Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Dress cool" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Finishing agent of polyester silk-like fabric and preparation and post-treatment methods of fabric

The invention provides a finishing agent for preparing comfortable and cool polyester silk-like fabric and a post-treatment method of the comfortable and cool polyester silk-like fabric, aiming at overcoming the defects of the finishing agent of the polyester silk-like fabric, such as high processing cost and poor durability in the prior art. The finishing agent provided by the invention is composed of the following components in parts by weight: 5-7 parts of silk peptide, 3-5 parts of polyethylene glycol, 3-5 parts of a cross-linking agent, 1.5-2.5 parts of a cross-linking catalyst, 1-2 parts of acetic acid, 1-2 parts of a softening agent, 0.5-1 part of chitosan and the balance of water. The post-treatment method of the polyester silk-like fabric comprises the following steps: desizing, alkali weight reduction treatment of the base fabric, and pad finishing. By utilizing the finishing agent and the post-treatment method in the invention, the defect, such as hard feel, of the polyester fabric is overcome so that the polyester fabric has the advantages of excellent wrinkle resistance and soft feel, and is air-permeable, cool and comfortable to wear.

Owner:ZHEJIANG TAIHUA NEW MATERIAL

Functional intertwined medical textile fabric with natural antibacterial and moisture absorption quick-drying functions

InactiveCN102965792AGood deodorant performanceDimensionally stableWoven fabricsHemp fiberPlain weave

The invention discloses a functional intertwined medical textile fabric with natural antibacterial and moisture absorption quick-drying functions, which is formed by interweaving warp and weft, wherein the warp is selected from COOLMAX fiber / chitin viscose fiber blended yarns, and the weft is selected from cotton fiber / hemp fiber / silver fiber blended yarns; and the warp and the weft adopt an up-and-down plain weave structure. The selected fiber has the special durable functions of moisture absorption quick-drying, green health care and the like, so that the textile fabric not only has good antibacterial and anti-odor properties, but also has the characteristics of ultra-strong moisture absorption quick-drying, static resistance, radiation resistance, stable size, washing resistance, comfortable wearing and cooling, can be used for medical professional clothing in summer such as nurse clothes, nurse caps and patient clothes, and is an excellent textile fabric with ultra-strong antibacterial and green health care functions in a medical system.

Owner:SHAOXING SHULILE TEXTILE PROD

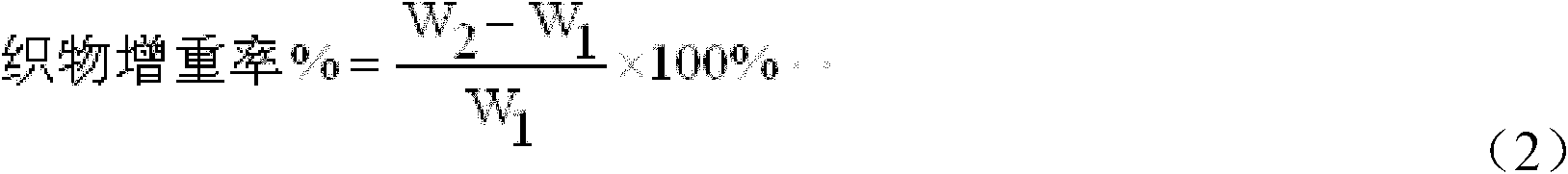

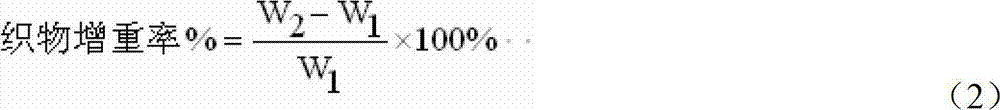

Post-treatment method for comfortable and cool terylene silk-like fabric

The invention discloses a post-treatment method for a comfortable and cool terylene silk-like fabric. The method includes steps of desizing, alkali decrement treatment on a base fabric and padding finishing. In the step of alkali decrement treatment on the base fabric, a treatment solution includes components of, by weight, 2-3% of caustic soda, 0.15-0.25% of penetrating agent, 0.15-0.25% of scouring agent, and the balance of water; a bath ratio is 1:15-20; a treatment temperature is 120+ / -5 DEG C; a treatment time is 40+ / -3min; and a reduction rate is 10-12%. Adoption of the method in the invention to prepare terylene fabric overcomes the hard handle of terylene fabric, improves wearing conformability of polyester fabric; and the product has the advantages of convenient processing and high resource utilization rate.

Owner:ZHEJIANG TAIHUA NEW MATERIAL

Hollow fiber cool healthcare socks and full-automatic linking machine

The invention provides a pair of hollow fiber cool healthcare socks and a full-automatic linking machine, and belongs to the technical field of textiles. Each hollow fiber cool healthcare sock comprises a sock body; the sock body is formed by weaving blended yarns; the blended yarns include yarns prepared from porous polyester fibers and special fibers by adopting hollow spinning; the sock body comprises a sock opening, a sock leg, a sock heel, the sock body and a sock toe; the front end of the sock body is the sock toe; the turning joint of the sock leg and the sock body is the sock heel; the upper end of the sock leg is the sock opening; the sock body comprises a sock surface and a sock bottom; the sock toe and the sock surface are linked by adopting the full-automatic linking machine; the sock bottom is embedded with viscose fibers; the full-automatic linking machine comprises a machine frame; the machine frame comprises a base and a working table; and a first conveying mechanism, a second conveying mechanism, a guide hole mechanism, a trimming mechanism, a first machine head, a yarn frame and a second machine head are arranged on the working table. The healthcare socks are good in moisture absorbing and sweat releasing property, have a cool feeling, are high in comfort level, and are suitable to be worn in summer.

Owner:海宁威尔斯针织股份有限公司

Anti-radiation environmental-friendly health-care clothing fabric

The invention relates to an anti-radiation environmental-friendly health-care clothing fabric, which is suitable for close fitting. The anti-radiation environmental-friendly health-care clothing fabric comprises surface basic yarn and inside basic yarn, wherein the surface basic yarn is formed by combining fur, cotton, blended yarn or synthetic fiber with anti-radiation stainless steel fiber; and the inside basic yarn is flax, hemp, bamboo fiber, corn, soybean fiber or blended yarn. The clothing fabric is manufactured by using a weaving principle of coil hiding, drawing and replacement in a circular weft knitting machine. After the surface basic yarn is combined with the anti-radiation metal fiber, the surface basic yarn is interwoven and drawn with the inside basic yarn to be made into a gray fabric and then to be manufactured into the fabric through dyeing and finishing. The fabric has gorgeous surface and certain flexibility and air permeability, while the inside is the environmental-friendly flax blended yarn, people can feel cool and comfortable when the fabric is in close fitting; and the fabric has a certain health-care and physical therapy function under the action of the temperature of a human body. The anti-radiation environmental-friendly health-care clothing fabric has the advantages of gorgeous surface, environmental-friendly lining, anti-radiation function and health-care and physical therapy function for skin of the human body, and suitability for health-care clothing with higher technological content.

Owner:孙晋保

Double-thick double-wire six-into-one antivirus and antibacterial compound yarn and preparing method thereof

The invention relates to healthcare yarn, in particular to a producing method and application of double-thick double-wire six-into-one anti-ultraviolet antivirus and antibacterial comfortable skincarehealthcare compound yarn. The blended yarn is prepared from, by weight, 15-85% of long staples, 15-85% of Outlast air conditioning fiber, 15-75% of white bamboo charcoal fiber and 25-85% of moistureabsorption and sweat releasing Topocool fiber. The compound functional knitted yarn is good in moisture absorption property and breathability, good in dyeing property, elasticity and plump performance, soft in hand feel, bright in color, rich in color and luster, free of adverse reaction when making contact with a human body, not prone to worm damage or corrosion and unique in appearance, has healthcare functions of bacterial resistance, inflammation elimination, skincare and bodybuilding, skin beautifying, skin moisturizing and good skincare property, and is good in draping, excellent in comfort, good in wear resistance, natural in color and luster and wide in application range.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Production technology for jacquard fabric with multiple components such as cotton and modal/mulberry silk

InactiveCN108085827ALow costGood hygroscopicityVegetal fibresSwivel-woven fabricsPolymer scienceMoisture absorption

The invention discloses a production technology for a jacquard fabric with multiple components such as cotton and modal / mulberry silk. The technology comprises the following steps of product main point implementation, spooling, beaming, sizing, drawing-in and weaving. The jacquard fabric with multiple components such as the cotton and the modal / mulberry silk is a high imitation silk fabric, defects of mulberry fiber on performance are overcome, original excellent advantages of being noble, elegant, graceful, good in moisture absorption, cool in wearing and the like of the mulberry fiber are kept, the defects of the mulberry fiber that acid resistance and alkali resistance are poor, protein fiber is likely to age and yellow after solarization, and the crease resistant property is poor are overcome, performance complementation is achieved, and the cost of the fabric is greatly lowered. Compared with a cotton fabric, the color is bright, the hand feeling is smooth, the wearing comfort isvery good, and the fabric is a high-end wearing fabric and the future development direction of silkworm industry.

Owner:IANGSU COLLEGE OF ENG & TECH

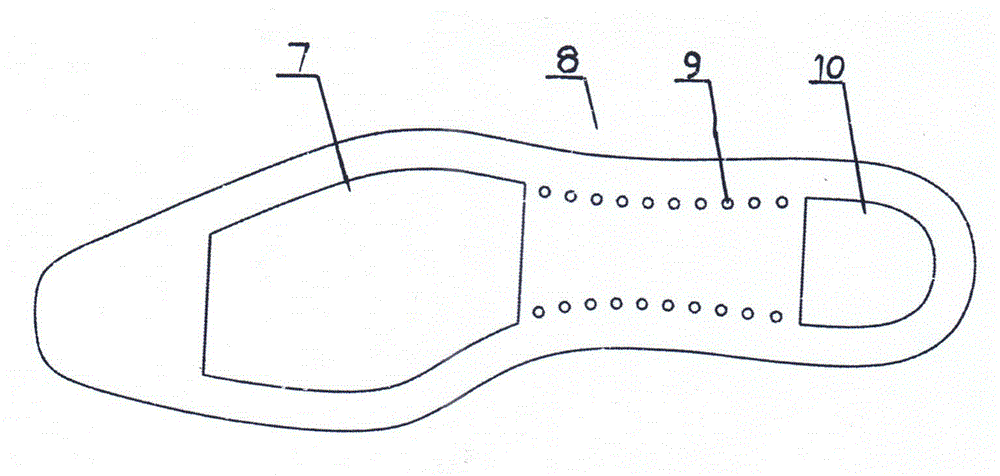

Sole and upper double-acting breathable type ventilating shoe

The invention relates to a sole and upper double-acting breathable type ventilating shoe. The sole and upper double-acting breathable type ventilating shoe mainly comprises a shoe pad, an insole, an outsole and an upper surface, the shoe pad is positioned at the upper end of the insole and comprises a shoe pad surface layer and a shoe pad bottom layer, the insole which is a breathing device is positioned at the lower end of the shoe pad and between the shoe pad and the outsole, the outsole is positioned at the lower end of the insole, transverse and vertical ventilating through grooves which are recessed downwards on the upper end face of the outsole are arranged in the front and at the back of the upper end face of the outsole, and at least one micro-porous ventilating hole area consisting of a plurality of laser micro-pores is arranged on the upper surface. A sole and an upper of the shoe have the ventilating function, namely, double ventilating effects are achieved as the sole can generate the breathable type forced ventilating function according to walking of feet and the upper surface is provided with the micro-porous ventilating hole areas, and further, the sole and upper double-acting breathable type ventilating shoe is good in breathability, dustproof, waterproof, wear-resistant, comfortable, warm and attractive.

Owner:曹平

Pearl composite fibre and its production method

InactiveCN100368611CGood skin affinityDress coolConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsFiberPolyvinyl alcohol

This invention discloses a pearl compound fiber and its making method, the pearl compound fiber is produced by the mixture and co-gather of the hydrolysis pearl and polyvinylalcohols, the method as follows: first dissolving the material, filtering, and sending them into the action kettle by a certain proportion, then stirring, mixing up, and heating the spinning original liquid, then filtering and sending it into the deaeration barrel, warming the deaeration barrel, and then spinning, drawing, drying and shaping, cutting off, curling, acetaling and tying, finally obtaining the product. The effect is that the product's bleaching and dying capability, its white and bright are all improved greatly.

