Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Easy to remove glue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

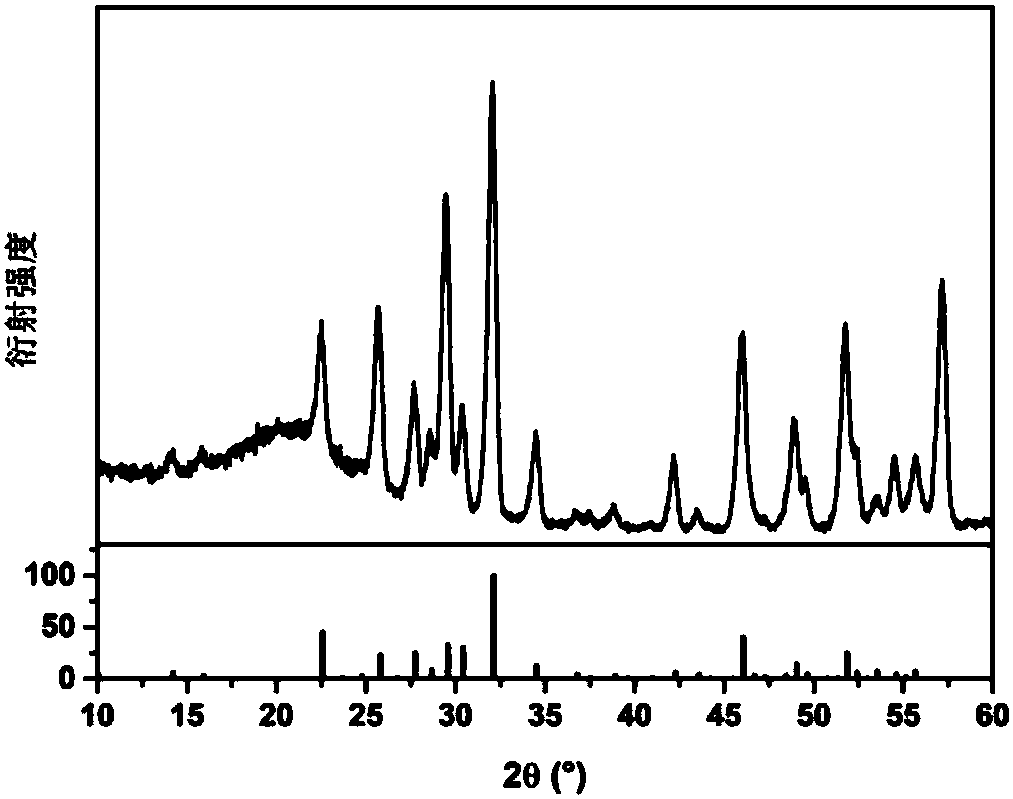

Method for producing permanent ferrite magnet with less shrinkage

InactiveCN108101529AFast sinteringShorten the timeInorganic material magnetismInductances/transformers/magnets manufactureSlurryFilter press

The invention discloses a method for producing a permanent ferrite magnet with less shrinkage. The method comprises following steps: step 1), a main component is added to a ball mill and ground for 4-6 h, and slurry is obtained, wherein the main components comprise constituents in percentage by mass as follows: 10.8%-11.5% of SrCO3, 3.2%-3.7% of La2O3, 1.1%-1.4% of Co2O3 and the balance of Fe2O3,and the sum of all main components in percentage by mass is 100%; step 2), the slurry obtained in the step 1) is stirred with a wet method firstly and subjected to primary mixed grinding, obtained slurry is subjected to filter pressing by a filter press to be dewatered, and water content of the slurry is enabled to be 35%-38%; step 3), the slurry obtained in the step 2) is pumped into a rotary kiln for pre-sintering and subjected to a solid-phase reaction at the temperature of 1230-1260 DEG C, and a permanent ferrite magnet pre-sintered material is obtained; step 4), after the permanent ferrite magnet pre-sintered material obtained in the step 3) is subjected to ball milling to be coarse powder, the coarse powder and additives are mixed uniformly, a mixture is put in the ball mill for secondary fine grinding, and a dispersing agent and an emulsifier are added during secondary ball milling; step 5), fine slurry obtained in the step 4) is subjected to wet press molding, a magnetic shoe blank is obtained and sintered, and the permanent ferrite magnet is obtained.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

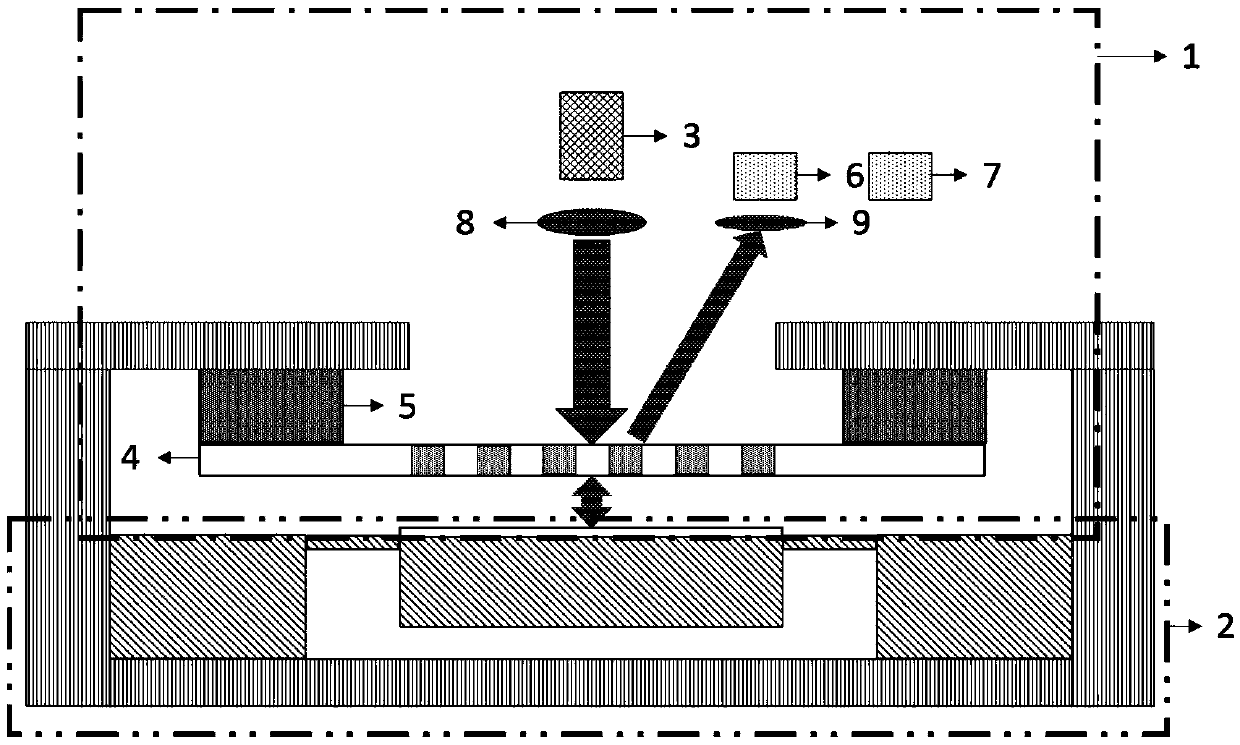

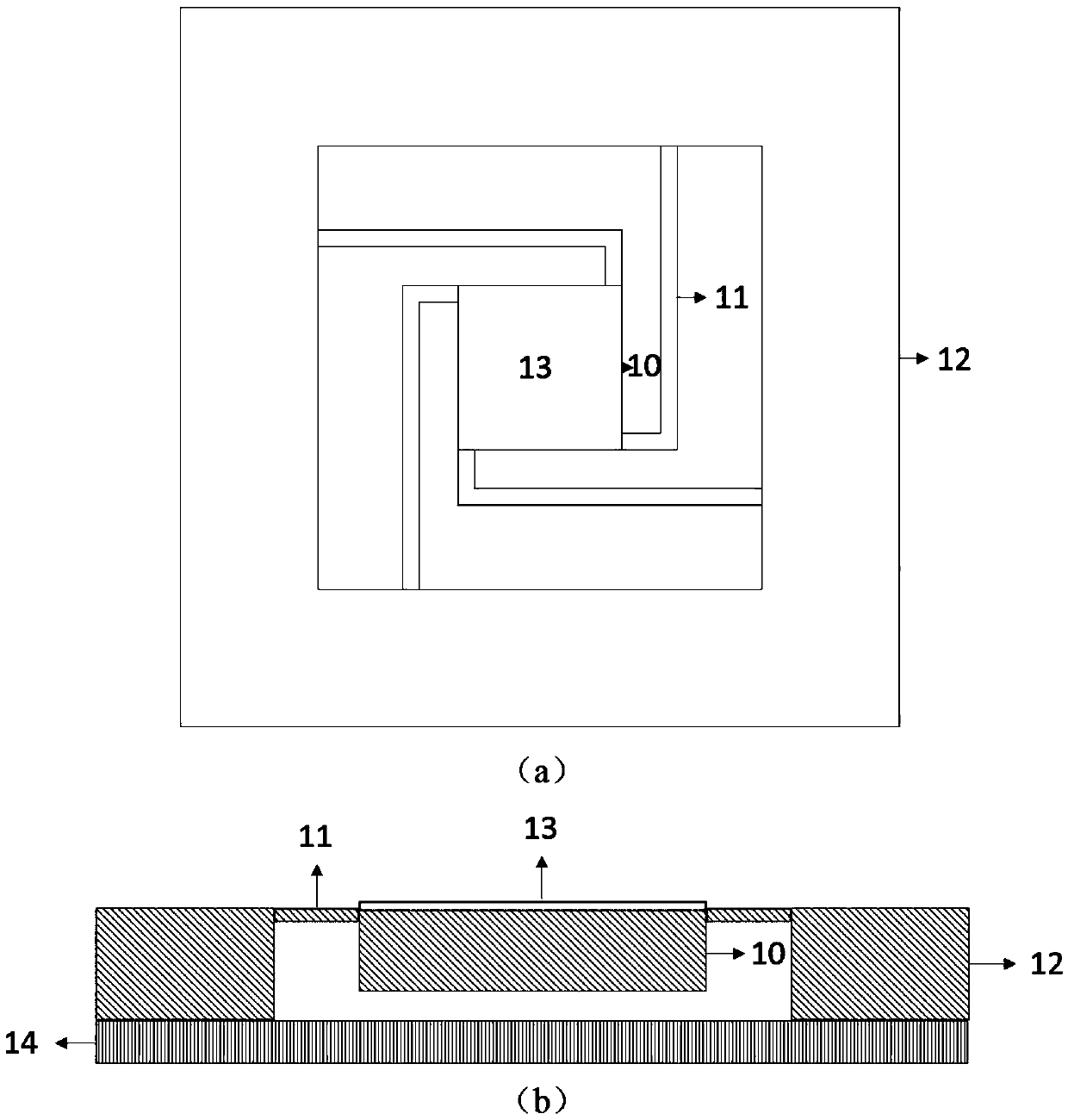

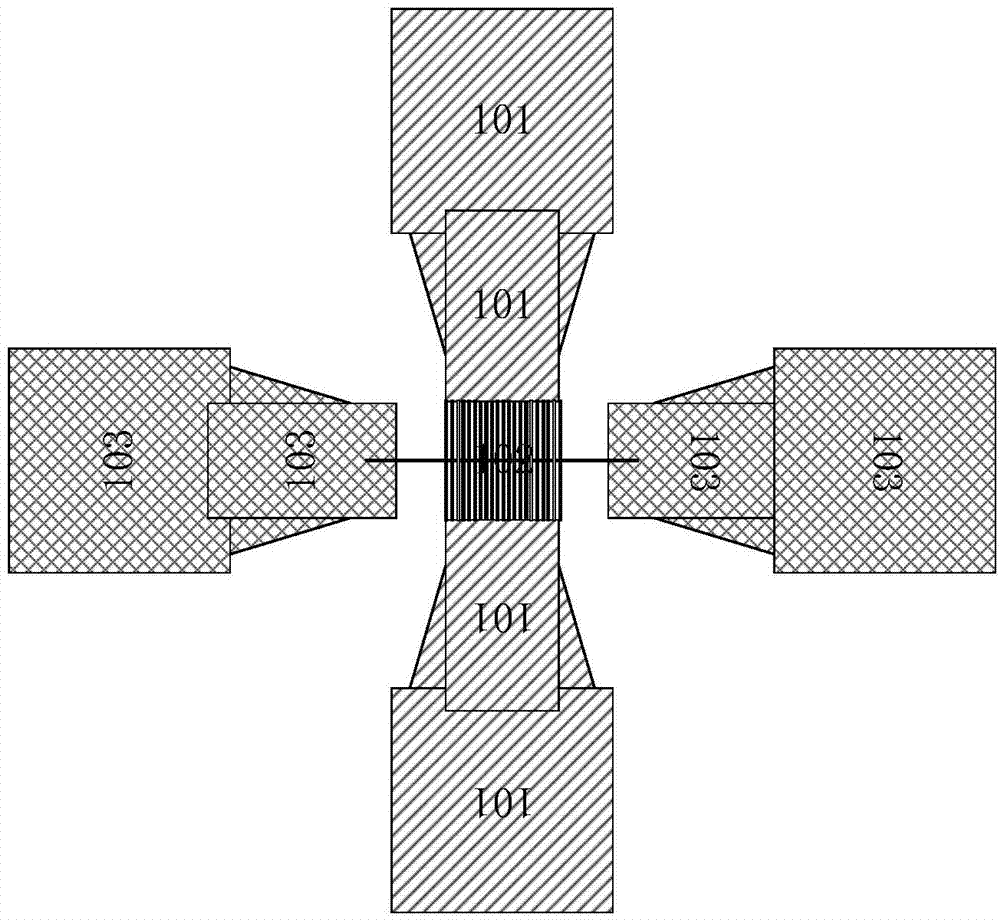

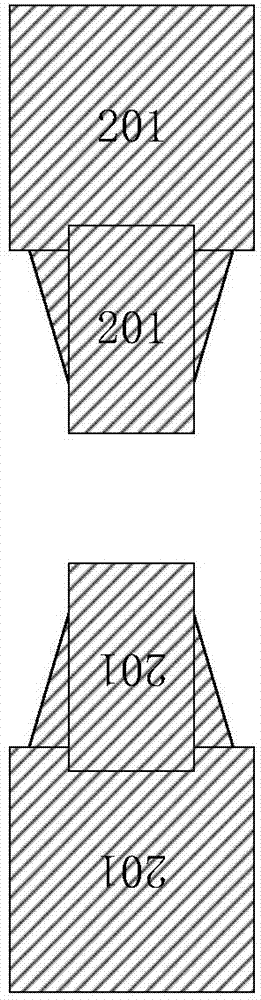

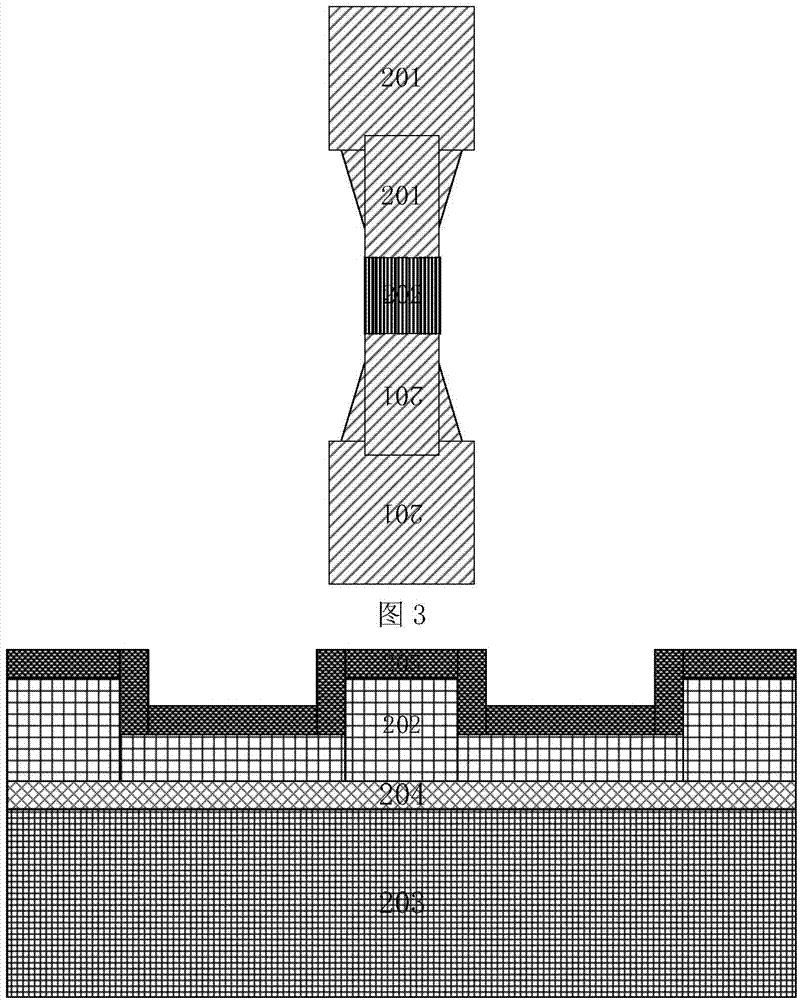

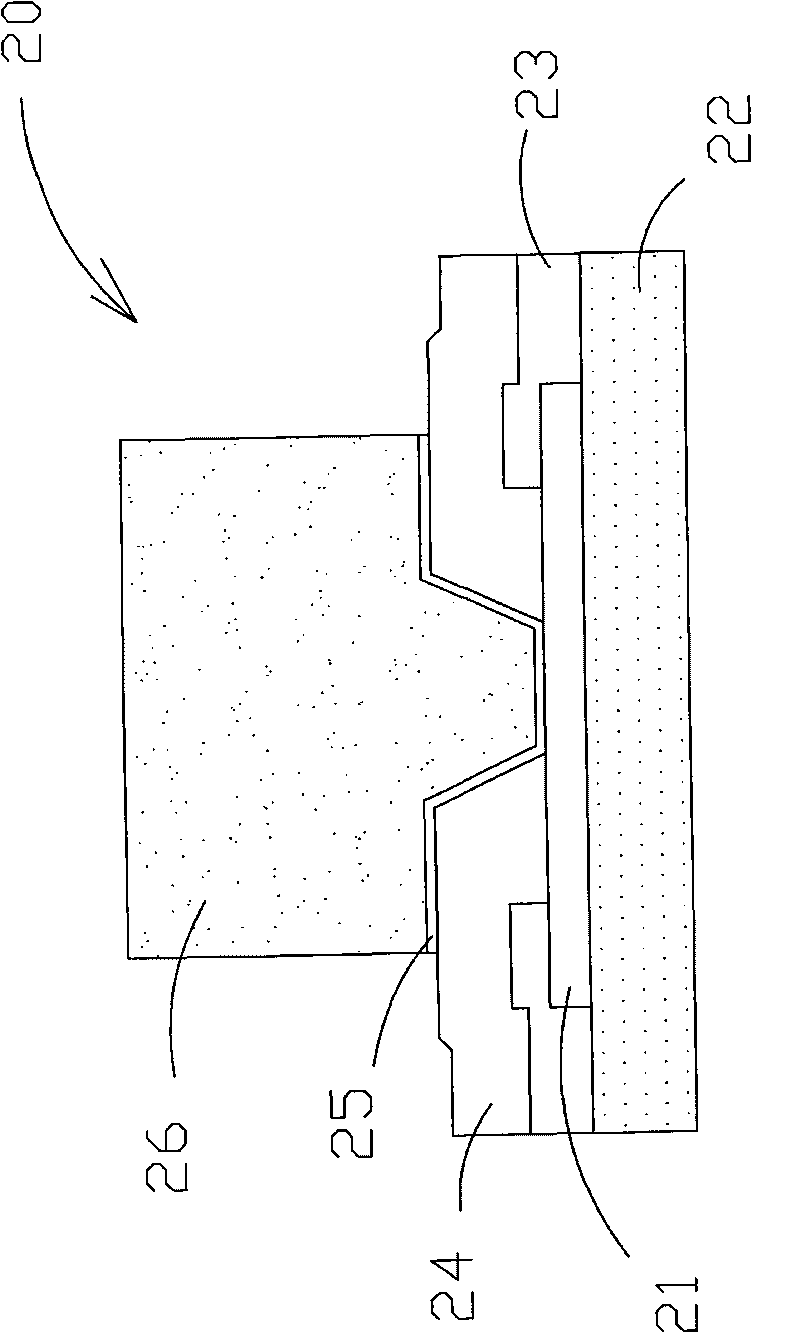

Micro mechanical acceleration sensitive structure for inhibiting crosstalk in high-precision single-shaft optical micro-accelerometer, and manufacturing method thereof

ActiveCN105372449ASuppresses Off-Axis CrosstalkLarge acceleration-displacement sensitivityAcceleration measurementSurface micromachiningCantilevered beam

The invention discloses a micro mechanical acceleration sensitive structure for inhibiting crosstalk in a high-precision single-shaft optical micro-accelerometer, and a manufacturing method thereof. The micro mechanical acceleration sensitive structure comprises a bulk silicon sensitive mass block, four symmetrically distributed crab-leg-shaped cantilever beams, a silicon substrate connected with the cantilever beams, and a reflective film plated on the surface of the sensitive mass block. It can be ensured that the gravity center of the sensitive mass block is disposed at a center plane of the cantilever beams through a specially designed microprocessing process, the direction of the sensitive shaft of the single-shaft optical micro-accelerometer is vertical to the center plane, and thus off-axis crosstalk is fundamentally inhibited through adjustment of the position of the gravity center; and the micro mechanical acceleration sensitive structure cooperates with the diffraction grating based optical micro-accelerometer so that the off-axis crosstalk can be effectively inhibited under the condition that the sensitivity of high-acceleration measurement is ensured, the applied surface microprocessing technology can be compatible with an IC technology, and batch manufacture is realized.

