Thermoregulation cashmere yarn and production method thereof

A manufacturing method and technology of cashmere yarn, applied in the direction of yarn, textile and paper making, to achieve the effect of smooth spinning, good temperature adjustment function and comfortable wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Manufacture temperature-adjusted cashmere yarn for underwear, the product count is designed to be 18tex.

[0041] Raw material selection: the fineness of temperature-adjusting fiber is 1.7dtex, and the length is 38mm; the fineness of modal fiber is 1.7dtex, and the length is 40mm; the fineness of cashmere is 14.8um, and the length is 38mm. The mass blending ratio of the three fibers is 40:30:30.

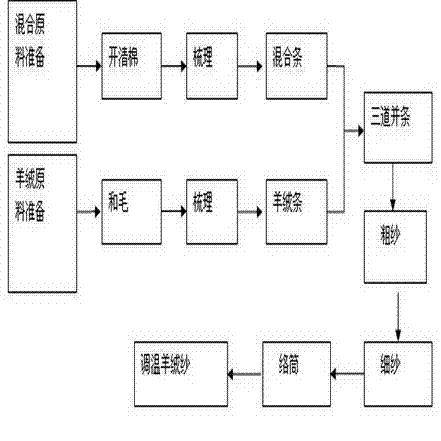

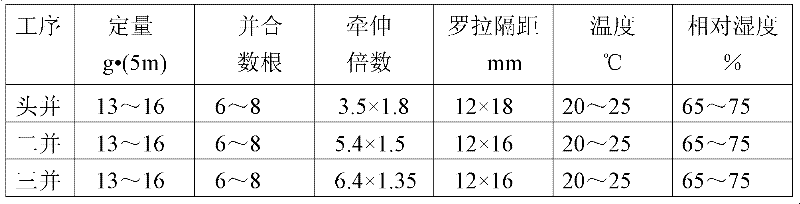

[0042] process such as figure 1 shown.

[0043] Raw material preparation: antistatic treatment of 40% of heat storage and temperature regulating fibers with special spinning auxiliary for heat storage and temperature regulation. The auxiliary agent is prepared by antistatic agent, smoothing agent and water in a ratio of 2:8:90 , the PH value is 6, and the addition amount of the spinning auxiliary agent is 5% of the mass of the blended fiber. Spray evenly on the surface of the heat storage and temperature regulating fiber, the treatment requires the moisture regain of the fi...

Embodiment 2

[0055] The temperature-adjusted cashmere yarn used in the manufacture of T-shirts is designed to be 24tex.

[0056] Raw material selection: the fineness of temperature-adjusting fiber is 1.7dtex, and the length is 38mm; the fineness of polyester fiber is 1.8dtex, and the length is 40mm; the fineness of cashmere is 14.8um, and the length is 40mm. The blend ratio is 40 / 20 / 40.

[0057] Technological process: the temperature-adjusting fiber and the polyester fiber are mixed in the opening and cleaning process, and the remainder is the same as in Example 1.

[0058] Raw material preparation: the pretreatment of the temperature-adjusting fiber is the same as in Example 1; the polyester fiber is prone to static electricity due to its low moisture regain, and is pretreated with a cationic antistatic agent, which is a prior art.

[0059] Mixing method: the temperature-adjusting fiber and the polyester fiber are mixed in the opening and cleaning process, and the remainder is the same a...

Embodiment 3

[0068] The temperature-adjusted cashmere yarn used in the manufacture of cashmere sweaters is designed to be 28tex.

[0069] Raw material selection: temperature regulating fiber fineness is 1.7dtex, length is 40mm; milk protein fiber fineness is 1.7dtex, length is 40mm; cashmere fineness is 14.8um, length is 40mm, blending ratio is 30:10:60.

[0070] Technological process: the mixture of temperature-adjusting fiber and milk protein fiber is opened, cleaned, and carded; cashmere is wooled and carded; the rest is the same as in Example 1.

[0071] Raw material preparation: Antistatic treatment is carried out on the 40% mixture composed of temperature-regulating fiber and milk protein fiber with a special spinning auxiliary for heat storage and temperature regulation, and the addition amount is 6% of the mass of the mixture fiber, and the remainder is the same as in Example 1.

[0072] Mixing method: use strip mixing method. Specifically, the mixed strips of temperature-adjustin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com