Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Cause bodily harm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

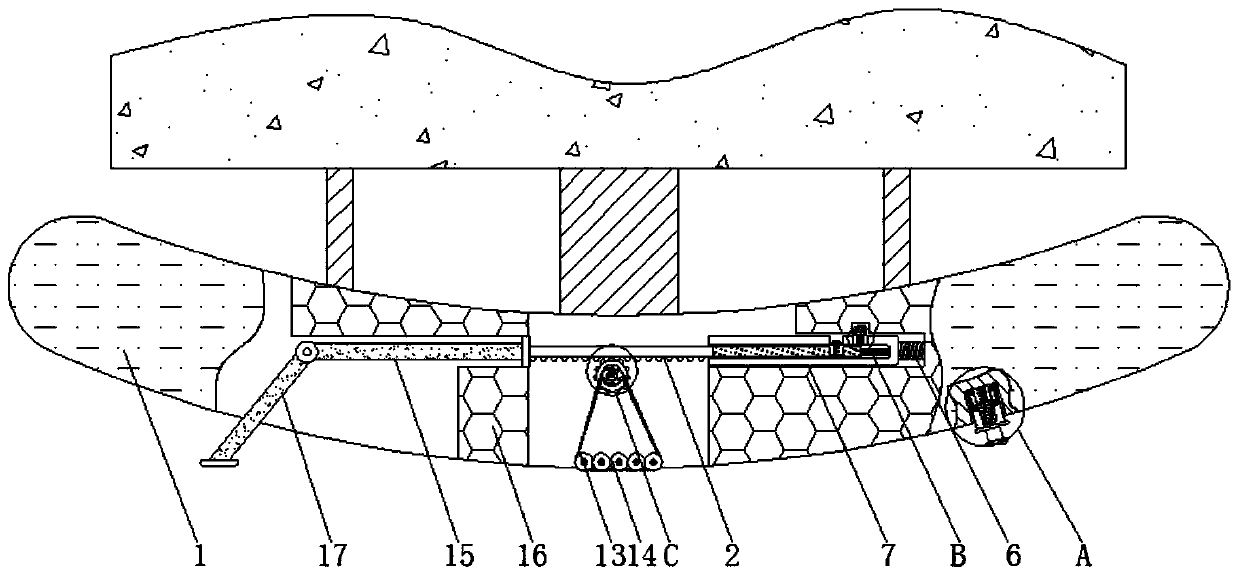

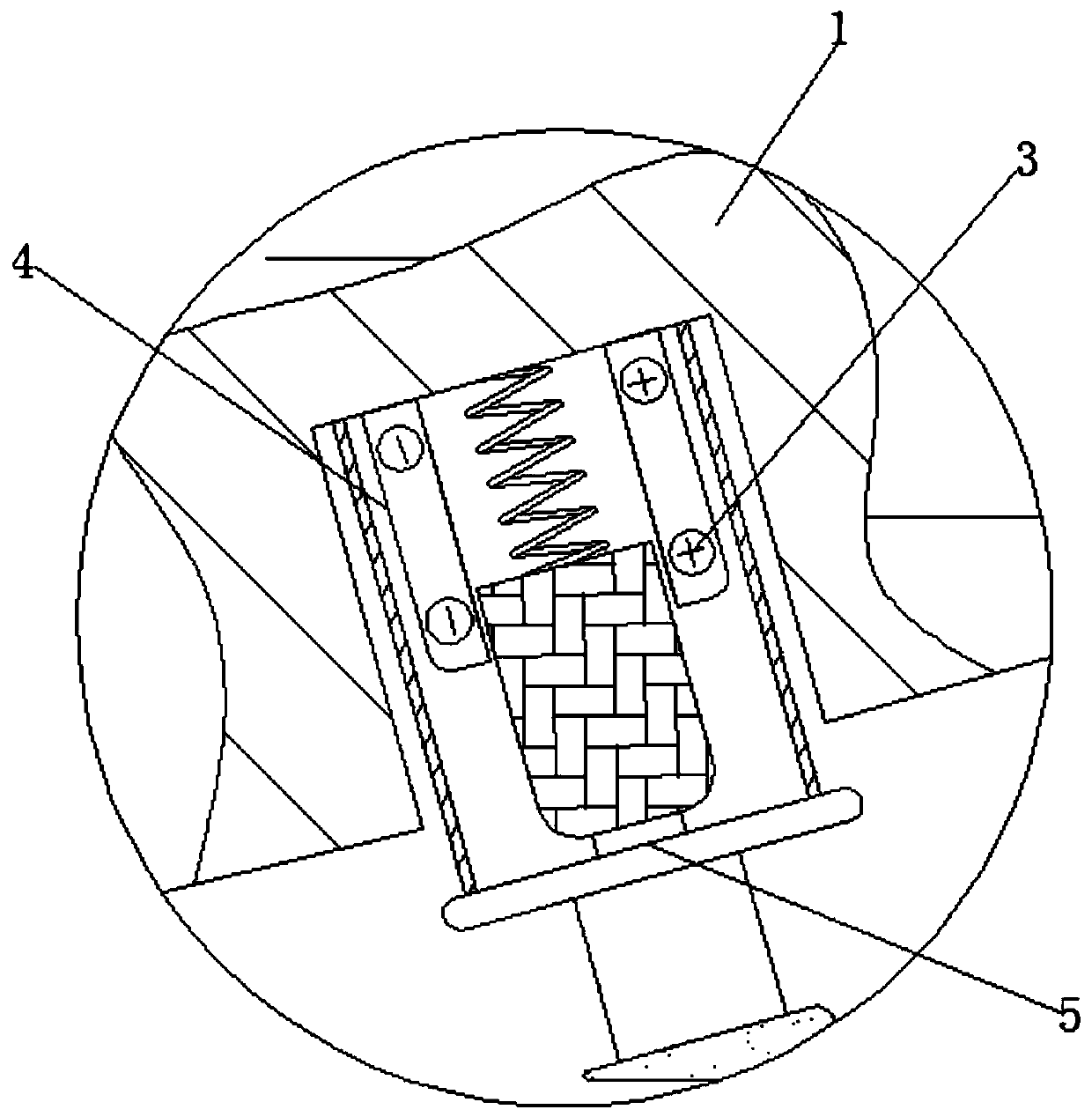

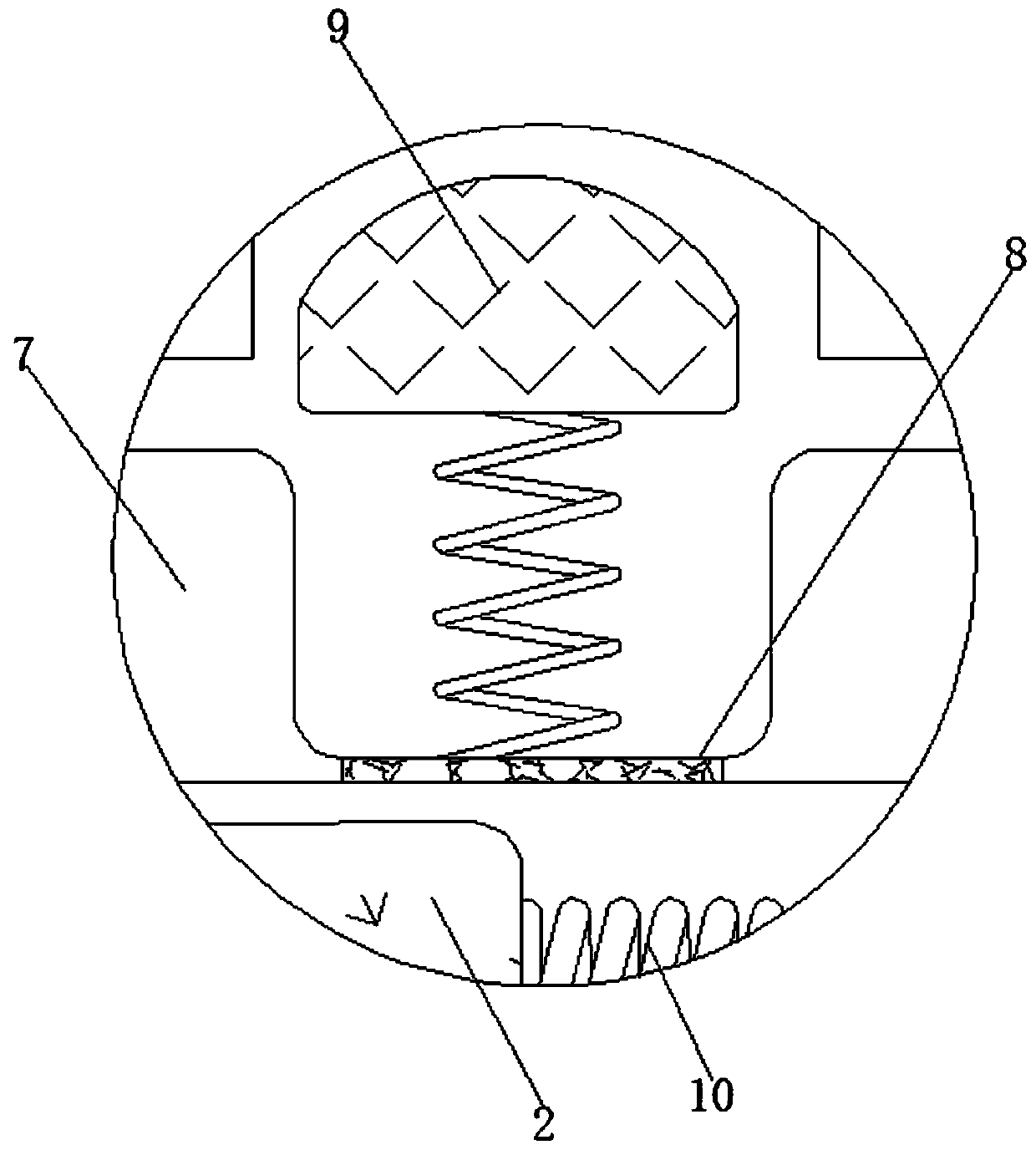

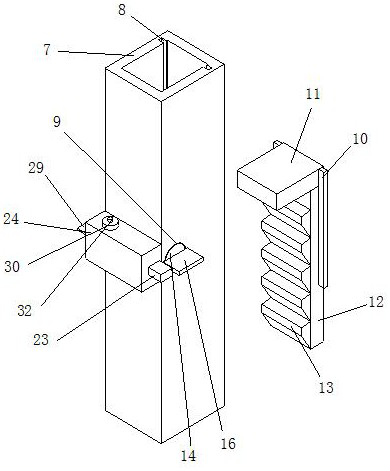

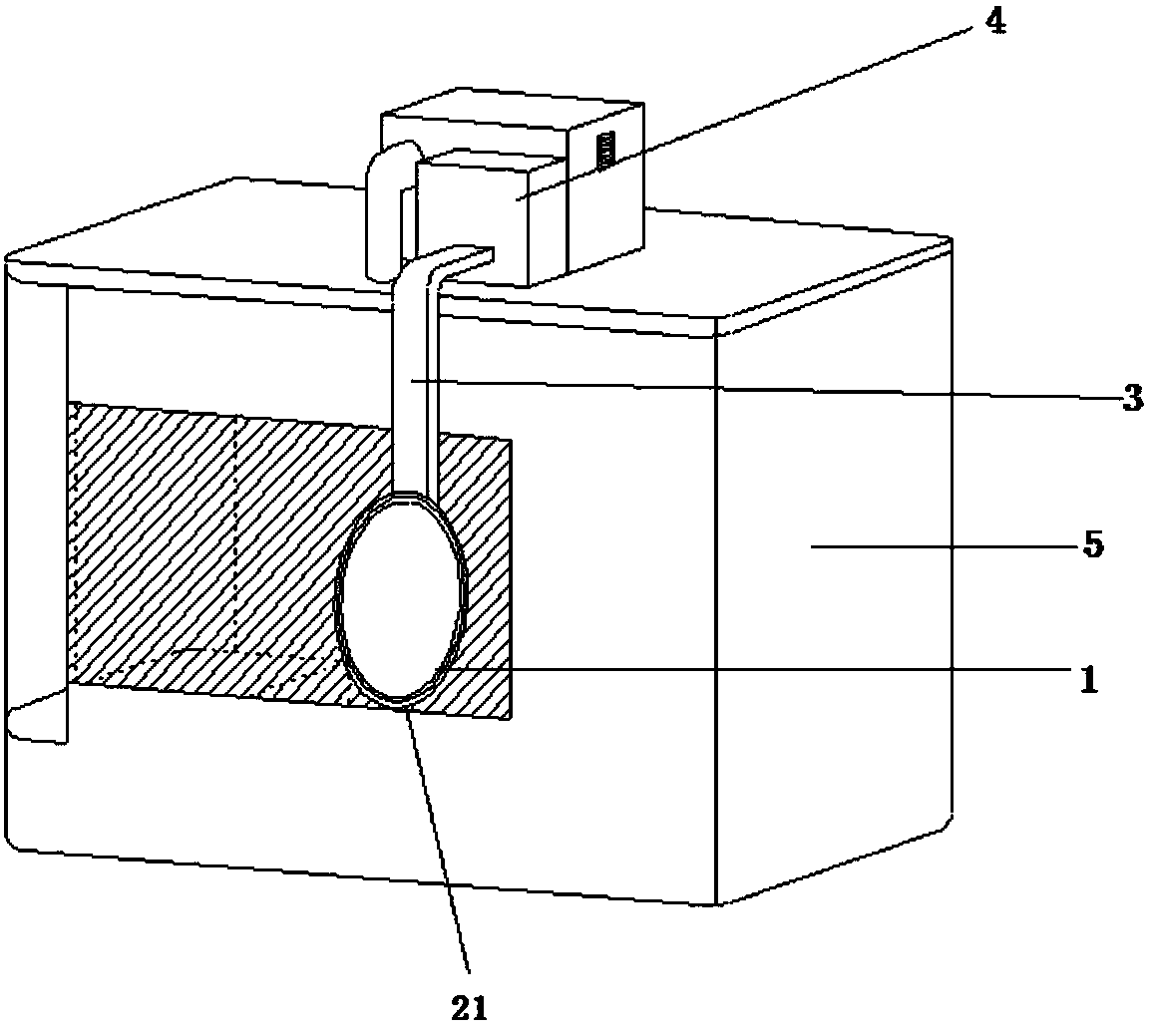

Intelligent wall grinding robot

InactiveCN106271941AAvoid bodily harmImprove work efficiencyProgramme-controlled manipulatorGrinding feed controlControl engineeringRobot

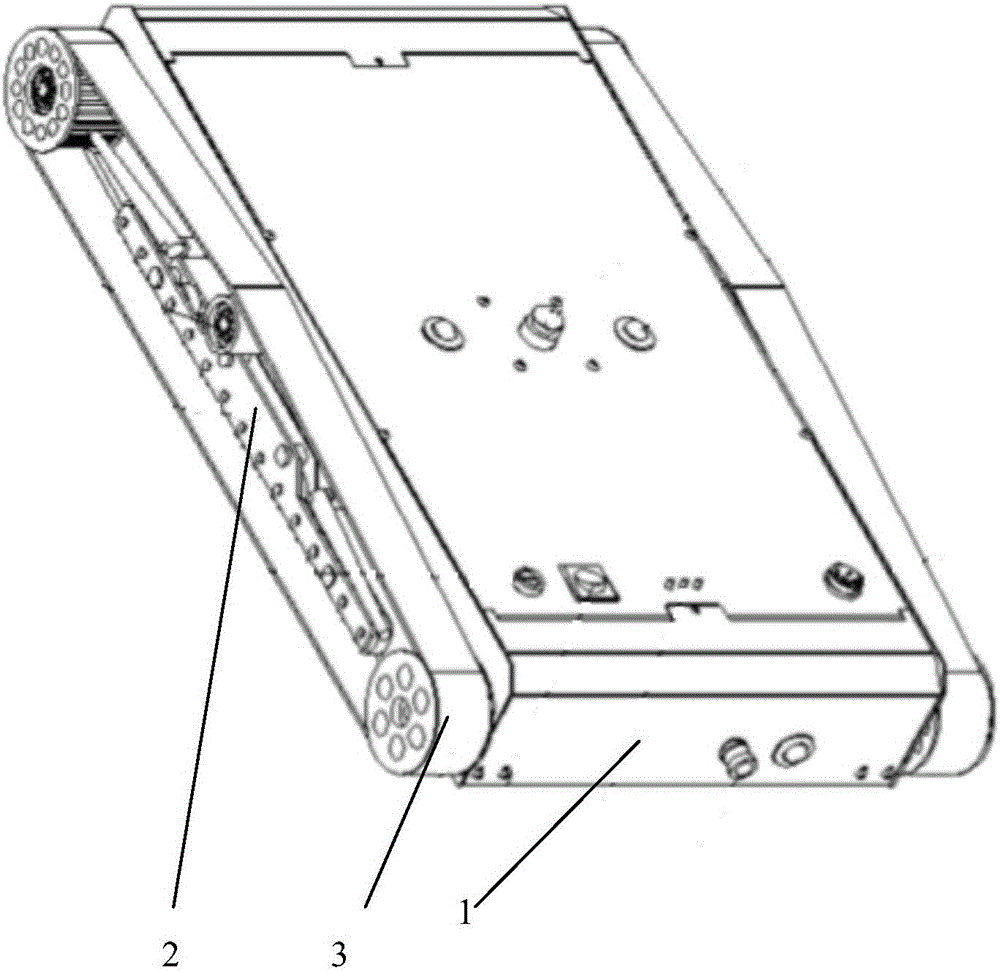

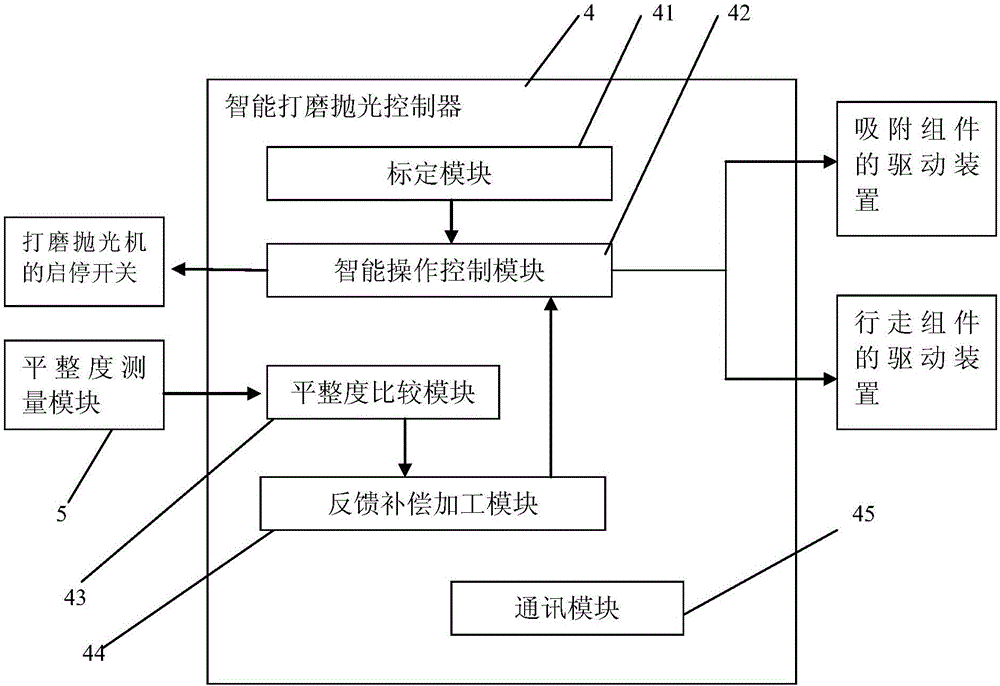

The invention discloses an intelligent wall grinding robot which comprises a grinding and polishing head provided with a start and stop switch. The wall grinding robot further comprises a shell, an attraction assembly used for attracting the robot to a wall and a walking assembly used for making the robot walk along the wall; the attraction assembly is installed at the bottom of the shell, the walking assembly is installed on the side edge of the bottom of the shell, and the grinding and polishing head is installed at the bottom of the shell; an intelligent grinding and polishing controller is installed in the shell and comprises a calibration module and an intelligent operation control module, the calibration module is used for setting a reference coordinate system according to the size of the wall which is about to be ground and polished and controlling a track according to a calibration stroke, and the intelligent operation control module is used for controlling the grinding and polishing head to operate according to the stroke control track. Through the intelligent wall grinding robot, robot operation is realized, bodily injuries to decorating workers are avoided, work efficiency is improved, and the polishing effect is improved.