Owner:ZHEJIANG UNIV

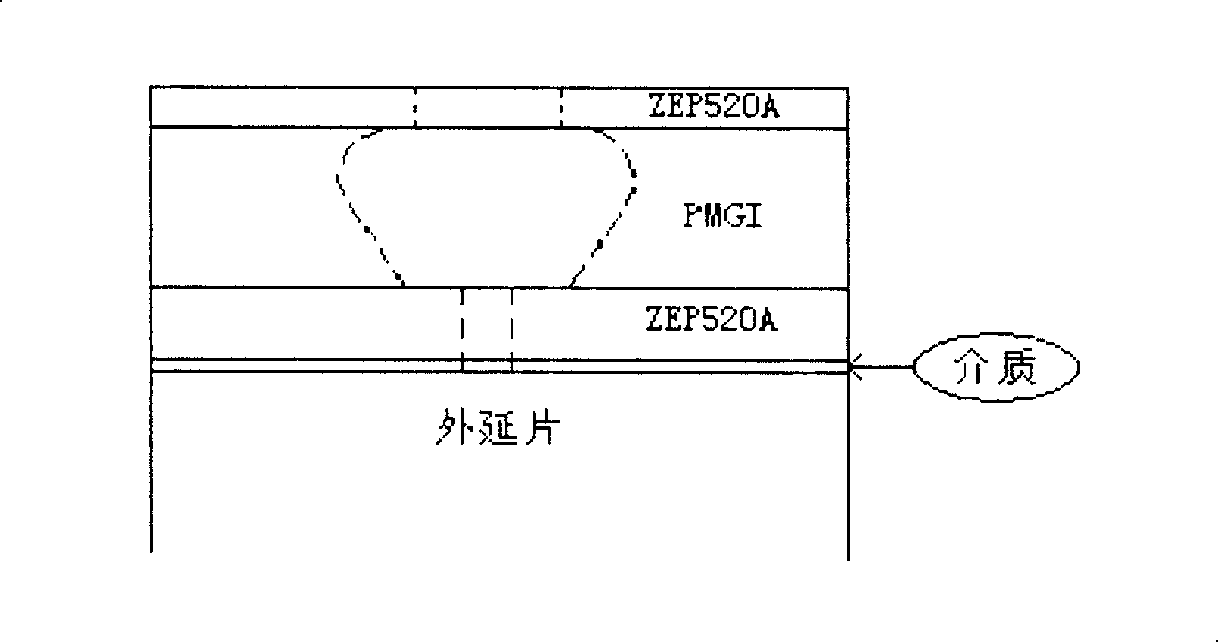

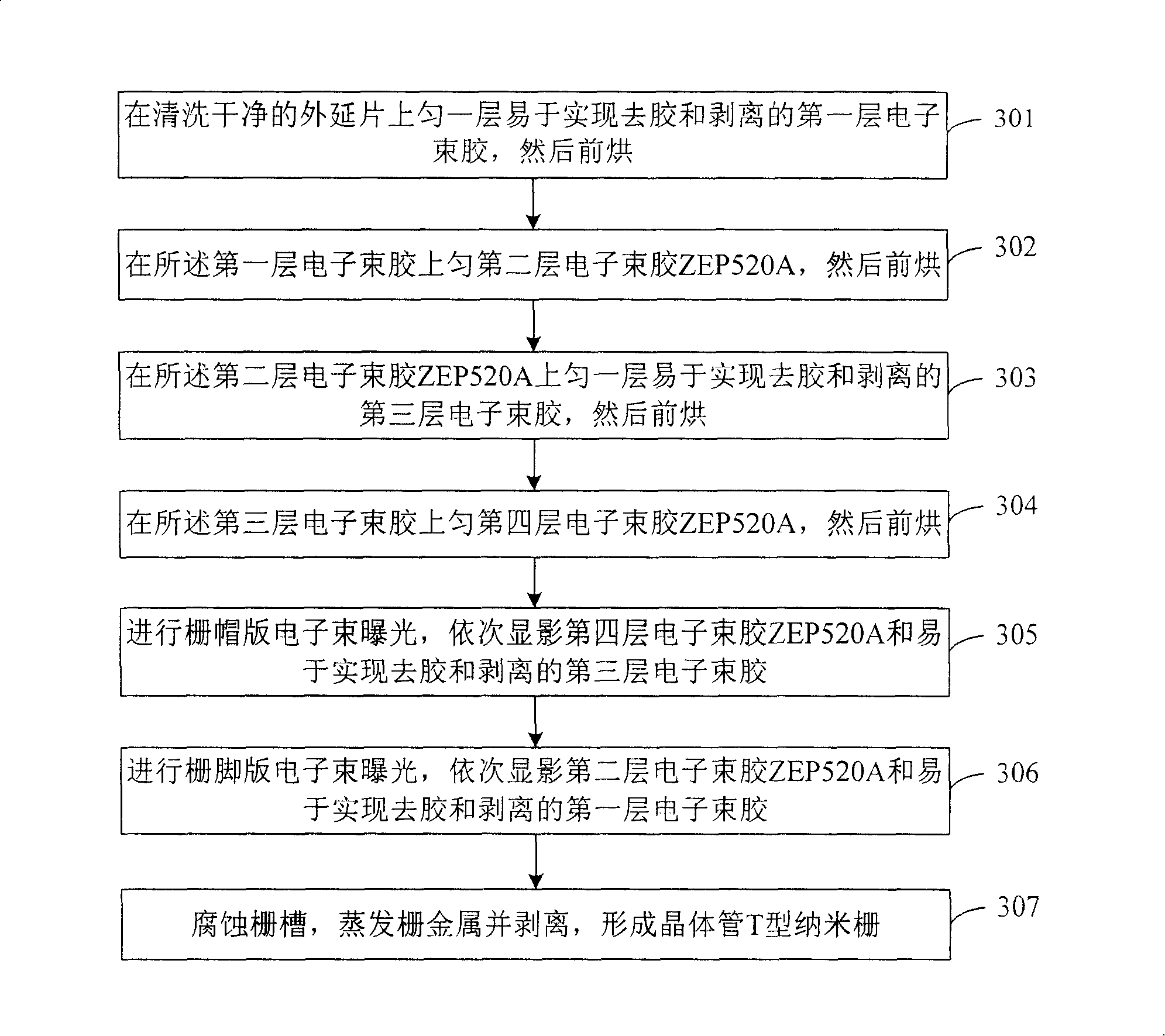

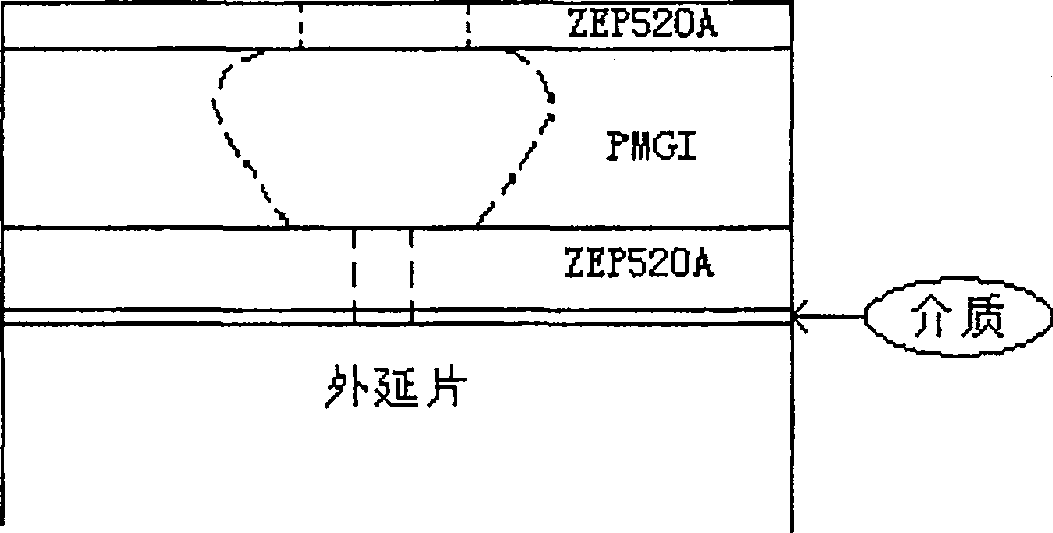

Production method of transistor T-shaped nano grid

InactiveCN101221903AEasy to makeEasy to remove glueSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusNano gridOptoelectronics

The invention discloses a fabrication method for a T-Shaped nanometer-gate of a transistor, which comprises the following steps of: A. coating a first layer of electronic beam glue which is easy to erase and strip and prebaking; B. coating a second layer of electronic beam glue ZEP520A on the first layer of electronic beam glue and prebaking; C. coating a third layer of electronic beam glue which is easy to erase and strip on the second layer of electronic beam glue ZEP520A and prebaking; D. coating a fourth layer of electronic beam glue ZEP520A on the third layer of electronic beam glue and prebaking; E. exposing grid electronic beam and developing the third layer of electronic beam glue and the fourth layer of electronic beam glue ZEP520A in sequence; F. Exposing grid electronic beam and developing the second layer of electronic beam glue ZEP520A and the first layer of electronic beam glue in sequence; G. corroding a gate channel and evaporating gate metal and stripping to form a transistor T-shaped nanometer-gate. With the invention, extreme small gate bars can be fabricated very easily with strong reliability but without growing and etching medium, greatly reducing the difficulty of the technology.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

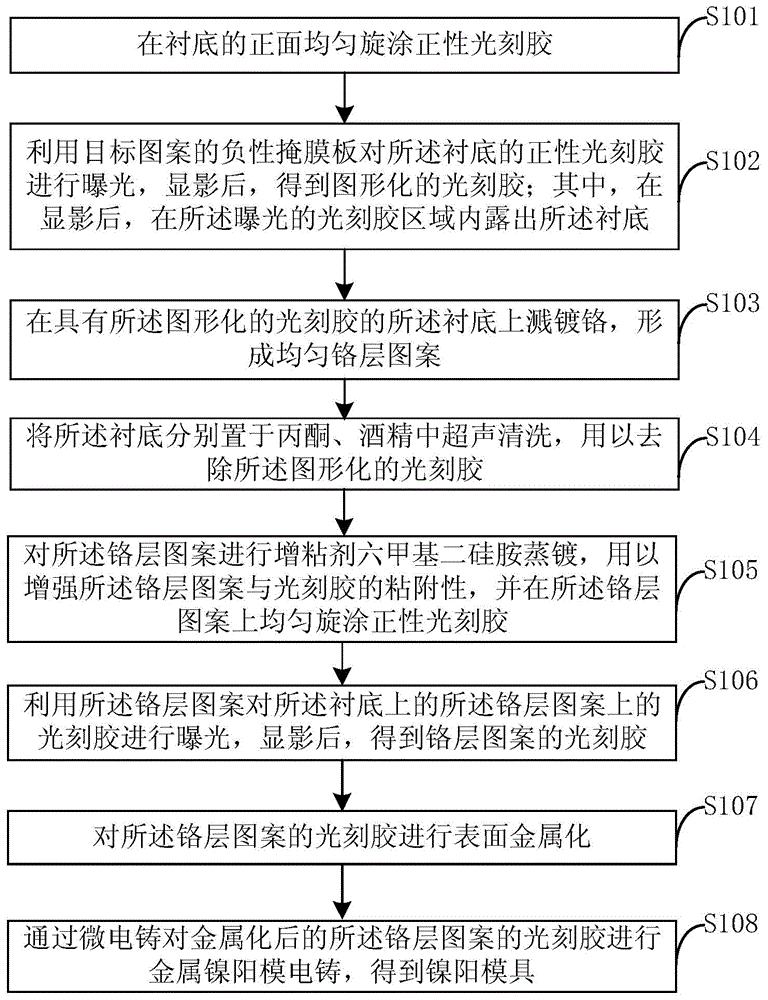

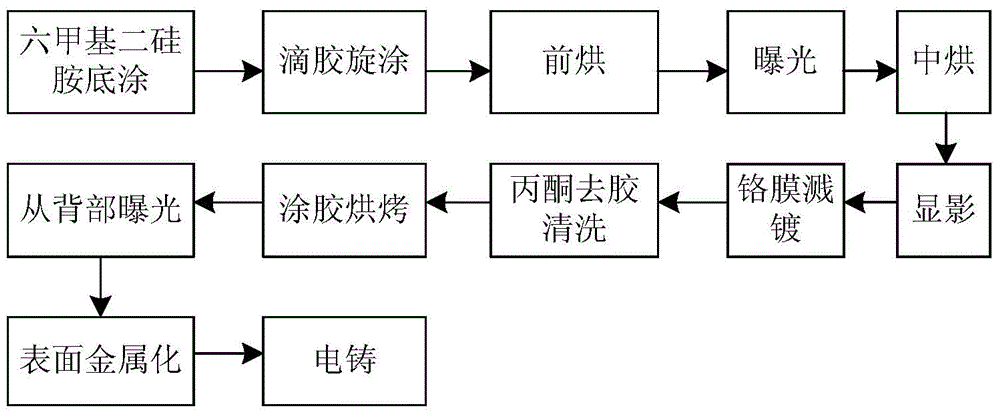

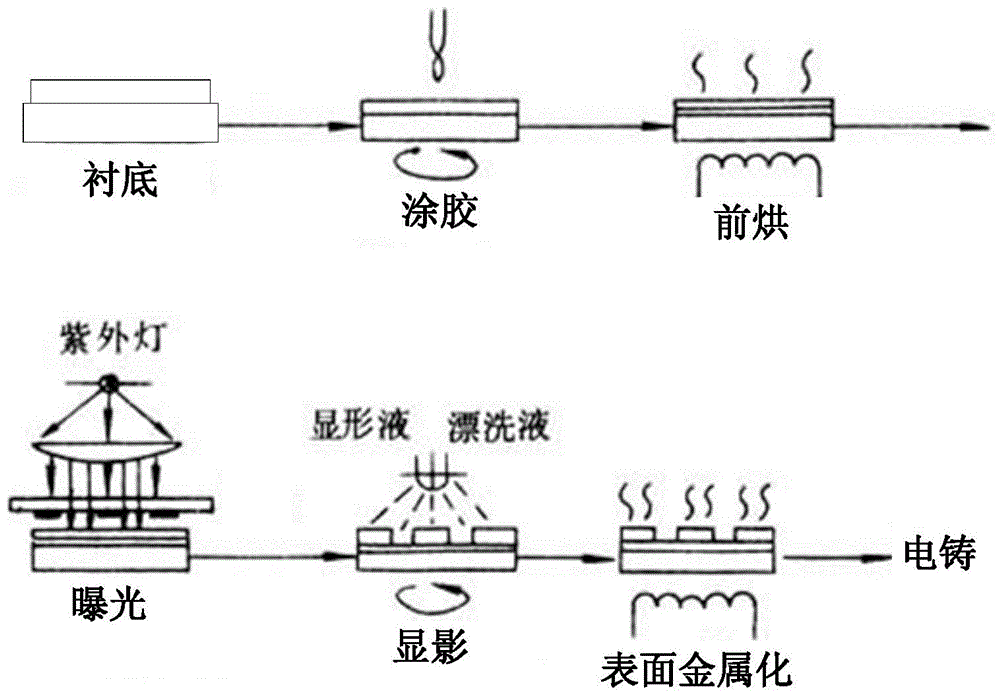

Positive photoresist-based nickel positive mold production method

ActiveCN104597719ASimple preparation processEasy to remove gluePhotomechanical exposure apparatusPhotosensitive material processingPhotoresistChromium

The embodiment of the invention relates to a positive photoresist-based nickel positive mold production method. The method comprises the following steps: evenly spin-coating the front side of a substrate with a positive photoresist; exposing the positive photoresist of the substrate by utilizing a negative mask plate of a target pattern, and developing to obtain the patterned photoresist; splash-plating chromium on the substrate with the patterned photoresist, to form a uniform chromium layer pattern; performing tackifier hexamethyldisilazane evaporation on the chromium layer pattern so as to enhance the adhesiveness of the chromium layer pattern and the photoresist, and evenly spin-coating the chromium layer pattern with the positive photoresist; exposing the photoresist on the chromium layer pattern on the substrate by utilizing the chromium layer pattern, and developing to obtain the photoresist of the chromium layer pattern; performing surface metallization on the photoresist of the chromium layer pattern; and performing metal nickel positive mold electroforming on the photoresist of the metalized the chromium layer pattern, to obtain the nickel positive mold. For the nickel positive mold, the production technology is simple and convenient, the photoresist removal is convenient, and the upwarping edges of the nickel positive mold can be avoided.

Owner:北京同方光盘股份有限公司

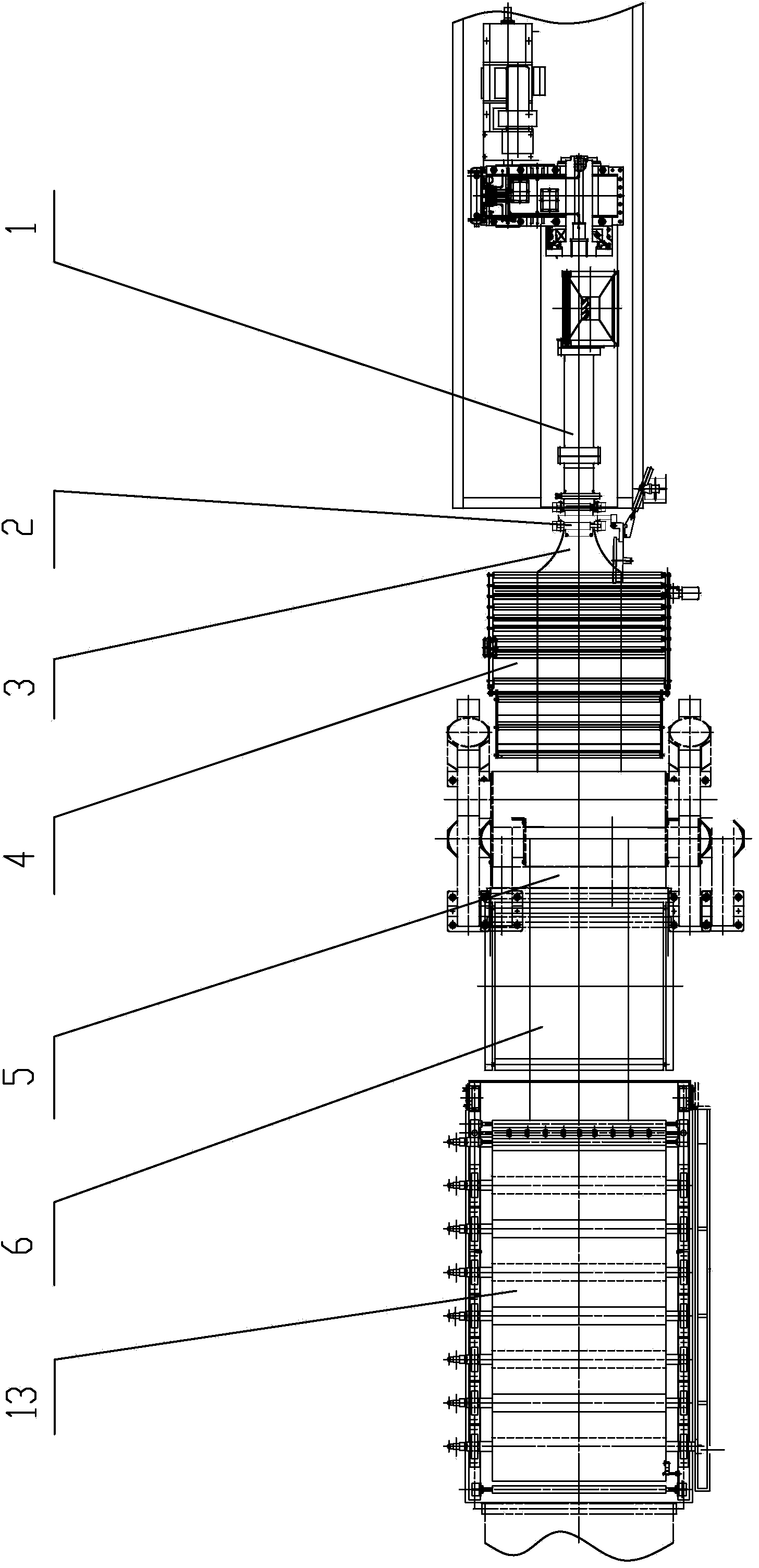

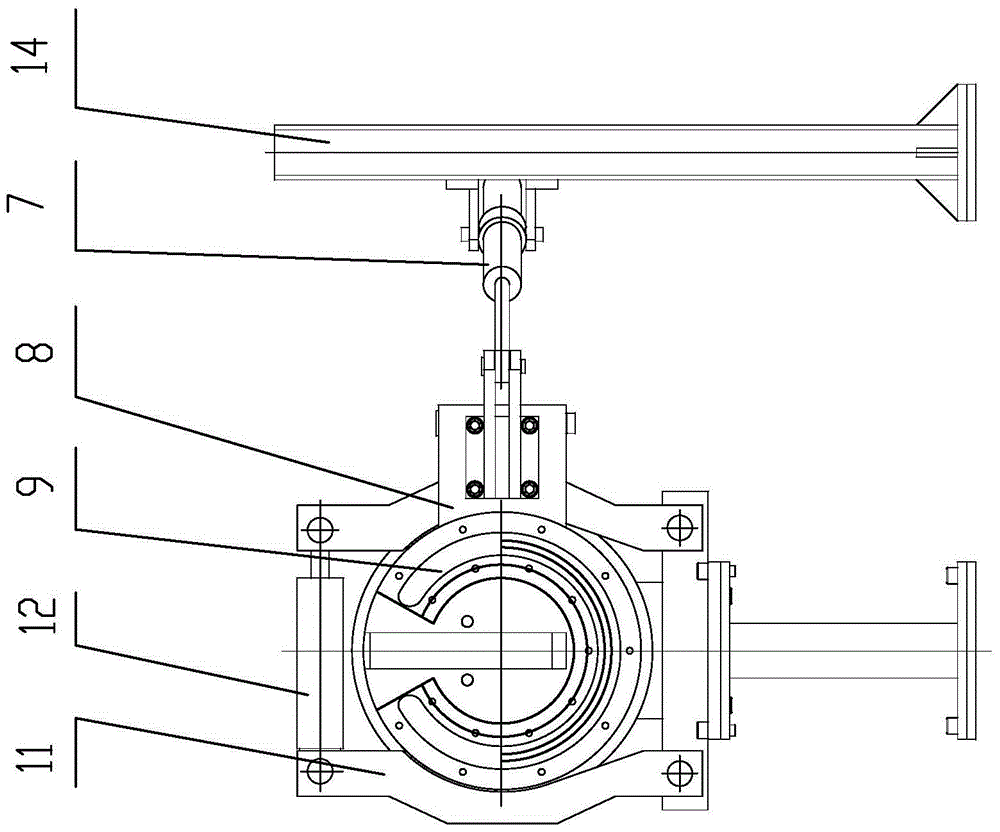

Machine head of rubber supply extruder of three-roller calender

The invention discloses a machine head of a rubber supply extruder of a three-roller calender. The machine head comprises a mold body which consists of a movable machine head mold and a fixed machine head mold, wherein the fixed machine head mold is arranged at a machine head cylinder opening of a pin cold feed extruder; the movable machine head mold is arranged on a mold opening and closing device; under a mold closing state, the mold body is locked by a mold locking device; a machine head opening is formed in the movable machine head mold and is provided with a small semicircular arc, a semicircular arc or a large semicircular arc which is downward and bilaterally-symmetric; the arc length of the machine head opening corresponds to the width of a wide-amplitude extrusion rubber tape, and the arc width of the machine head opening corresponds to the thickness of the wide-amplitude extrusion rubber tape; a material supply frame supplying rubber to the three-roller calender is arranged on an extrusion path of the wide-amplitude extrusion rubber tape, and the position of the material supply frame corresponds to the flattening spreading part of the wide-amplitude extrusion rubber tape. An extrusion calendering rubber supply path is greatly shortened, the temperature loss is small in the conveying process of rubber sheets, and the calendered rubber sheets are dense, uniform in thickness, smooth and flat in surface, bubble-free, and high in product quality.

