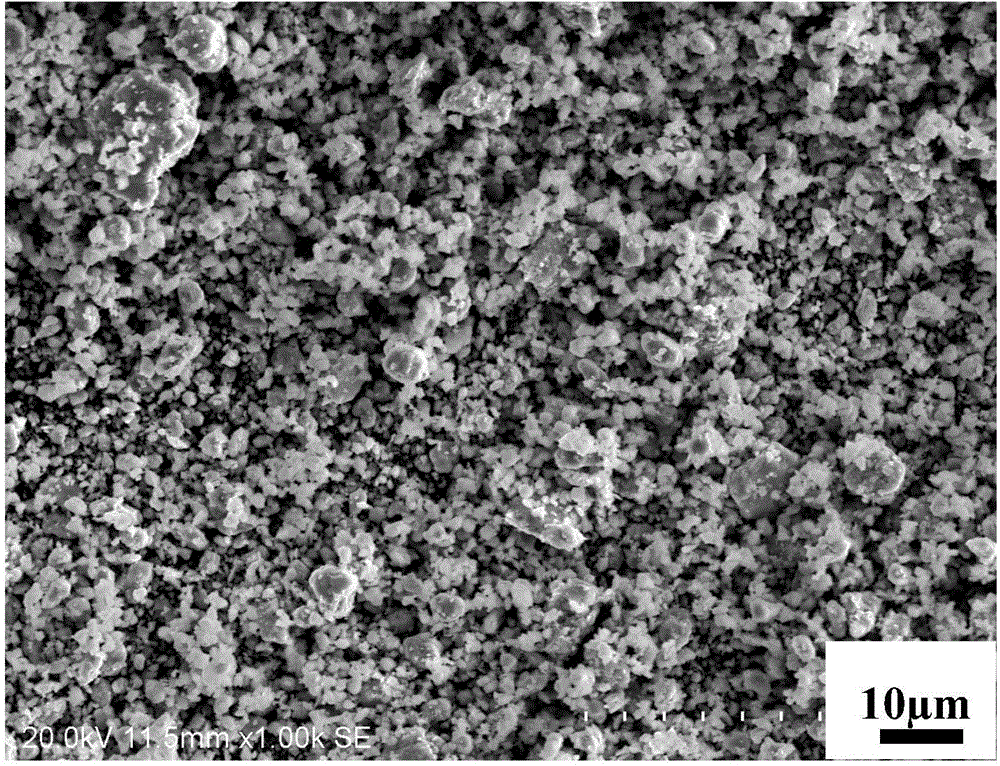

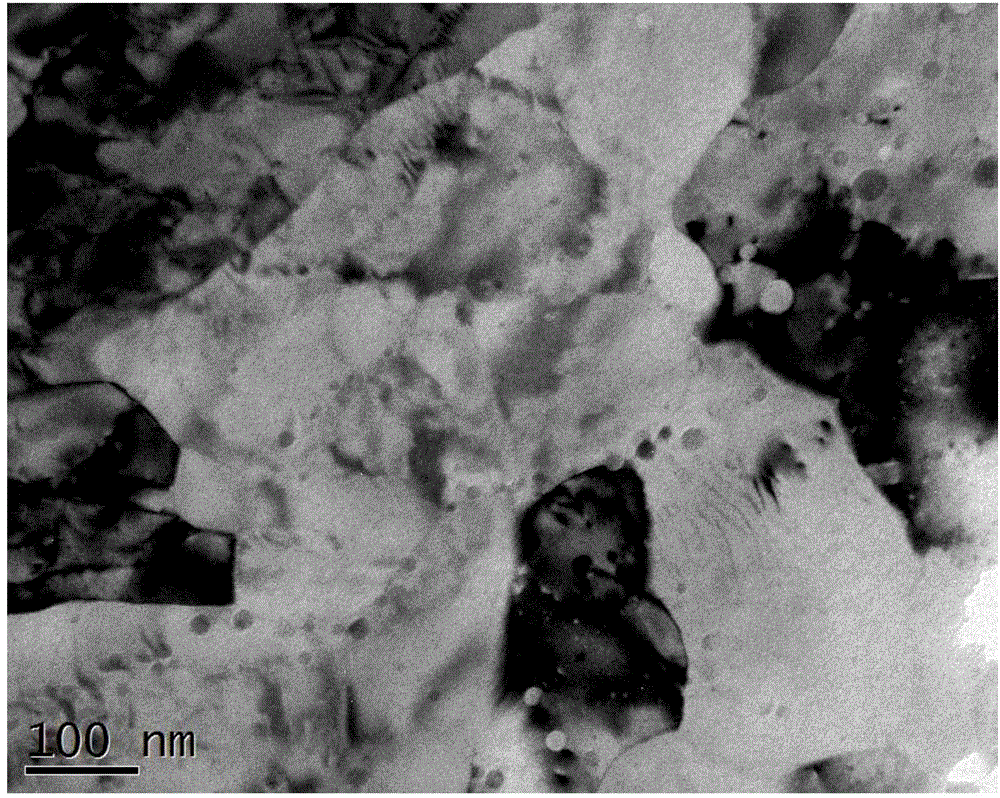

[0033] Preparation method: First, prepare Cr-Y ball mill powder (the mass ratio of Cr-Y pure metal powder is Cr:Y=9:1, the ball milling medium is Φ6 hard steel balls, the ball milling atmosphere is 99.99% argon, and the mass ratio of ball to material is is 10:1, the ball milling time is 4h, and the rotating speed is 1425r / min), and then the Cr-Y ball mill powder (the scanning electron microscope photo is shown in figure 2 As shown) is added to Fe-C-Cr-W-V-Ta-Mn-Si steel powder for high-energy ball milling (the ball milling medium is Φ6 and Φ10 mixed hard steel balls, the ball milling atmosphere is 99.99% argon, and the mass ratio of balls to materials is 10 : 1, ball milling time 70h, rotating...

Embodiment 2

[0035] The alloy element content of the oxide dispersion strengthened steel is the same as that of the steel of Example 1.

[0036] Preparation method: First, prepare Cr-Y ball mill powder (the mass ratio of Cr-Y pure metal powder is Cr:Y=9:1, the ball milling medium is Φ6 hard steel balls, the ball milling atmosphere is 99.99% argon, and the mass ratio of ball to material is 10:1, ball milling time 4h, rotating speed 1425r / min), then add Cr-Y ball mill powder into Fe-C-Cr-W-V-Ta-Mn-Si steel powder for high-energy ball milling (ball milling medium is Φ6 and Φ10 Mix hard steel balls, the ball milling atmosphere is 99.99% argon, the mass ratio of balls to material is 10:1, the ball milling time is 70h, and the rotating speed is 450r / min). Secondly, the mixed powder is first packed into a bag and evacuated (vacuum degree 10 -1 Pa, temperature 450°C, time 4h), and then cured by hot isostatic pressing (pressure 130MPa, temperature 1050°C, holding time 3h). Finally, after preparin...

Embodiment 3

[0038] The difference from Example 1 is that the heat treatment system is different: normalizing at 1150-1200°C / 50min / air cooling + tempering at 820°C / 90min / air cooling, finally obtaining oxide dispersion strengthened low activation steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com