Owner:朱德进

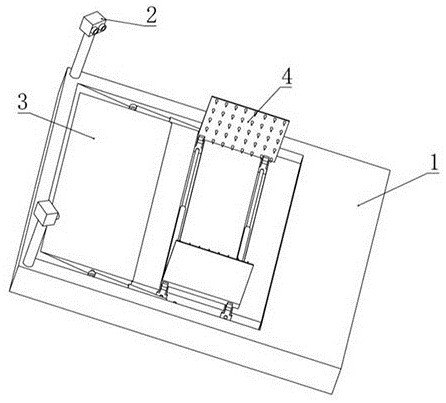

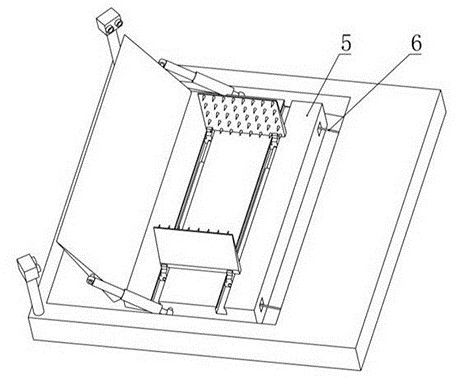

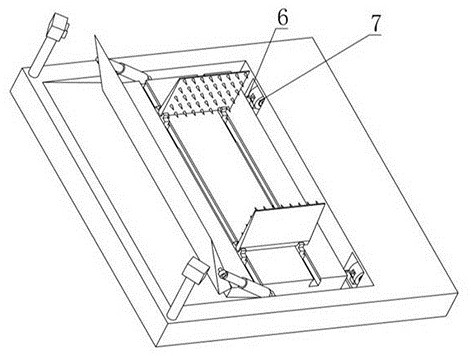

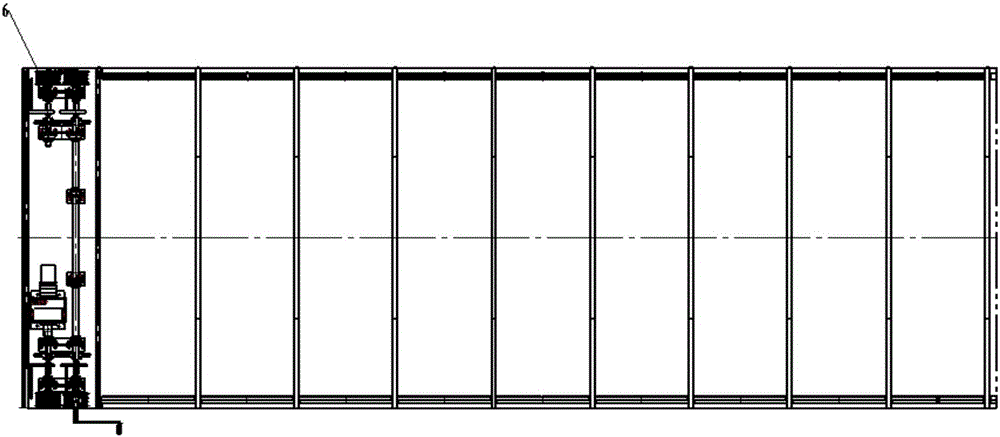

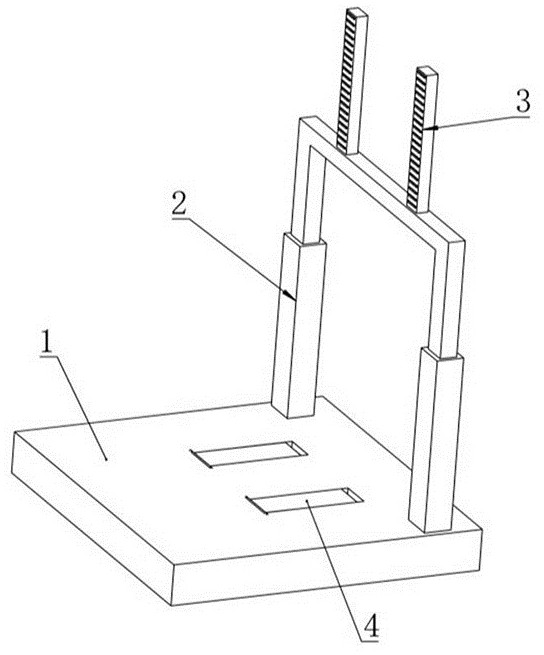

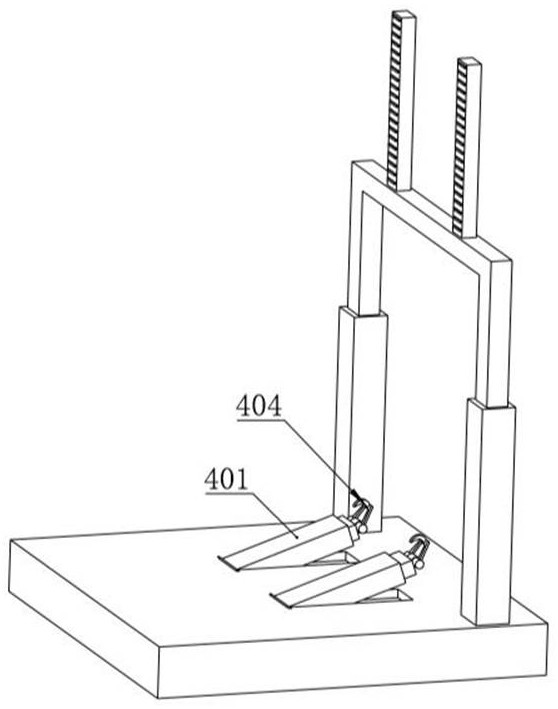

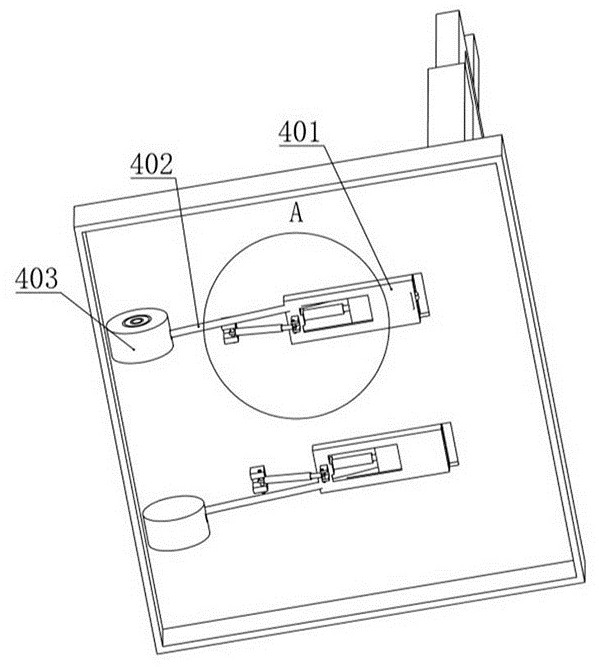

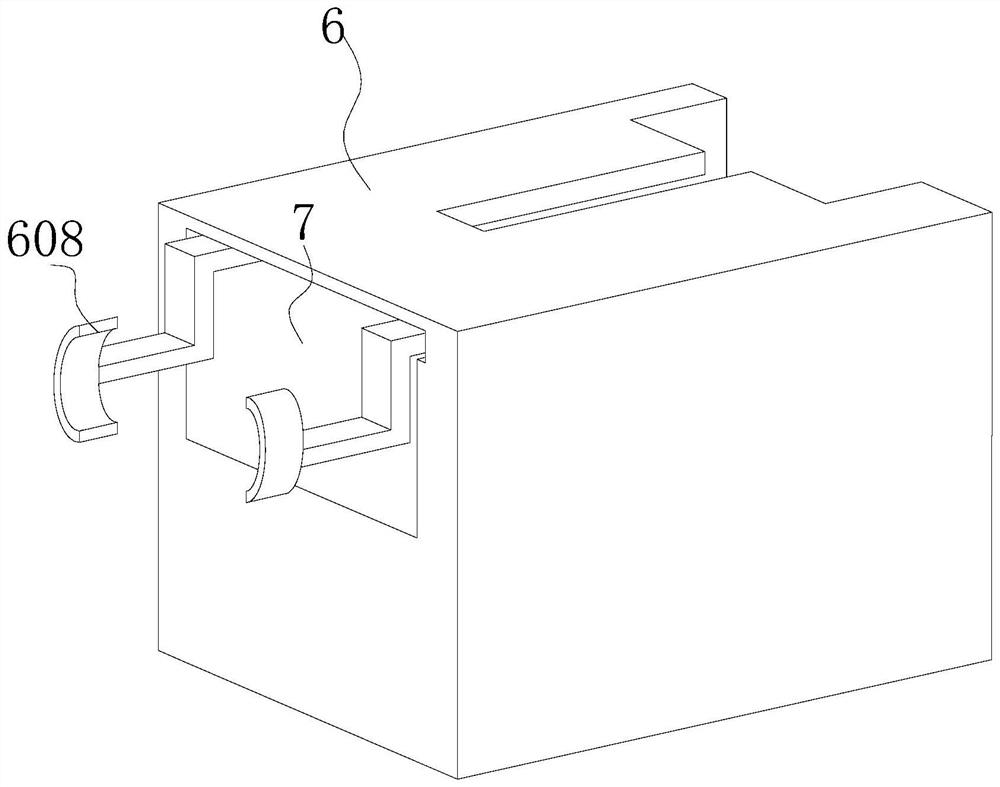

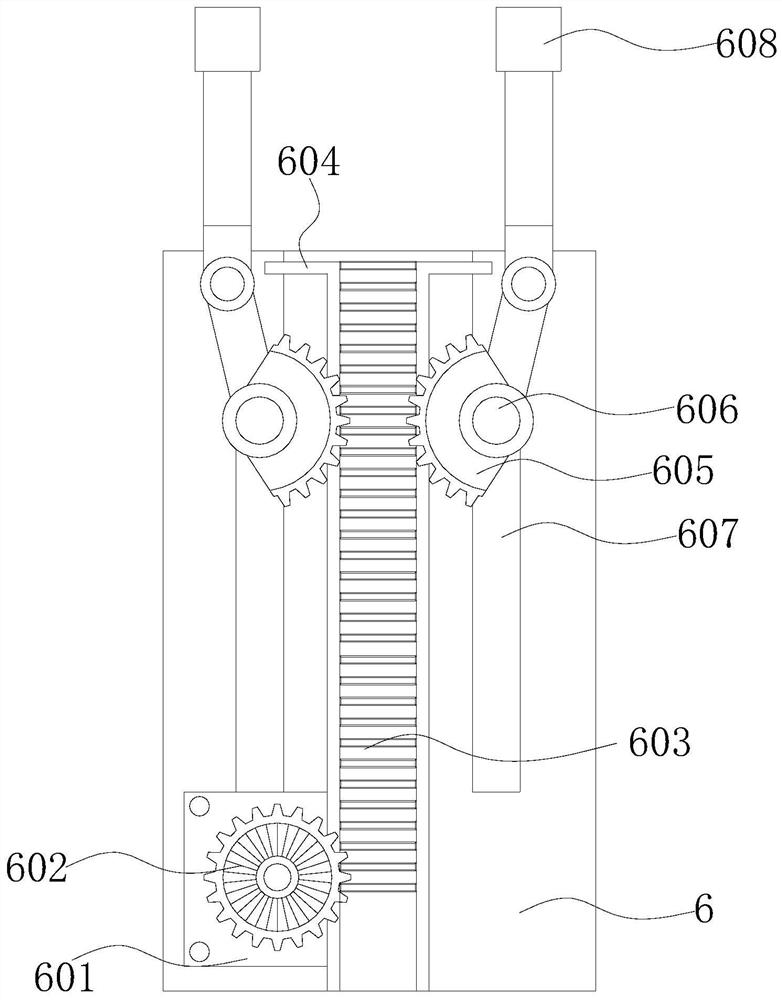

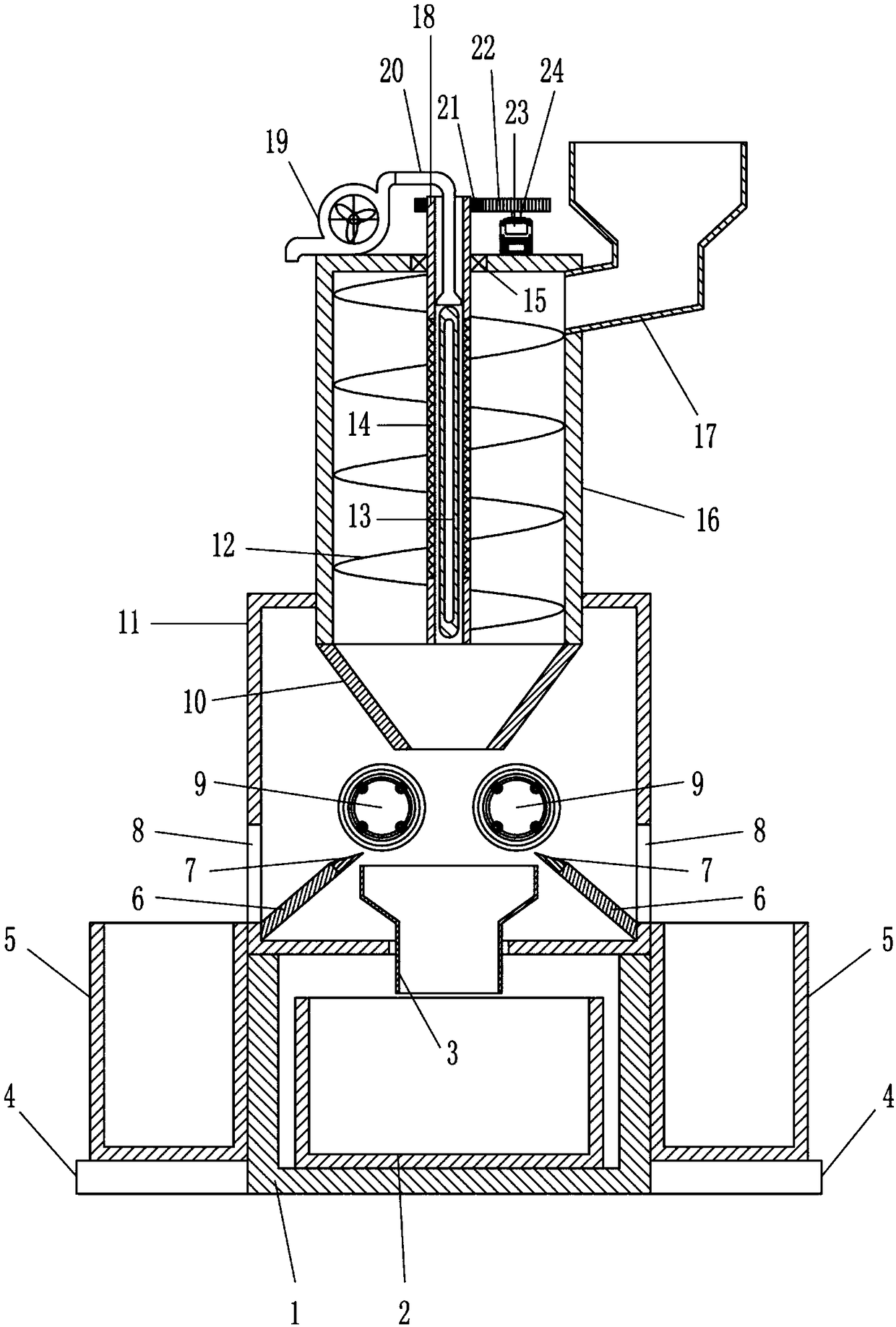

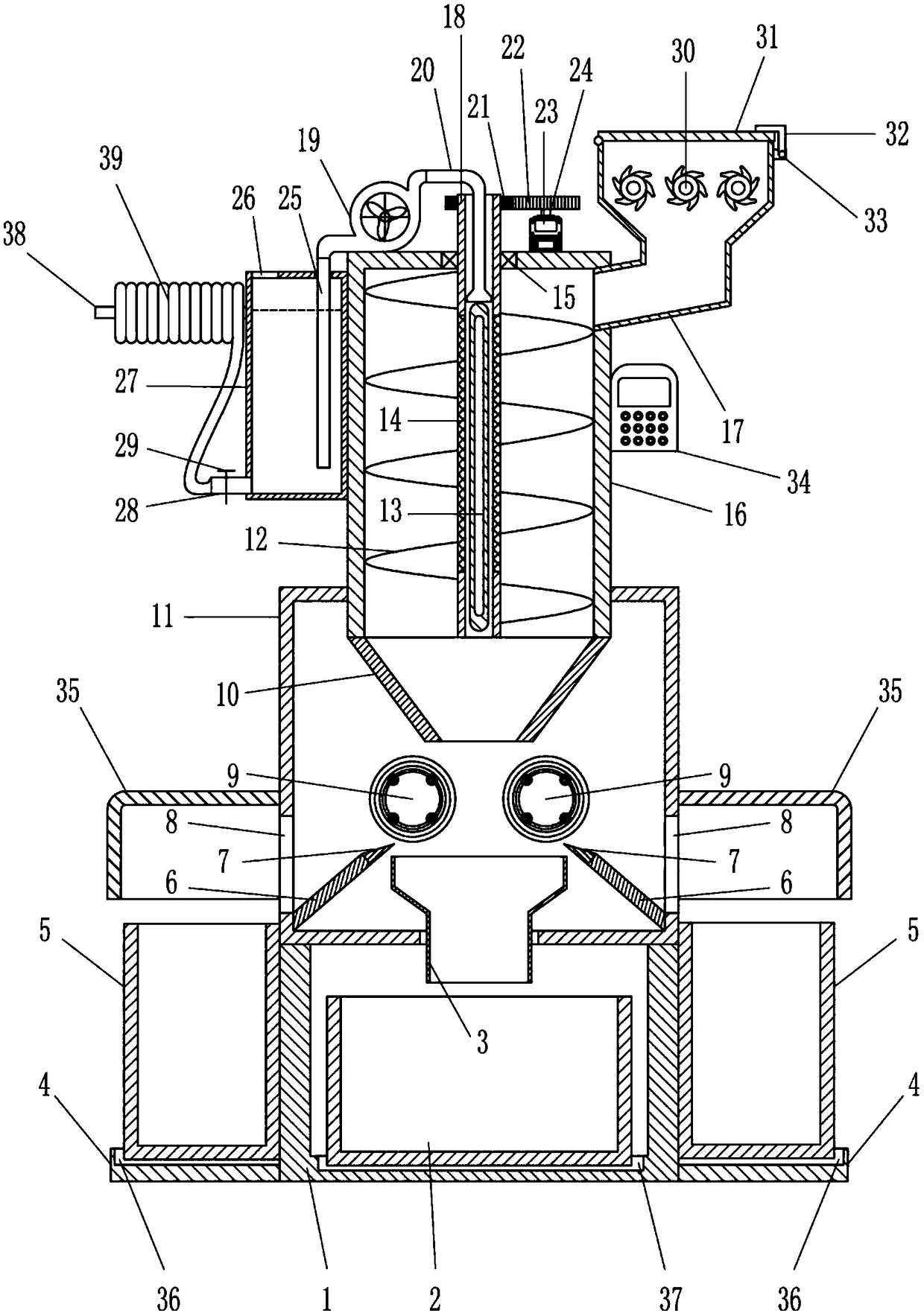

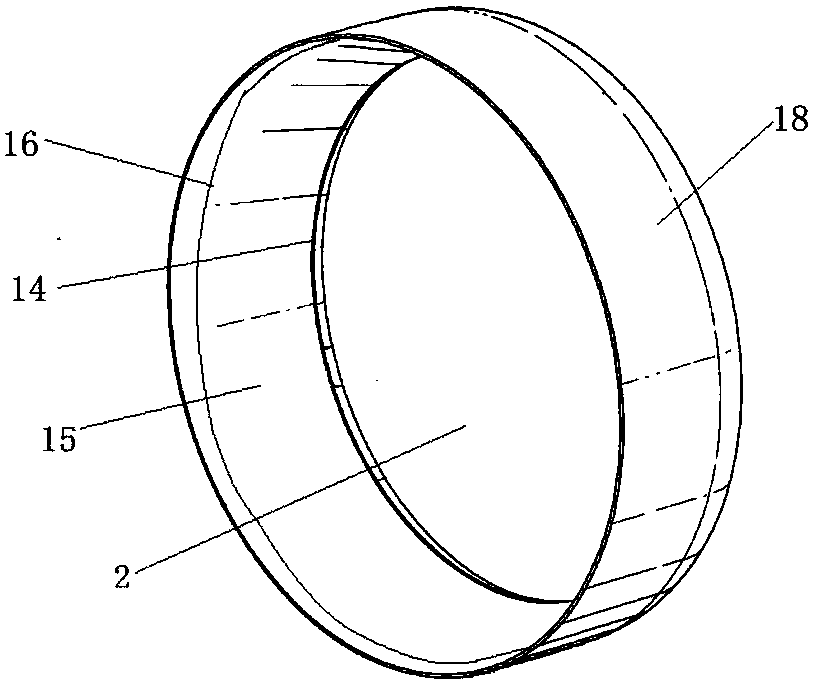

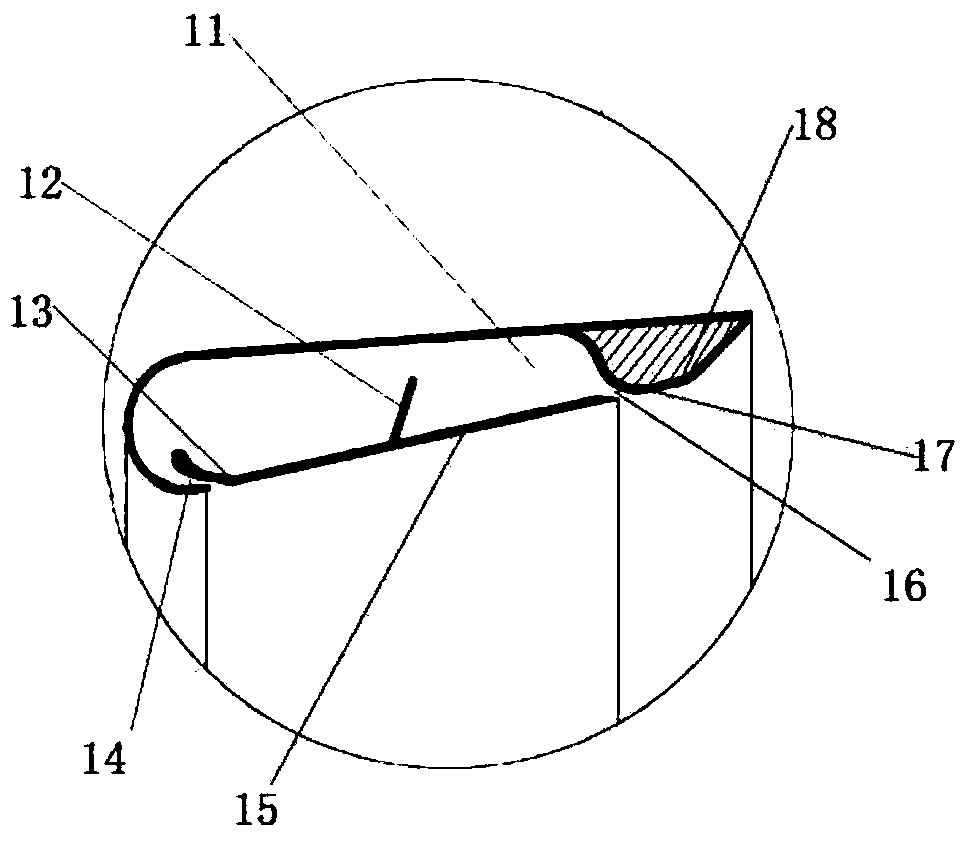

Intelligent wall face grinding and polishing device

ActiveCN105729264ACause bodily harmImprove work efficiencyGrinding feed controlPlane surface grinding machinesMechanical engineering

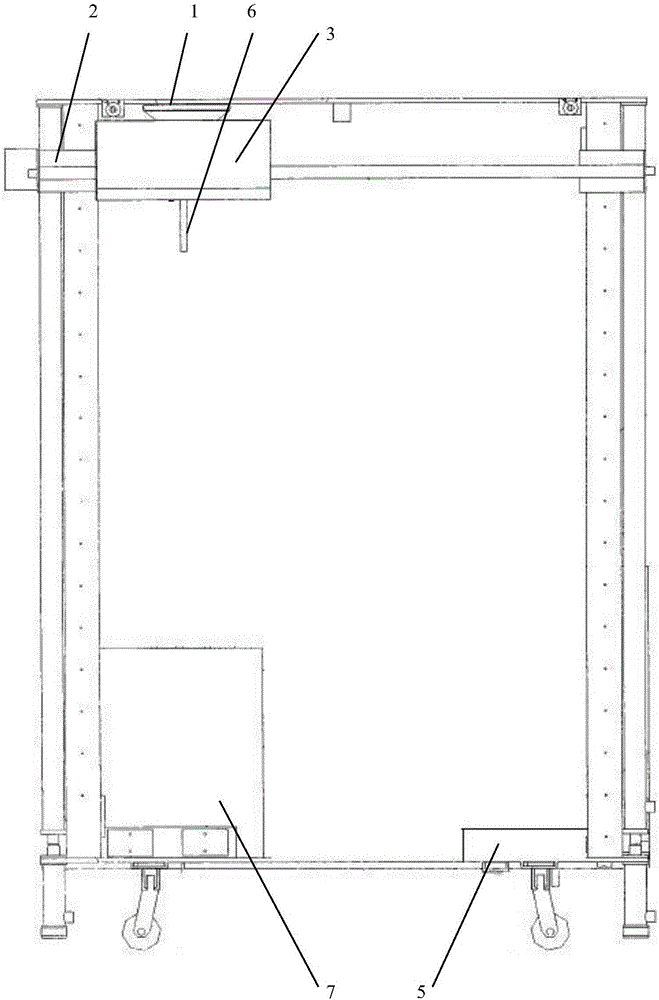

