Novel multifunctional cladding yarn and preparation method

A multi-functional, yarn technology, applied in the direction of yarn, melt spinning, textiles and papermaking, etc., can solve the problems of reducing the economic effect of covered yarn, achieve the effect of increasing product added value, soft hand feeling, and improving the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

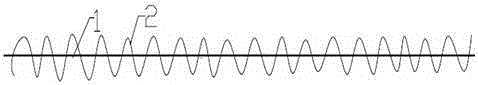

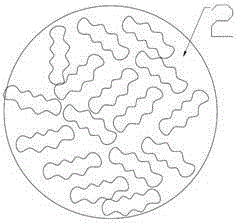

[0023] In one embodiment, a novel multi-functional covered yarn, the multi-functional covered yarn includes a core wire 1 and an outer covering wire 2 wrapped around the core wire 1, the outer covering wire 2 It is made of ultra-fine denier nylon 6 yarn with a double 8-shaped structure on the transversely laminated surface, and the core thread 1 is spandex yarn.

[0024] Further, in the double 8-shaped structure, the double 8s are the same central line.

[0025] A preparation method for a novel multifunctional covering yarn, comprising the following steps:

[0026] (1) Preparation of special double-8 cross-section ultra-fine nylon yarn: put the caprolactam chips into the rod extruder for melt extrusion, the melting temperature is 300 °C, pass through the spinning assembly, and then in the hole with a fineness of 0.425 The denier double 8-hole spinneret is sprayed out, and then is blown and cooled by side wind through the spinning tunnel. The air cooling temperature is 22°C, a...

Embodiment 2

[0031] A preparation method for a novel multifunctional covering yarn, comprising the following steps:

[0032] (1) Preparation of special double-8 cross-section ultra-fine nylon yarn: put caprolactam slices into a rod extruder for melt extrusion at a melting temperature of 320°C, pass through the spinning assembly, and then pass through the spinning assembly with a hole fineness of 0.625 The double-denier 8-shaped spinneret is sprayed out, and then passed through the spinning tunnel for side wind blowing and cooling. The air-cooling temperature is 20°C, and it becomes a double-8-shaped nylon yarn;

[0033] (2) Nylon yarn winding; the winding adopts an online tension device with a tension controller, adjust the tension to 3CN±3%, and the winding speed is 800 / min, and then wind the nylon yarn from the nylon bobbin to the bag evenly. on the aluminum-clad bobbin;

[0034] (3) Draw and twist the spandex yarn with nylon yarn with double 8 cross-section. When twisting, the speed of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com