Finishing agent of polyester silk-like fabric and preparation and post-treatment methods of fabric

A technology of fabric finishing agent and artificial silk, which is applied in the directions of fiber treatment, textile and papermaking, fiber type, etc., can solve the problems of high processing cost and poor durability, and achieve the effect of convenient product processing, good hygroscopicity and comfortable touch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The base fabric is polyester. The warp and weft materials of the base fabric are 1 / 75D / 72f polyester filaments, and the warp and weft density is 580×380 threads / 10cm; the square meter weight is 83g / m 2 .

[0039] Post-processing proceeds as follows:

[0040] (1) Desizing: use an open-width desizing machine. The temperature of the desizing tank is 95°C; the running speed of the fabric is 40m / min.

[0041] The formulation of the treatment liquid, by weight, includes 2.5% caustic soda; 0.45% stabilizer; 0.225% penetrant; 0.225% scouring agent, and the rest is water.

[0042] (2) Base weight reduction treatment: use high temperature and high pressure overflow reduction machine. The bath ratio is 1:18; the treatment temperature is 120°C; the treatment time is 40 minutes, and then washed with water and dried.

[0043] The formulation of the treatment liquid, by weight: 2.5% caustic soda; 0.2% penetrating agent; 0.2% scouring agent.

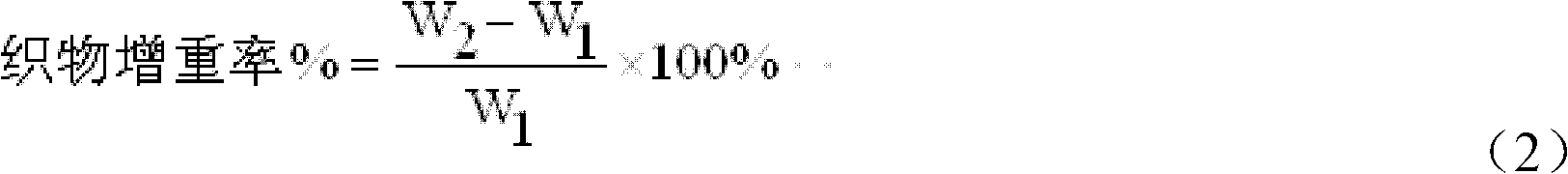

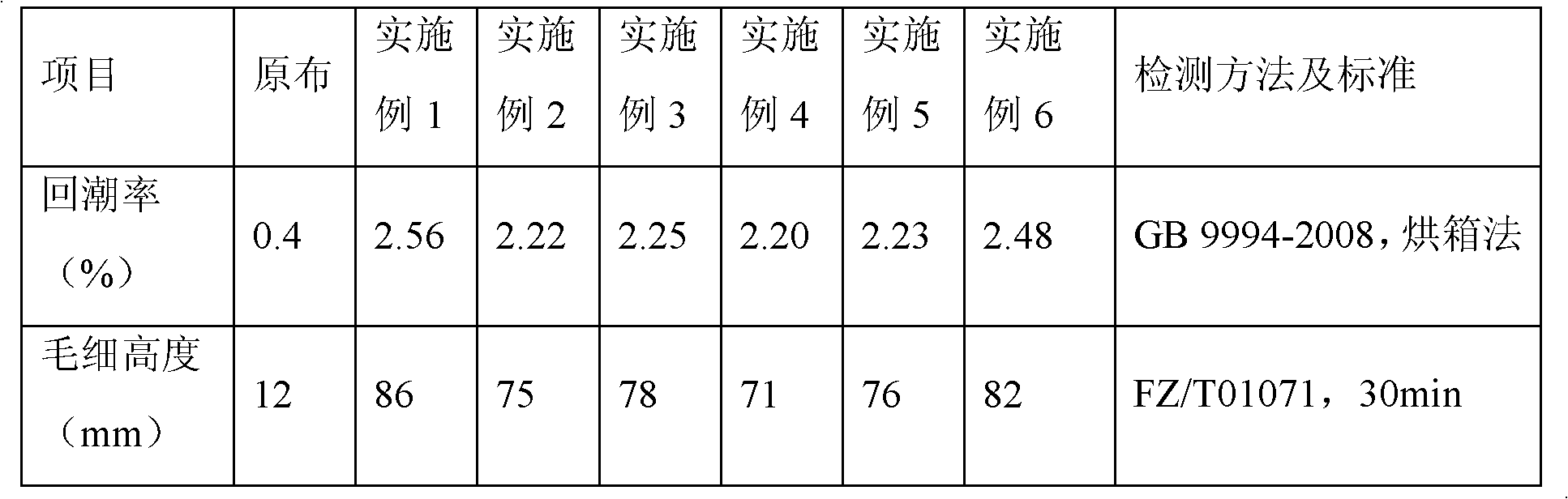

[0044] The weight reduction rate of th...

Embodiment 2

[0050] (1) desizing: with embodiment 1

[0051] (2) Base weight reduction treatment: use high temperature and high pressure overflow reduction machine. The bath ratio is 1:15; the treatment temperature is 115°C; the treatment time is 43 minutes, and then washed with water and dried.

[0052] The formulation of the treatment liquid, by weight: 2% caustic soda; 0.25% penetrating agent; 0.25% scouring agent.

[0053] The weight reduction rate of the fabric after finishing in step (2) is 10%.

[0054] (3) Padding finishing solution: padding at room temperature. The fabric running speed is 20±1m / min; the drying temperature is 120°C; the baking temperature is 158°C.

[0055] The finishing agent is prepared according to the following formula (parts by weight), including 5 parts of silk peptide; 3 parts of polyethylene glycol; 3 parts of citric acid, 1.5 parts of sodium dihydrogen phosphate, 2 parts of acetic acid, 2 parts of denatured silicone, and 1 part of chitosan share.

[0...

Embodiment 3

[0059] (1) desizing: with embodiment 1

[0060] (2) Base weight reduction treatment: use high temperature and high pressure overflow reduction machine. The bath ratio is 1:20; the treatment temperature is 125°C; the treatment time is 37 minutes, and then washed with water and dried.

[0061] The formulation of the treatment liquid, by weight: 3% caustic soda; 0.15% penetrating agent; 0.15% scouring agent.

[0062] The weight reduction rate of the fabric after finishing in step (2) is 12%.

[0063] The finishing agent is prepared according to the following formula (parts by weight), including 7 parts of silk peptide; 5 parts of polyethylene glycol; 5 parts of maleic anhydride, 2.5 parts of disodium hydrogen phosphate, 1 part of acetic acid, 1 part of softening agent, and 0.5 parts of chitosan share.

[0064] The preparation process of the finishing solution is as follows: by weight, dissolve 1 part of acetic acid in 75 parts of water, then add 0.5 parts of chitosan, dissolve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com