Owner:范伟杰

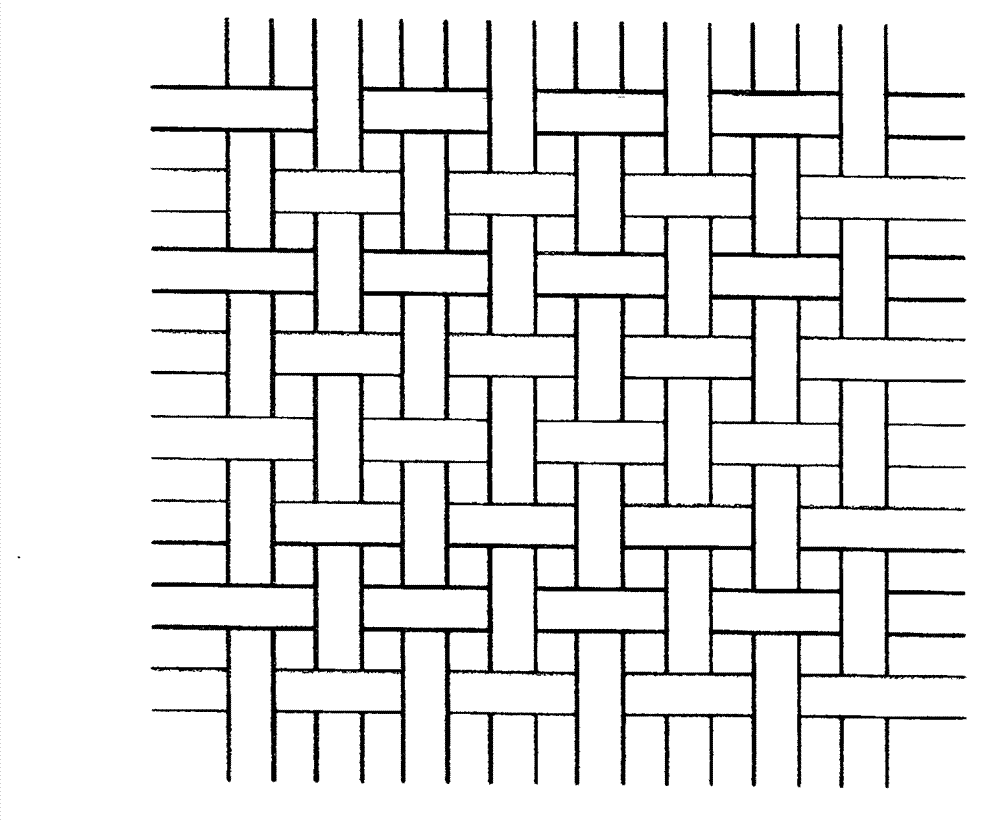

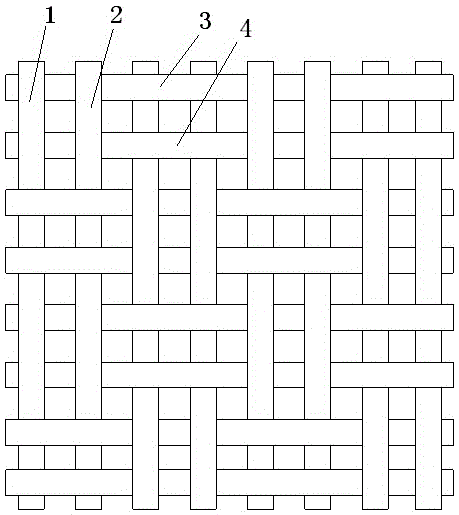

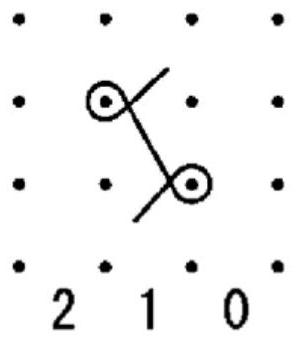

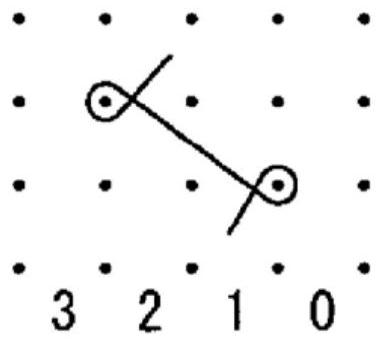

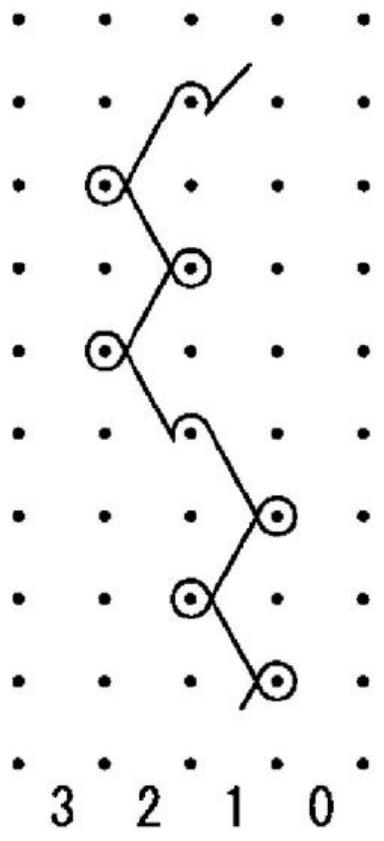

Mechanical stretching fabric

Disclosed in the invention is a mechanical stretching fabric formed by intersection of longitudinal lines and altitude lines. The longitudinal lines contain longitudinal lines A (1) and longitudinal lines B (2); and the altitude lines contain altitude lines A (3) and altitude lines B (4). The longitudinal lines A (1) and the altitude lines A (3) are SSY yarns A; and the longitudinal lines B (2) and the altitude lines B (4) are composite yarns. The composite yarns are formed by spiral entwisting of one strand of SSY yarn B (5) and one strand of POY yarn (6). The fabric has characteristics of high rebound resilience and good using effect.

