Ceramic material SiC whisker suitable for stereolithography, and preparation method thereof

A stereolithography and stereolithography molding technology, applied in the field of additive manufacturing, can solve problems such as anisotropy, and achieve the effects of high molding precision, high manufacturing precision and manufacturing efficiency, and microstructure and designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

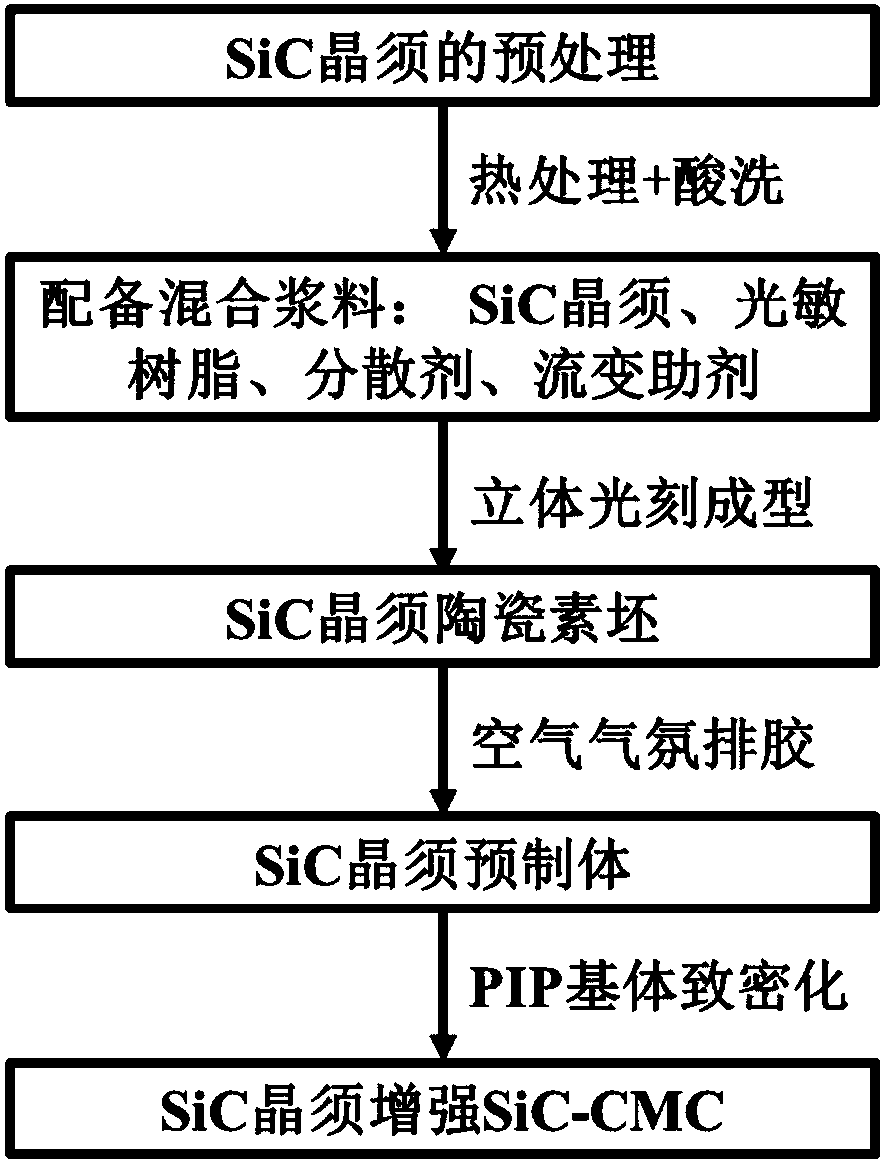

Method used

Image

Examples

preparation example Construction

[0038] Step 2. Preparation of SiC whisker blank

[0039] The mass fraction is 10-40wt.% of SiC whiskers, 5-10wt.% of UV dispersant (JZA-1101), 5-10wt.% of rheological additives, and 40-80wt.% of photosensitive resin. Mix slurry.