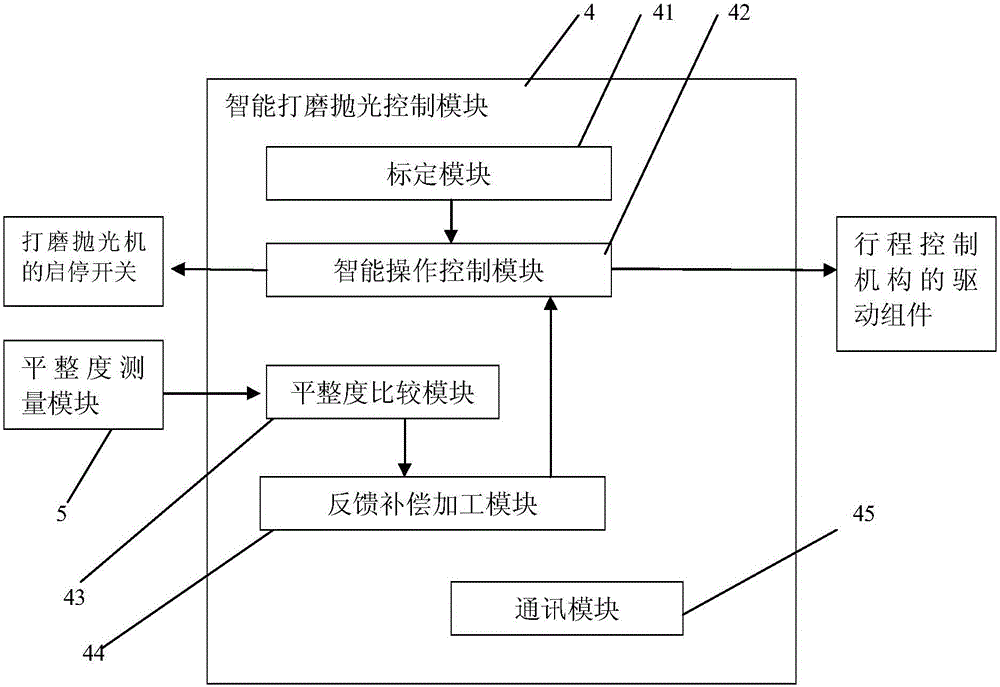

The invention relates to an intelligent wall face grinding and polishing device. The intelligent wall face grinding and polishing device comprises a grinding and polishing head which is provided with a starting and stopping switch; the intelligent wall face grinding and polishing device is characterized by further comprising a stroke control mechanism; the motion end of the stroke control mechanism is connected with a mechanical arm, the mechanical arm is provided with the grinding and polishing head, and a driving assembly of the stroke control mechanism and the starting and stopping switch of the grinding and polishing head are both connected with an intelligent grinding and polishing controller used for achieving intelligent grinding and polishing; and the intelligent grinding and polishing controller comprises a calibration module and an intelligent operation and control module, wherein the calibration module is used for calibrating a motion shaft of the stroke control mechanism according to the size of a wall face to be ground and polished and giving out a stroke control track, and the intelligent operation and control module is used for controlling the grinding and polishing head to operate according to the stroke control track. According to the intelligent wall face grinding and polishing device, mechanization operation is achieved, the body of a fitment worker is prevented from being hurt, the working efficiency is improved, and the polishing effect is improved.