Owner:HUZHOU NANXUN JINJIBAO TEXTILE

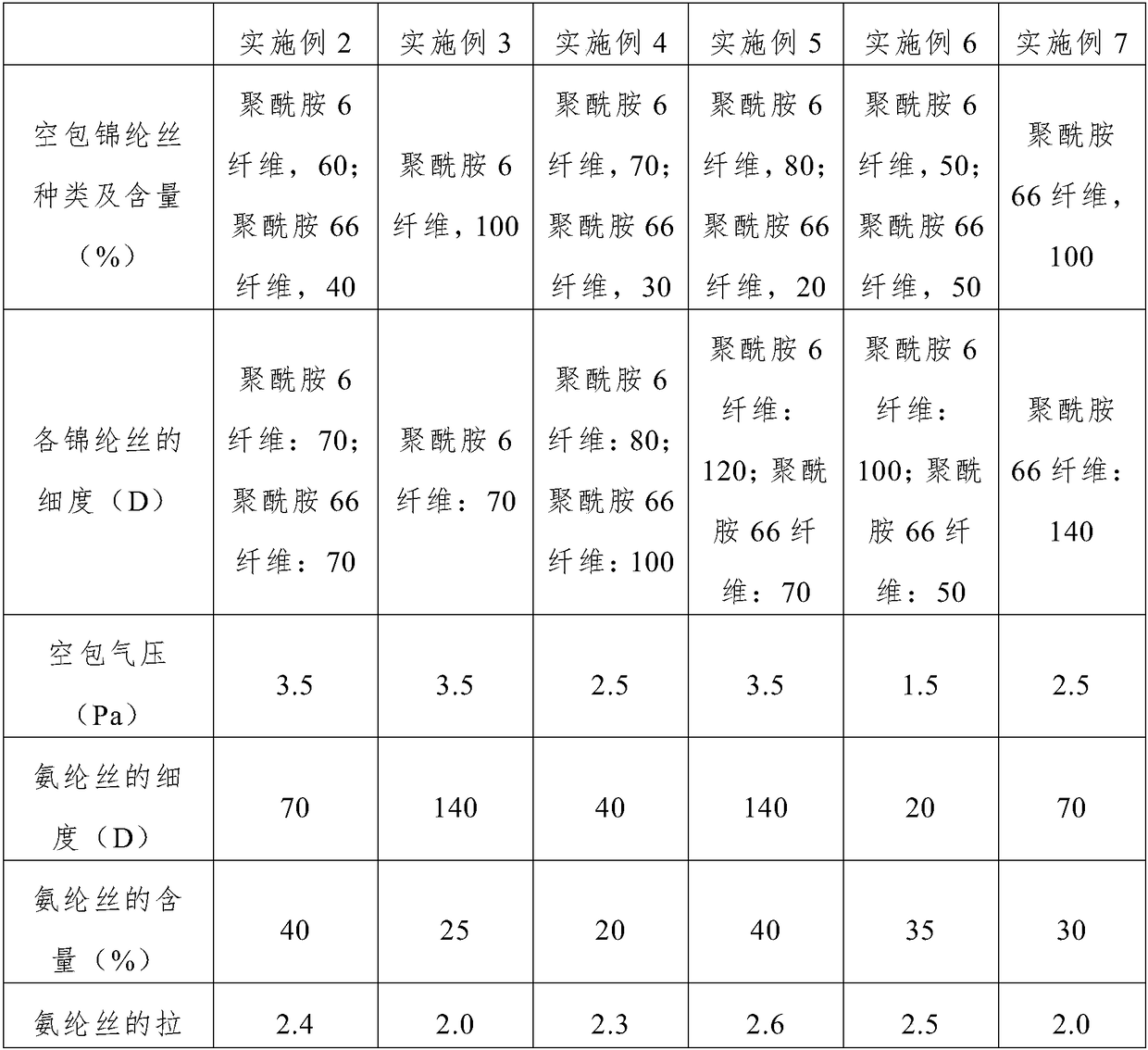

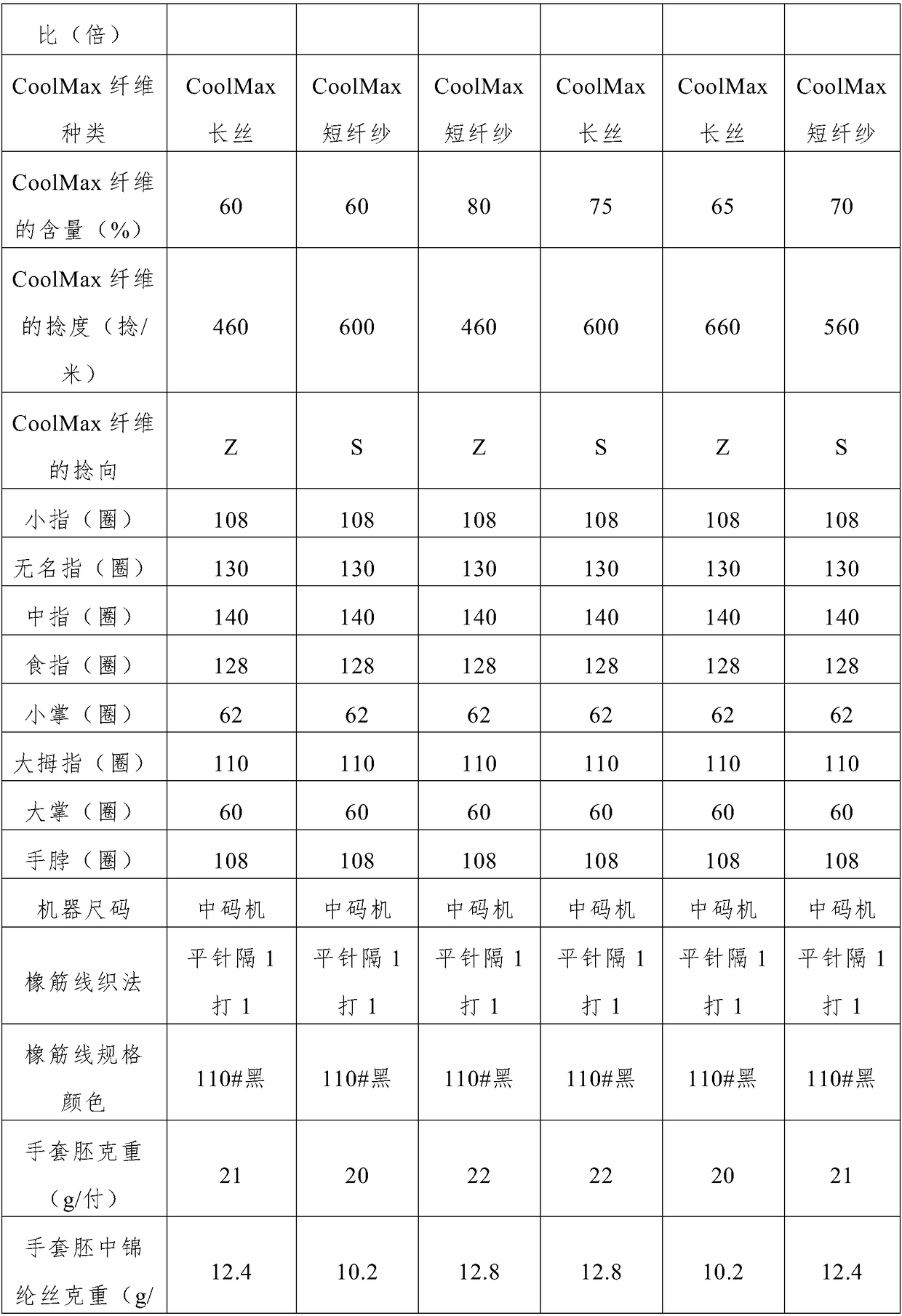

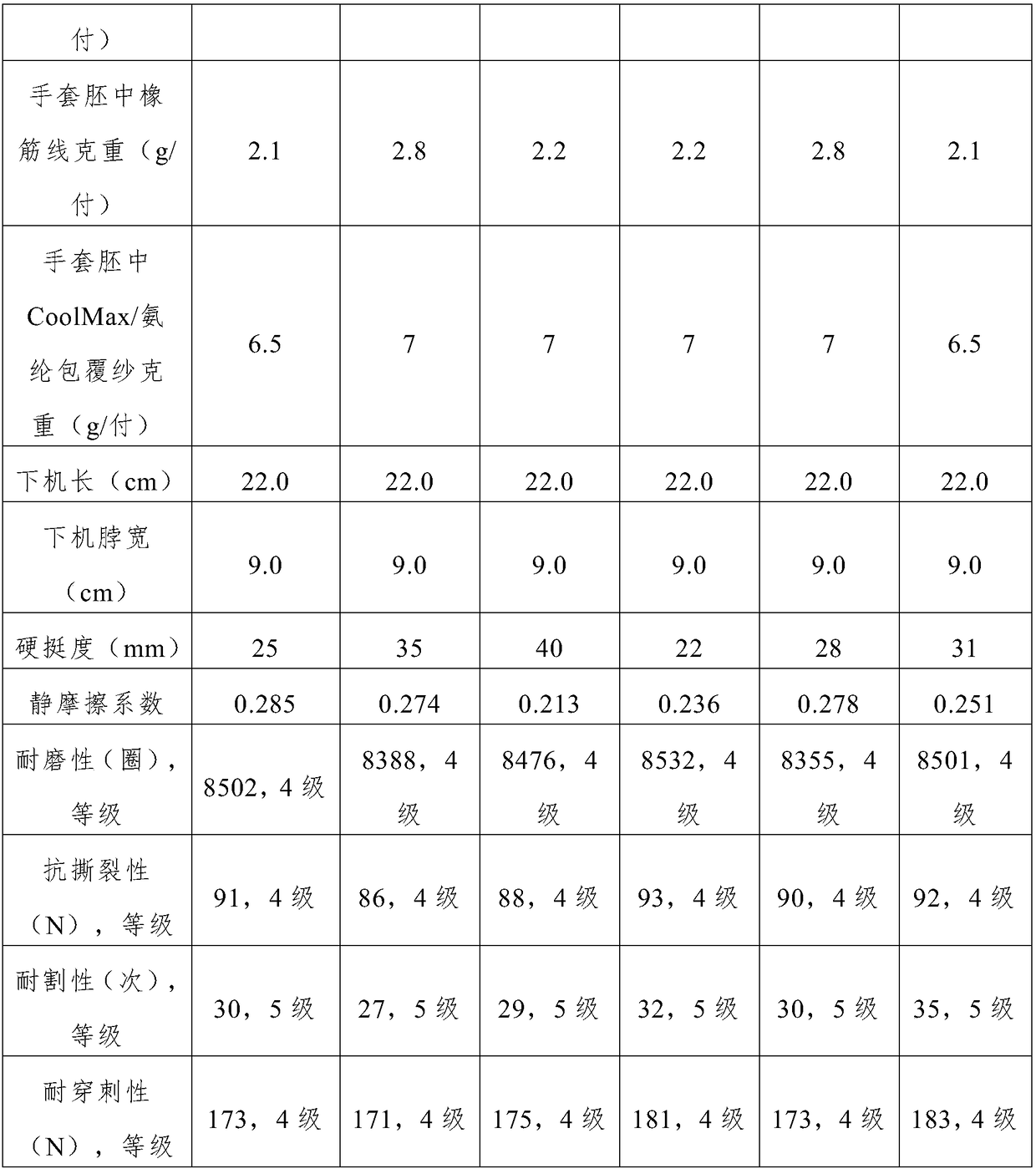

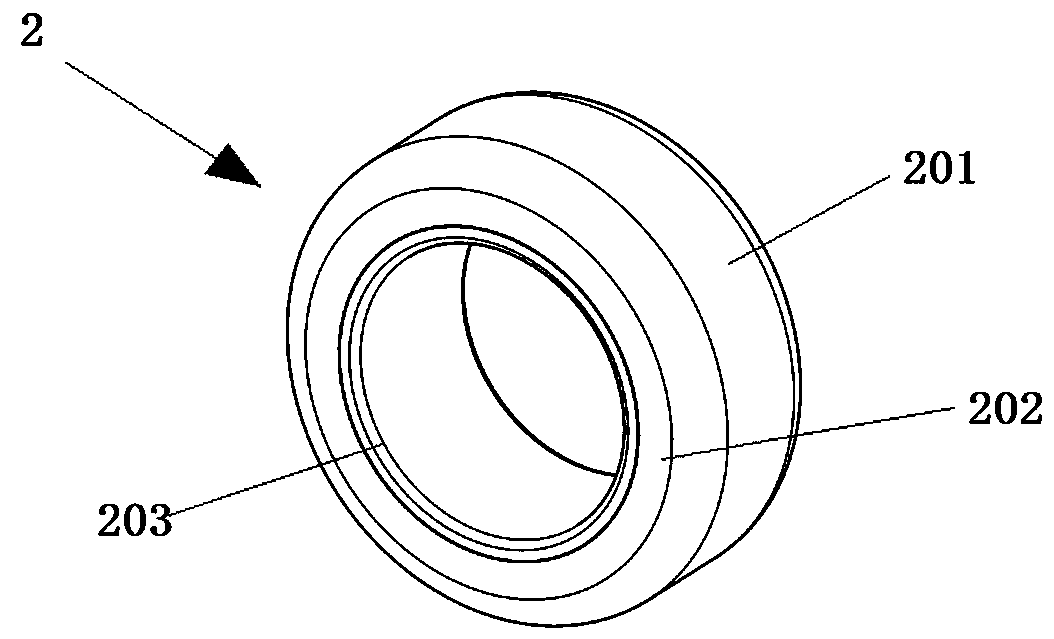

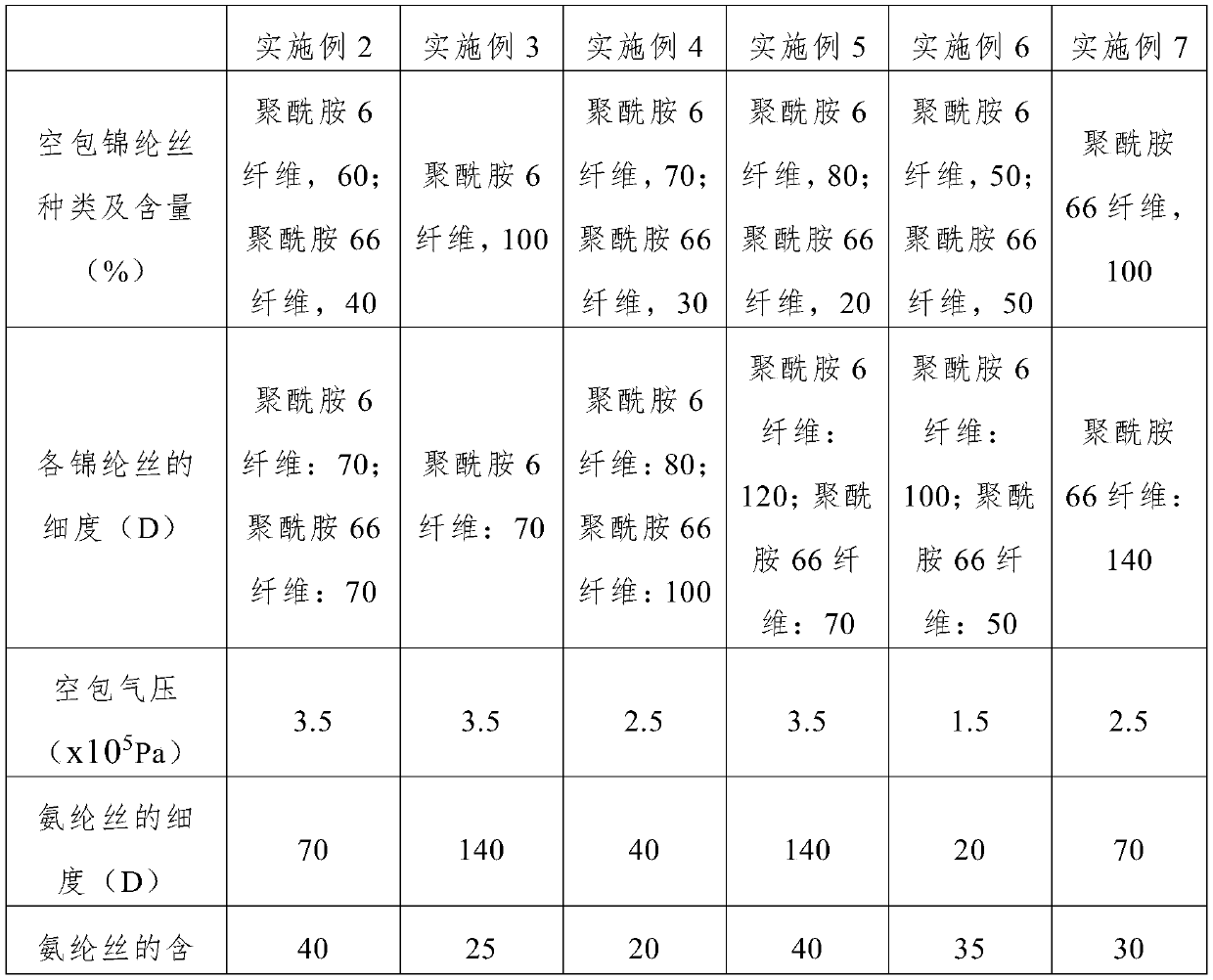

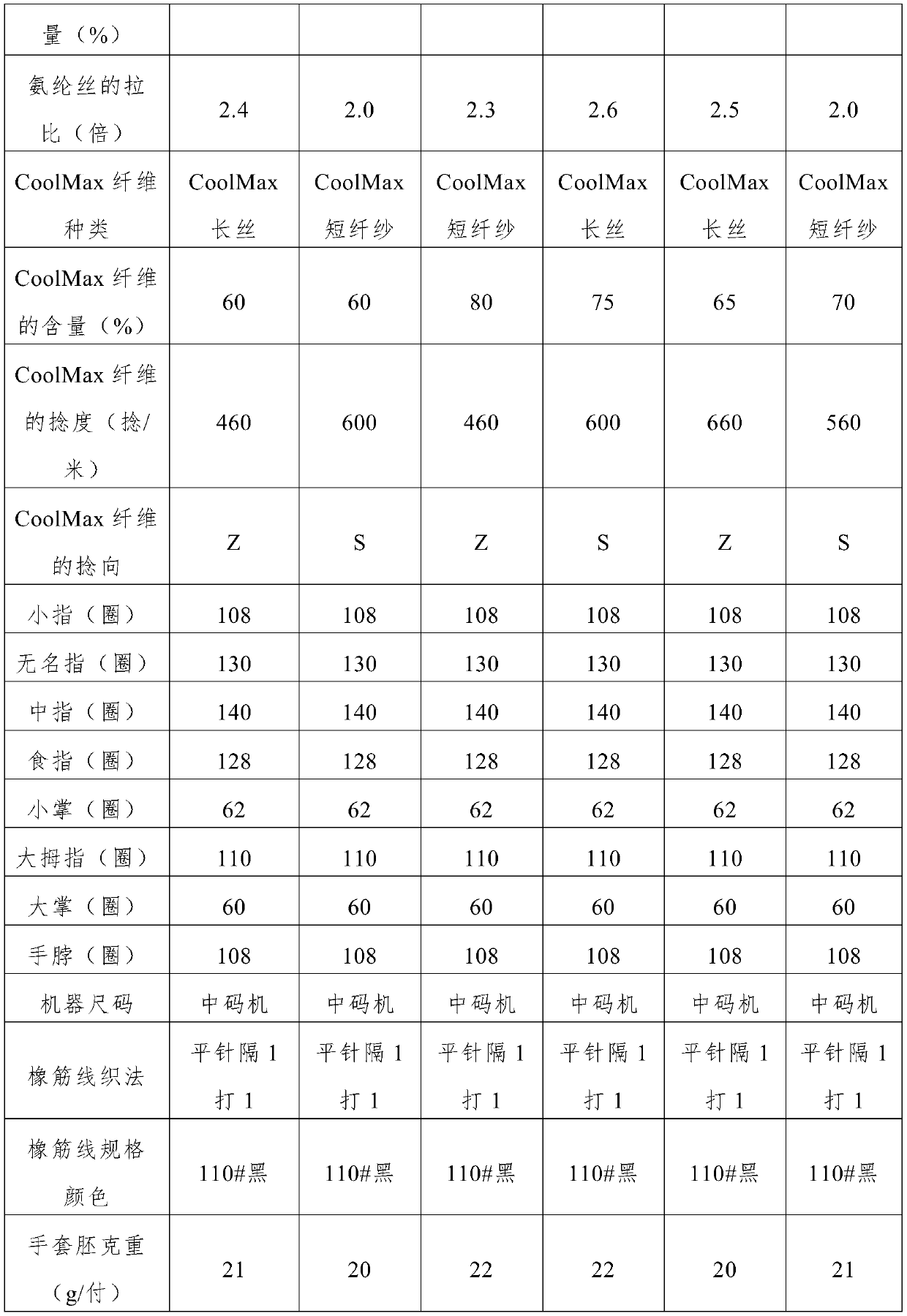

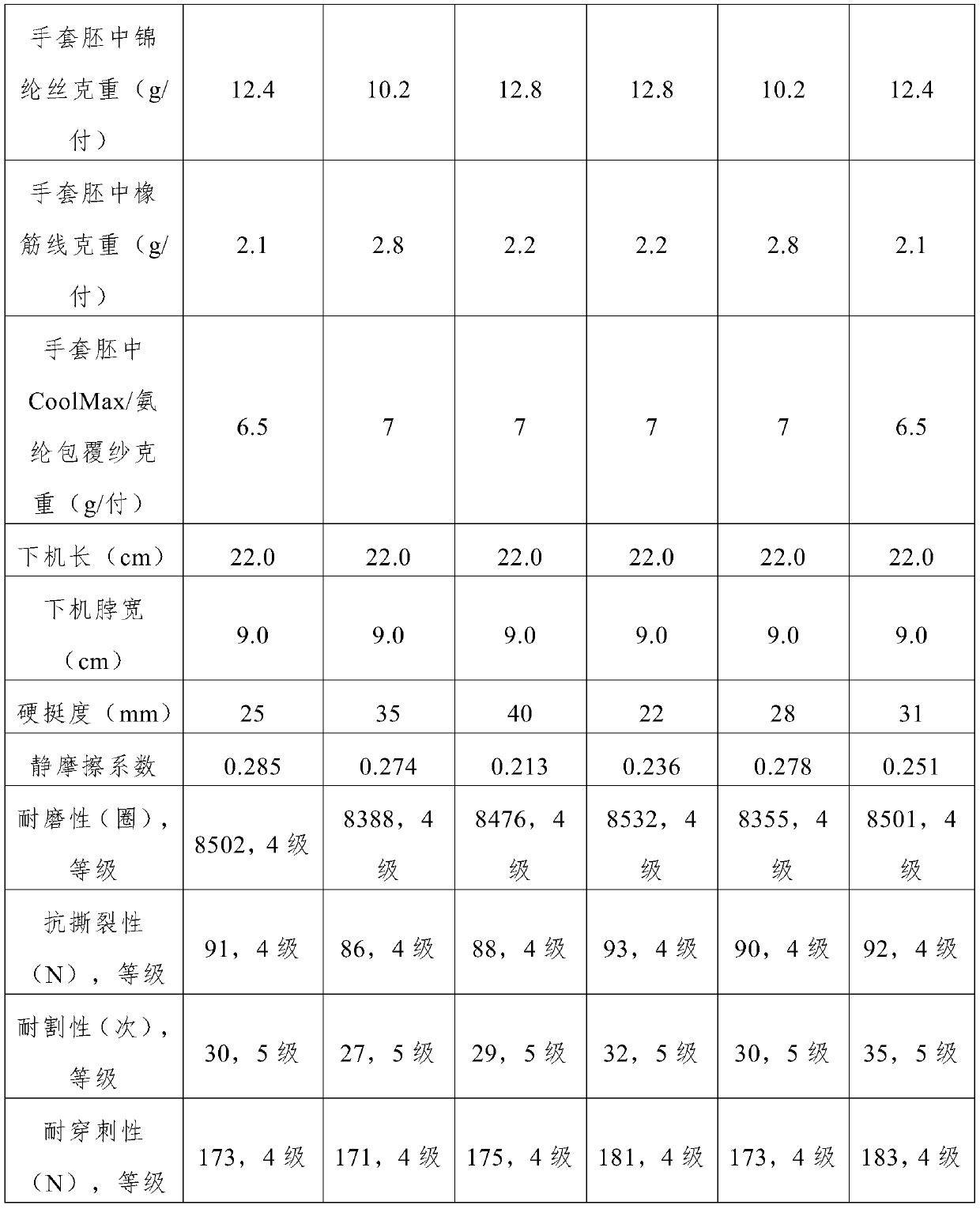

Weaving method for glove body and glove body

The invention discloses a weaving method for a glove body and the glove body, and belongs to the technical field of weaving of glove bodies. The weaving method of the glove body comprises the following steps that polyamide yarns are drafted, and compressed air is sprayed through a grinding nozzle to form empty wrapping yarns; polyurethane filaments are taken as core yarns, CoolMax fibers are adopted to rotate and be wound around the core yarns spirally, and CoolMax / polyamide covered yarns are obtained; the empty wrapping yarns and the CoolMax / polyamide covered yarns are mixedly weaved into theglove body. The invention further discloses the weaved glove body by adopting the weaving method for the glove body. The weaved glove body by adopting the method has excellent performance of moistureabsorption, softness, gas permeability, abrasive resistance, tear resistance, cutting resistance, puncturing resistance and the like, and the wearing is more comfortable.

Owner:SHANDONG XINGYU GLOVES

Post-treatment method for comfortable and cool terylene silk-like fabric

The invention discloses a post-treatment method for a comfortable and cool terylene silk-like fabric. The method includes steps of desizing, alkali decrement treatment on a base fabric and padding finishing. In the step of alkali decrement treatment on the base fabric, a treatment solution includes components of, by weight, 2-3% of caustic soda, 0.15-0.25% of penetrating agent, 0.15-0.25% of scouring agent, and the balance of water; a bath ratio is 1:15-20; a treatment temperature is 120+ / -5 DEG C; a treatment time is 40+ / -3min; and a reduction rate is 10-12%. Adoption of the method in the invention to prepare terylene fabric overcomes the hard handle of terylene fabric, improves wearing conformability of polyester fabric; and the product has the advantages of convenient processing and high resource utilization rate.

Owner:ZHEJIANG TAIHUA NEW MATERIAL

Blended antistatic conductive fiber fabric

InactiveCN103799589AImprove anti-static effectImprove conductivityYarnProtective garmentCarbon compositesFiber

The invention discloses a blended antistatic conductive fiber fabric which is blended and woven from four fibers of an acrylic copper complexing conductive fiber, a carbon composite conductive fiber, a polyaniline conductive fiber and a ramie fiber, wherein the acrylic copper complexing conductive fiber accounts for 21%-25%, the carbon composite conductive fiber accounts for 10%-14%, the polyaniline conductive fiber accounts for 15%-19%, and the ramie fiber accounts for 42%-54%. The fabric is blended and woven from four fibers of the acrylic copper complexing conductive fiber, the carbon composite conductive fiber, the polyaniline conductive fiber and the ramie fiber, and the woven fabric has excellent antistatic property and conductive property, and can avoid the static electricity, and meanwhile, the fabric is cool to wear and has the advantages of excellent moisture absorbance, high dehumidification speed, and excellent heat resistance.

