Ultraviolet curing type adhesive as well as preparation method and application thereof

A curing type, adhesive technology, used in adhesives, adhesive additives, chemical industry and other directions, can solve the problems of alkali resistance to be improved, unable to meet the requirements of thinner and lighter display devices, etc., and achieve excellent adhesion and low shrinkage. , the effect of uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

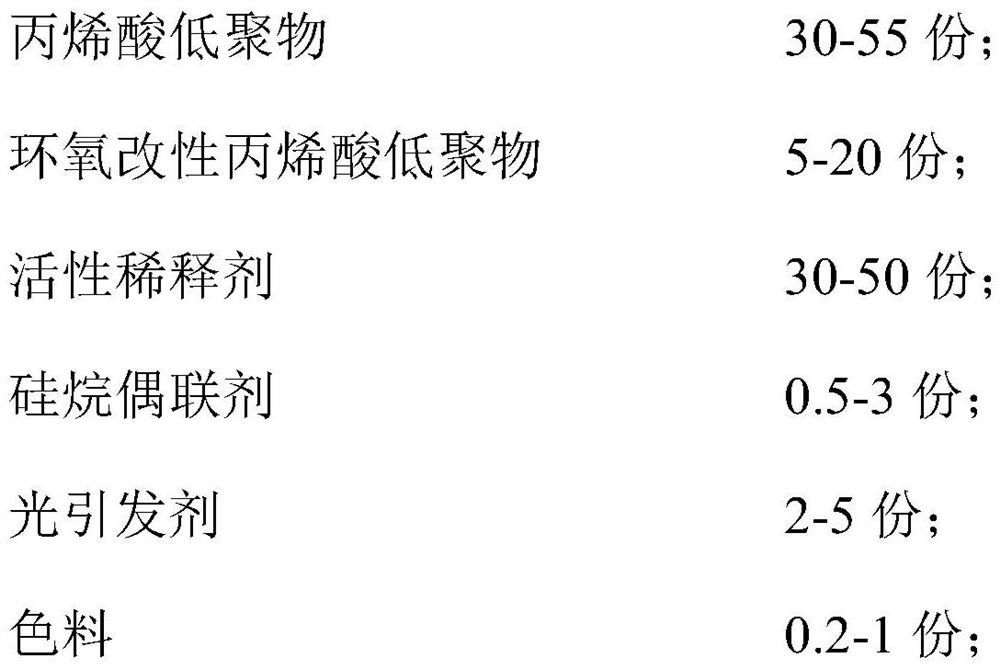

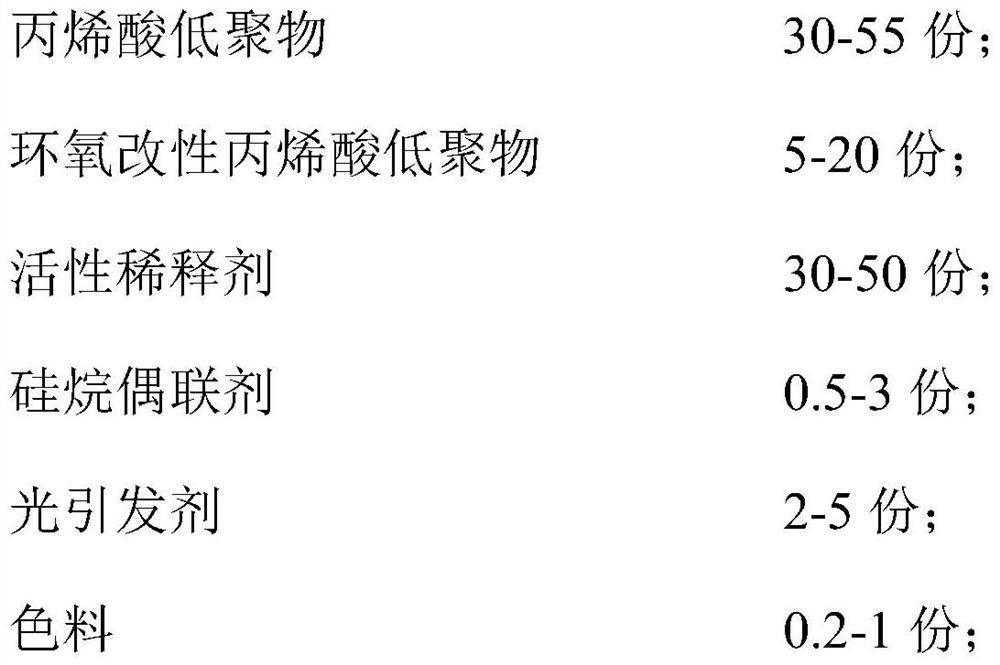

[0059] This embodiment provides a UV-curable adhesive. The raw materials for the preparation of the UV-curable adhesive include the following components in parts by weight:

