Clamp, glue dispensing clamp assembly and glue removing clamp assembly

A jig and glue dispensing technology, which is applied to devices and coatings that apply liquid to the surface. glue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

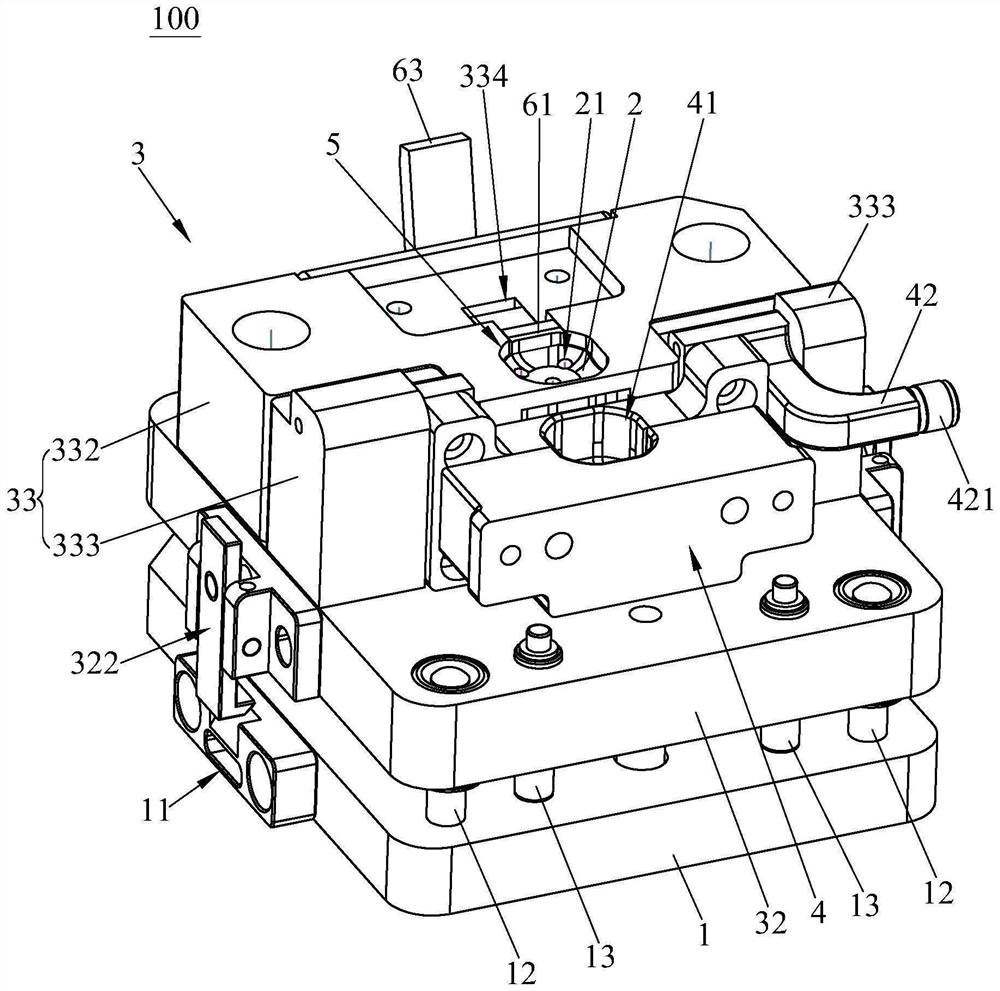

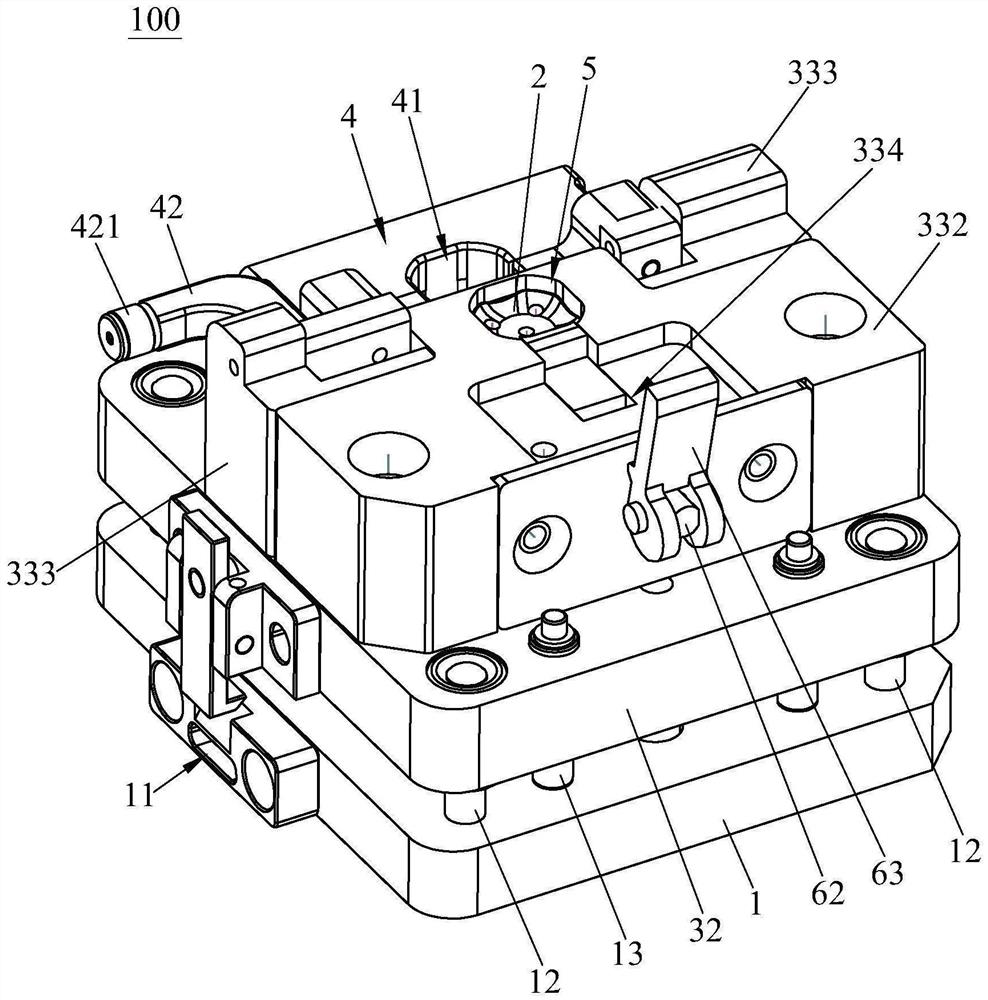

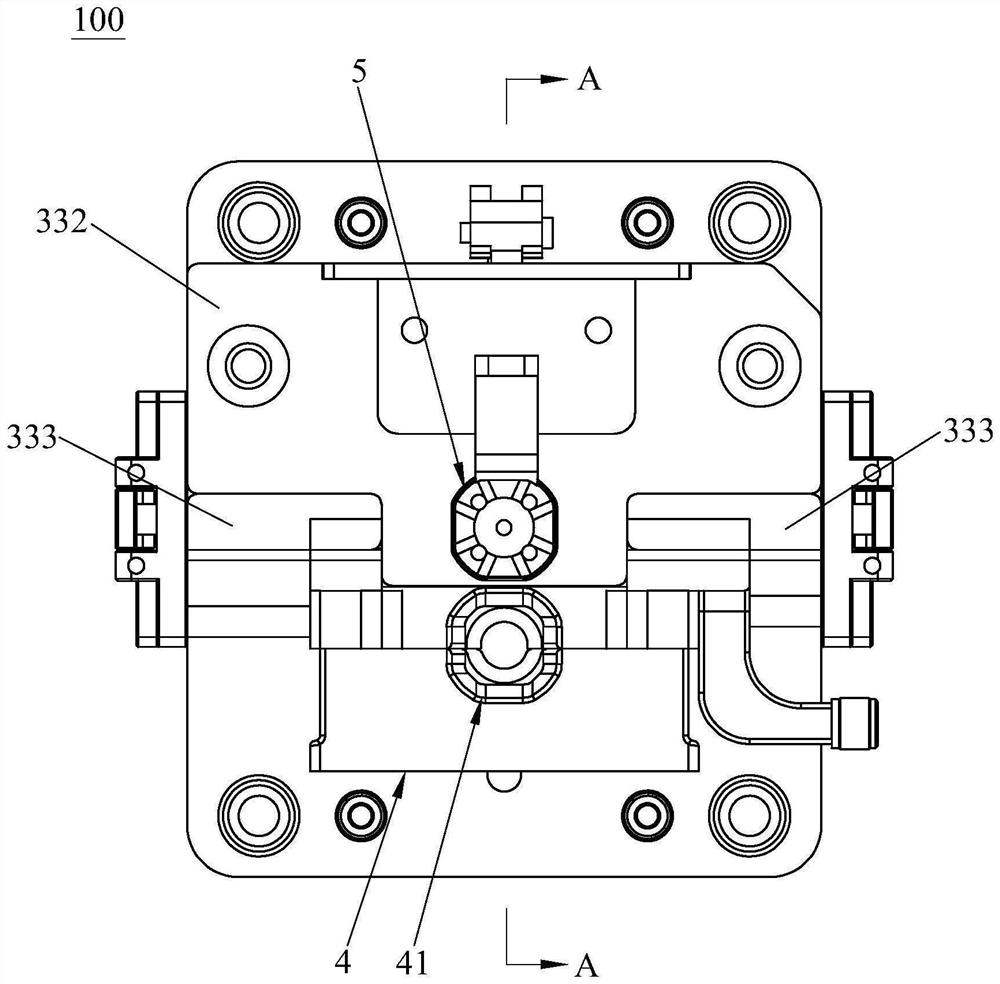

[0028] see Figure 1 to Figure 4 , the fixture 100 of the present invention includes a fixture base 1, a fixed module 2, a lifting module 3 and a rotating module 4, the fixed module 2 is fixed on the fixture base 1, and the lifting module 3 is arranged on the fixture base 1 in a liftable manner , and the lifting module 3 is provided with a through hole 31, the lifting module 3 is sleeved on the fixed module 2 through the through hole 31, and the upper end of the fixed module 2 and the inner wall of the through hole 31 are provided with a hole for positioning the first workpiece The first accommodating chamber 5; specifically, the upper end of the fixed module 2 has a bearing concave surface for bearing workpieces. The rotating module 4 is rotatably connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com