Owner:TAICANG SIXIN TEXTILE

Herbal deodorizing composition and application thereof on absorptive article

InactiveCN104983860AImprove dysmenorrheaEasy to shrinkHeavy metal active ingredientsHydroxy compound active ingredientsMentholIrregular uterine contractions

The invention relates the field of hygiene products, provides a herbal deodorizing absorptive article, which can relieve dysmenorrheal and itching, inhibit bacteria, remove odor, and improve the symptoms of abnormal leucorrhea, bad blood circulation, and irregular uterine contraction, and provides a herbal deodorizing composition, which is composed of the following raw materials in parts by weight: 65 to 75 parts of nano silver, 11 to 14 parts of borneol, 5 to 7 parts of menthol, 4 to 6 parts of phellodendron, 4 to 6 parts of common cnidium fruit, and 4 to 6 parts of motherwort.

Owner:NANAN HENGYUAN WOMEN & CHILDREN PROD CO LTD

Novel multifunctional cladding yarn and preparation method

The invention discloses a novel multifunctional cladding yarn and a preparation method, wherein the multifunctional cladding yarn comprises a core wire and an external cladding wire covering the core wire; the external layer cladding wire is made of a kind of super fine denier nylon 6 yarn with the cross section in a double 8 structure; and the core wire is spandex filament. The yarn is made by the steps of (1) preparing the super fine denier nylon yarn that has a special double 8 structure on the cross section; (2) winding nylon wire, wherein the nylon wire is wound with n on-line tension apparatus with a tension controller; (3) drawing-off and twisting the spandex filament with the nylon yarn that has a double 8 cross section; (4) using a rewinder of the on-line tension to roll the finished product, so as to manufacture a multifunctional cladding yarn. The novel multifunctional cladding yarn prepared by the invention has the advantages of good moisture absorption and rapid drying by reconstructing the yarn surface structure and increasing yarn permeability; increased contact area with skin; soft feeling; tight fabrics; and greatly improved enjoy performance; and it's cool on wearing and the yarn is smooth like the silk.

Owner:JIANGSU JIADE FIBER TECH

Mosquito-expelling cool fabric for infant garments

The invention discloses a mosquito-expelling cool fabric for infant garments. A manufacturing method comprises the following steps: preparing blended yarns, preparing base cloth, preparing a mosquito-expelling solution, preparing mosquito-expelling microcapsules, preparing a finishing liquid, and performing a finishing process. The mosquito-expelling cool fabric has the beneficial effects that the fabric is cool to wear and good in sweat absorption effect, that is, sweat can be rapidly guided to the surface of the fabric and is rapidly evaporated off, excellent in breathability, good in dry and comfortable wearing feeling, that is, clothes do not adhere to bodies, excellent in mosquito-expelling effect, free of mosquito drug resistance, good in water washing, free of irritation to infant skin, relatively healthy to wear by infants, certain in antibacterial sterilization property, simple and easy in manufacturing method operation, stable in fabric quality, high in production efficiency and easy in large-scale industrial production, and an expelling agent is released slowly.