Owner:GUILIN RUBBER MACHINERY CO LTD

Preparation method of KSr2Nb5O15 transparent ferroelectric ceramic

Owner:NORTHWESTERN POLYTECHNICAL UNIV

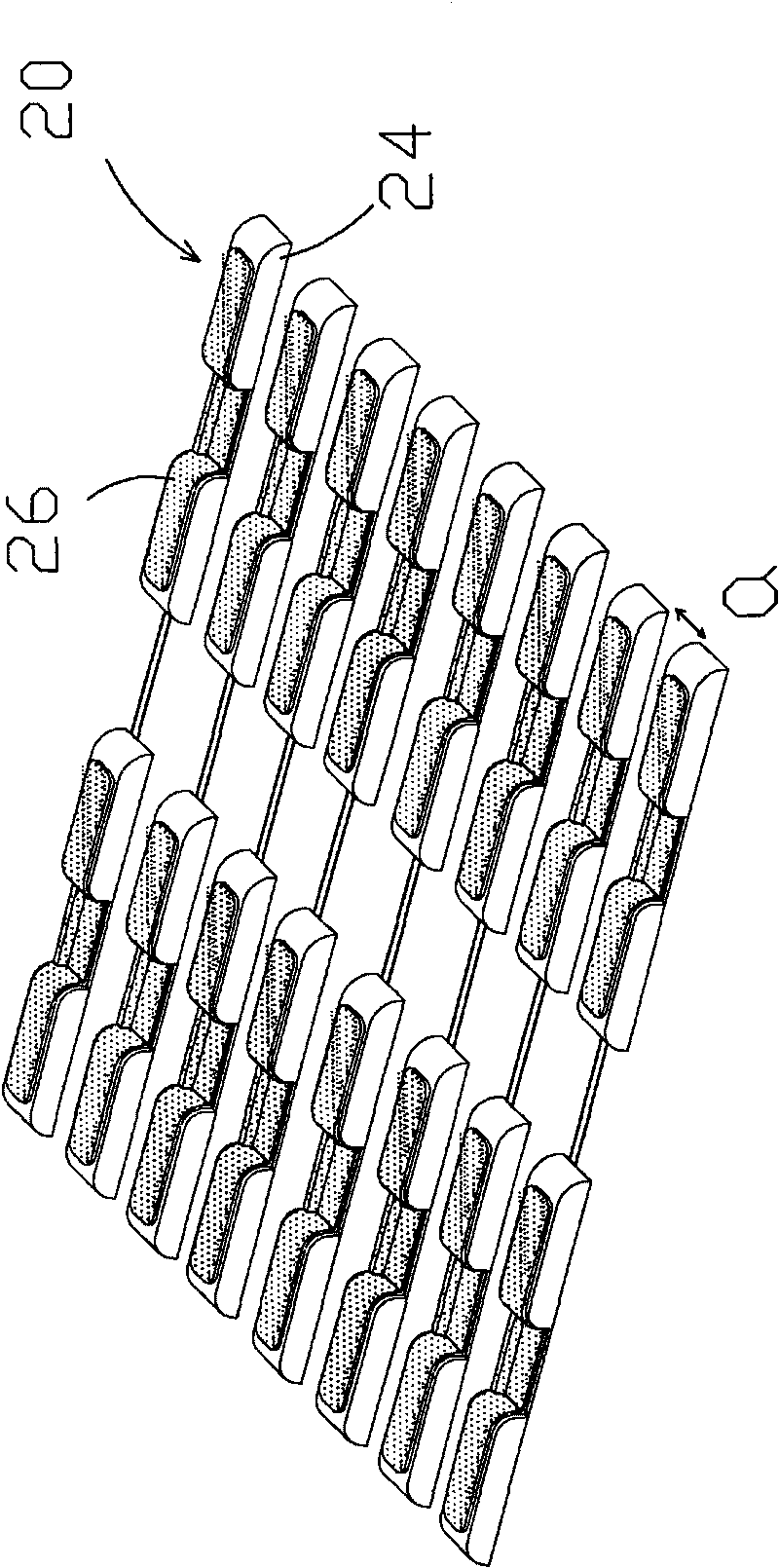

Graphene nanoribbons Fin-FET (Field Effect Transistor) device with controllable channel width and preparation method thereof

InactiveCN103500761ALow costPrecise control of line widthSemiconductor/solid-state device manufacturingSemiconductor devicesGraphene nanoribbonsField-effect transistor

The invention belongs to the technical field of graphene nanometer devices, and particularly relates to a graphene nanoribbons Fin-FET (Field Effect Transistor) device with controllable channel width and a preparation method thereof. The preparation method is suitable for preparing the graphene nanoribbons Fin-FET device on a large scale, and comprises the following steps of: firstly preparing a registration mark and a source / drain electrode of the Fin-FET device on grapheme by utilizing a general electron beam lithography method; then sequentially preparing a grapheme island and a hundred-nanoscale photoresist line pattern on a grapheme sample by utilizing an electron beam registration method; depositing a side wall through an atomic layer, and realizing accurate control on the width of the side wall; and etching by adopting the side wall as a mask through side wall transfer technology, so that the accurate control on the channel width of the graphene nanoribbons is realized. Through adjusting the periodicity of atomic layer deposition, a graphene nanoribbons Fin-FET device array with the channel width being less than 10nm can be prepared on a large scale.

Owner:FUDAN UNIV

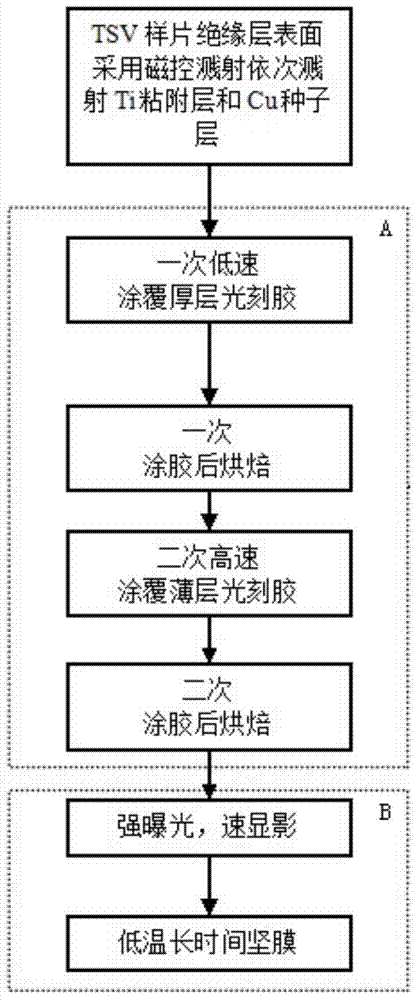

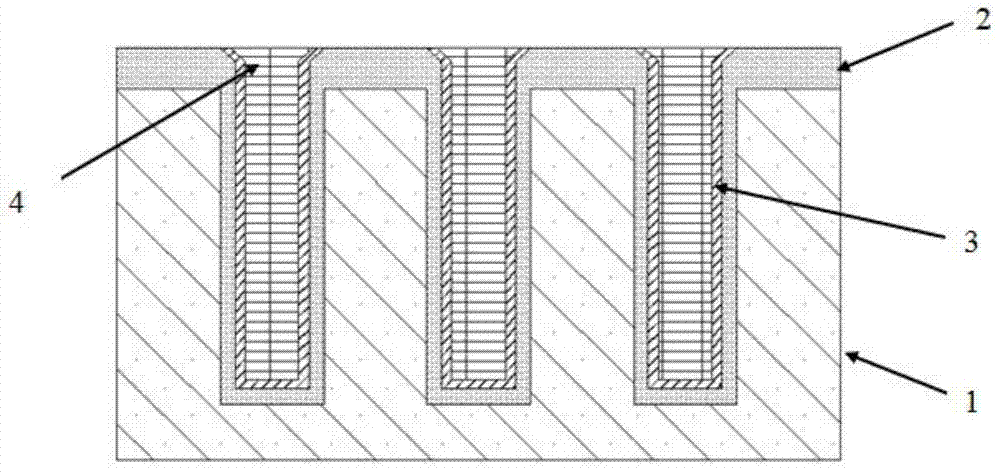

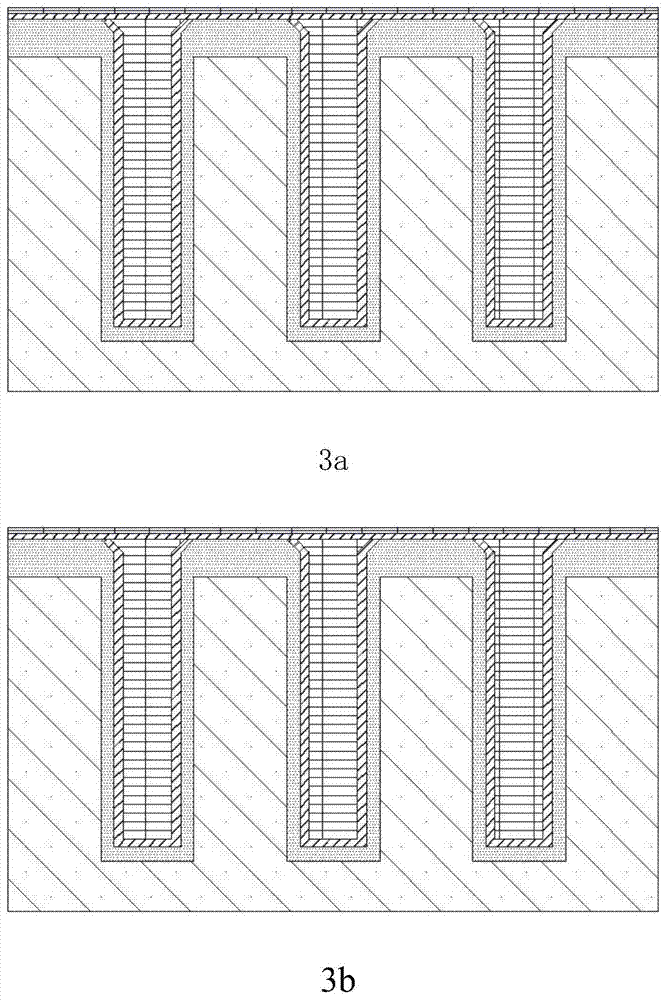

Thick-film coating process for preparing TSV three-dimensional integrated RDL electroplated mask

ActiveCN104332393AHigh precisionSteep side wallsSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusLow temperature long timeFilm coating

The invention discloses a thick-film coating process for preparing a TSV three-dimensional integrated RDL electroplated mask. The technology comprises the following steps: a Ti adhesion layer and a Cu seed layer are sequentially sputtered on the surface of an insulated layer of a TSV blind hole electroplated wafer; a thick film is prepared in a mode of gluing for two times and baking for two times, a thick photoresist is coated at low speed for the first time, a thin photoresist is coated at high speed for the second time, time and temperature of the two-time baking vary according to the thickness ratio of the upper glue layer to the lower glue layer, and the ratio of the accumulated baking time of the bottom glue layer to the baking time of the surface glue layer is the thickness ratio of the two; and exposure, development and hardbaking are then carried out for preparing the RDL electroplated mask. Through adjusting parameters of two-time gluing and conditions of baking, uniformity of the thick film layer and resolution of lithography can be ensured; through strong exposure, quick development and low-temperature and long-time hardbaking, the mask which is high in precision, steep in side wall, higher in thickness and higher in uniformity can be manufactured; and the technology of the invention can be applied to RDL interconnecting wire whose electroplated layer is higher than 20mum and appearance is clear and neat.

Owner:NO 771 INST OF NO 9 RES INST CHINA AEROSPACE SCI & TECH

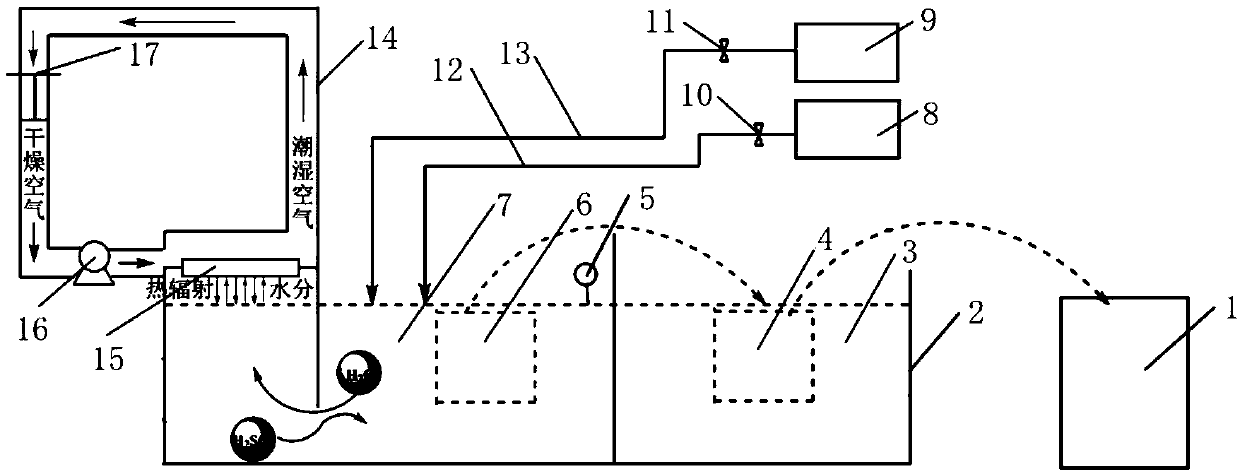

Glass water degumming device and degumming method

PendingCN109570174AEasy to cleanGood removal effectDispersed particle separationSemiconductor/solid-state device manufacturingWater pipeMicroprocessor

The invention discloses a glass wafer degumming device. The glass wafer degumming device comprises a degumming tank, a dehydrating component, a concentrated sulfuric acid tank, a hydrogen peroxide tank and a microprocessor; the degumming tank comprises a washing tank and a rinsing tank which are arranged adjacently; the washing tank is filled with concentrated hydrochloric acid and hydrogen peroxide; the upper portion inside the washing tank is provided with a washing basket; the upper portion inside the rinsing tank is provided with a rinsing basket; the concentrated sulfuric acid tank communicates with the washing tank via concentrated sulfuric acid pipe; the hydrogen peroxide tank communicates with the washing tank via a hydrogen peroxide pipe; one side of the upper portion of the washing tank is provided with a tank cover; the other side of the upper portion of the washing tank is used for arranging the dehydrating component; and the dehydrating component comprises an electric heating plate, an absorption bin, a temperature sensor, a circulating pipe, a desiccant bag and a fan. The invention further provides a method for degumming glass wafers by using the glass wafer degummingdevice. The glass wafer degumming device can be used for effectively removing ultraviolet curing glue on the glass wafer, can realize continuous proceeding of a degumming process without frequently replacing the degumming liquid, improves the work efficiency, saves resources and protects the environment.