Owner:ZHEJIANG BURLEY TOOLS

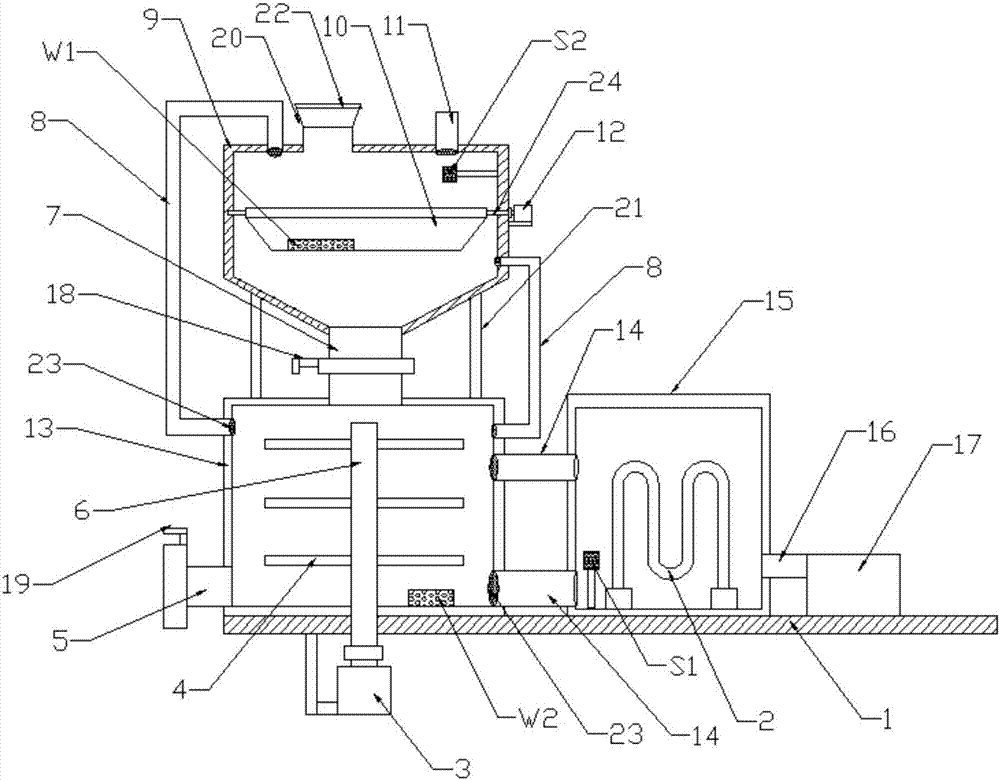

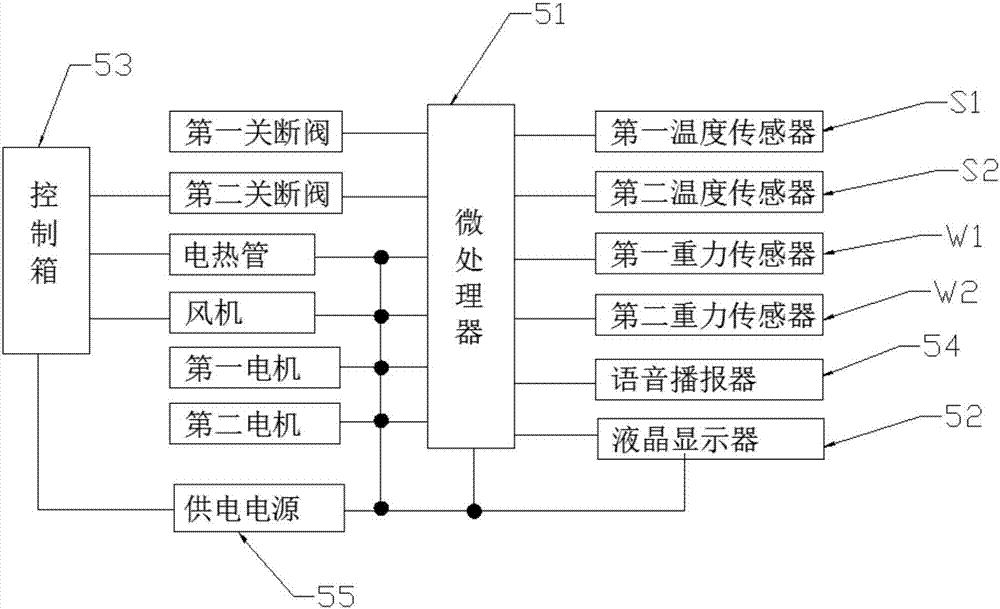

Efficient drying machine

InactiveCN107101459AImprove drying efficiencySpeed up coolingDrying gas arrangementsDrying chambers/containersElectric heatingEngineering

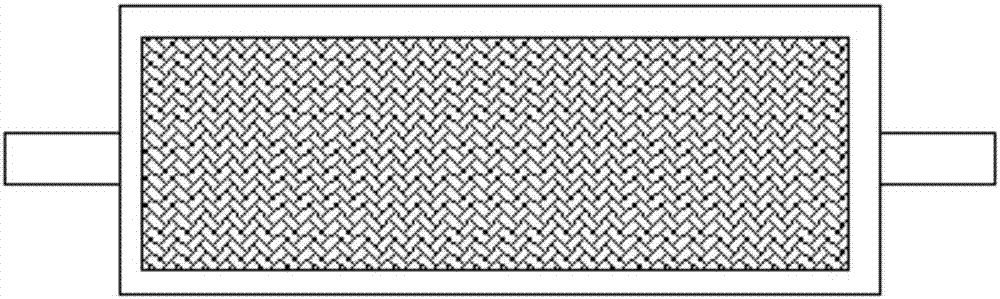

The invention discloses an efficient drying machine. The efficient drying machine comprises a base plate; a fan is arranged on the base plate; an air outlet of the fan communicates with a first connecting pipe; the end, far away from the fan, of the first connecting pipe communicates with a heating box; the heating box is internally provided with an electric heating pipe; the side edge of the heating box communicates with second connecting pipes; the ends, far away from the heating box, of the second connecting pipes communicate with a drying box; a first motor is arranged at the bottom of the drying box; an output shaft of the first motor is connected with a stirring shaft; the side edges of the stirring shaft are fixedly provided with stirring blades; the side edge of the drying box communicates with a discharging channel and third connecting pipes; the top of the drying box communicates with a feeding channel; the end, far away from the drying box, of the feeding channel communicates with a preheating box; and a metal net disc is arranged in the preheating box and is of a cuboid structure. The efficient drying machine has the advantages that pre-drying of materials in the preheating box and deep drying of materials in the drying box can be carried out at the same time, and therefore the material drying efficiency can be greatly improved.

Owner:CHENGDU FUYANG TECH DEV

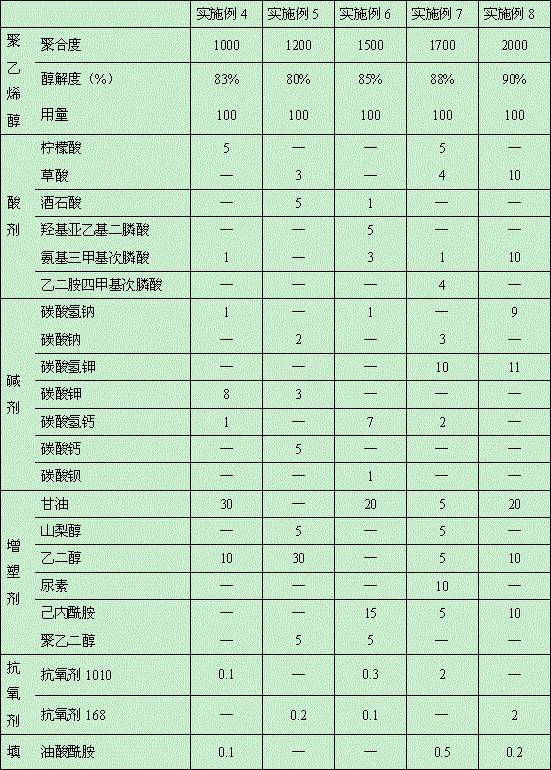

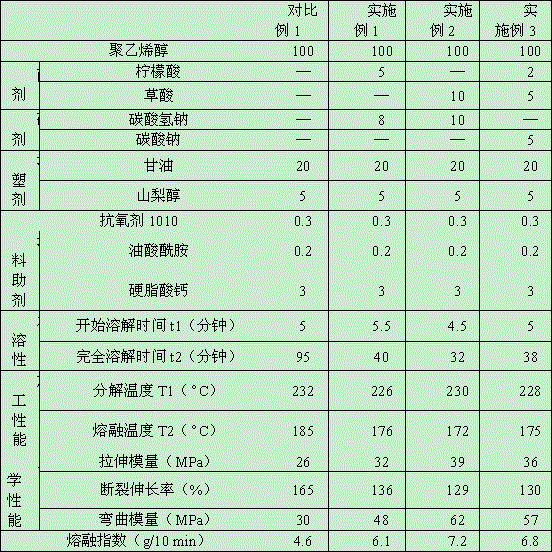

Quickly-removable propping material for melt deposition molding and preparation method thereof

ActiveCN105585804AImprove mechanical propertiesImprove processing performanceAdditive manufacturing apparatusChemistryAqueous solution

The invention discloses a quickly-removable propping material for melt deposition molding and a preparation method thereof. The propping material contains 100 parts of polyvinyl alcohol, 5-20 parts of acid, 5-20 parts of alkali, 25-40 parts of plasticizer, 0.1-2 parts of antioxidant and 0.1-10 parts of filler aid. The acid and alkali in the propping material can quickly react to generate gas when contacting water, so that the propping material can be disintegrated and pulverized, thereby accelerating the dissolution; and thus, the propping material can be completely removed within a short time (40 minutes). Meanwhile, the propping material can be removed without any strongly-acidic or strongly-alkaline water solution, can be quickly removed in common tap water, and thus, can not cause physical injury to the operating personnel. The added acid and alkali can enhance the mechanical properties of the propping material, and can further enhance the processability of the polyvinyl alcohol wire under the synergistic action of the plasticizer.