Owner:NINGBO HI TECH ZONE DAKANG IND TECH CO LTD

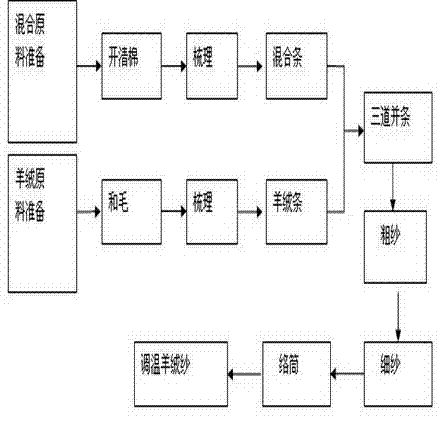

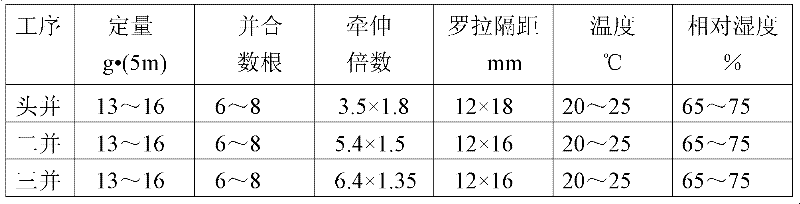

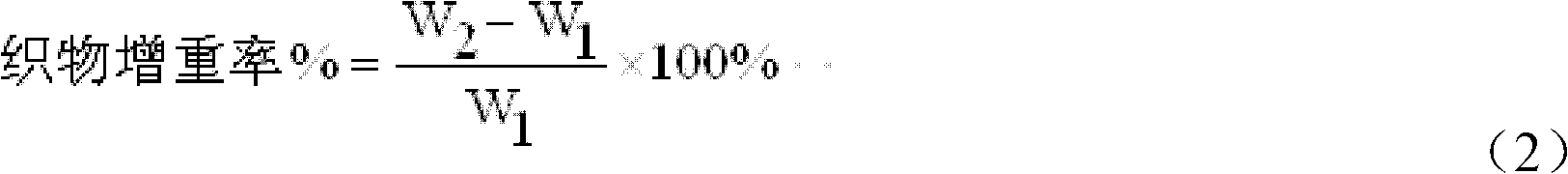

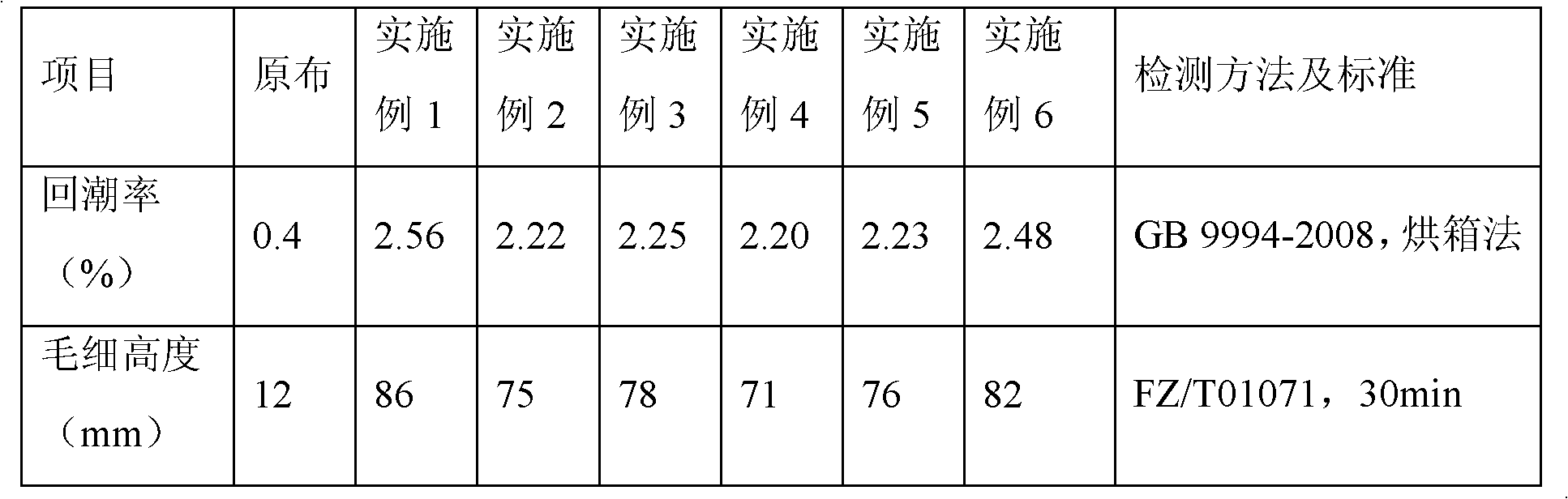

Thermoregulation cashmere yarn and production method thereof

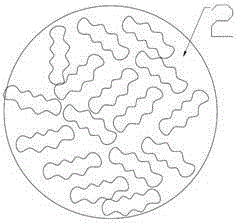

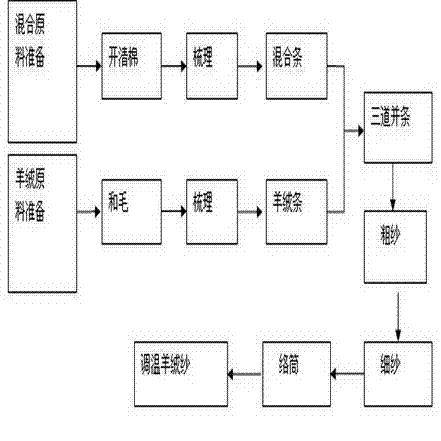

The invention discloses a thermoregulation cashmere yarn and a production method thereof. The thermoregulation cashmere yarn is characterized in that the fineness is 33.3-100tex, the thermoregulation cashmere yarn is formed by blending the following components according to mass ratio: 30-60% of thermoregulation fiber, 30-60% of cashmere fiber and 10-30% of third fiber; the thermoregulation fiber is rayon-based thermal-storage thermoregulation fiber, the fineness is 1.7-2.2dtex, and the length is 38-42nm; for the cashmere fiber, the fineness is 14-16mum, and the length is 36-44mm; and the third fiber is modal fiber, polyster fiber or milk protein fiber, the fineness is 1.7-2.2dtex, and the length is 38-42mm. The production method is suitable for the thermoregulation cashmere yarn, and comprises the following steps: respectively producing the thermoregulation fiber, third fiber mixed strips and cashmere strips, then drawing and doubling the mixed strips and the cashmere strips according to design, then roving, finely spinning and spooling the mixed strips and the cashmere strips in sequence, and finally obtaining the thermoregulation cashmere yarn.

Owner:内蒙古焱太经贸有限责任公司 +1

Finishing agent of polyester silk-like fabric and preparation and post-treatment methods of fabric

The invention provides a finishing agent for preparing comfortable and cool polyester silk-like fabric and a post-treatment method of the comfortable and cool polyester silk-like fabric, aiming at overcoming the defects of the finishing agent of the polyester silk-like fabric, such as high processing cost and poor durability in the prior art. The finishing agent provided by the invention is composed of the following components in parts by weight: 5-7 parts of silk peptide, 3-5 parts of polyethylene glycol, 3-5 parts of a cross-linking agent, 1.5-2.5 parts of a cross-linking catalyst, 1-2 parts of acetic acid, 1-2 parts of a softening agent, 0.5-1 part of chitosan and the balance of water. The post-treatment method of the polyester silk-like fabric comprises the following steps: desizing, alkali weight reduction treatment of the base fabric, and pad finishing. By utilizing the finishing agent and the post-treatment method in the invention, the defect, such as hard feel, of the polyester fabric is overcome so that the polyester fabric has the advantages of excellent wrinkle resistance and soft feel, and is air-permeable, cool and comfortable to wear.