Owner:SUZHOU JIMCEL ELECTRONICS NEW MATERIAL

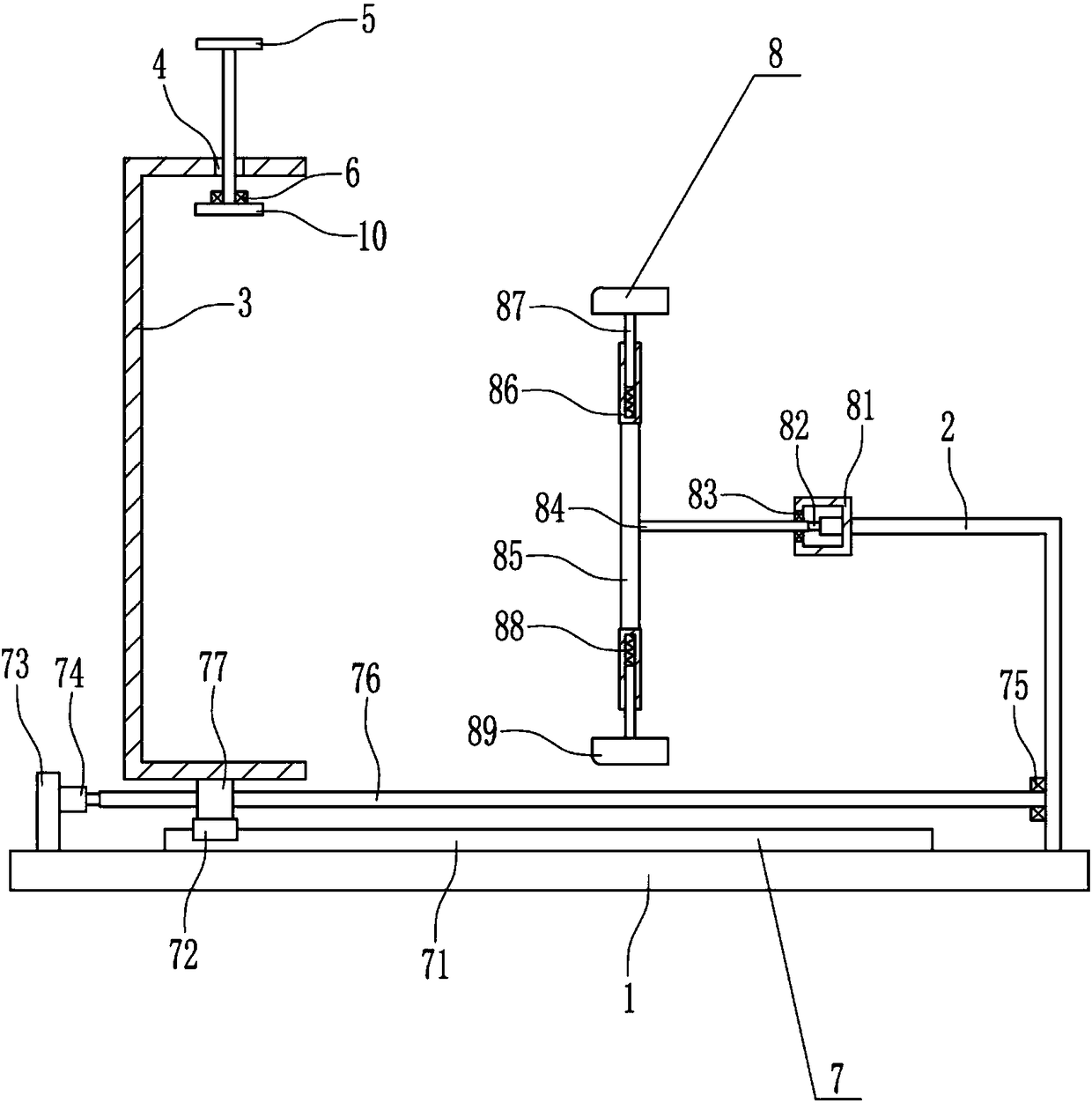

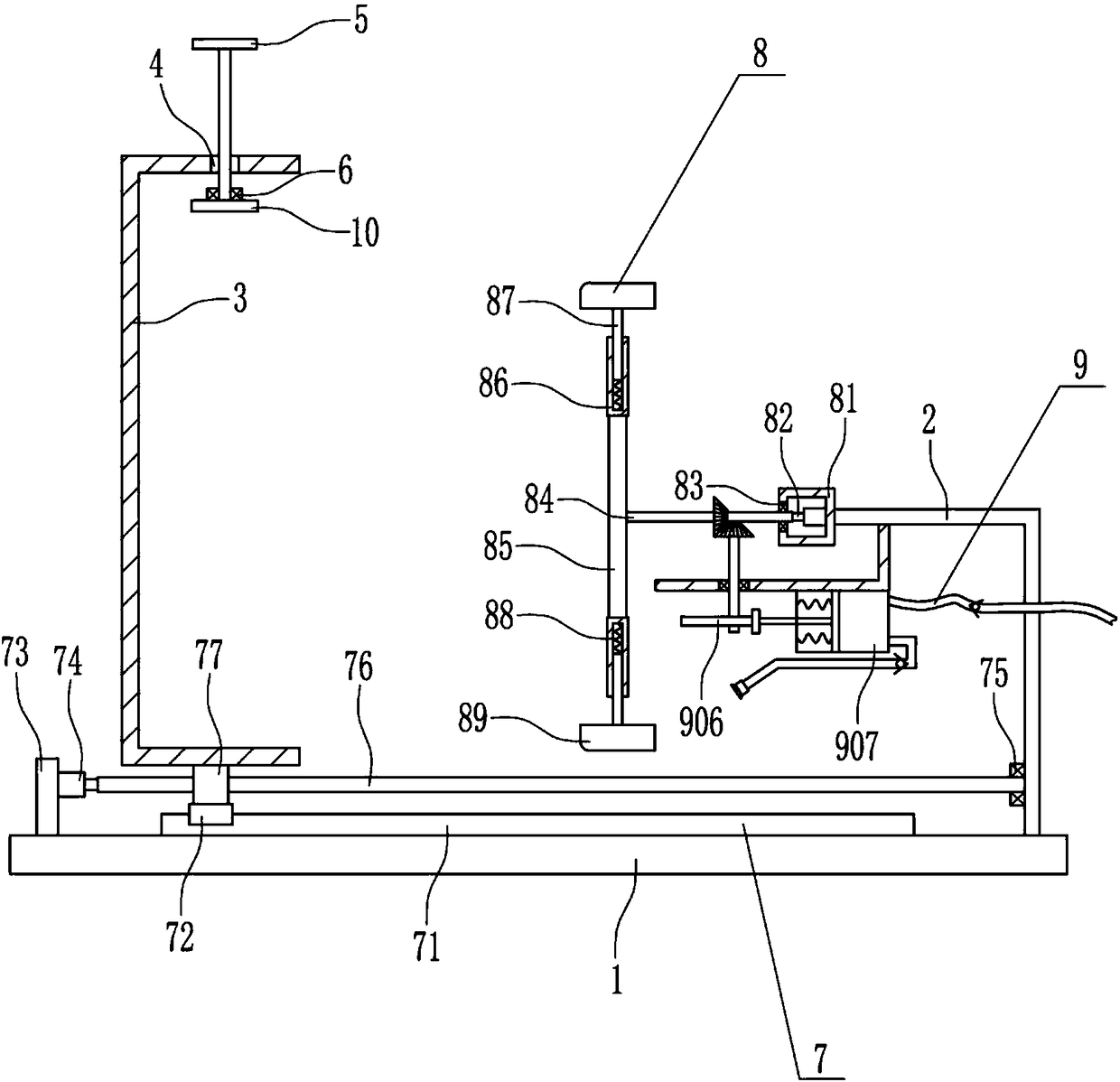

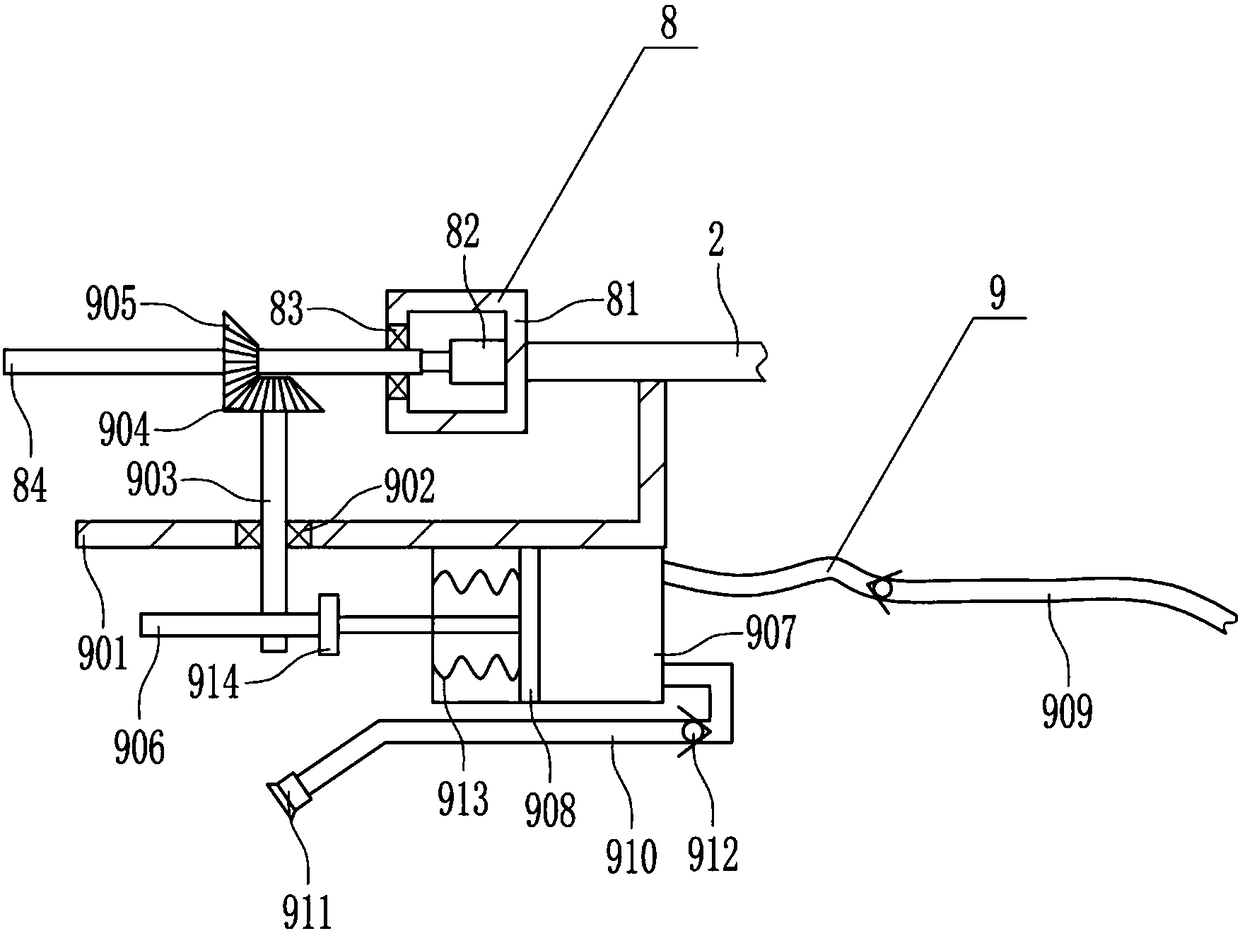

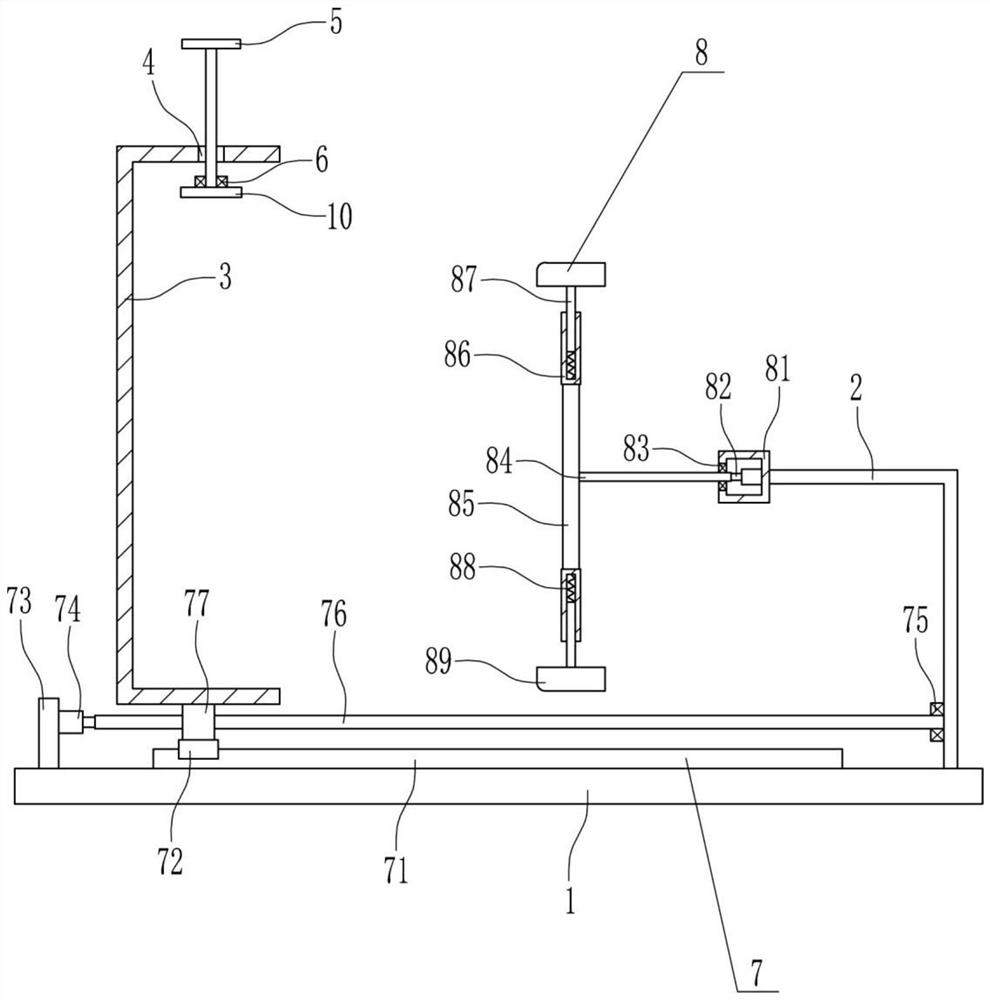

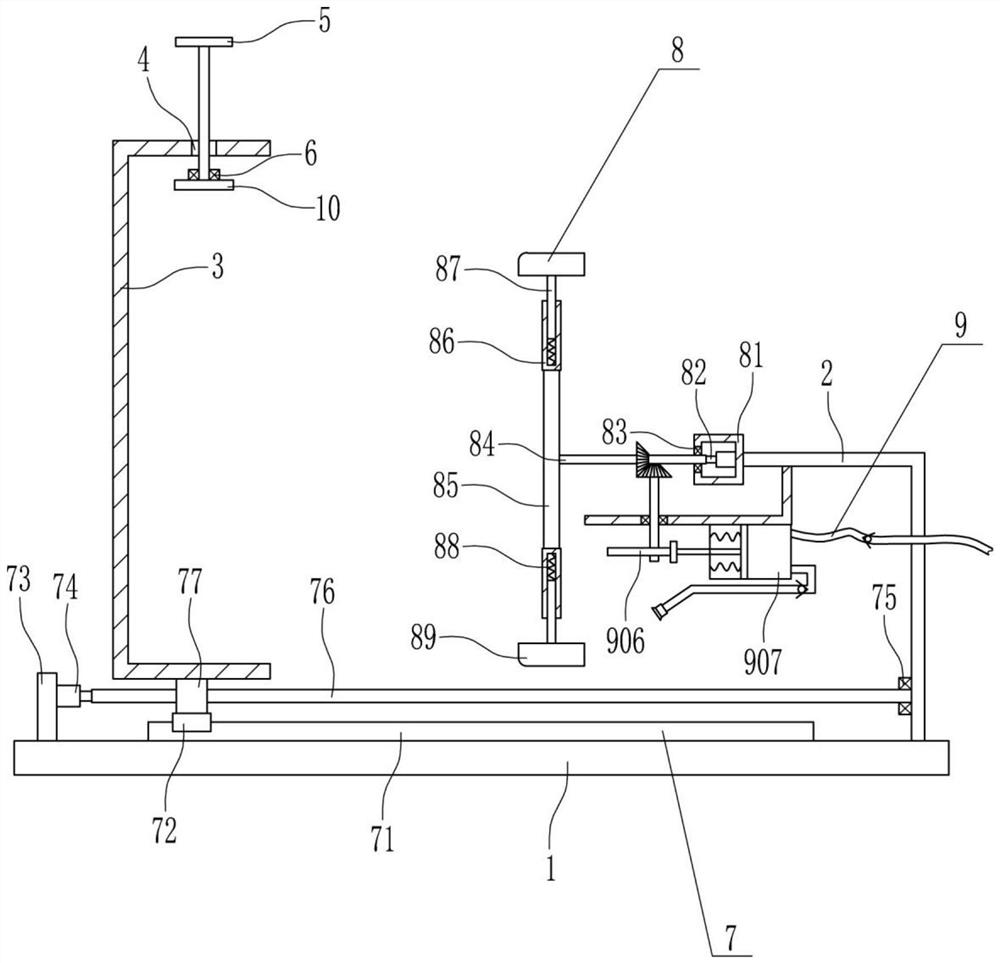

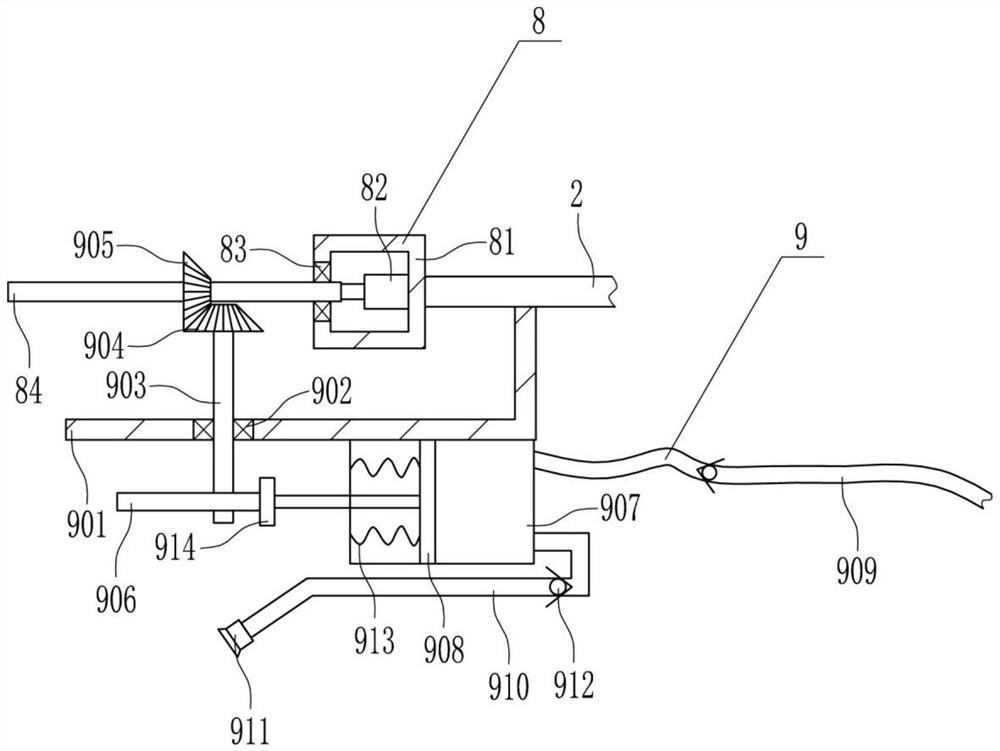

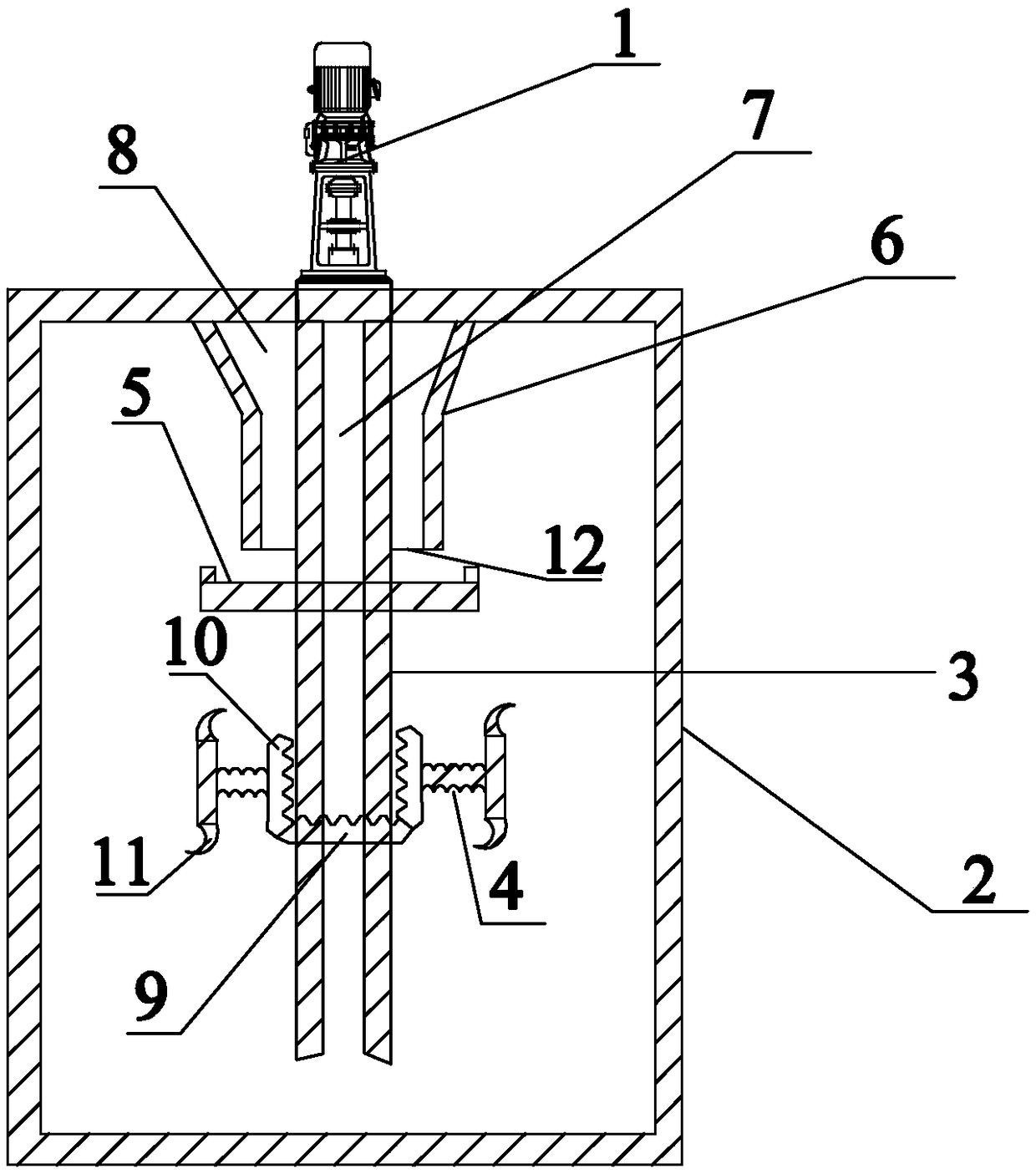

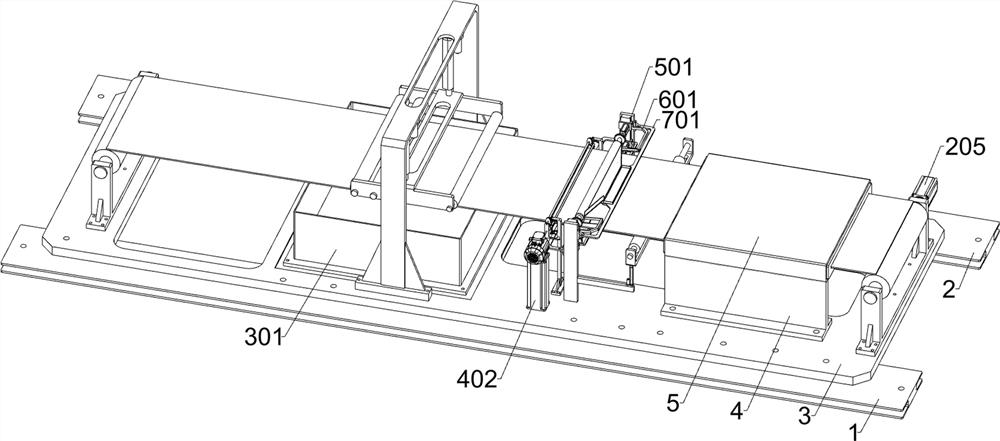

Adhesive removal equipment for adhesive tank for adhesive dispensing of LED lamps

ActiveCN108568371AScrape off thoroughlyPrevent tamperingLiquid surface applicatorsSpraying apparatusAdhesiveEngineering

The invention relates to adhesive removal equipment, in particular to adhesive removal equipment for an adhesive tank for adhesive dispensing of LED lamps. In order to solve the technical problems, the adhesive removal equipment for the adhesive tank for adhesive dispensing of the LED lamps is provided, does not easily stain a hand with an adhesive and is comparatively convenient. The adhesive removal equipment for the adhesive tank for adhesive dispensing of the LED lamps comprises a bottom plate, a 7-shaped plate, a u-type storage frame, a T-type screw, a first bearing block, a leftward-rightward moving device and the like, wherein the leftward-rightward moving device is mounted at the top of the bottom plate, the u-type storage frame is connected to the leftward-rightward moving device,a screw hole is formed in the top of the u-type storage frame, the T-type screw is movably arranged in the screw hole, and a fixing plate is arranged below the T-type screw. Through cooperation of the leftward-rightward moving device and an adhesive removal device, the adhesive on the inner wall of the adhesive tank can be removed, manual adhesive removal is not required, the adhesive removal device can drive a liquid spraying device to work, the adhesive removal device can better remove the adhesive on the inner wall of the adhesive tank, so that the effects that the adhesive does not easilystain the hand and adhesive removal is comparatively convenient are realized.