Owner:西安泰辉机械科技有限公司

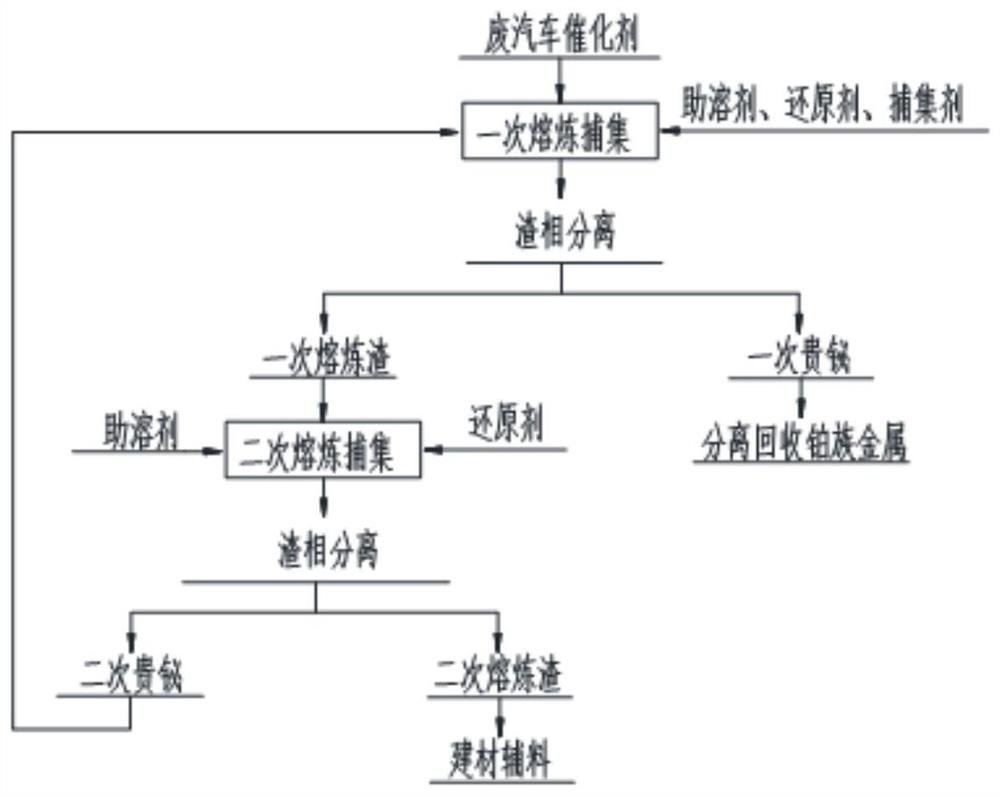

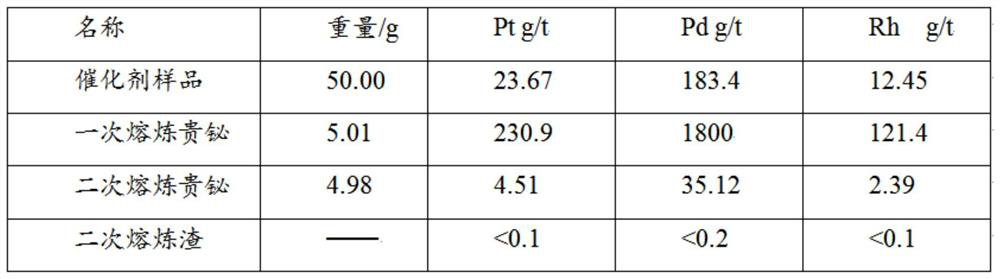

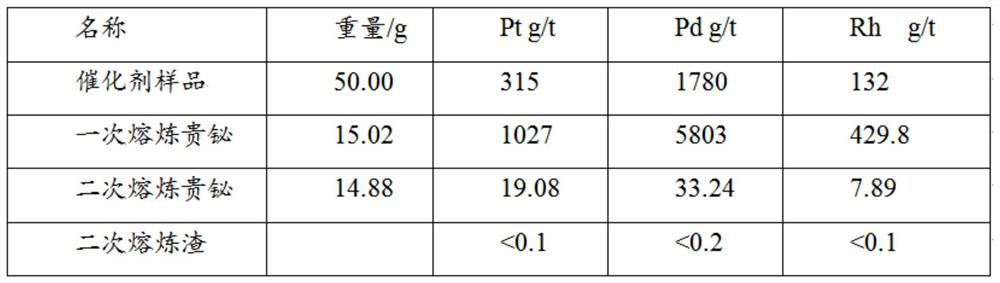

Method for accurately detecting contents of platinum, palladium and rhodium in waste automobile exhaust catalyst

ActiveCN110530850AHigh recovery rateAccurate detectionPreparing sample for investigationAnalysis by thermal excitationProcess optimizationTrapping

The invention, which belongs to the field of platinum group metal analysis and detection, discloses a method for accurately detecting contents of platinum, palladium and rhodium in a waste automobileexhaust catalyst. According to the invention, burdening, smelting trapping, ash blowing separation of metal bismuth and platinum, palladium and rhodium content detection are performed based on bismuthtest gold pyrometallurgy metal enrichment technological process and the process optimization is performed, so that problems of matrix interference and incapability of ash blowing in the traditional method are solved and a defect that platinum, palladium and rhodium in the waste automobile tail gas catalyst are difficult to effectively capture, separate and detect by adopting the existing method is overcome. Therefore, the recovery rate of platinum, palladium and rhodium is increased and the accurate detection of the contents of platinum, palladium and rhodium in the waste automobile tail gascatalyst is ensured.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

