Sole and upper double-acting breathable type ventilating shoe

A dual-action, ventilating shoe technology, applied to soles, shoe uppers, footwear, etc., can solve the problems of poor wearing comfort, breeding of bacteria, beautiful appearance, poor wear resistance, etc., and achieve a balanced gas temperature in the shoe to keep warm and balanced gas temperature. , the effect of good waterproof function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

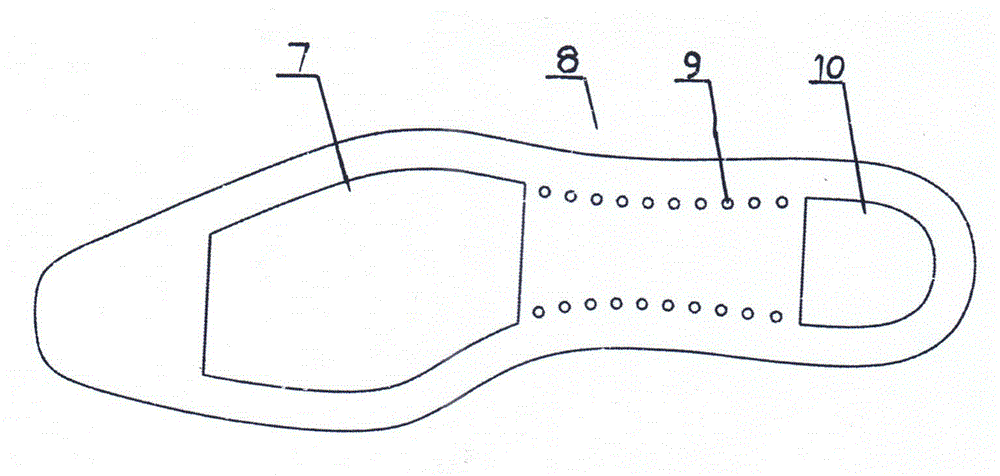

[0022] Such as Figure 1 to Figure 7 As shown in Fig. 1 , a breathing ventilation shoe with a sole and a double function, which is mainly composed of an insole and an upper surface. include:

[0023] Such as figure 1 and figure 2 As shown, the insole 2; the insole is located at the upper end of the midsole 8. Insole is made up of insole top layer 4 and insole bottom layer 5. The surface layer of the insole is a surface in contact with the sole of the human body, and the front and rear parts of the surface layer of the insole are densely covered with semi-ventilation holes 1 penetrating through the surface layer of the insole. The diameter of the semi-ventilation hole is 1-2.5 mm, and the distance between each hole is 3-6 mm. At least two rows of through holes 3 are provided in the middle of the insole surface corresponding to the arch of the human body. The diameter of the through holes is the same as that of the semi-ventilating holes, and the distance between adjacent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com