Owner:浙江罗丹照明电器有限公司

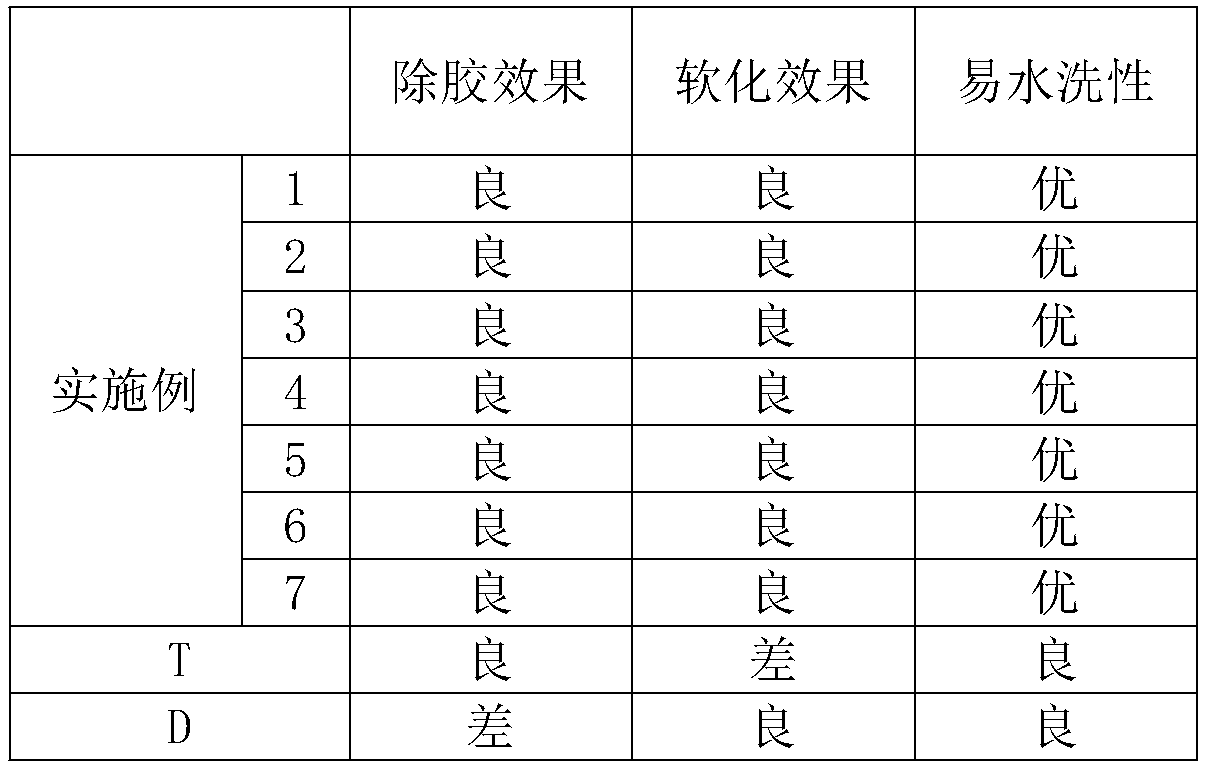

QFN (quad flat no-lead package) adhesive removal and softening integrated soak solution

InactiveCN109370792AEasy to remove glueImprove softening effectInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPolymer sciencePolypropylene

The invention belongs to the technical field of package, and relates to QFN (quad flat no-lead package) adhesive removal and softening integrated soak solution. The QFN adhesive removal and softeningintegrated soak solution in a formula comprises 0.5-5 wt% of block polyether surfactants, 20-40 wt% of organic alkali, 0.1-5 wt% of inorganic alkali, 30-50 wt% of organic solvents, 20-30 wt% of alcohol ether dispersing agents, 0.01-0.05 wt% of metal corrosion inhibitors and the balance deionized water. The block polyether surfactants comprise one or two types of propylene glycol polyoxyethylene polypropylene oxide block polymers and allyl polyoxyethylene polypropylene oxide methyl ether. The QFN adhesive removal and softening integrated soak solution has the advantages that the QFN adhesive removal and softening integrated soak solution is excellent in adhesive removal and softening ability and easy to clean, integral technologies only take the total time of 25-45 min, processes can be shortened to be 1 / 4 of the original processes, and accordingly the productivity can be greatly improved; the solution soak time is only 1 / 4 of the original solution soak time, and plastic package bodiescan be prevented from being damaged.

Owner:JIANGSU AISEN SEMICON MATERIAL CO LTD

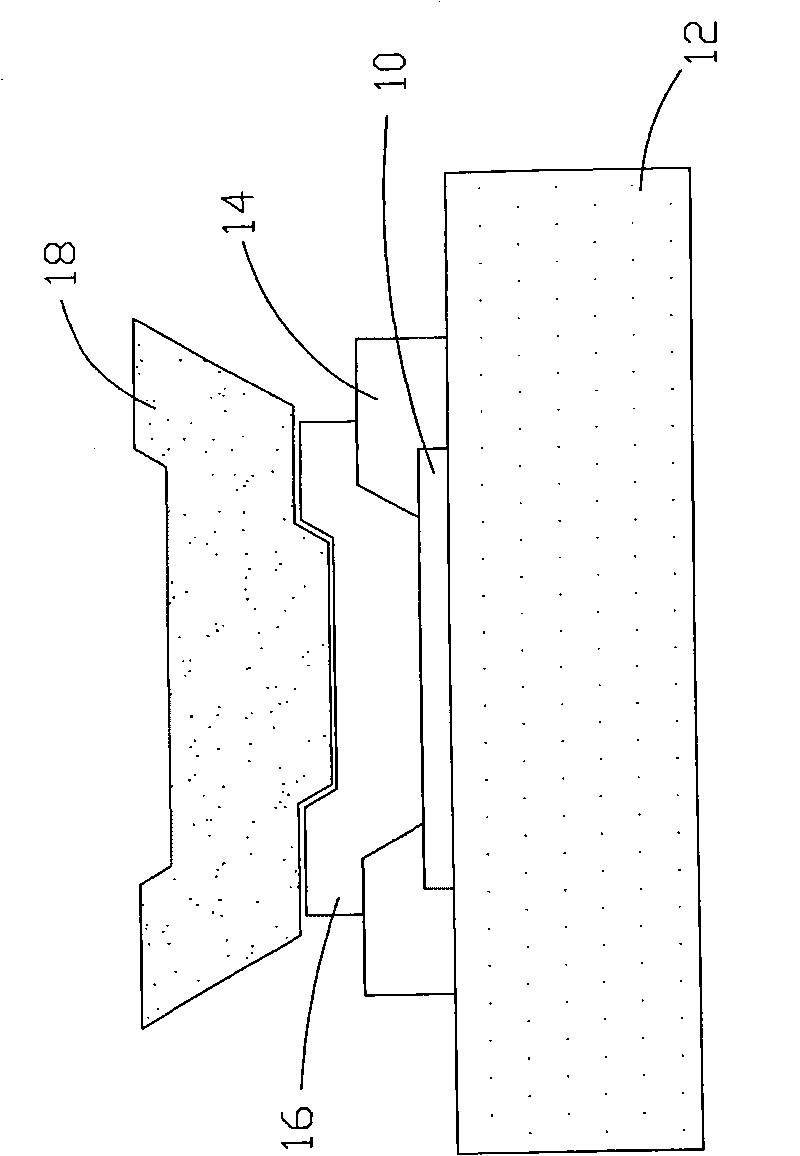

Lug structure and making method thereof

InactiveCN101728346AEasy to remove glueSemiconductor/solid-state device detailsSolid-state devicesSemiconductorLarge size

The invention relates to a lug structure and a making method thereof. The lug structure comprises a semiconductor substrate, a protective layer, an elastic layer and a plurality of lugs, wherein a plurality of connection pads are formed on the surface of the semiconductor substrate; the protective layer is covered on the substrate and provided with openings corresponding to the connection pads, thereby exposing part of each connection pad as the electric connection position; the elastic layer is positioned on the protective layer; and each lug is positioned on the electric connection position and extends to the elastic layer, thereby providing the space between the lug elasticity and the amount of deformation by means of the elastic layer. In the invention, a large-size (at least 20 mu m) elastic layer pattern making procedure is utilized to form the elastic layer with a proper pattern, so that the lug structure can be suitable for IC elements with superfine pitch.

Owner:HANNSTAR DISPLAY CORPORATION

Adhesive removing agent and adhesive removing method

ActiveCN109576086ASimple processStable in natureInorganic/elemental detergent compounding agentsOrganic non-surface-active detergent compositionsAdhesiveSurface structure

The invention provides an adhesive removing agent and an adhesive removing method, and relates to the field of adhesive removing. The adhesive removing agent comprises, by weight, 8%-25% of phytic acid, 5%-12% of sodium gluconate, 23%-35% of titanium dioxide and 28%-64% of additive. The adhesive removing agent solves the problem that no adhesive removing agent in the prior art can remove adhesiveresidues without damaging a surface structure of a metal decorating part, affecting reliability and appearance and corroding a main material of the metal decorating part, and by the aid of the adhesive removing agent, a panel, appearance and usability of the metal decorating part cannot be affected during adhesive removing.

Owner:LENS TECH CHANGSHA

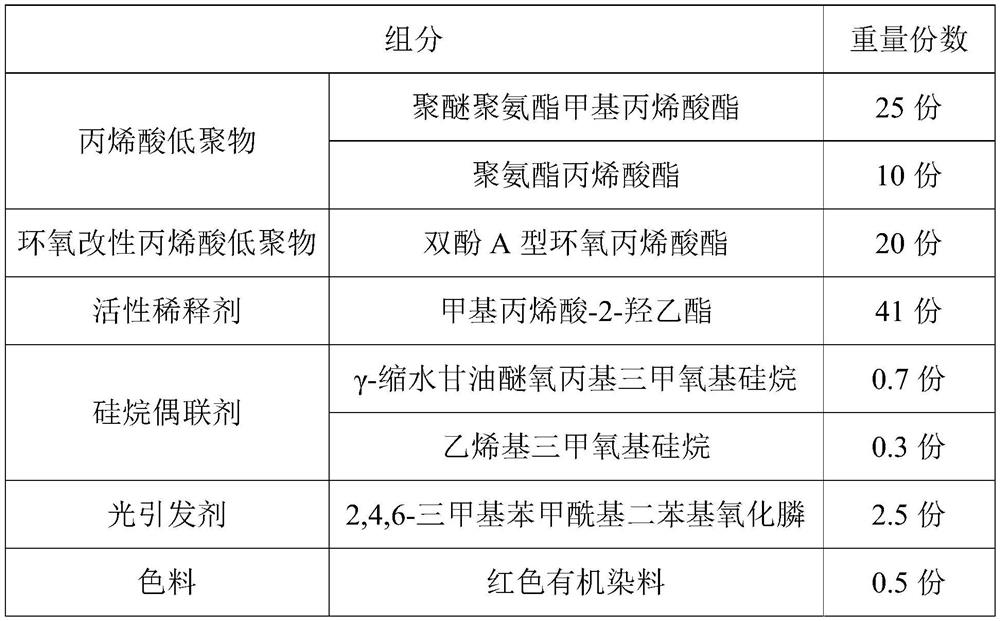

Ultraviolet curing type adhesive as well as preparation method and application thereof

ActiveCN112063356ALow shrinkageImprove densification performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesMethacrylatePolymer science

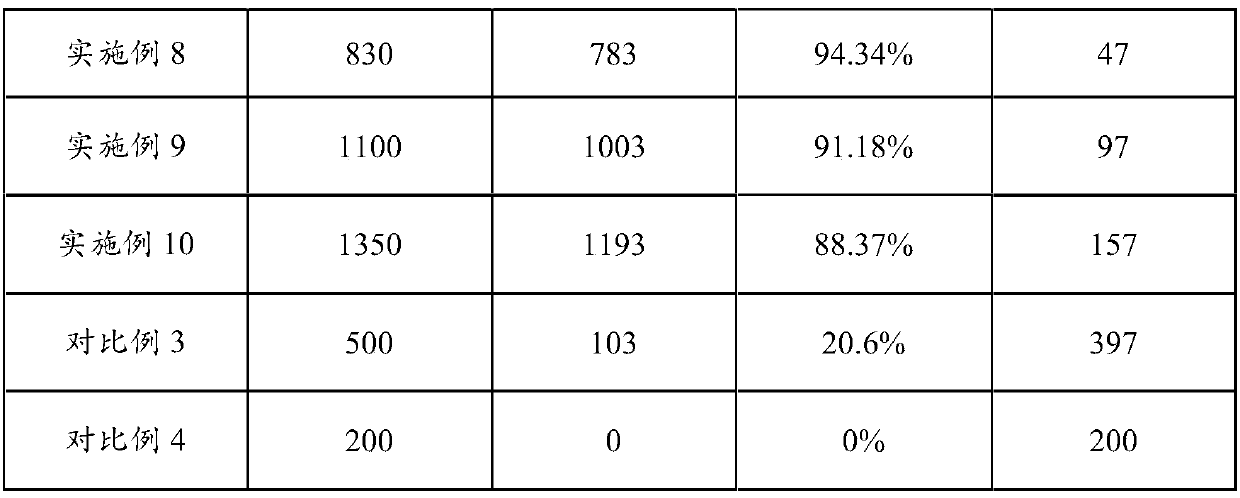

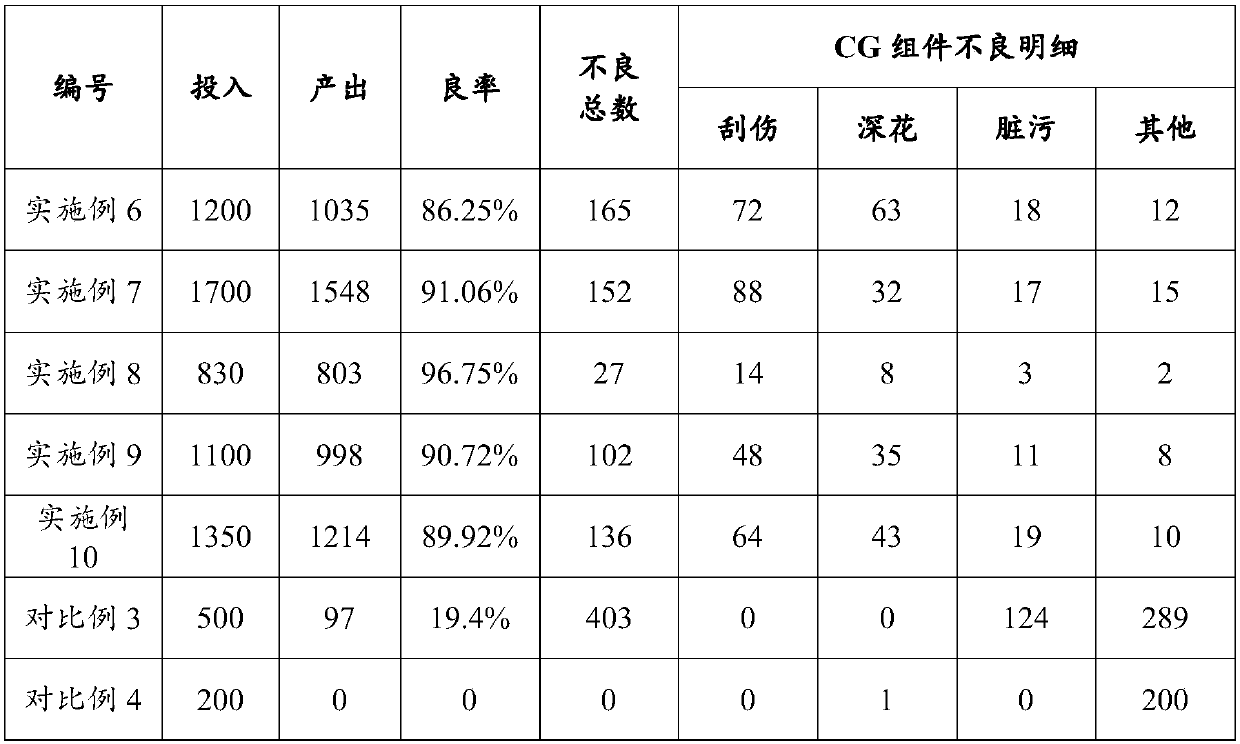

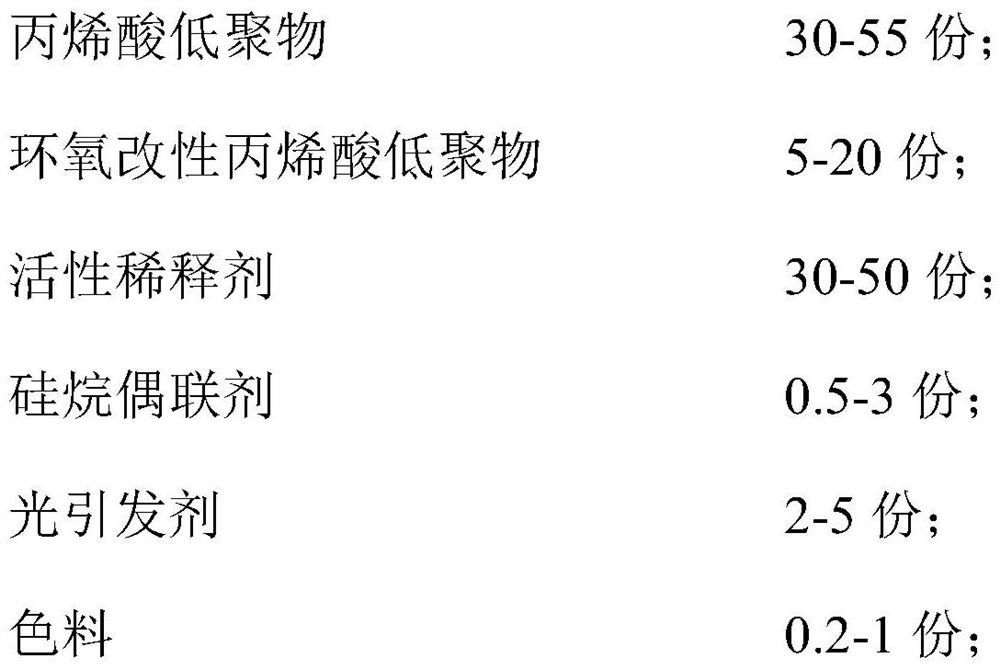

The invention provides an ultraviolet curing type adhesive as well as a preparation method and application thereof. The ultraviolet curing type adhesive comprises the following preparation raw materials in parts by weight: 30-55 parts of acrylic acid oligomer, 5-20 parts of epoxy modified acrylic acid oligomer, 30-50 parts of a reactive diluent, 0.5-3 part of a silane coupling agent, 2-5 parts ofa photoinitiator and 0.2-1 part of a pigment. the acrylic acid oligomer comprises polyether polyurethane methacrylate and / or polyurethane acrylate. The ultraviolet curing type adhesive disclosed by the invention is proper in adhesive film hardness, excellent in acid and alkali resistance and mechanical property, capable of enabling glass to be thinned to be thicker, convenient in adhesive removal,simple in preparation process and good in stability.

Owner:DONGGUAN POWERBOND NEW MATERIALS TECH DEV

A glue tank removal equipment for LED lamp dispensing

ActiveCN108568371BScrape off thoroughlyPrevent tamperingLiquid surface applicatorsSpraying apparatusAdhesive glueEngineering

The invention relates to adhesive removal equipment, in particular to adhesive removal equipment for an adhesive tank for adhesive dispensing of LED lamps. In order to solve the technical problems, the adhesive removal equipment for the adhesive tank for adhesive dispensing of the LED lamps is provided, does not easily stain a hand with an adhesive and is comparatively convenient. The adhesive removal equipment for the adhesive tank for adhesive dispensing of the LED lamps comprises a bottom plate, a 7-shaped plate, a u-type storage frame, a T-type screw, a first bearing block, a leftward-rightward moving device and the like, wherein the leftward-rightward moving device is mounted at the top of the bottom plate, the u-type storage frame is connected to the leftward-rightward moving device,a screw hole is formed in the top of the u-type storage frame, the T-type screw is movably arranged in the screw hole, and a fixing plate is arranged below the T-type screw. Through cooperation of the leftward-rightward moving device and an adhesive removal device, the adhesive on the inner wall of the adhesive tank can be removed, manual adhesive removal is not required, the adhesive removal device can drive a liquid spraying device to work, the adhesive removal device can better remove the adhesive on the inner wall of the adhesive tank, so that the effects that the adhesive does not easilystain the hand and adhesive removal is comparatively convenient are realized.