Owner:ZHEJIANG TAIHUA NEW MATERIAL

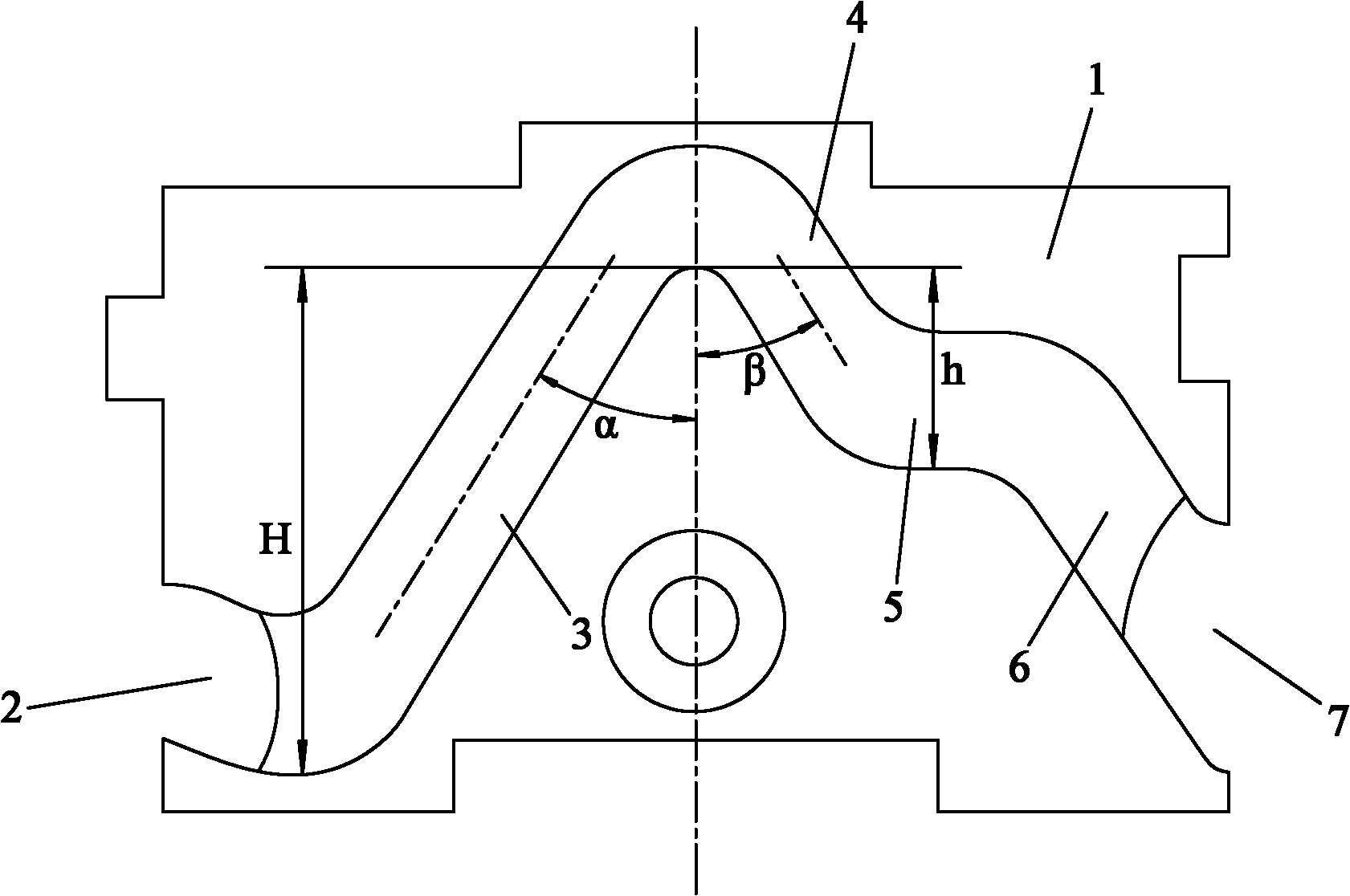

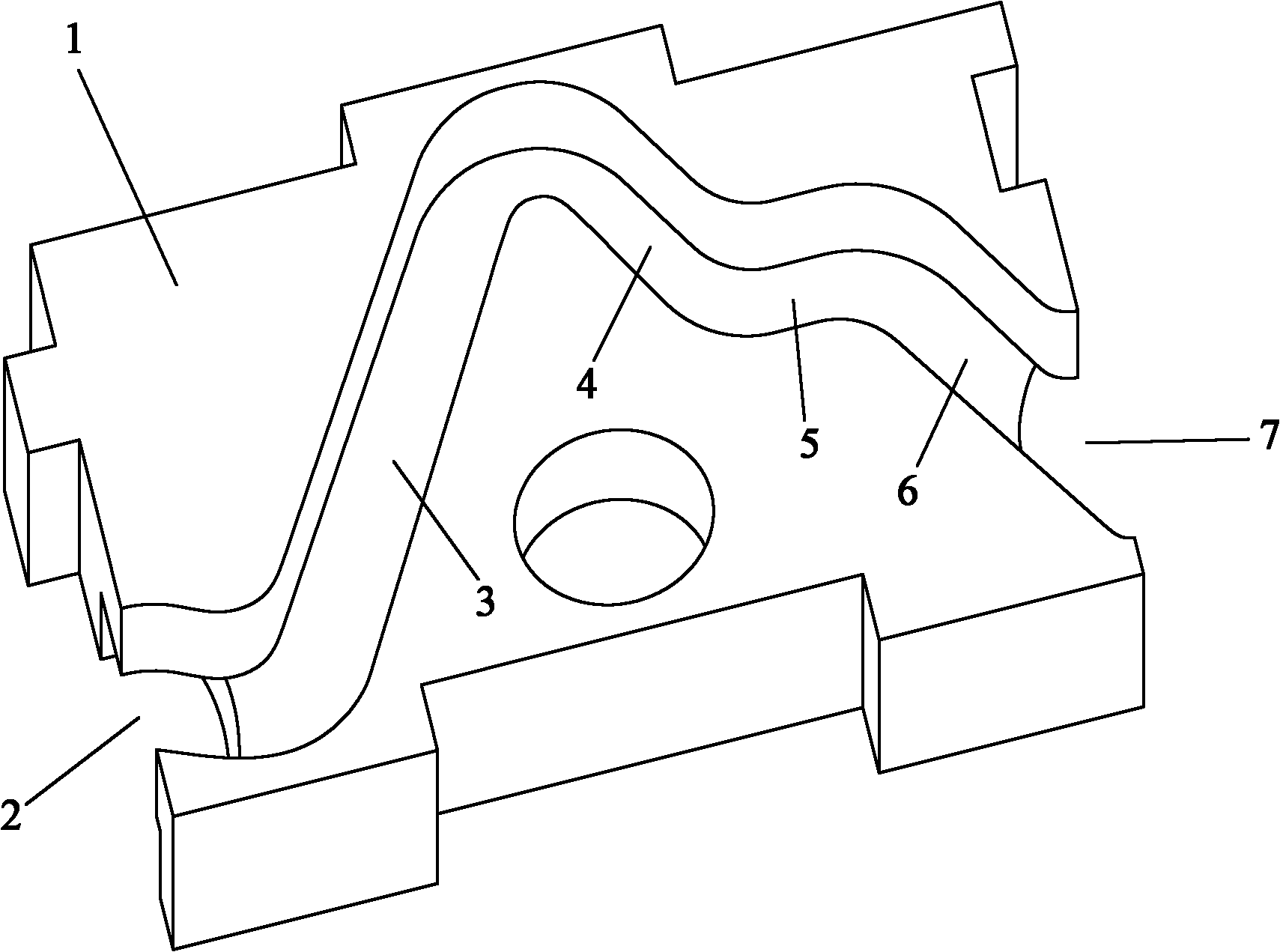

Thick needle triangular block of knitting machine

The invention discloses a thick needle triangular block of a knitting machine. The triangular block body is provided with a knitting guide groove, the knitting guide groove comprises a needle inlet chute section and a return needle chute section, the upper ends of the needle inlet chute section and the return needle chute section are in smooth transition, the lower end of the return needle chute section is connected with a translation groove section, the lower end of the translation groove section is connected with a needle withdrawing chute section, the joints of the return needle chute section and the translation groove section are in smooth transition, and the joints of the translation groove section and the needle withdrawing chute section are also in smooth transition; and the oblique included angle alpha of the needle inlet chute section is 25 to 30 degrees, the oblique included angle beta of the return needle chute section is 25 to 30 degrees, and the height h from the translation groove section to the top of the knitting guide groove is 2 / 5 to 3 / 5 of the height H of the knitting guide groove. By increasing the translation groove section, reasonably setting the height from the translation groove section to the top of the knitting guide groove and matching corresponding knitting processes, the woven fabric has light and thin structure, softness, good air permeability, elasticity and extensibility and low loosening property, is cool to wear, is not easy to stick the skin and is popular among people.

Owner:绍兴维格网络科技有限公司

Cooling textile fabric processing technology

InactiveCN107881624ASave on electricity billsLower body temperatureSucessive textile treatmentsWoven fabricsYarnEngineering

The invention discloses a cooling textile fabric processing technology. The technology includes the following steps of preparing multiple dacron raw materials and cool master batch, and adding the cool master batch into the dacron raw materials for melt blending; adopting warp and weft for weaving the fabric, wherein a yarn covering process is adopted for the weft; conducting sizing, and then carrying out beaming, drafting, denting, weaving, white body detection and desizing; conducting alkali peeling; conducting dyeing and controlling the temperature rising speed; taking out the fabric from dyeing tanks for drying, conducting soaping for removing floating colors, and then conducting color fixation; conducting reduction cleaning, dehydration for scotching and drying; after drying is completed, conducting heat shaping finish and pre-shrink washing on the fabric; after the previous steps are completed, detecting qualified products, and measuring the reduction value of allowable tearing strength in the damage process; conducting trimming, packing and warehouse-out inspection on the fabric. The technology has the advantages that the fabric is high in strength, highly endurable to wearing, acid and alkaline and more endurable in use.

Owner:苏州蓝纳青医用材料科技有限公司

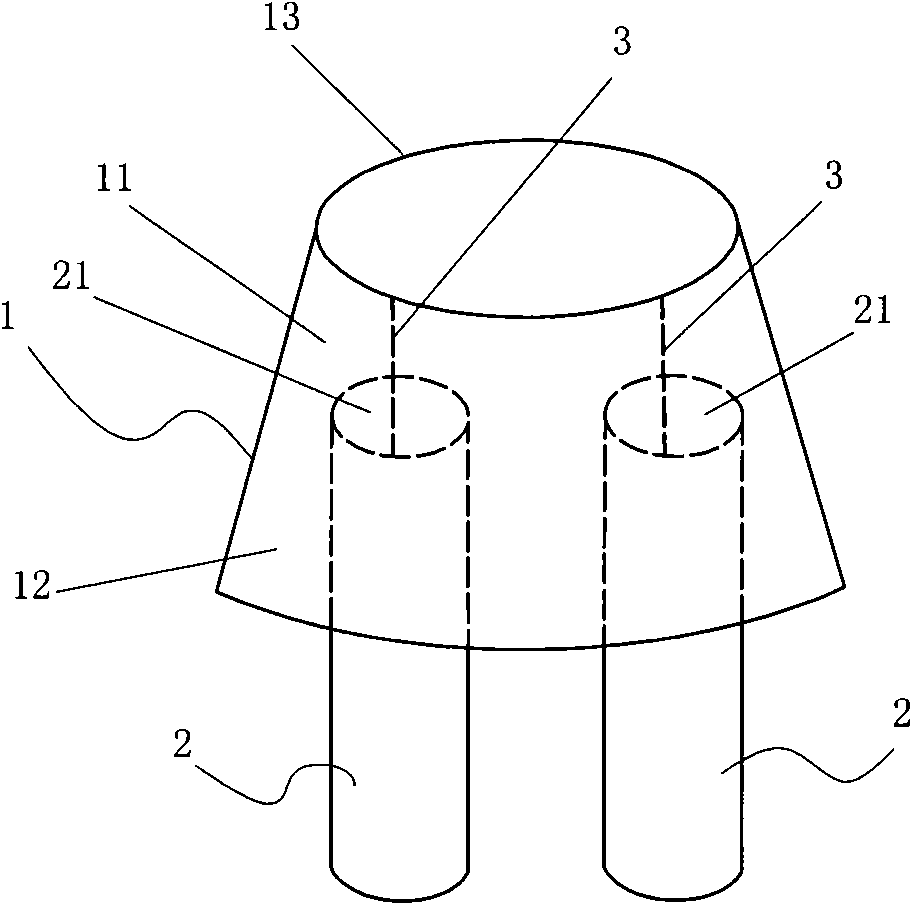

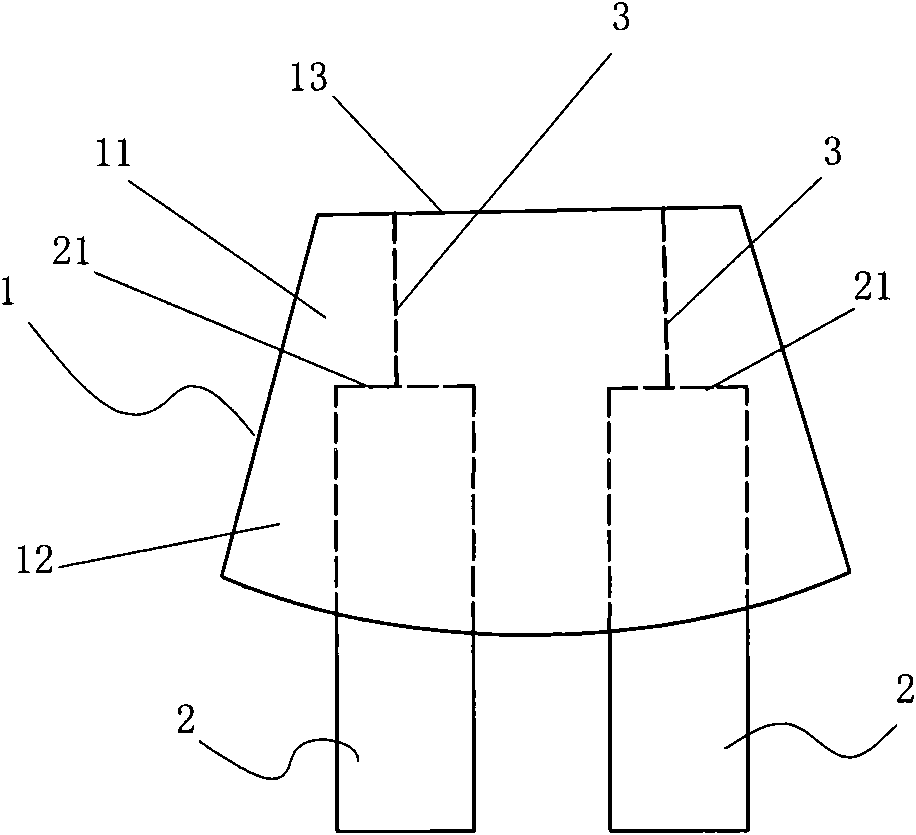

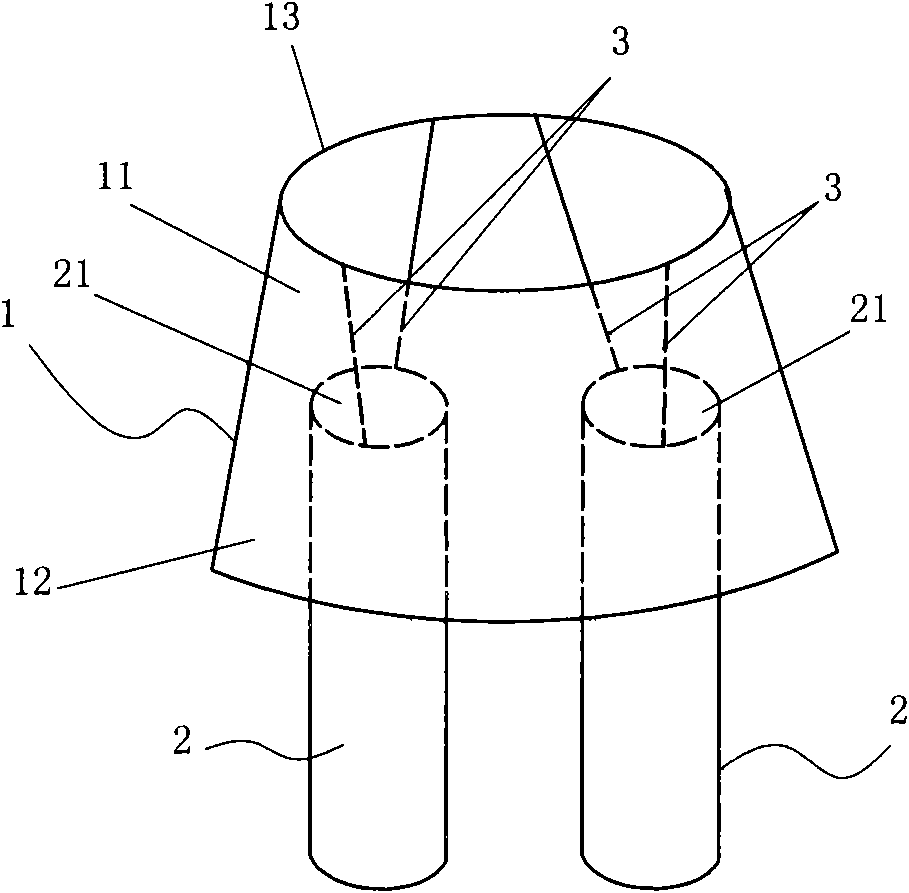

Divided skirt structure

The invention provides a divided skirt structure which comprises a skirt body and two trouser legs connected with the skirt body, wherein the skirt body comprises a waist part and a skirt flare part connected with the waist part; each trouser leg is provided with an upper end which forms a wearing opening of the trouser leg; the trouser legs are connected with the skirt body at the upper ends to form the divided skirt structure only having a layer of waist part. The divided skirt structure is cool for wearing and improves the comfort and the aesthetic property.

