Metal films, methods for production thereof, methods for production of laminated electronic components, and laminated electronic components

A metal film and manufacturing method technology, applied in the field of laminated electronic components, can solve the problems of the decrease of the electrostatic capacity of the laminated ceramic capacitor, the reduction of the effective area of the conductor layer, the interruption and the void of the conductor layer, etc., so as to suppress the structural defects such as interruption and void, The effect of increasing the effective area and suppressing shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

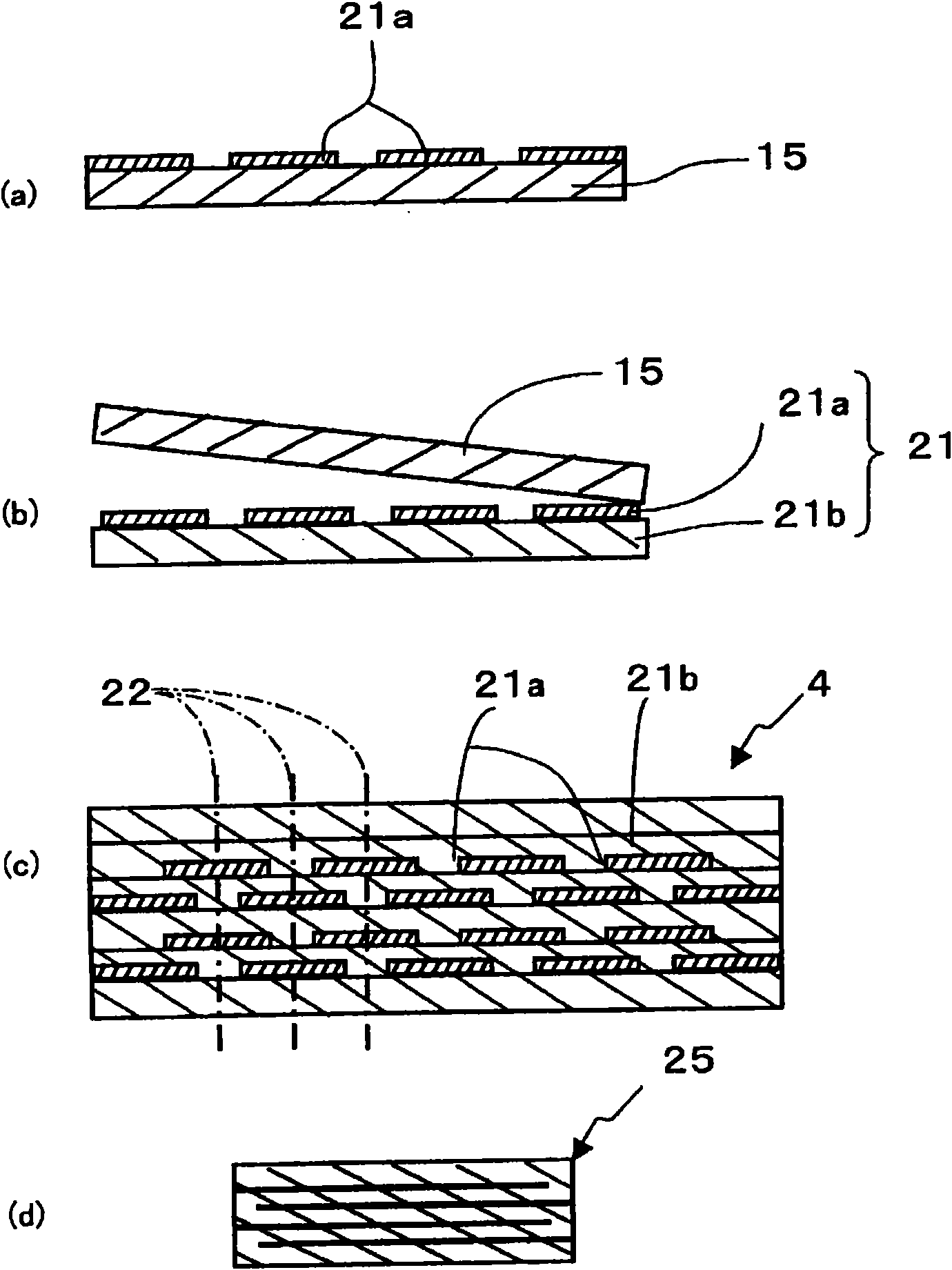

[0064] Regarding the metal film 21a and the multilayer electronic component of the present invention, a multilayer ceramic capacitor was fabricated and evaluated. First, a mirror-finished stainless steel substrate was used as a base material, and a photosensitive resist resin was applied to the surface to form a resist pattern. The resist pattern is a rectangular pattern arranged in a plurality of zigzags. The size of one pattern is 5 mm on the long side and 1.5 mm on the short side.

[0065] Next, electroplating was performed with a Ni plating solution 11 containing Mn and group 3A to 6A elements to form a Ni plating film with a thickness of 0.3 μm having a predetermined content of these added elements on a substrate made of stainless steel.

[0066] At this time, sulfuric acid ions containing, for example, group 3A to 6A elements are dissolved in the plating bath, and Mn is dissolved in manganese sulfate and electrolyzed in combination with a Ni anode. The concentration ad...

Embodiment 2

[0089] Next, the multilayer ceramic capacitors of sample Nos. 2 to 7 in Example 1 were fired within the firing temperature range shown in Table 2 to prepare samples, and the same evaluation was performed. Table 2 shows the results.

[0090] [Table 2]

[0091]

[0092] * represents samples outside the scope of the present invention.

[0093] Nos. 12 to 16, which are samples using the metal film 21a of the present invention, have a firing temperature of 1150 to 1200°C, exhibit capacitance equivalent to the characteristics at 1170°C, and have a high failure rate in the thermal shock resistance test. Below 1 / 100.

[0094] On the other hand, sample No. 11 using a composite metal powder other than the present invention had a firing temperature of 1150 to 1200°C, a capacitance as low as 9 μF or less, or a large number of delaminations in the thermal shock resistance test. In addition, There are also differences depending on the firing temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com