Owner:浙江罗丹照明电器有限公司

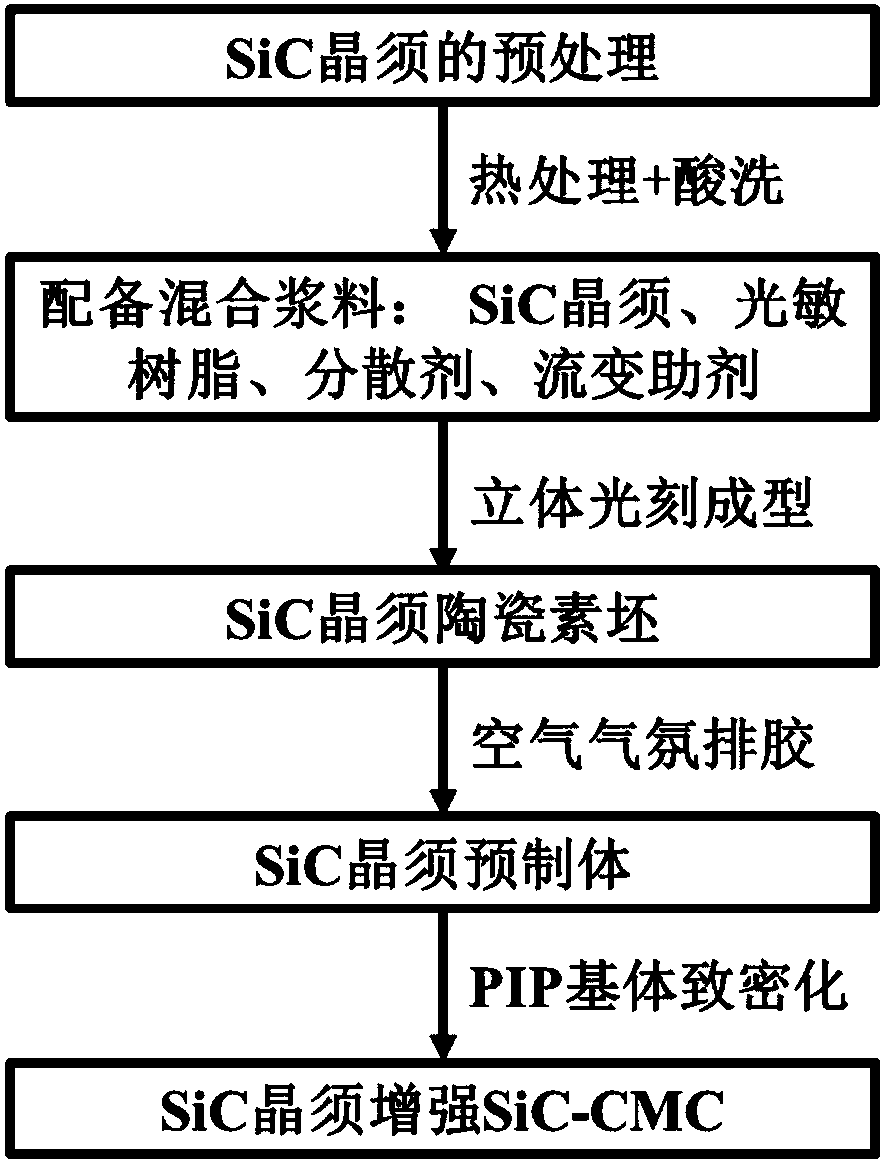

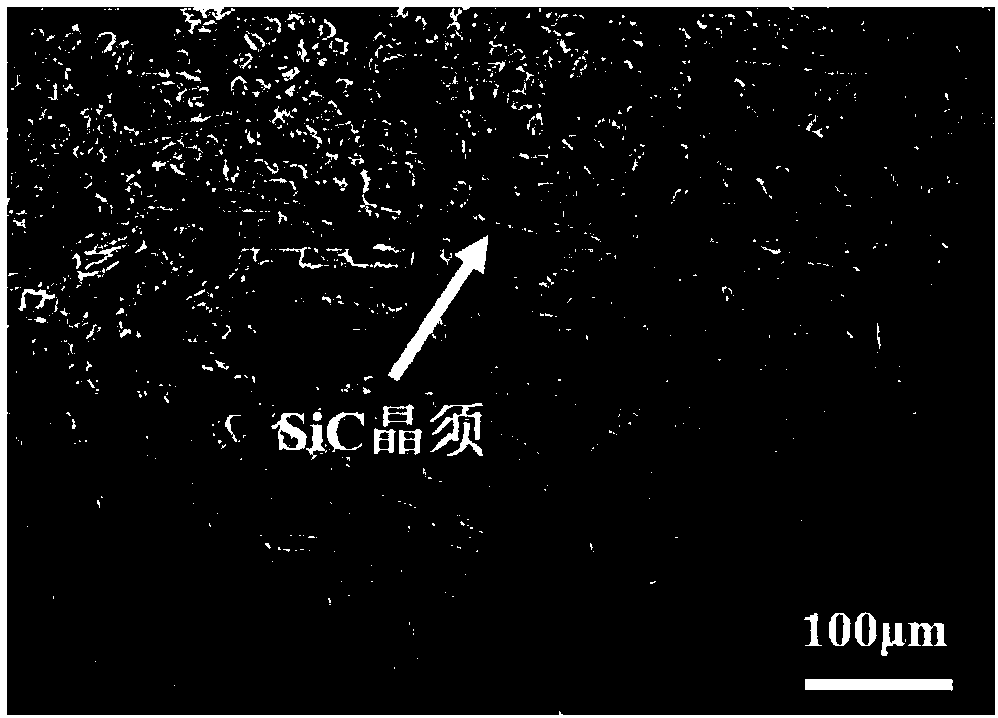

Ceramic material SiC whisker suitable for stereolithography, and preparation method thereof

ActiveCN108395249AHigh forming precisionUniform and programmable microstructureAdditive manufacturing apparatusCeramic shaping apparatusStress conditionsStructure and function

The invention relates to a ceramic material SiC whisker suitable for stereolithography, and a preparation method thereof. The ceramic material SiC whisker comprises a SiC whisker, photosensitive resin, a dispersant and a rheological assistant. The preparation method comprises the following steps: SiC whisker pretreatment, preparation of a SiC whisker biscuit, dumping of a SiC whisker preform, andpreparation of a SiC matrix. The preparation method has the advantages of high molding precision, uniform and designable microstructure, realization of molding a complex profile member, promotion of the application of the stereolithography technology in the ceramic field, and solving of problems of mold dependence, difficulty in molding the complex profile member and non-uniform microstructure inthe prior art, and the prepared SiC whisker reinforced SiC-CMC material is isotropic, that is, the structure and function characteristics in all directions are basically consistent, so the SiC whiskerreinforced SiC-CMC material has application potential in hot end components for bearing high and complex stress conditions in the aerospace field.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

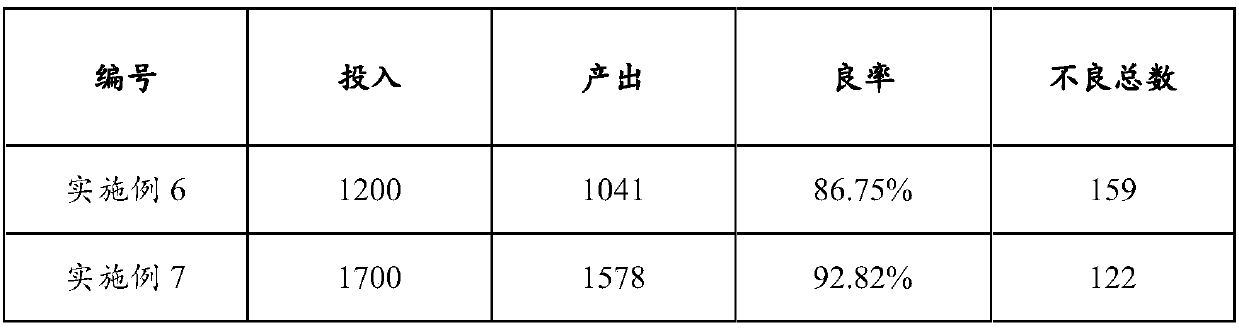

Ferrite material for motor and preparation method of ferrite material

The invention relates to the technical field of permanent magnetic ferrite materials, and provides a ferrite material for a motor and a preparation method of the ferrite material for solving the problems of easy blockage, low yield and the like in the traditional preparation process of the permanent magnet ferrite. The mole ratio and ion exchange content of the ferrite material for the motor are determined according to the following molecular formula: Sr1-xAxFe<3+>2n-yByO19, wherein A is selected from at least one of rare earth elements, and necessarily comprises La; B is selected from at least one element of Bi, Co, Mn and Zn, and necessarily comprises Co, and the component ratios of A, B and Fe are as follows: X is greater than or equal to 0.1 and smaller than or equal to 0.4, y is greater than or equal to 0.05 and smaller than or equal to 0.25, and n is greater than or equal to 5.9 and smaller than or equal to 6.1. The process disclosed by the invention is simple in steps, sufficient in grinding, high in yield, high in grinding speed, low in energy consumption and unlikely to block, and the prepared ferrite material for the motor has excellent magnetic property and is good in product consistency.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

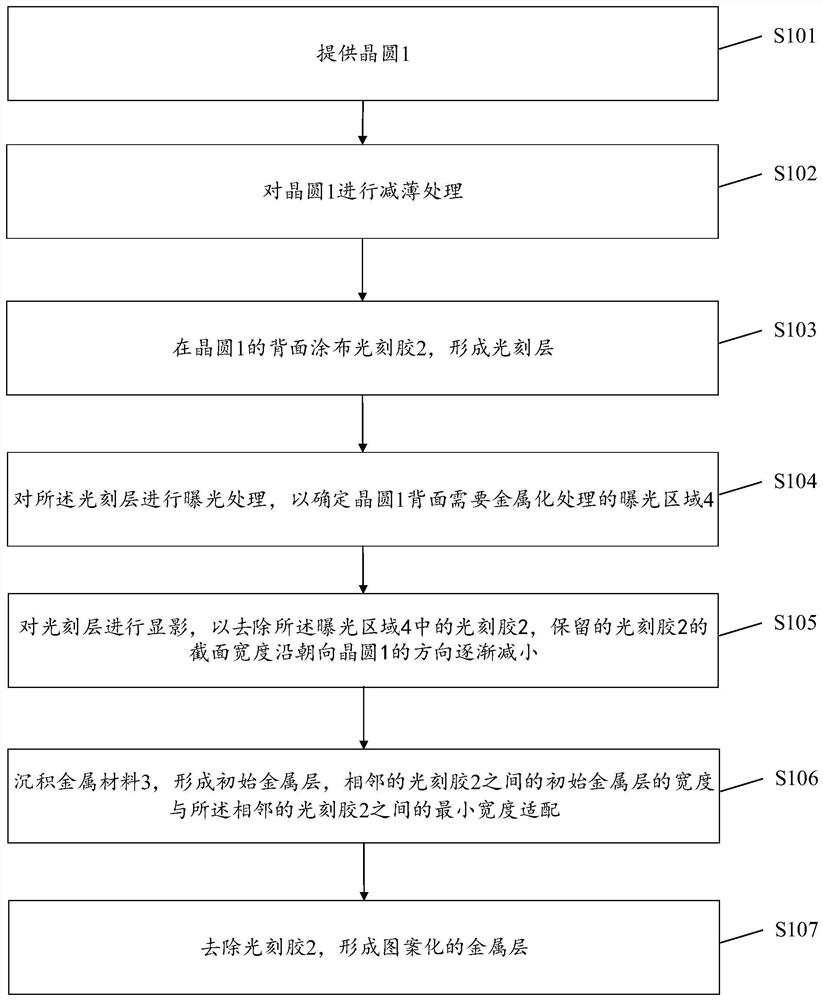

Wafer back metallization method

PendingCN113972132AInhibit sheddingAvoid short circuit and other problemsSemiconductor/solid-state device manufacturingWaferMetallic materials

The invention provides a wafer back metallization method. The method comprises the following steps of: providing a wafer; coating the back surface of the wafer with photoresist on to form a photoetching layer; performing exposure treatment on the photoetching layer to determine an exposure area needing metallization treatment on the back surface of the wafer; developing the photoetching layer to remove the photoresist in the exposure area, and making the section width of the reserved photoresist gradually reduced in the direction towards the wafer; depositing a metal material to form an initial metal layer, and enabling the width of the initial metal layer between adjacent photoresist to be matched with the minimum width between the adjacent photoresist; and removing the photoresist to form a patterned metal layer. According to the method of the invention, the yield of a wafer back gold process and subsequent packaging can be improved.

Owner:HYGON INFORMATION TECH CO LTD

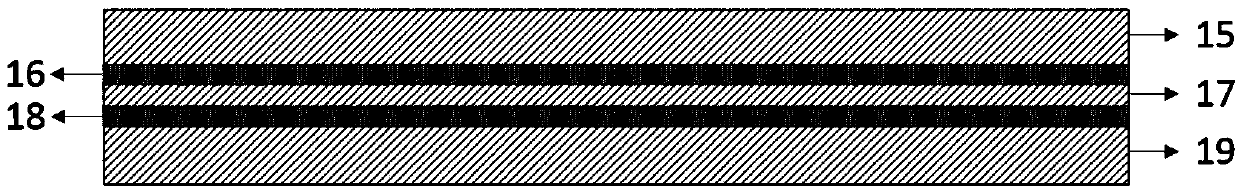

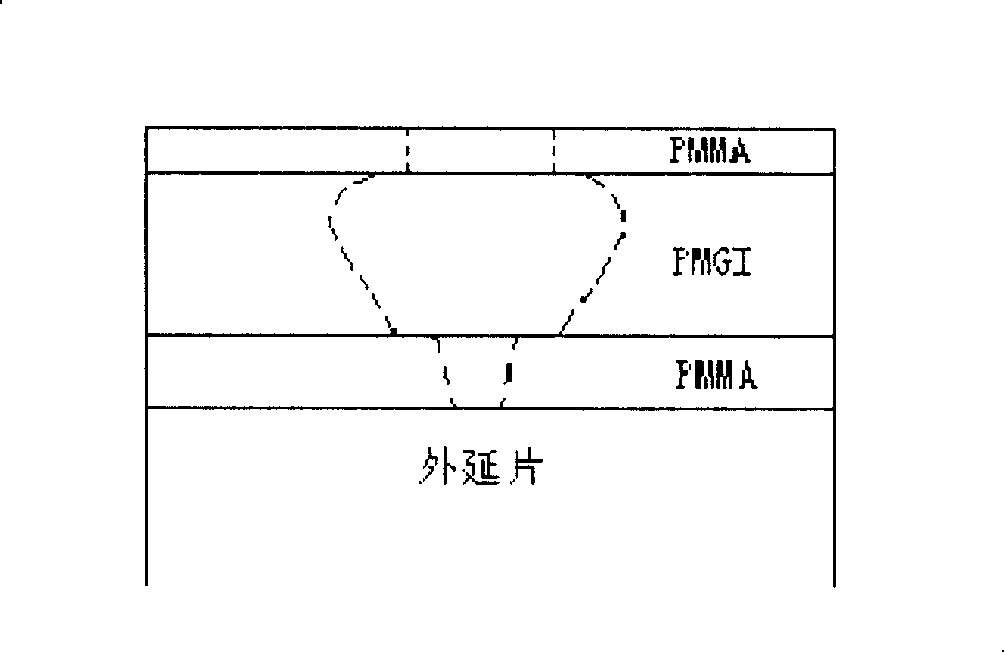

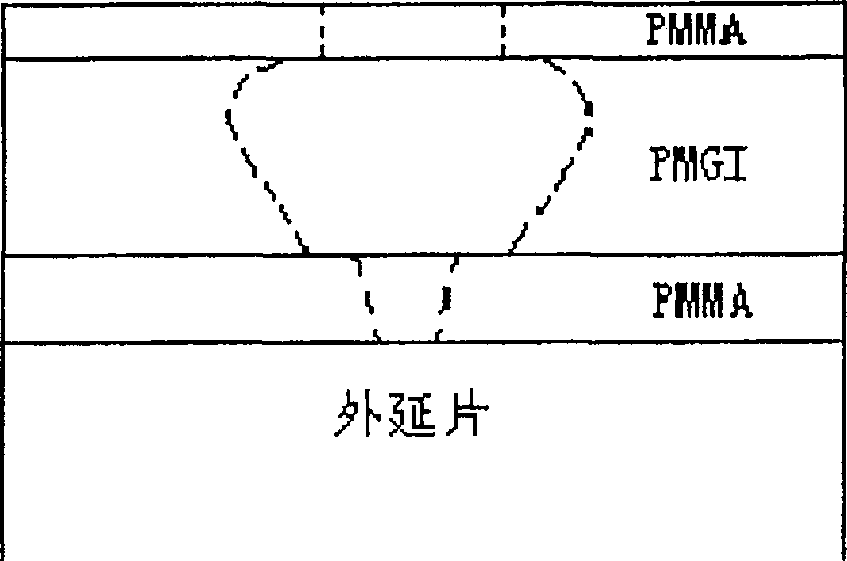

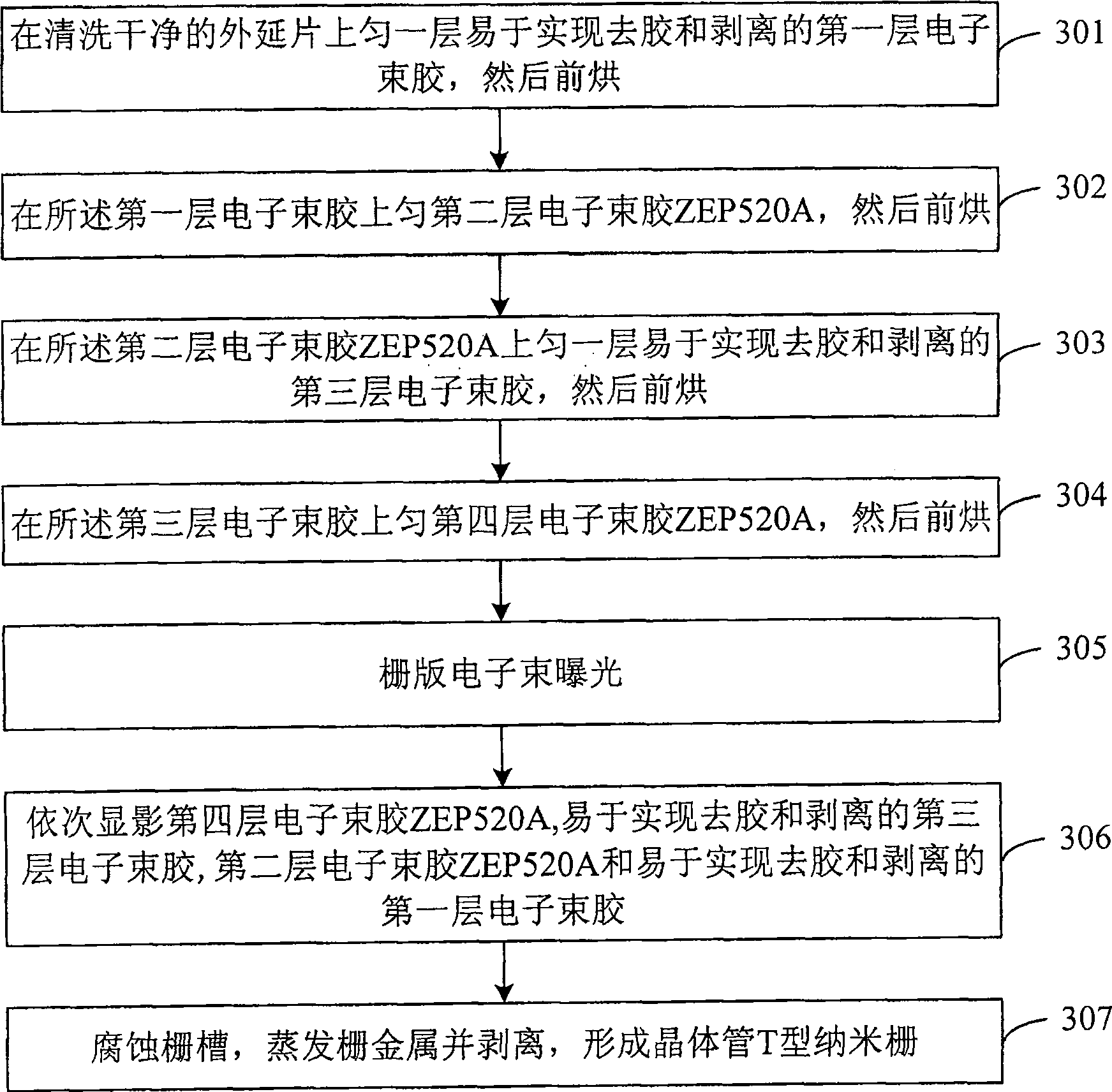

Method for producing transistor T type nano grid using once electron beam exposure

InactiveCN100511596CEasy to manufactureNo sleeve alignment issuesPhotomechanical apparatusSemiconductor/solid-state device manufacturingCooking & bakingElectron-beam lithography

The invention discloses a method for using once electric beam exposure to manufacture transistor T-shaped nanometer gate, comprising the steps of: A, coating a first layer electric beam glue which is liable to realize glue-stripping and peeling on a cleaned epitaxial wafer, and then soft-baking; B, coating a second layer electric beam glue ZEP520A on the first layer electric beam glue, and then soft-baking; C, coating a third layer electric beam glue which is liable to realize glue-stripping and peeling on the second layer electric beam glue ZEP520A, and then soft-baking; D, coating a fourth layer electric beam glue ZEP520A on the third layer electric beam glue, and then soft-baking; E, carrying out gate electric beam exposure; F, sequentially developing the four layer electric beam glue ZEP520A, the third layer electric beam glue which is liable to realize glue-stripping and peeling, the second layer electric beam glue ZEP520A and the first layer electric beam glue which is liable to realize glue-stripping and peeling; G, eroding the gate groove, evaporating and peeling off gate metals to form the transistor T-shaped nanometer gate. The invention has strong reliability, simple processes and is easy to peel off and strip the glue.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

High-strength wear-resistant corrugated carton packaging material

InactiveCN114108389AHigh strengthImprove wear resistanceNon-fibrous pulp additionFlexible coversCelluloseCarton

The invention provides a high-strength wear-resistant corrugated carton packaging material, and belongs to the field of packaging materials, and a preparation method of the high-strength wear-resistant corrugated carton packaging material comprises the following steps: carrying out coprecipitation on amino cellulose and paper pulp by using an alkali-urea water system to obtain modified paper pulp, carrying out dehydration, pulp distribution and drying on the modified paper pulp to obtain corrugating base paper, carrying out rolling and glue spraying reinforcement on the corrugating base paper, and carrying out drying to obtain the high-strength wear-resistant corrugated carton packaging material. And drying together with corrugated base paper, and then bonding through a binder to obtain the corrugated carton packaging material. According to the invention, amino cellulose is added through a coprecipitation method, so that the amino cellulose and paper pulp fibers are fully entangled and interpenetrated, the strength and wear resistance of the product are improved, and the mechanical strength of the corrugated carton is further improved by adding graphene.