Owner:李湘怡

Antibacterial skin-caring polypropylene fiber fabric

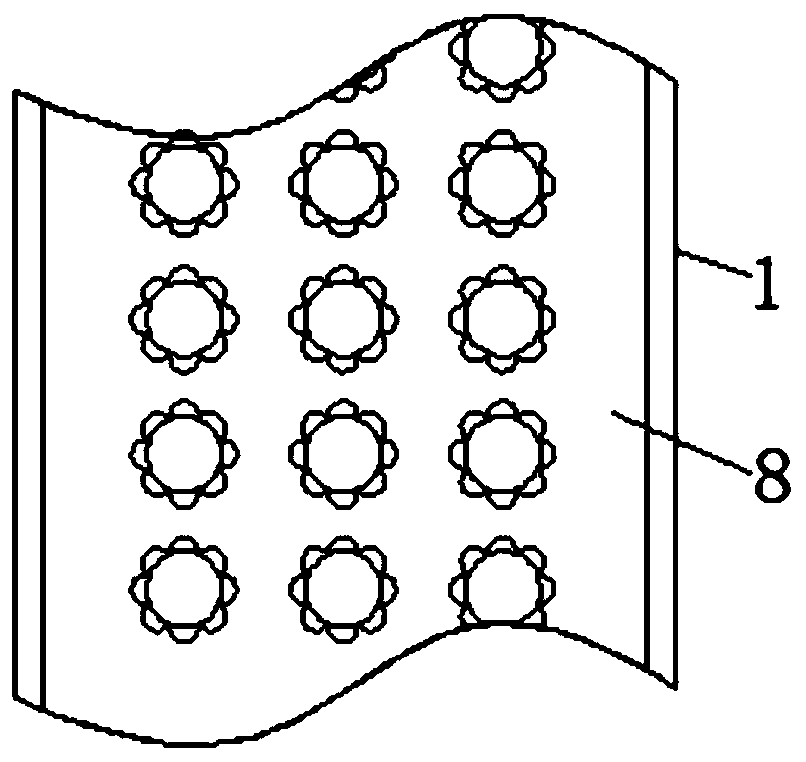

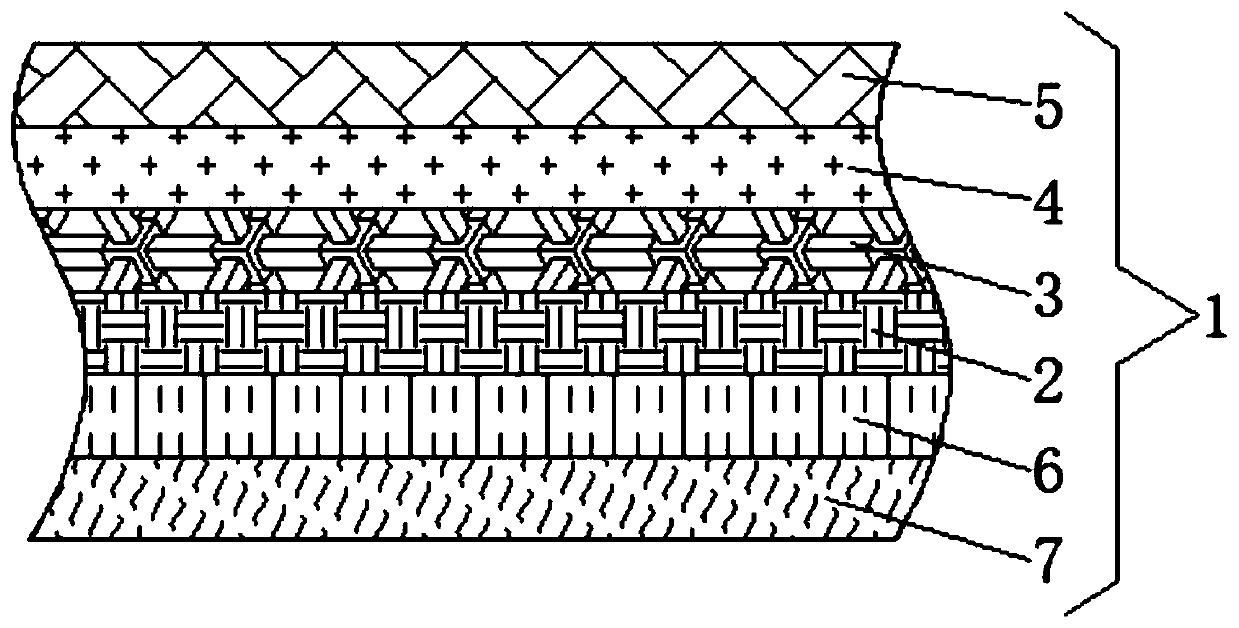

InactiveCN110341256AWith antibacterial skin careResolve dissatisfactionSynthetic resin layered productsClothingsEngineeringNonwoven fabric

The invention discloses an antibacterial skin-caring polypropylene fiber fabric. The polypropylene fiber fabric comprises a fabric body, the fabric body comprises a base fabric layer, the top of the base fabric layer is fixedly connected with a spunlace nonwoven fabric layer, the top of the spunlace nonwoven fabric layer is fixedly connected with an antibacterial layer, and the top of the antibacterial layer is fixedly connected with a gas permeable layer; the bottom of the base fabric layer is fixedly connected with a bamboo fiber layer, and the bottom of the bamboo fiber layer is fixedly connected with a skin caring layer; the front surface of the fabric body is fixedly connected with a decorative material; and the base fabric layer is prepared from polypropylene fibers, and the spunlacenonwoven fabric layer is prepared from a spunlace nonwoven fabric. According to the polypropylene fiber fabric provided by the invention, the base fabric layer, the spunlace nonwoven fabric layer, the antibacterial layer, the gas permeable layer, the bamboo fiber layer and the skin caring layer cooperate for use, so that the polypropylene fiber fabric has the advantages of inhibiting bacteria andcaring skin, and solves the problems that current fabrics have poor antibacterial skin-caring effects, and easily cause skin damage to people with sensitive skin, thereby causing dissatisfaction to users.

Owner:吴江市欣逸纺织有限公司

A kind of preparation method of cool summer clothes fabric

ActiveCN104522915BImprove crispnessImprove mechanical propertiesSucessive textile treatmentsBleaching apparatusPolyesterWear resistance

The invention discloses a method for making cool summer uniform fabric. The fabric has the good stiff and smooth performance and the good mechanical property, and further has the good hygroscopic, sweat-releasing and breathable performance, so that a wearer feels cool when a summer uniform is worn, the original characteristics of high strength, high abrasive resistance, high heat resistance, high corrosion resistance and the like of polyester ramie fabric are retained, the method is higher in color fastness and has the advantages of being hygroscopic, capable of achieving sweat releasing, breathable, soft in hand feeling, stiff, smooth and resistant to wrinkles, and the advantages are brought by the higher color fastness; the using requirement of the summer uniform fabric is met. The method is reasonable in process design and environmentally friendly, and utilization of energy resources and water resources is greatly reduced.

Owner:安徽中天新材料科技股份有限公司

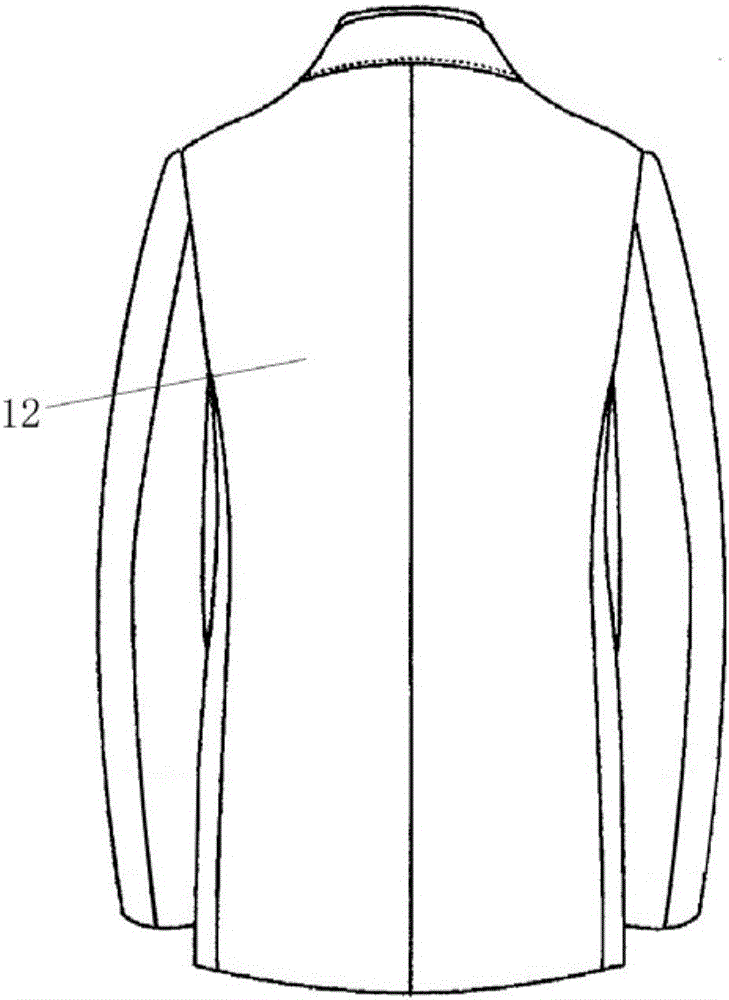

A formal top for summer

The invention relates to an upper garment suitable for summer. The upper garment comprises a coat, a shirt collar and a pair of shirt sleeves. The coat is formed by sewing two oppositely-opened front pieces, a rear piece, two sleeve pieces and a turn-down collar. The upper garment is characterized in that shoulder pads which are excessively light in weight and good in breathability and are formed by sewing multi-layer large-aperture 3D mesh materials are fixed to the positions, located at the two shoulders, of the bottom face of the coat through pull threads respectively, collar hanging edges with a plurality of button holes are sewn inside the positions, located at the chest portions and on the inner faces of the front pieces, of the front pieces respectively, and circles of sleeve hanging edges are sewn on the lower portions, located at the elbow portions, inside the sleeve pieces of the coat respectively. The shirt collar is formed by sewing two oppositely-opened front chest pieces, an over shoulder piece and a collar. Opening parts of the two front chest pieces are connected through an upper row of buttons and a lower row of buttons to form an inverted trapezoid shape. A plurality of buttons which are connected with the collar hanging edges of the coat are sewn on the lateral side of each front check piece. Each shirt sleeve is formed by sewing the corresponding sleeve piece and a cuff which can be opened and closed. A welt is sewn on the edge of each sleeve piece. The upper garment can be widely used for summer.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

warp knitted fabric

ActiveCN109790661BDress coolDoes not curlOrnamental textile articlesWarp knittingYarnPolymer science

The present invention provides a warp knitted fabric that is excellent in stretchability and cool feeling when worn, does not cause curling at the cut portion of the knitted fabric, and can be processed after cutting. The present invention is a warp-knitted fabric woven from synthetic fibers from the first bar, cellulose fibers from the second bar, and elastic yarns from the third bar, and is characterized in that the warp-knitted fabric The number of crossing points where the sinker loops of the synthetic fiber and the sinker loops of the elastic yarn intersect between the spanning wales existing in 1 complete course is relative to the number of crossing points that exist in the 1 complete course and spanning The ratio of the number of sinkers of the synthetic fibers between the wales is 50% or less.