[0060]

[0061] The preparation method of the ultraviolet curable adhesive described in this embodiment comprises the following steps:

[0062] (1) Mix acrylic oligomer, epoxy-modified acrylic oligomer, reactive diluent and photoinitiator according to the above formula, first stir and disperse at a speed of 400r / min for 5min, and then stir and disperse at a speed of 800r / min 60min, obtain mixture;

[0063] (2) Mix the mixture obtained in step (1), the silane coupling agent and the coloring material according to the above formula, stir and disperse for 20 minutes at a speed of 800r / min, filter with a 400-mesh filter cloth, and let it stand for defoaming after filtering , to obtain the UV-curable adhesive.

Embodiment 2

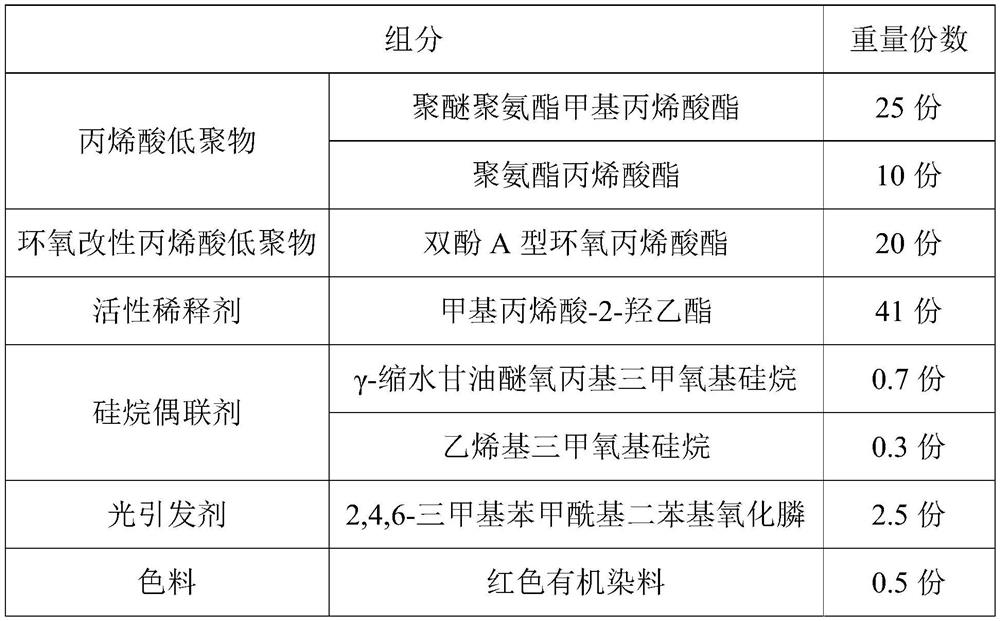

[0065] This embodiment provides a UV-curable adhesive. The raw materials for the preparation of the UV-curable adhesive include the following components in parts by weight:

[0066]

[0067] The preparation method of the ultraviolet curable adhesive described in this embodiment comprises the following steps:

[0068] (1) Mix acrylic oligomer, epoxy-modified acrylic oligomer, reactive diluent and photoinitiator according to the above formula, first stir and disperse at a speed of 400r / min for 5min, and then stir and disperse at a speed of 800r / min 60min, obtain mixture;

[0069] (2) Mix the mixture obtained in step (1), the silane coupling agent and the coloring material according to the above formula, stir and disperse for 20 minutes at a speed of 800r / min, filter with a 400-mesh filter cloth, and let it stand for defoaming after filtering , to obtain the UV-curable adhesive.

Embodiment 3

[0071] This embodiment provides a UV-curable adhesive. The raw materials for the preparation of the UV-curable adhesive include the following components in parts by weight:

[0072]

[0073] The preparation method of the ultraviolet curable adhesive described in this embodiment comprises the following steps:

[0074] (1) Mix acrylic oligomer, epoxy-modified acrylic oligomer, reactive diluent and photoinitiator according to the above formula, first stir and disperse at a speed of 400r / min for 5min, and then stir and disperse at a speed of 800r / min 60min, obtain mixture;

[0075] (2) Mix the mixture obtained in step (1), the silane coupling agent and the coloring material according to the above formula, stir and disperse for 20 minutes at a speed of 800r / min, filter with a 400-mesh filter cloth, and let it stand for defoaming after filtering , to obtain the UV-curable adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com