Thick needle triangular block of knitting machine

A triangular block and knitting machine technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problem that the cloth cannot meet the wearing requirements, and achieve the effects of not easy to stick to the skin, light and thin cloth structure, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

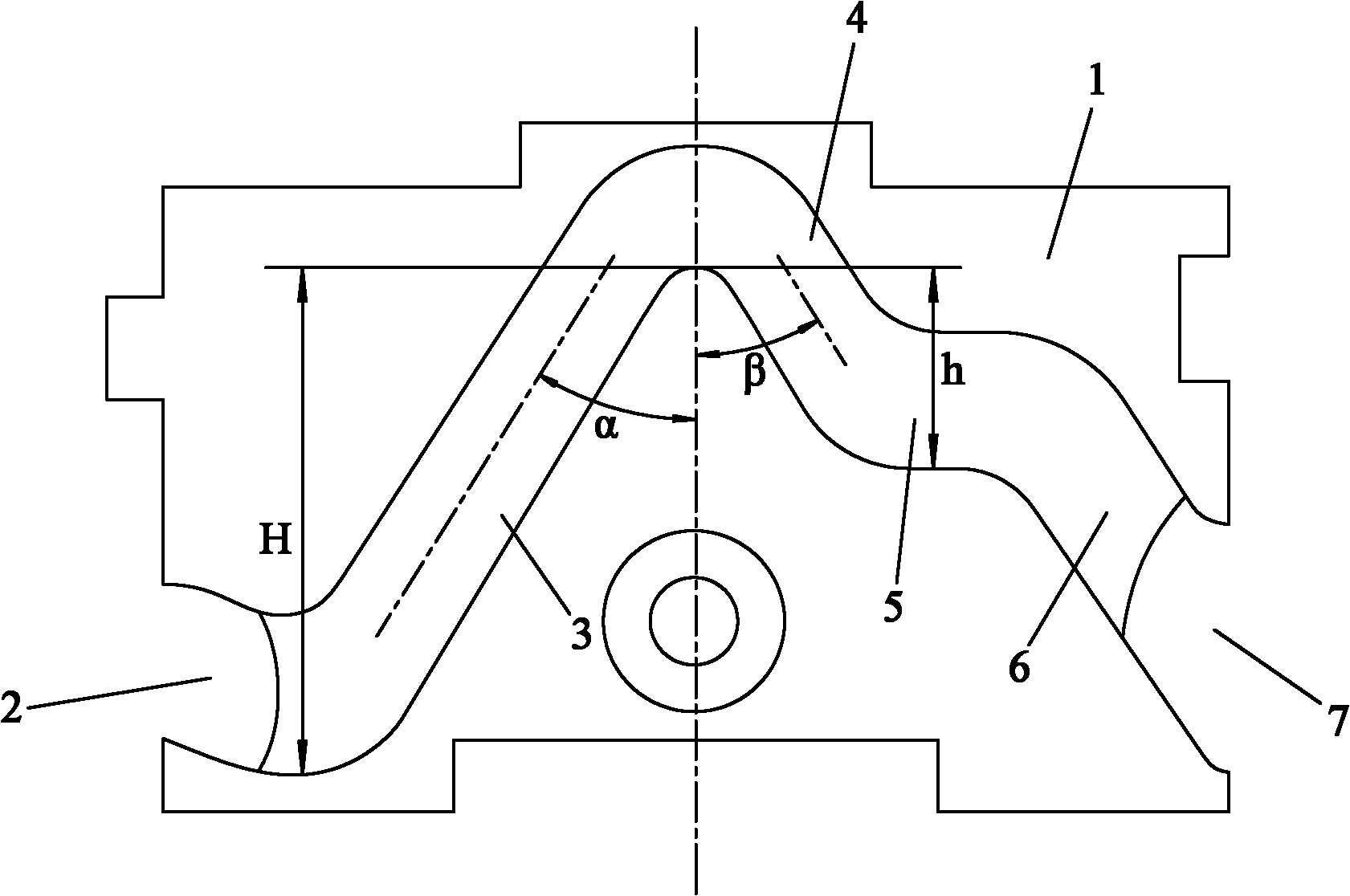

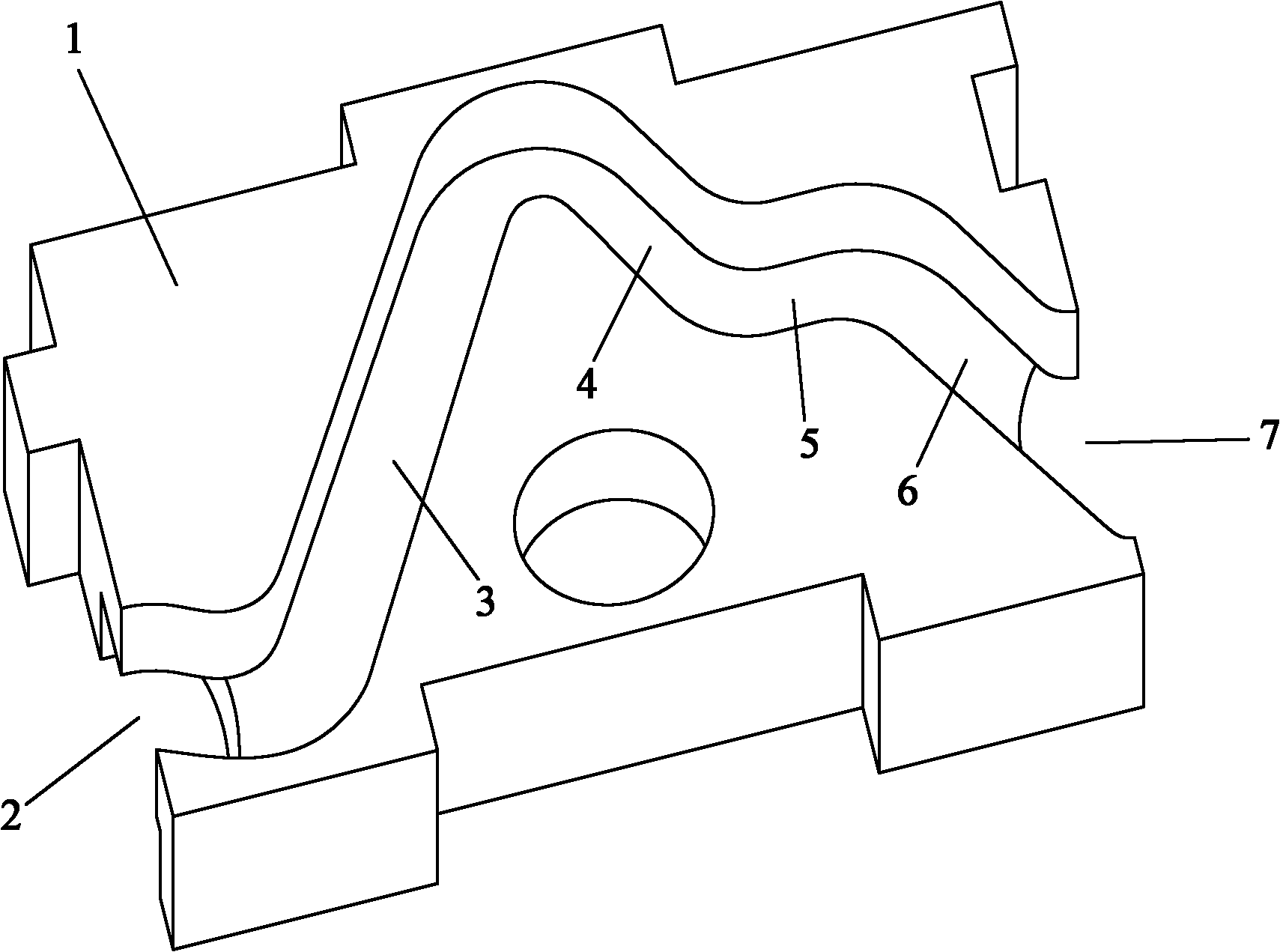

[0009] Example: see figure 1 and figure 2 According to the present invention, a knitting needle guide groove is provided on the triangular block body 1, and the knitting needle guide groove includes a needle entry chute section 3, a return chute section 4, a needle entry chute section 3 and a return chute section The upper end of 4 is round and smooth, and the lower end of the return needle chute section 4 is connected with a translation groove section 5, and the lower end of the translation groove section 5 is connected with the needle withdrawal chute section 6, and the connection between the return needle chute section 4 and the translation groove section 5 The smoothness at the position is excessive, and the connection between the translation groove section 5 and the needle withdrawal chute section 6 is also smooth and excessive; the inclination angle α of the needle entry chute section 3 is 25-30 degrees, and the return needle chute section The inclination angle β of 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com