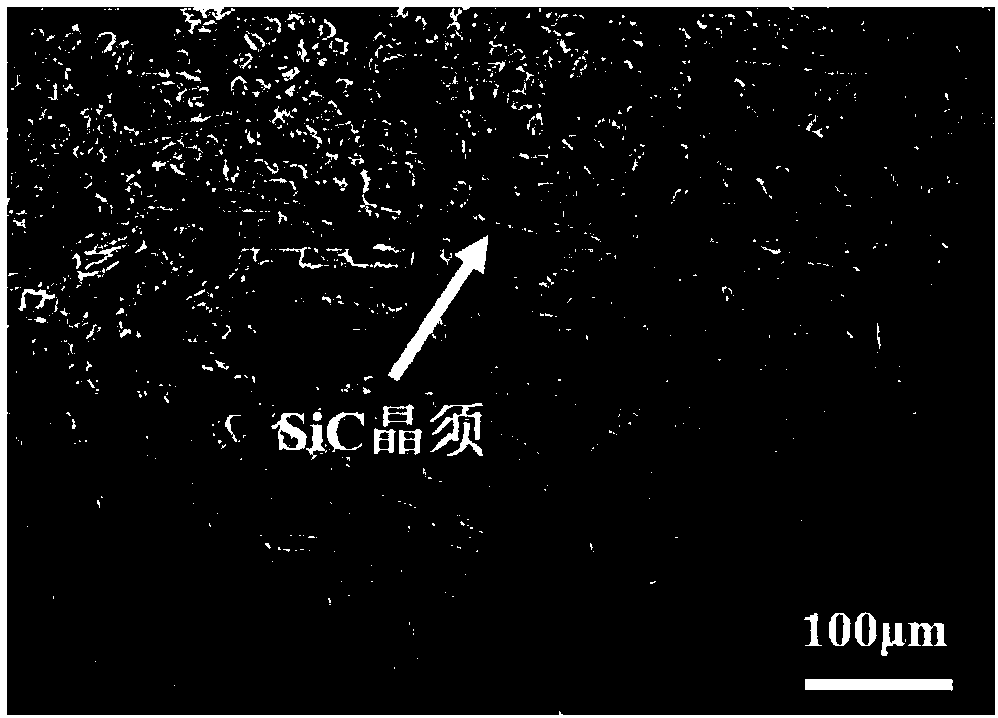

[0040] Use a glass rod to stir and mix the slurry for 5-10 minutes, disperse for 20-40 minutes at the second speed of the homogenizer, and then put it into a ball mill for 2-4 hours. The ratio of material to ball is 3:1-2:1, and the speed is controlled at 400- 500r / min. The distribution of well-dispersed SiC whiskers in the slurry is a three-dimensional network structure with random orientation, so that the formed and solidified SiC whisker preform can be isotropic.

[0041] The mixed slurry with good dispersion and moderate viscosity is subjected to stereolithography molding, and the SiC whisker blank is obtained after molding. Among them, the printing layer thickness is set to the lowest 0.02mm, the number of bottom layers is 1-5 layers, the exp...

Embodiment 1

[0047] Step 1: Pretreatment of SiC whiskers. The SiC whiskers are first heat-treated: the temperature is raised to 1700° C. for 1 hour in a vacuum heat treatment furnace, and then cooled to room temperature. Then carry out pickling: prepare 9wt.% hydrofluoric acid aqueous solution, soak the SiC whiskers for 5 hours, and wash away the hydrofluoric acid until pH=7. Finally, the obtained SiC whiskers were dried in an oven at 150°C.

[0048] Step 2: Preparation of SiC whisker blank. Put 66.4g of photosensitive resin, 18g of SiC whiskers, 8.35g of UV dispersant (JZA-1101), 4.8g of diluent EOEOEA (ethoxy ethoxy ethyl acrylate) into a beaker to form a mixed slurry. Stir with a glass rod for 5 minutes, then disperse for 20 minutes with a homogenizer at the second gear speed, and then pour the mixed slurry into a ball mill jar for ball milling for 2.5 hours, the ratio of material to ball is 2:1, and the speed is 435r / min. Put the fully dispersed mixed slurry in the stereolithography...

Embodiment 2

[0052] Step 1: Pretreatment of SiC whiskers. The SiC whiskers are first heat-treated: the temperature is raised to 1700° C. for 1 hour in a vacuum heat treatment furnace, and then cooled to room temperature. Then carry out pickling: prepare 9wt.% hydrofluoric acid aqueous solution, soak the SiC whiskers for 5 hours, and wash away the hydrofluoric acid until pH=7. Finally, the obtained SiC whiskers were dried in an oven at 150°C.

[0053] Step 2: Preparation of SiC whisker blank. Put 60.5g of photosensitive resin, 10.3g of SiC whiskers, 4.05g of UV dispersant (JZA-1101), and 5.2g of rheology modifier BYK410 into a beaker to form a mixed slurry. Stir with a glass rod for 5 minutes, then disperse for 25 minutes with the second speed of the homogenizer, and then pour the mixed slurry into a ball mill jar for ball milling for 3 hours, the ratio of material to ball is 2:1, and the speed is 425r / min. Put the fully dispersed mixed slurry in the stereolithography molding equipment, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com