Owner:ASAHI KASEI KK

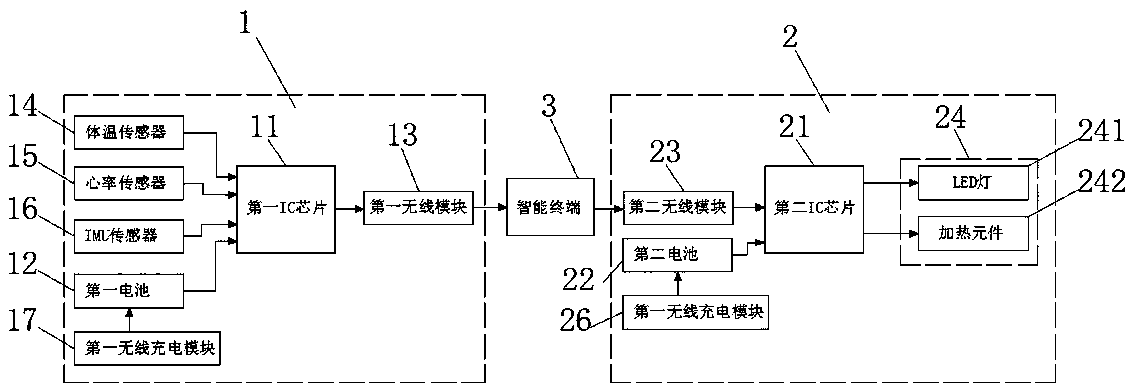

Infant health monitoring device

InactiveCN109497975AComfortable to wearLess discomfortCatheterDiagnostic recording/measuringIntegrated circuitElectricity

The invention relates to an infant health monitoring device which comprises a sensing device, a feedback device and an in intelligent terminal. At least part of the sensing device contacts with an infant, the sensing device comprises a first IC (integrated circuit) chip, a first power supply, a first wireless module and a sensor unit, the first power supply and the first wireless module are electrically connected with the first IC chip, the sensor unit is used for acquiring infant health indexes, the first IC chip acquires monitored information sensed on the sensor unit, is connected with theintelligent terminal through the first wireless module and transmits the monitored information onto the intelligent terminal, the feedback device is wore on a body of an infant guardian and comprisesa second IC chip, a second power supply, a second wireless module and a reminding device, the second power supply, the second wireless module and the reminding device are electrically connected with the second IC chip, and the second IC chip is connected with the intelligent terminal through the second wireless module, acquires the monitored information on the intelligent terminal and controls actions of the reminding device to remind infant health conditions according to the acquired monitored information.

Owner:林戎 +3

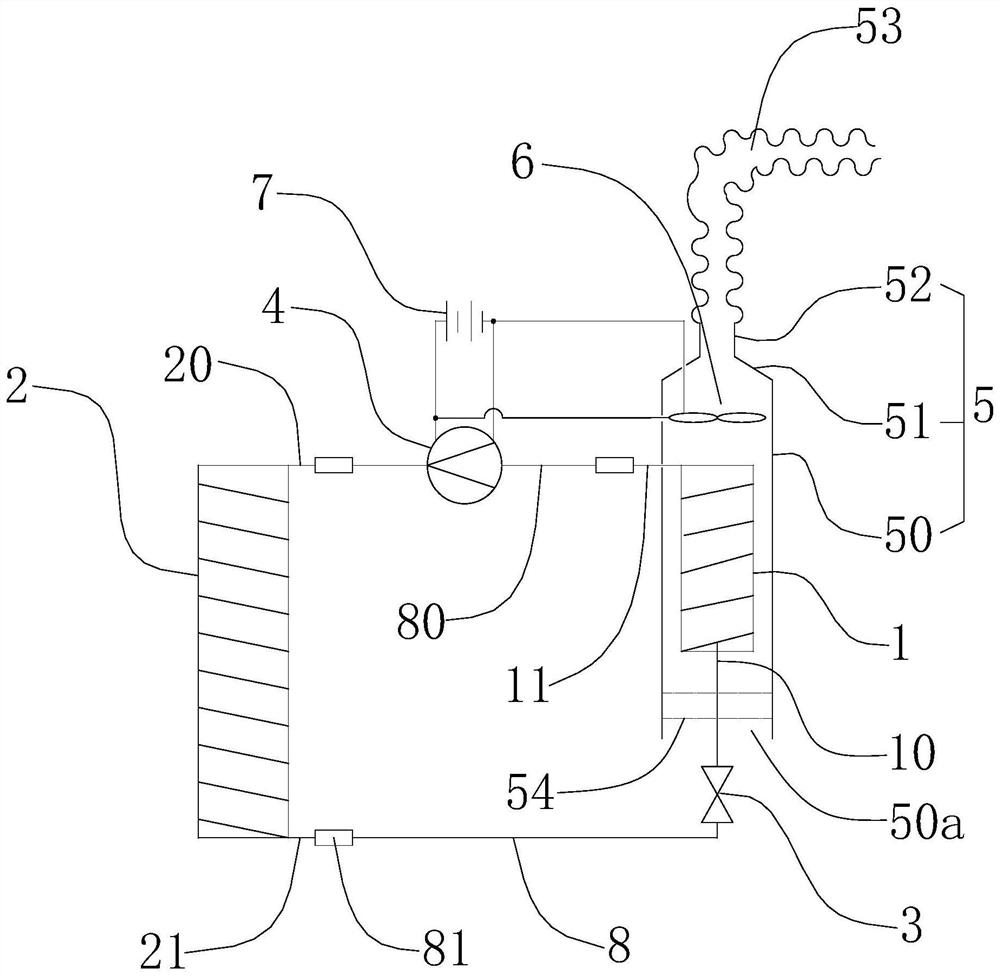

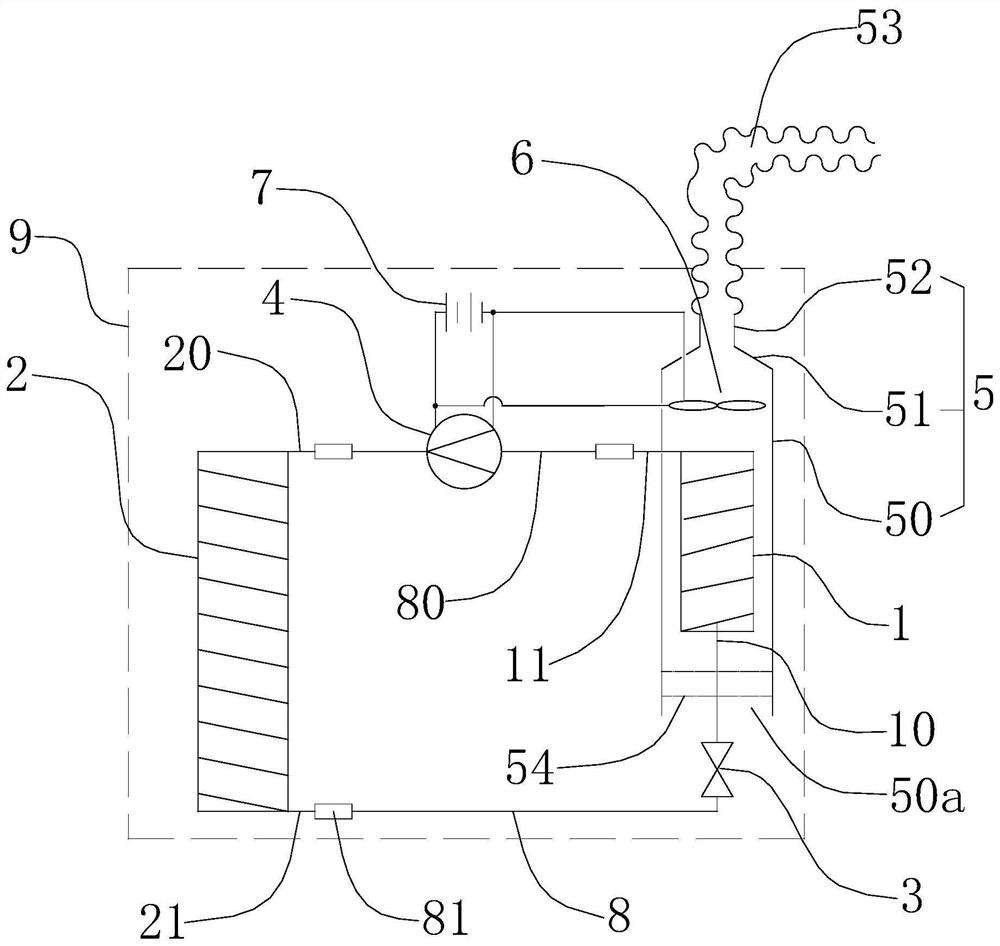

Miniature portable protective clothing refrigerating system

PendingCN111870835ADress coolComfortable to wearChemical protectionHeat protectionCold airEngineering

The invention discloses a miniature portable protective clothing refrigerating system which comprises an evaporator, a condenser, a throttling device, a vacuum pump, a wind gathering shell, a fan anda power supply. The evaporator, the condenser, the throttling device and the vacuum pump are connected through pipelines, and the miniature portable protective clothing refrigerating system further comprises a refrigerant arranged in the pipelines. The refrigerant is driven by the vacuum pump to circularly flow among the condenser, the throttling device and the evaporator in sequence, the fan is arranged in a manner of corresponding to the evaporator and used for blowing cold air around the evaporator into protective clothing, and the power supply is used for supplying power to the vacuum pumpand the fan. According to the miniature portable protective clothing refrigeration system, refrigeration is conducted through phase state changes of the refrigerant, the refrigeration efficiency is higher, the cooling capacity needed by human body heat dissipation can be effectively provided, heat dissipated from the human body is rapidly absorbed, and the protective clothing is more cool and comfortable to wear.

Owner:焦永生

Glove blank weaving method and glove blank

Owner:SHANDONG XINGYU GLOVES

Production method of antibacterial and high-hygroscopicity blended fiber

InactiveCN108754724AMoisture wickingGood ventilation and thermal conductivityConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsHeat stabilityThermal conductivity

The invention discloses a production method of antibacterial and high-hygroscopicity blended fiber. The production method comprises the following steps of hemp fiber preparation, antibacterial fiber preparation, and blending. Compared with the prior art, the blended fiber has the advantages of being good in water-retaining property, high in heat stability, antibacterial and environmentally friendly and has the antibacterial characteristic, hemp fiber is excellent in hygroscopicity, sweat discharge property, air permeability and thermal conductivity, and the blended fiber is cool to wear and isnot attached to the body.

Owner:ANHUI ZHAOBAO TEXTILE TECH CO LTD

Comfortable wrinkle-resistant fabric and preparation method thereof

InactiveCN101942730BGood hygroscopicityImprove wearing comfortWoven fabricsYarnEngineeringMoisture absorption

The invention provides a comfortable wrinkle-resistant fabric, which is prepared by weaving high-twist wrap yarns, wherein the high-twist wrap yarns are wrapped by leather yarns and core yarns; the core yarns are comfortable short fibers; the leather yarns are chemical fiber filaments; the weight ratio of the chemical fiber filaments to the comfortable short fibers is 10-80:20-90; the leather yarns are wrapped on the core yarns in spiral wrapping mode; the degree of twist of the chemical fiber filaments and the comfortable short fibers in the Z-direction or S-direction is 1 to 25T / cm; the chemical fiber filaments are made of terylene, chinlon, polypropylene, PTT, silk, or terylene FDY; and the comfortable short fibers are one or more fibers in pure cotton, viscose, fur, flax, bamboo fiber, corn fiber, soybean fiber and milk fiber. The comfortable wrinkle-resistant fabric has the advantages of high wrinkle resistance, moisture absorption, wear resistance, pilling resistance, sense of flax, air permeability and machine-wash property, comfortable wear, high strength and quick drying of absorbed moisture, and is an ideal comfortable wrinkle-resistant shell fabric.

Owner:汕头市奥山服饰有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com