Owner:连云港市申润包装材料有限公司

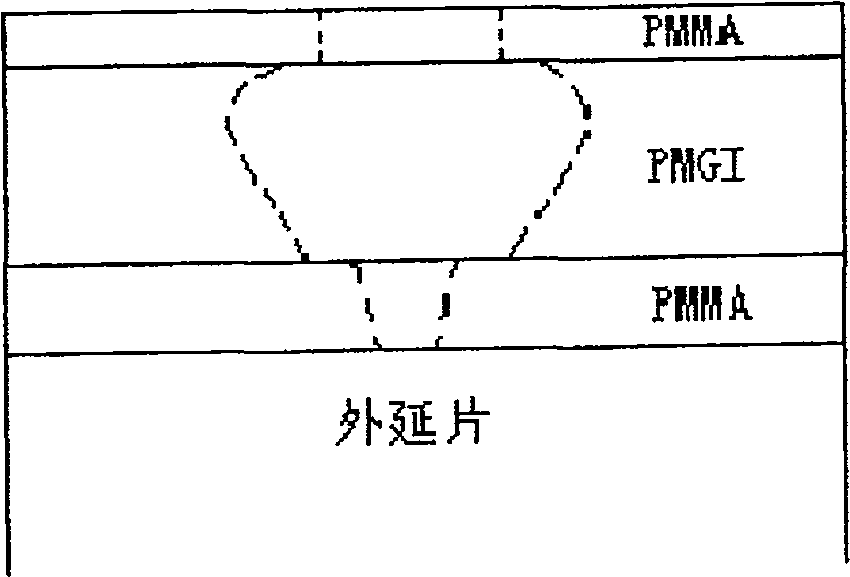

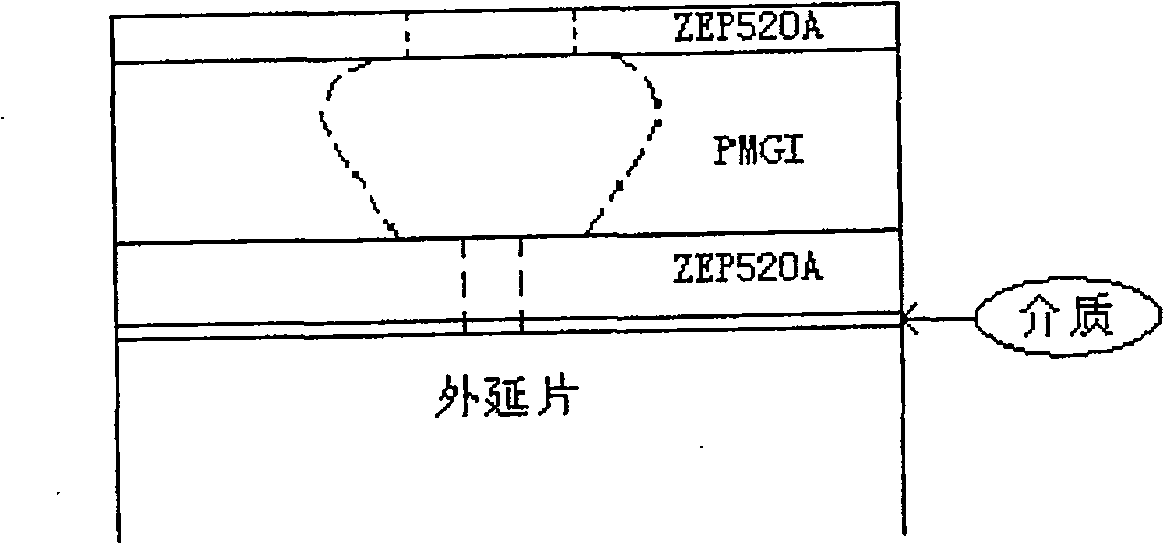

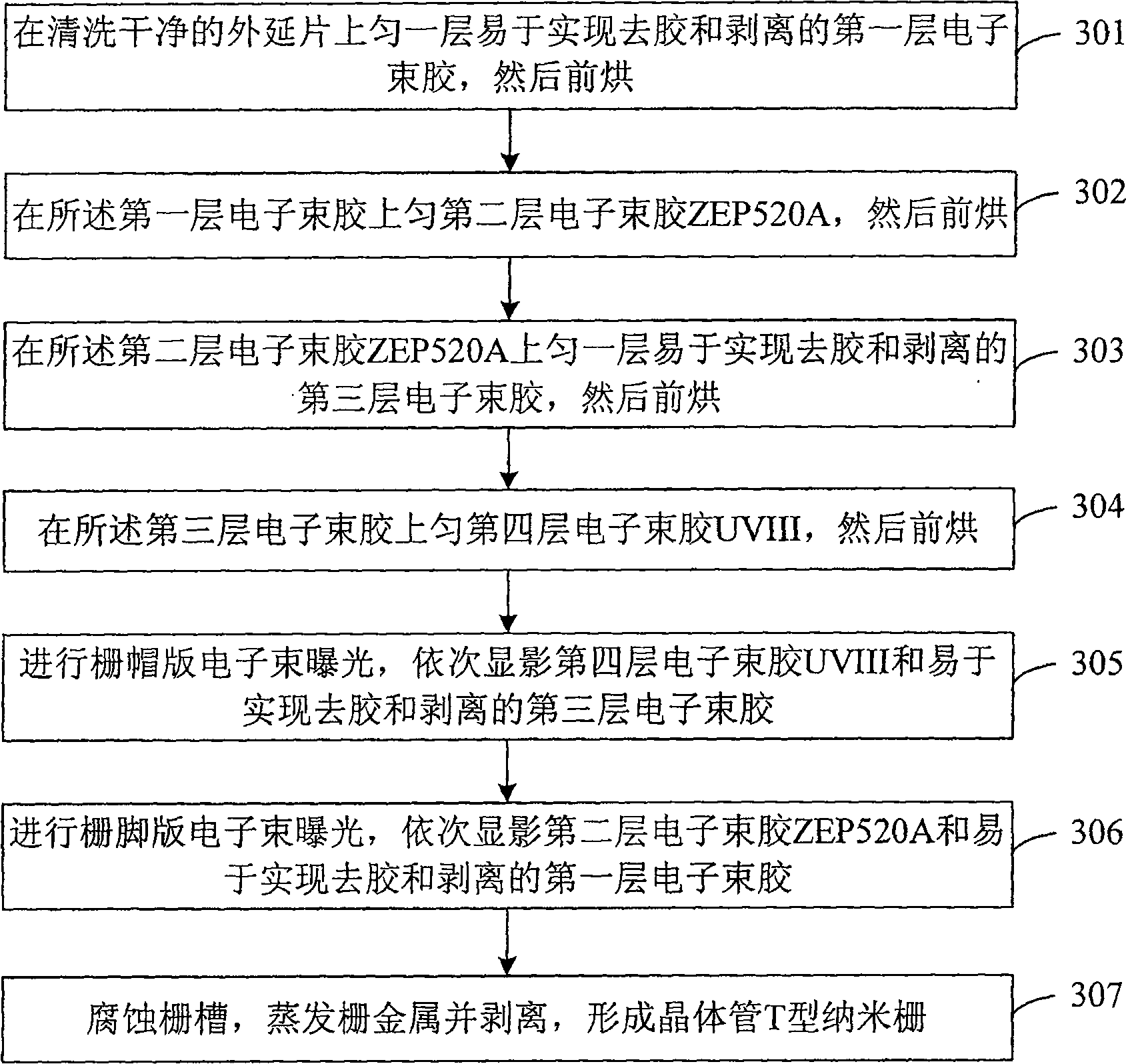

Method for preparing transistor T type nano grid

ActiveCN100543940CEasy to manufactureLoose conditionsSemiconductor/solid-state device manufacturingSemiconductor devicesCooking & bakingElectron-beam lithography

The invention discloses a method for manufacturing transistor T-shaped nanometer gate, comprising the steps of: A, coating a first layer electric beam glue which is liable to realize glue-stripping and peeling on a cleaned epitaxial wafer, and then soft-baking; B, coating a second layer electric beam glue ZEP520A on the first layer electric beam glue, and then soft-baking; C, coating a third layer electric beam glue which is liable to realize glue-stripping and peeling on the second layer electric beam glue ZEP520A, and then soft-baking; D, coating a fourth layer electric beam glue UVIII on the third layer electric beam glue, and then soft-baking; E, carrying out gate cap electric beam exposure, and sequentially developing the four layer electric beam glue UVIII, the third layer electric beam glue which is liable to realize glue-stripping and peeling; F, carrying out the gate feet electric beam exposure, and sequentially developing the second layer electric beam glue ZEP520A and the first layer electric beam glue which is liable to realize glue-stripping and peeling; G, eroding the gate groove, evaporating and peeling off gate metals to form the transistor T-shaped nanometer gate. Usage of the invention can easily manufacture the gate lines having small size, greatly reducing the process difficulty.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

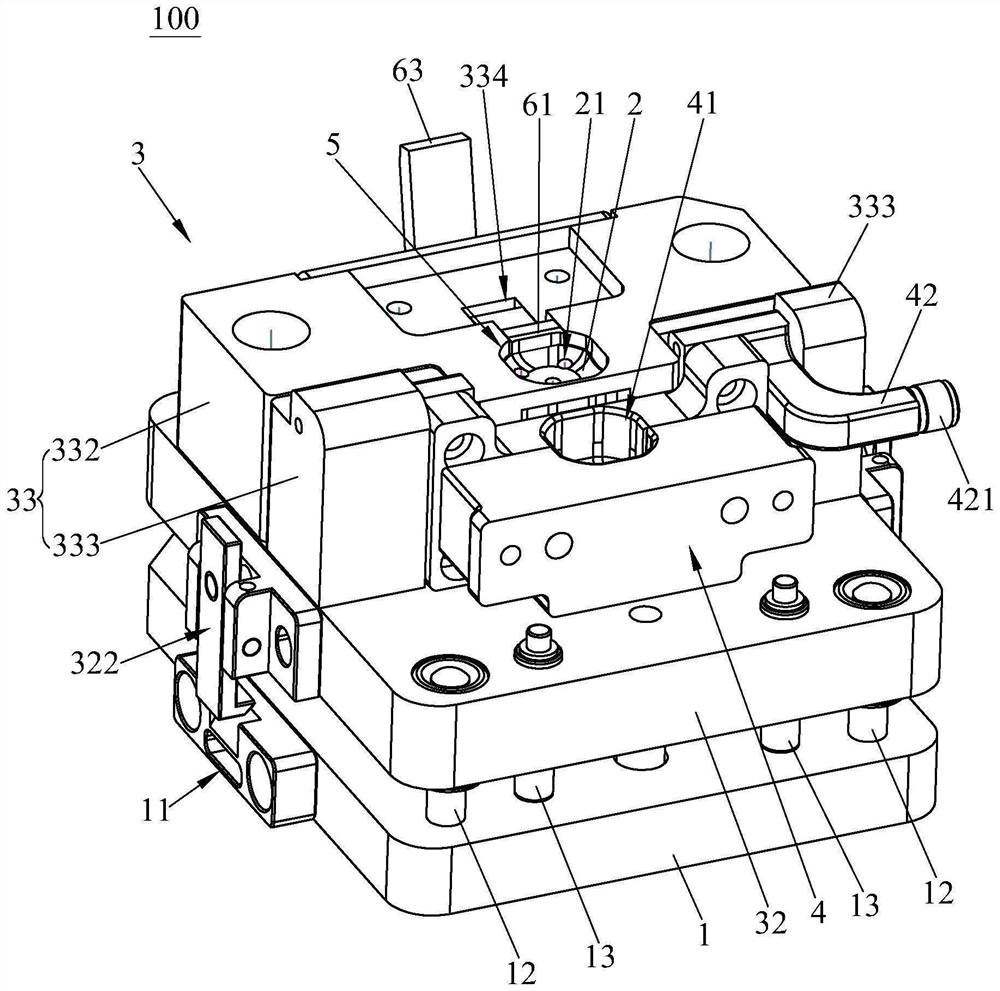

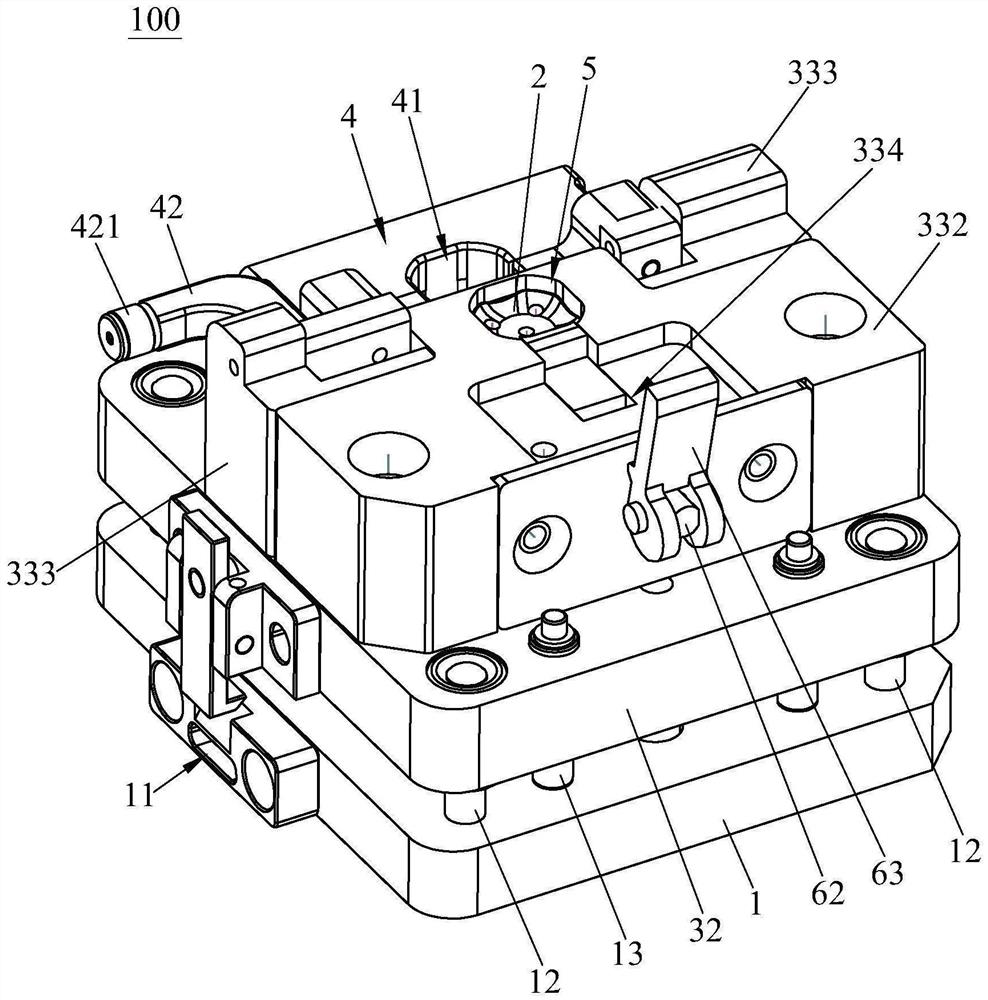

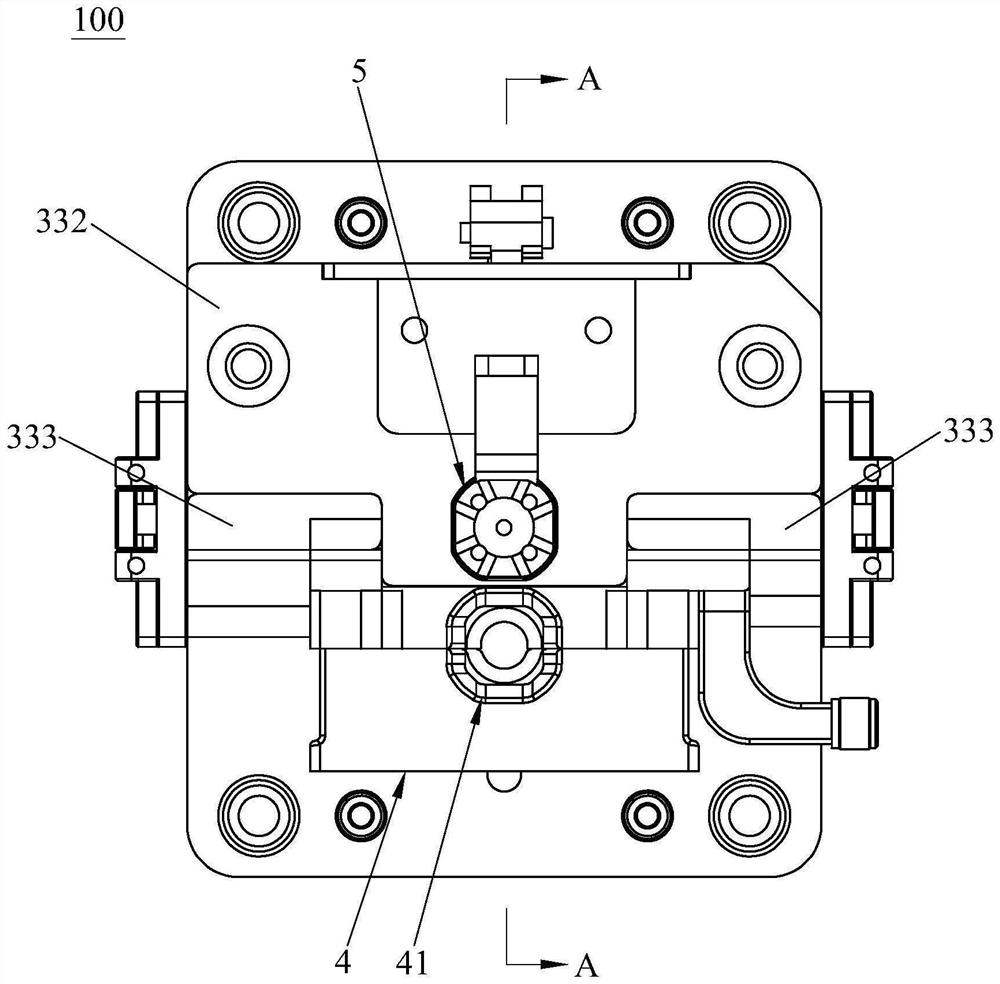

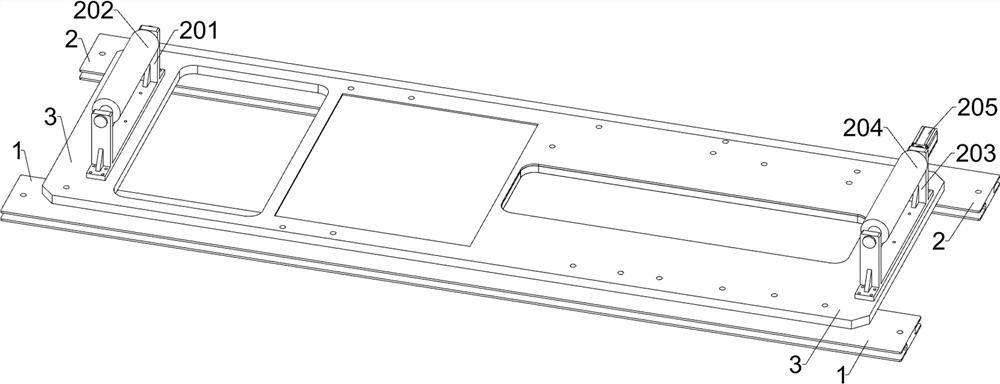

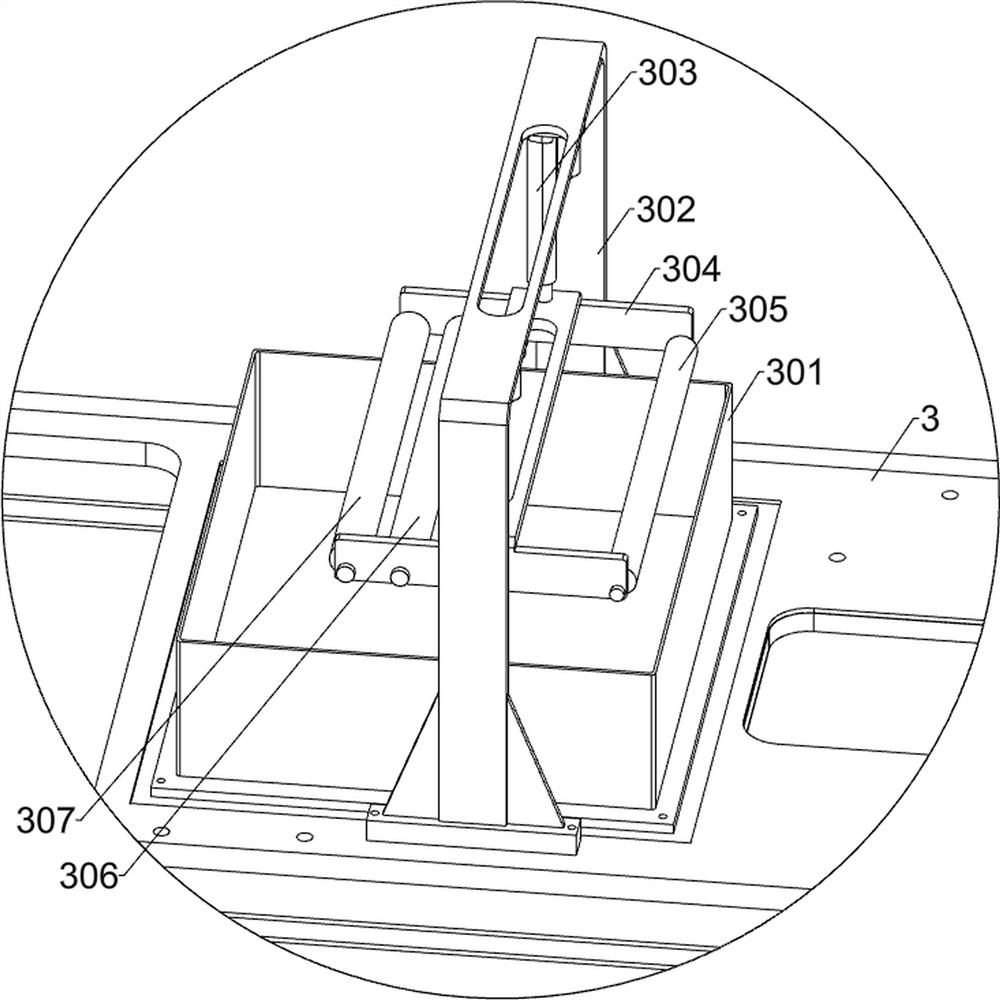

Clamp, glue dispensing clamp assembly and glue removing clamp assembly

ActiveCN114273156AEasy to remove glueWill not shiftLiquid surface applicatorsFinal product manufactureEngineeringMachine

The invention provides a clamp, a dispensing clamp assembly and a glue cleaning clamp assembly.The clamp comprises a clamp base, a fixing module, a lifting module and a rotating module, the fixing module is fixed to the clamp base, the lifting module is arranged on the clamp base in a lifting mode, a through hole is formed in the lifting module, the fixing module is sleeved with the lifting module through the through hole, and the rotating module is arranged on the lifting module; a first containing cavity is defined by the upper end of the fixed module and the inner wall of the through hole, the rotating module is rotationally connected to the lifting module, and a second containing cavity is formed in the rotating module. The fixture can be matched with the dispensing machine, and the rotating module of the fixture is driven by the dispensing machine to rotate, so that the second workpiece positioned in the second accommodating cavity and the first workpiece positioned in the first accommodating cavity are covered together, and circumferential dispensing can be performed on a product formed by the first workpiece and the second workpiece in multiple directions; the lifting module of the clamp has the function of driving the product to be automatically demoulded, so that the product can be completely exposed out of the glue cleaning surface, and glue cleaning is facilitated.

