Ceramic-reinforced cobalt-based cladding material, cobalt-based cladding coating and preparation method thereof

A technology of ceramic materials and cladding materials, which is applied in the coating process and coating of metal materials, can solve the problems of few types of ceramic materials, and achieve the effect of good wear resistance and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Use the preset powder method. Calculate the rare earth oxide Y according to the mass percentage 2 o 3 , the quality of Co-based powder and ZrC, the powder is ground, weighed with an analytical balance (accuracy is 0.0001g) and mechanically mixed evenly. The specific parameter ratio is shown in Table 1. Place an appropriate amount of prepared powder on the surface of the sample evenly by hand, and control the coating thickness to about 1 mm. The Co-based powder is Co-01, and its composition is: 0.4% by mass of C, 2.1% by mass of B, 2.0% by mass of Si, 21.0% by mass of Cr, and 1.5% by mass of Fe %, the mass percentage of W is 5.2%, the mass percentage of Ni is 2.5%, and the balance is Co.

[0067] Table 1 Composition design of laser cladding layer

[0068]

[0069] Laser cladding process

[0070] The laser cladding experiment equipment is TEL-6000H type CO 2The laser is scanned under the protective gas argon, the spot diameter is 3mm, and the gas pressure is 0.2...

Embodiment 2

[0106] The process parameter table shown in Table 3 below was designed, and the cladding results were simply analyzed. In this test, the preset powder was 1mm thick, and the spot diameter was 4mm.

[0107] The processing parameters of the coating in table 3

[0108]

[0109]

[0110] ZrB 2 Influence of ceramic content on cladding layer

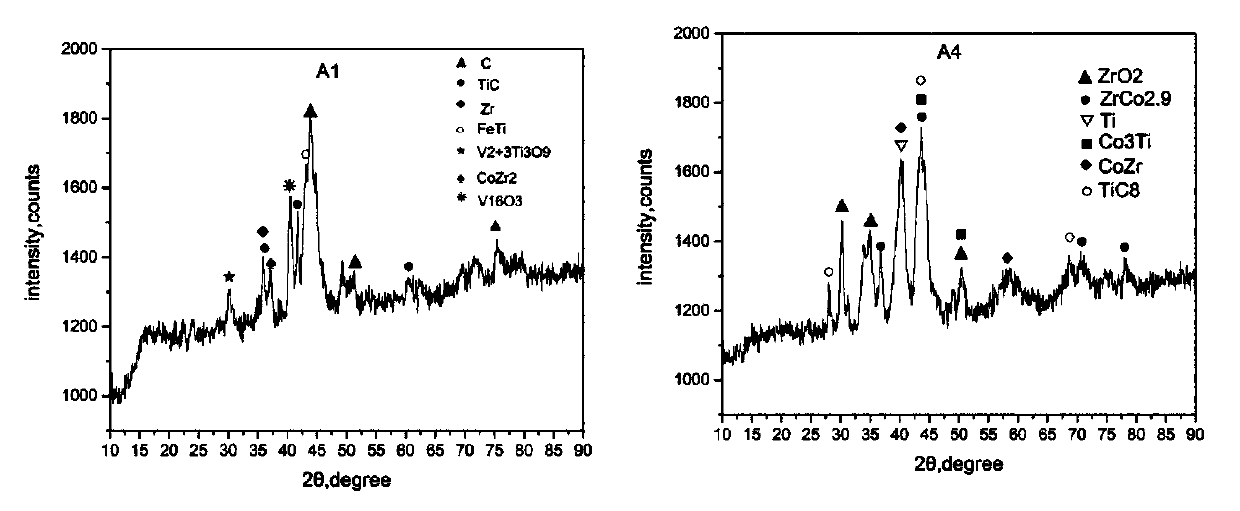

[0111] The phase composition of the coating

[0112] The X-ray diffraction images of cladding layers with different ceramic contents are as follows: Figure 16 shown. It can be seen that without adding ZrB 2 , the cladding layer is mainly composed of γ-Co, TiC, TiB, Cr 2 Ti, CoTi, Cr 23 C 6 、Co 3 Ti and Cr 7 C 3 Phase composition. After adding ZrB 2 , the cladding layer is mainly composed of γ-Co, TiC, TiB 2 、Cr 2 Ti, Co 2 Zr、Cr 23 C 6 、Co 3 Ti, Cr 2 B, CrB and ZrO 2 Equivalent phase composition. It can be seen from the X-ray diffraction patterns that in the cladding layers with different ceramic contents, most of th...

Embodiment 3

[0130] Use the preset powder method. The mass of Co-01 and ZrN was calculated according to the mass percentage, the powder was ground, weighed with an analytical balance (accuracy: 0.0001g), and mechanically mixed evenly. The specific parameter ratio is shown in Table 6. Place an appropriate amount of prepared powder on the surface of the sample evenly by hand, and control the coating thickness to about 1mm.

[0131] Table 6 Composition Design of Laser Alloyed Composite Coating

[0132]

[0133] Laser cladding process

[0134] The laser cladding experiment equipment is TEL-6000H type CO 2 The laser is scanned under the protective gas argon, the spot diameter is 3mm, and the gas pressure is 0.2-0.3MPa. The power used in the experiment was 2kW, 3kW and 4kW, and the scanning speed used was 200mm / min, 300mm / min and 400mm / min. The 10mm×10mm×10mm sample is subjected to single-pass lap jointing (for tissue morphology, microhardness and SEM analysis), and the 25mm×25mm×10mm sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com