Owner:DONGGUAN HUABEL ELECTRONICS TECH

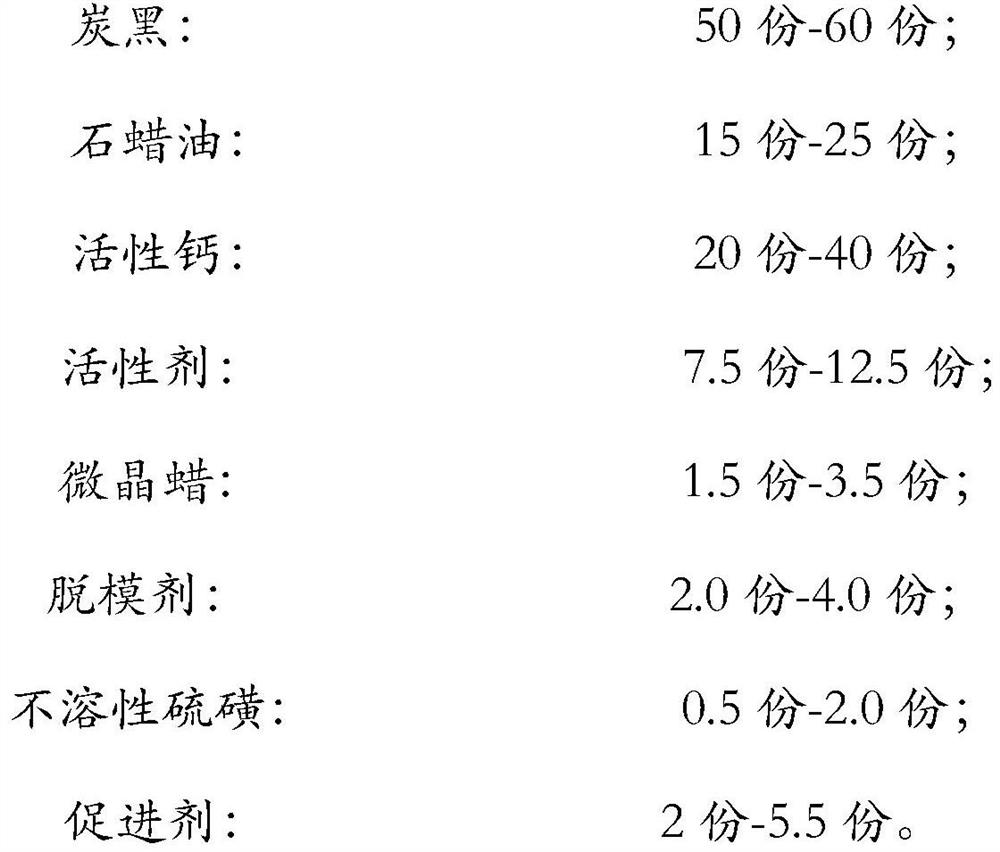

Standard rubber for checking sulfur analyzer and preparation method of standard rubber

The invention relates to standard rubber for checking a sulfur analyzer and a preparation method of the standard rubber. The standard rubber is applied to the technical field of checking of rubber compound testers, and comprises the following components in parts by mass: 100 parts of butyl rubber, 50-60 parts of carbon black, 15-25 parts of paraffin oil, 20-40 parts of active calcium, 7.5-12.5 parts of an active agent, 2.0-4.0 parts of a release agent, 0.5-2.0 parts of insoluble sulfur and 2-5.5 parts of an accelerant. The standard rubber has the effects that the data of the produced standard rubber is stable, the sulfur analyzer can be reversely calibrated by testing the data change of the standard rubber at the moment, so that the stability of the sulfur analyzer is predicted, and whether the sulfur analyzer needs to be cleaned and calibrated or not is determined by observing the fluctuation of the performance data of the standard rubber detected by the sulfur analyzer.

Owner:常熟市海虞橡胶有限公司

Glue spraying mechanism of hot-melting compounding machine

InactiveCN110481142AAvoid accumulationEasy to remove glueLaminationLamination apparatusHot meltEngineering

The invention discloses a glue spraying mechanism of a hot melting compounding machine. The mechanism comprises a first supporting frame, wherein a conveying belt is mounted at the upper end of the first supporting frame; a hot melting compounding machine is mounted on the conveying belt; a glue spraying head is arranged at the front end of the hot melting compounding machine; second supporting frames are arranged on the two sides of the bottom of the hot melting compounding machine; edge conveying belts are installed on the second supporting frames; the edge conveying belts are arranged on the two sides of the conveying belt; glue removing chambers are arranged at the bottom of the second supporting frames; glue removing scrapers are arranged in inner cavities of the glue removing chambers; a driving roller is arranged at the bottom of the glue removing chambers; and a first driving motor is installed on one side of the driving roller. Because the edge conveying belts are arranged onthe two sides of the conveying belt, redundant glue can be sprayed to the edge conveying belts, and scraped by the glue removing scrapers to achieve automatic glue removing, glue accumulation is prevented, normal use is achieved, glue removing is convenient and rapid, the working efficiency is improved, and the labor intensity is reduced.

Owner:ANHUI ZHICHENG ELECTROMECHANICAL SPARE PARTS

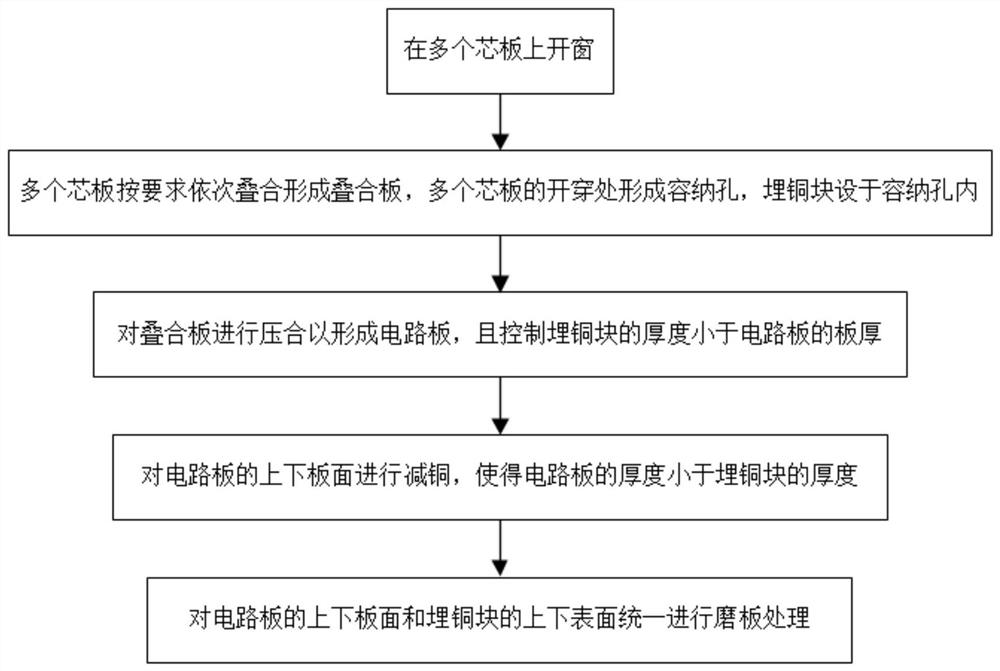

Manufacturing method of copper block-embedded circuit board

ActiveCN113194636AAvoid damage and deformationAvoid glue residuePrinted element electric connection formationMechanical engineeringPrinted circuit board

The invention discloses a manufacturing method of a copper-block-embedded circuit board, and relates to the technical field of printed circuit board manufacturing. The thickness of the embedded copper block is controlled to be smaller than that of the circuit board, the height difference prevents glue from flowing to the board surface of the circuit board after lamination, and the phenomenon of residual glue on the board surface is avoided; copper reduction treatment is carried out on the upper and lower surfaces of the circuit board, so that the thickness of the circuit board is smaller than that of the embedded copper block, and the height difference enables the upper and lower surfaces of the embedded copper block to protrude out of the circuit board, so that the upper and lower surfaces of the embedded copper block are subjected to glue removal; finally, the upper and lower board surfaces of the circuit board and the upper and lower surfaces of the embedded copper block are subjected to board grinding treatment to remove colloid on the upper and lower surfaces of the embedded copper block, and meanwhile it is guaranteed that the upper and lower board surfaces of the circuit board are flush with the upper and lower surfaces of the embedded copper block. According to the manufacturing method, the glue removing efficiency is improved, and meanwhile, the board surface of the copper block embedded circuit board is prevented from being deformed and damaged.

Owner:DONGGUAN SHENGYI ELECTRONICS

Three-roll calender for rubber extruder head

Owner:GUILIN RUBBER MACHINERY CO LTD

Water-based adhesive remover applied to OCA on mobile phone cover plate and preparation method of water-based adhesive remover

PendingCN113943610AHigh glue removal efficiencyGood effectOrganic detergent compounding agentsNon-ionic surface-active compoundsSolventChemistry

The invention provides a water-based adhesive remover applied to an OCA on a mobile phone cover plate. The water-based adhesive remover is prepared from the following components in percentage by mass: 10 to 25 percent of methyl salicylate, 35 to 55 percent of solubilizer, 0.2 to 0.8 percent of penetrant, 3 to 5 percent of softener, 1.5 to 3 percent of odor masking agent, 0.2 to 1.5 percent of PH value regulator and 10 to 40 percent of water; and the water-based adhesive remover is neutral. According to the water-based adhesive remover applied to the OCA on the mobile phone cover plate and the preparation method of the water-based adhesive remover of the invention, the methyl salicylate, the solubilizer, the penetrant, the softener, the odor masking agent and the pH regulator are scientifically proportioned, so that the functions of all the components are combined and cooperated, the OCA can be easily removed, the adhesive removal efficiency is high, the effect is good, the adhesive can be completely removed by 100%, no residue exists, the corrosion damage to black oil on the cover plate is avoided, and the practicability is high.

Owner:广州亦盛环保科技有限公司

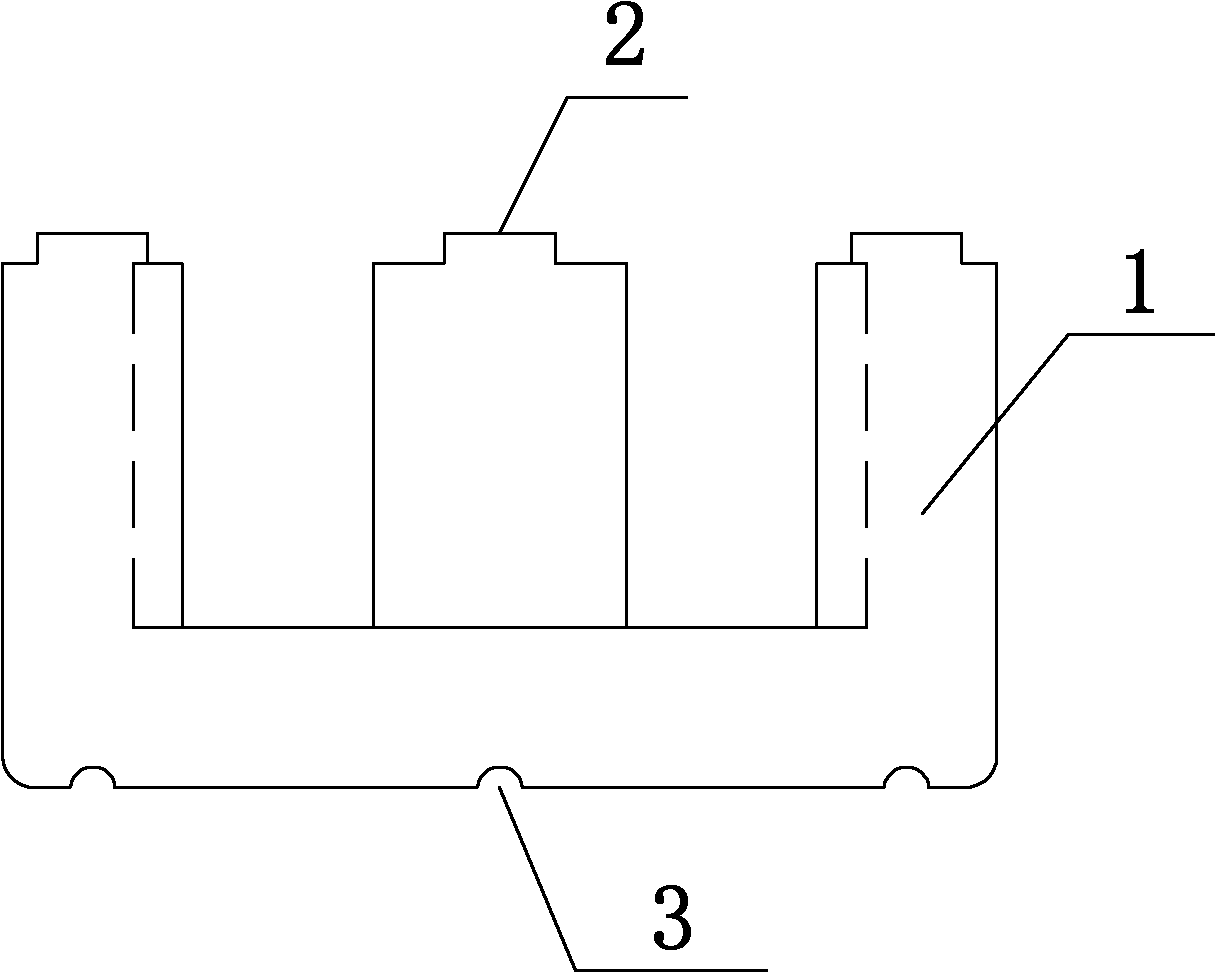

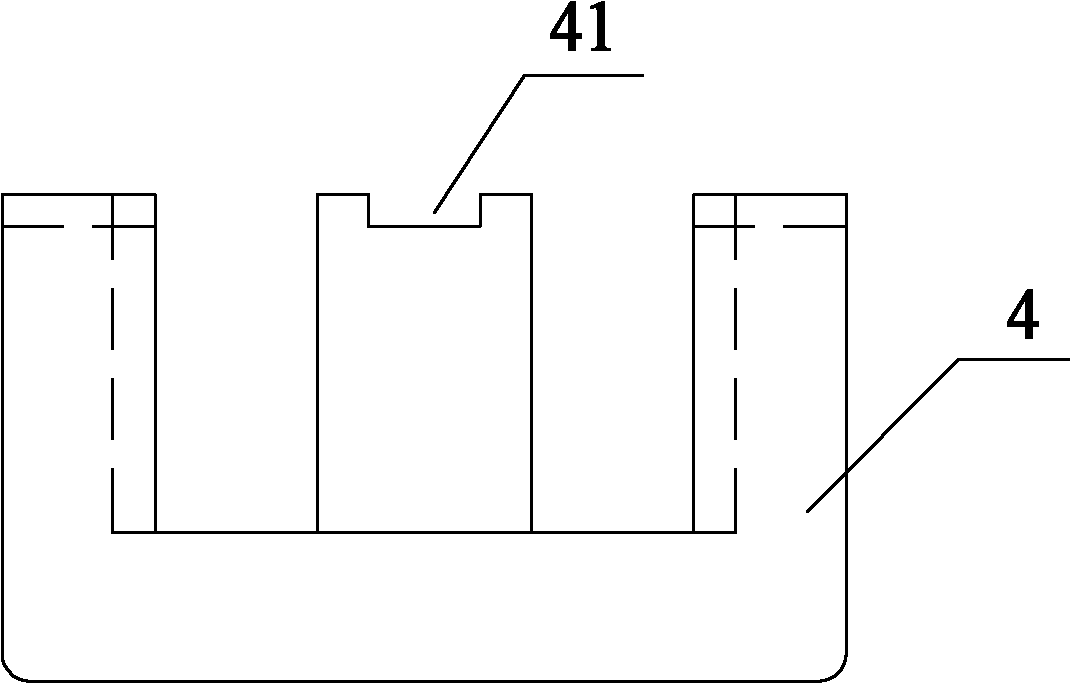

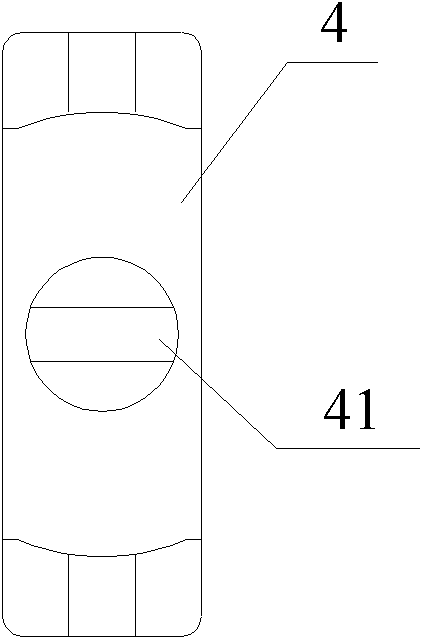

Die for preventing magnetic core from being cracked during sintering

InactiveCN102601365AOvercoming the problem of not having too many gapsSolve the lack of spaceEngineeringElectrical and Electronics engineering

The invention relates to a die for preventing a magnetic core from being cracked during sintering. The die is in a transverse E-shaped structure; the inner sides of projection parts at the left and right ends are in arc structures, and a projection part in the middle is in a column structure. Compared with the prior art, the die of the magnetic core is improved under the condition that the structure, the shape size and the performance of the magnetic core totally meet the requirements according to the invention; the problem caused by the fact that the loading capacity is large or a few gaps exist between blanks is overcome; enough space is provided to discharge water and rubber when the magnetic core is sintered; water and rubber discharge is facilitated, and the cracking problem of the magnetic core during sintering is solved.

Owner:上海康顺磁性元件厂有限公司 +1

High-elasticity flame-retardant fiber band glue removing equipment for wind energy cable

ActiveCN114160363APrecise thickness controlGuaranteed thicknessLiquid surface applicatorsInsulated cablesFiberEngineering

The invention relates to the field of wind energy, in particular to glue removing equipment for a high-elasticity flame-retardant fiber band for a wind energy cable. The technical problems that fluff on the surface of nylon-based fiber cloth is disordered, subsequent glue removing and drying are affected, and the glue solution removing thickness on the surface of the nylon-based fiber cloth cannot be accurately controlled are solved. According to the technical scheme, the glue removing equipment for the high-elasticity flame-retardant fiber band for the wind energy cable comprises a mounting bottom plate, a winding unit and the like; and a winding unit for conveying and winding nylon-based fiber cloth is mounted on the upper surface of the mounting bottom plate. According to the device, the surface fluff of the nylon-based fiber cloth is tidied, so that the fluff is tidy, later-stage glue removing and drying are facilitated, the thickness of the removed glue solution can be accurately controlled, meanwhile, the glue solution accumulated on the edges of the two sides of the nylon-based fiber cloth is cleaned, the glue solution adhered to the surface of the roller body after the glue solution is cleaned is cleaned, and the quality of the nylon-based fiber cloth is improved. Not only is the thickness of the cleaned glue solution ensured, but also the later manual cleaning work is omitted.

Owner:山东滨澳电线电缆有限公司

A kind of semi-closed structure inner core material bonding method

The invention belongs to the field of composite material manufacturing and relates to a method suitable for bonding core materials inside a semi-closed structure. The method for gluing the internal core material of the semi-closed structure proposed by the present invention is to manufacture a groove for adhesive exhaust or deglue on the surface of the internal core material to be glued, and then fill the groove with 1 / 2 volume of styrofoam, Apply a layer of room temperature curing adhesive evenly on the surface of the core material to be bonded and the surface to be bonded inside the composite material, then install the core material inside the composite material, pressurize the external composite material after installation, and perform room temperature curing at room temperature For the curing of the adhesive, the curing of the styrofoam is performed after the room temperature curing adhesive is cured. The process method is simple, easy to implement, and can improve the bonding strength and reliability of the core material and the composite material. The core material bonding method of the semi-closed structure has great application value in the manufacturing process of the electromagnetic function structure.

Owner:THE RES INST FOR SPECIAL STRUCTURES OF AERONAUTICAL COMPOSITE AVIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com