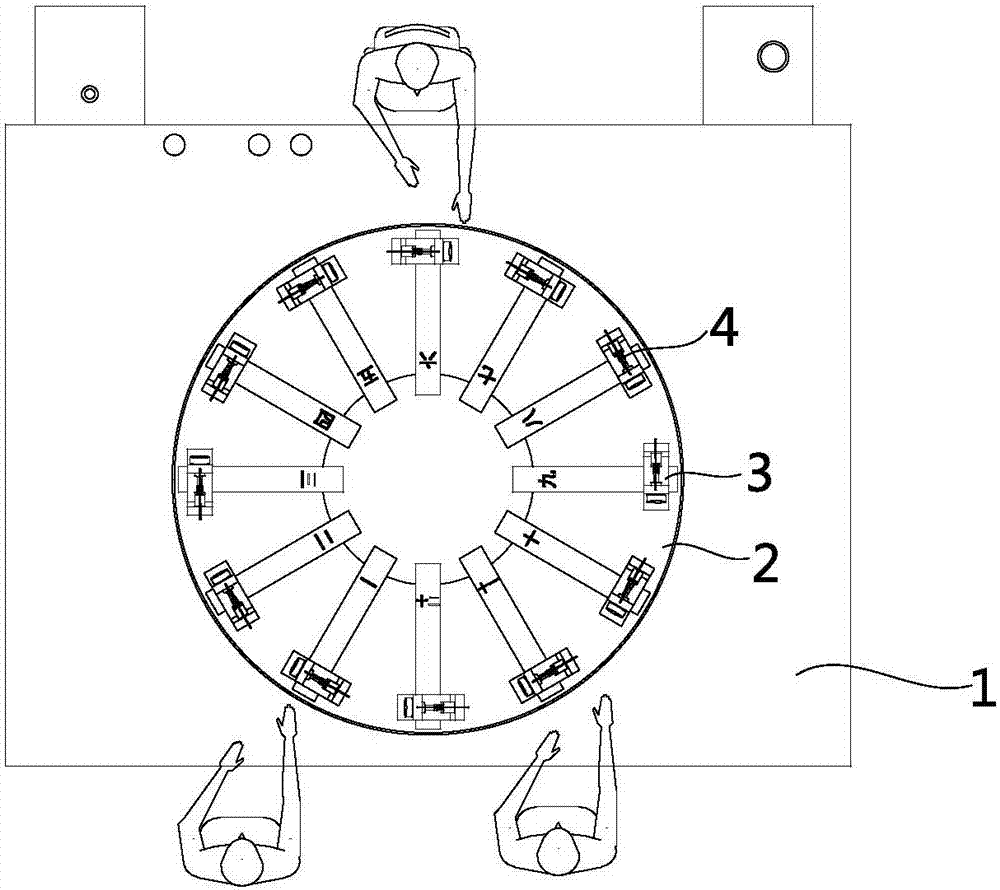

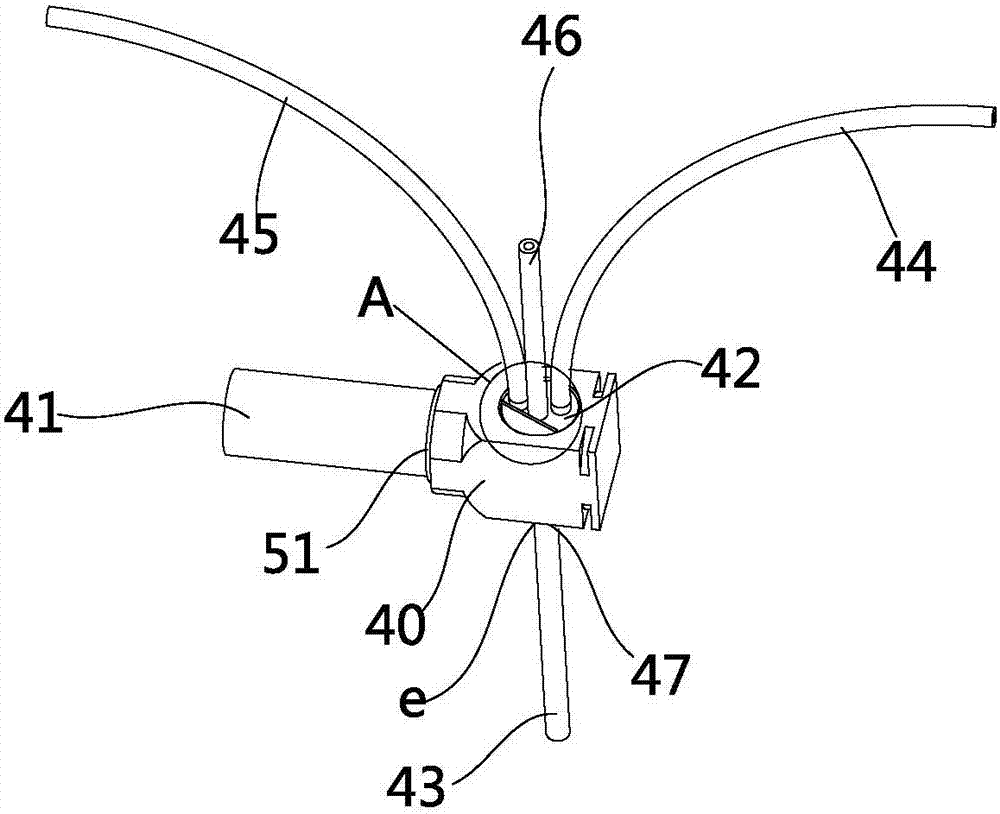

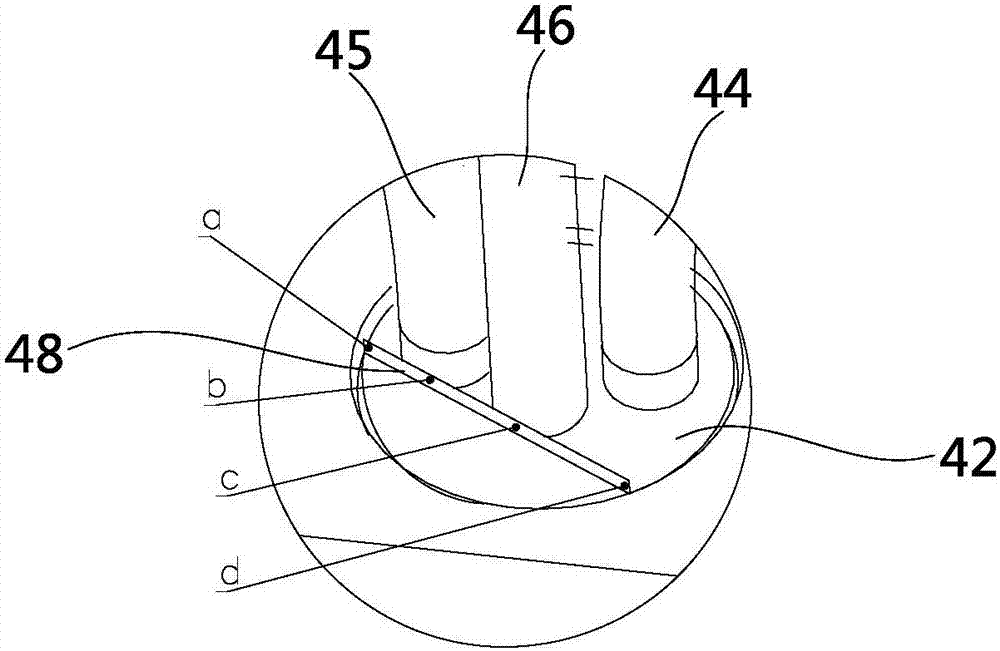

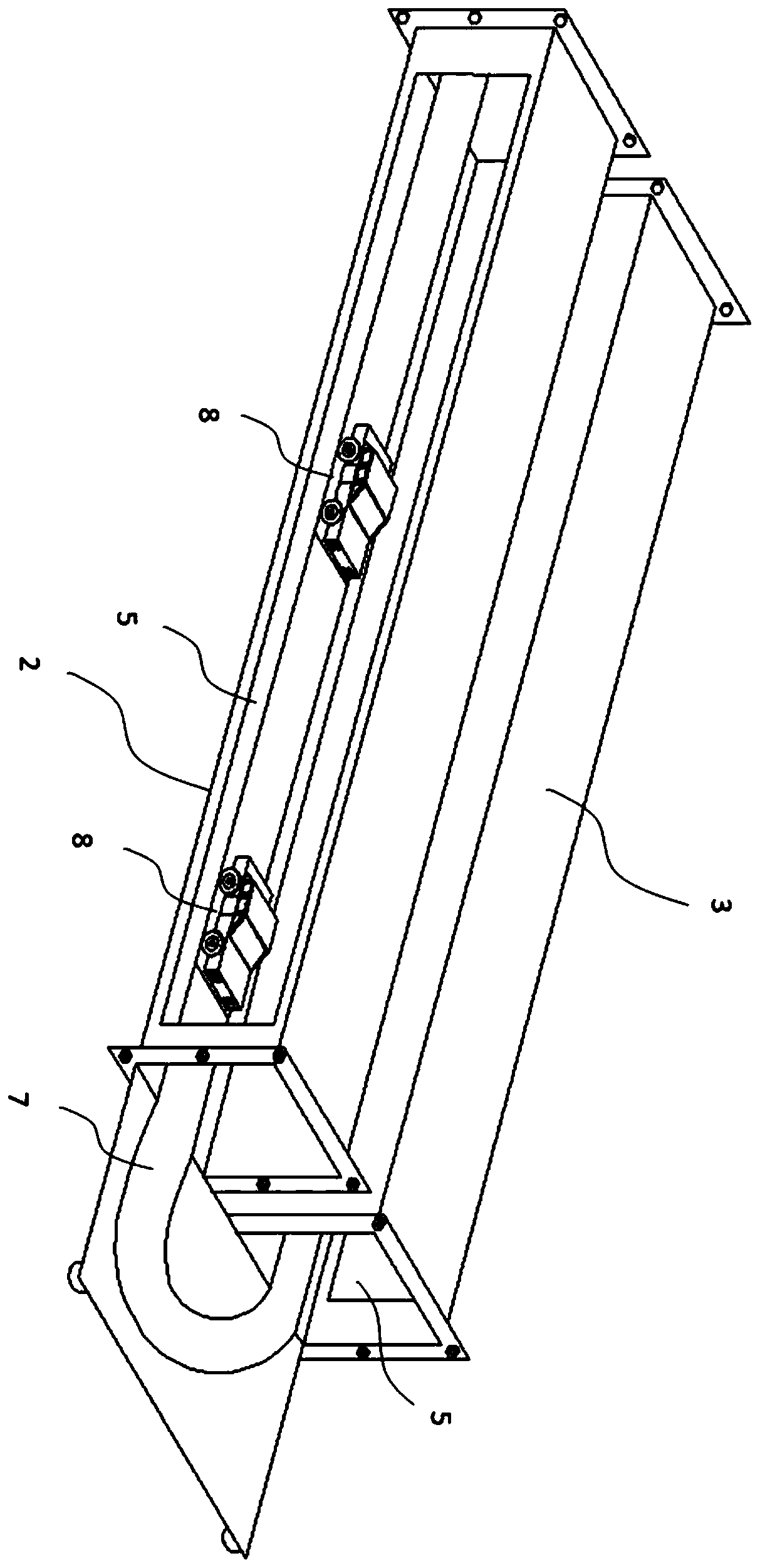

Automatic welding machine

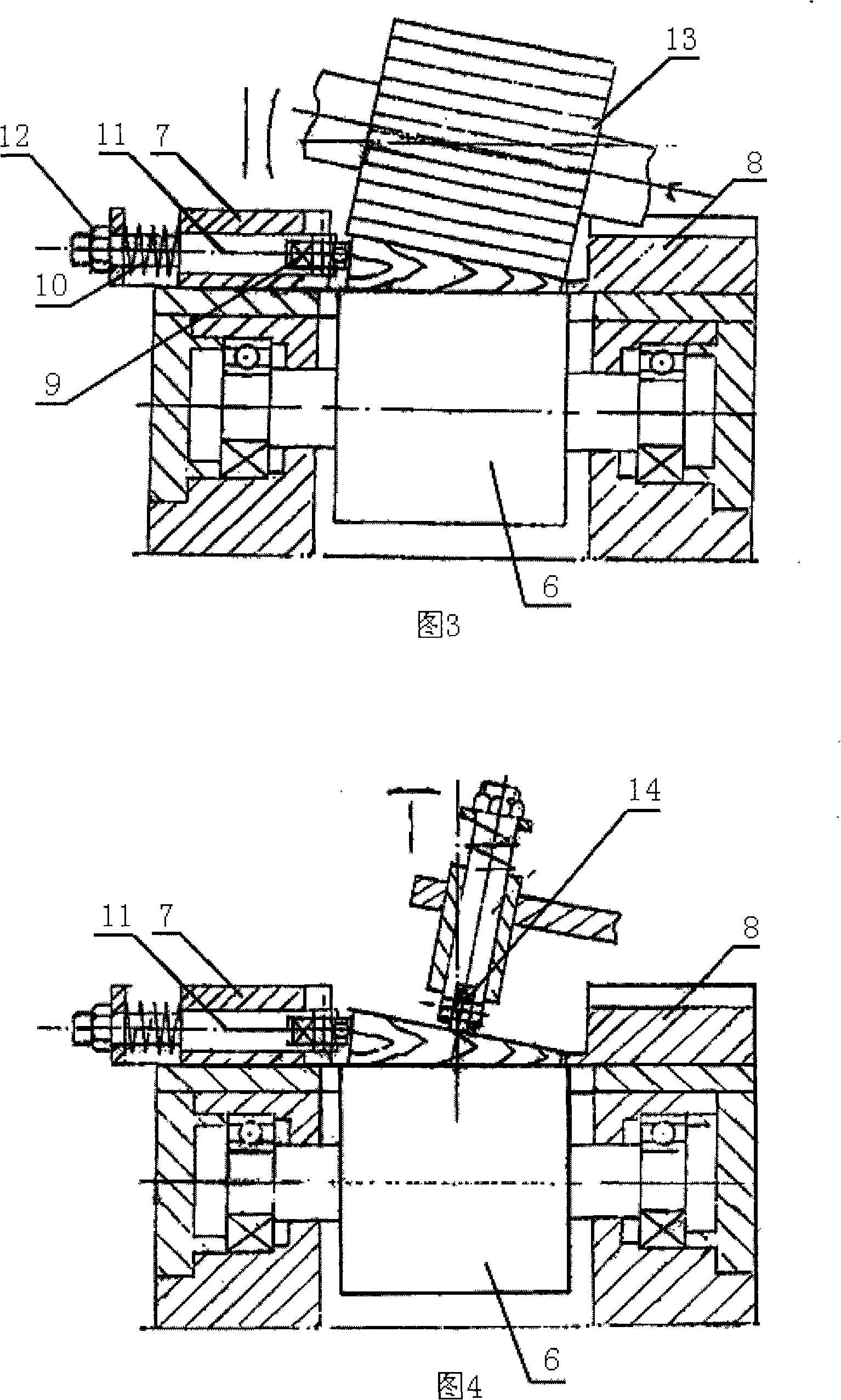

InactiveCN107363368AReduce labor intensityIncrease productivitySolder feeding devicesSoldering auxillary devicesEngineeringWelding

The invention discloses an automatic welding machine, and belongs to the technical field of automatic welding. The automatic welding machine solves the technical problems that the labor intensity of workers is high and the production efficiency is low in the prior art. The automatic welding machine comprises a welding device and a working table provided with a rotary disc, and a plurality of fixtures for clamping workpieces are arranged on the rotary disc circumferentially at intervals; welding stations are arranged on the working table; and the automatic welding machine further comprises a first wire feeding mechanism and a scaling powder brushing mechanism which are arranged on the welding stations, the first wire feeding mechanism conveys welding wires to a workpiece which rotates to the fixture of the corresponding welding station, and the scaling powder brushing mechanism is used for brushing a scaling powder on the welding wires conveyed by the first wire feeding mechanism.

Owner:ZHEJIANG DUNAN HETIAN METAL CO LTD

Blackboard

InactiveCN102350906ANo resource waste and environmental pollutionCause resource waste and environmental pollutionWriting boardsPermanent magnetsMagnetEngineering

The invention discloses a blackboard, comprising a common blackboard surface, wherein a layer of extremely thin and hard transparent white glass is paved in front of the common blackboard surface, a layer of magnetic sand capable of being absorbed by a magnet penetrates into the part between the glass and the blackboard to be absorbed on the glass not tightly, the cartridge of a writing pen is a small magnet, and a pen eraser is a long rolling strip installed between the blackboard and the glass. The blackboard has the advantages that in the use process, no dust is generated, no harm is generated to bodies of users, and environmental pollution and resource waste are not produced.

Owner:王静

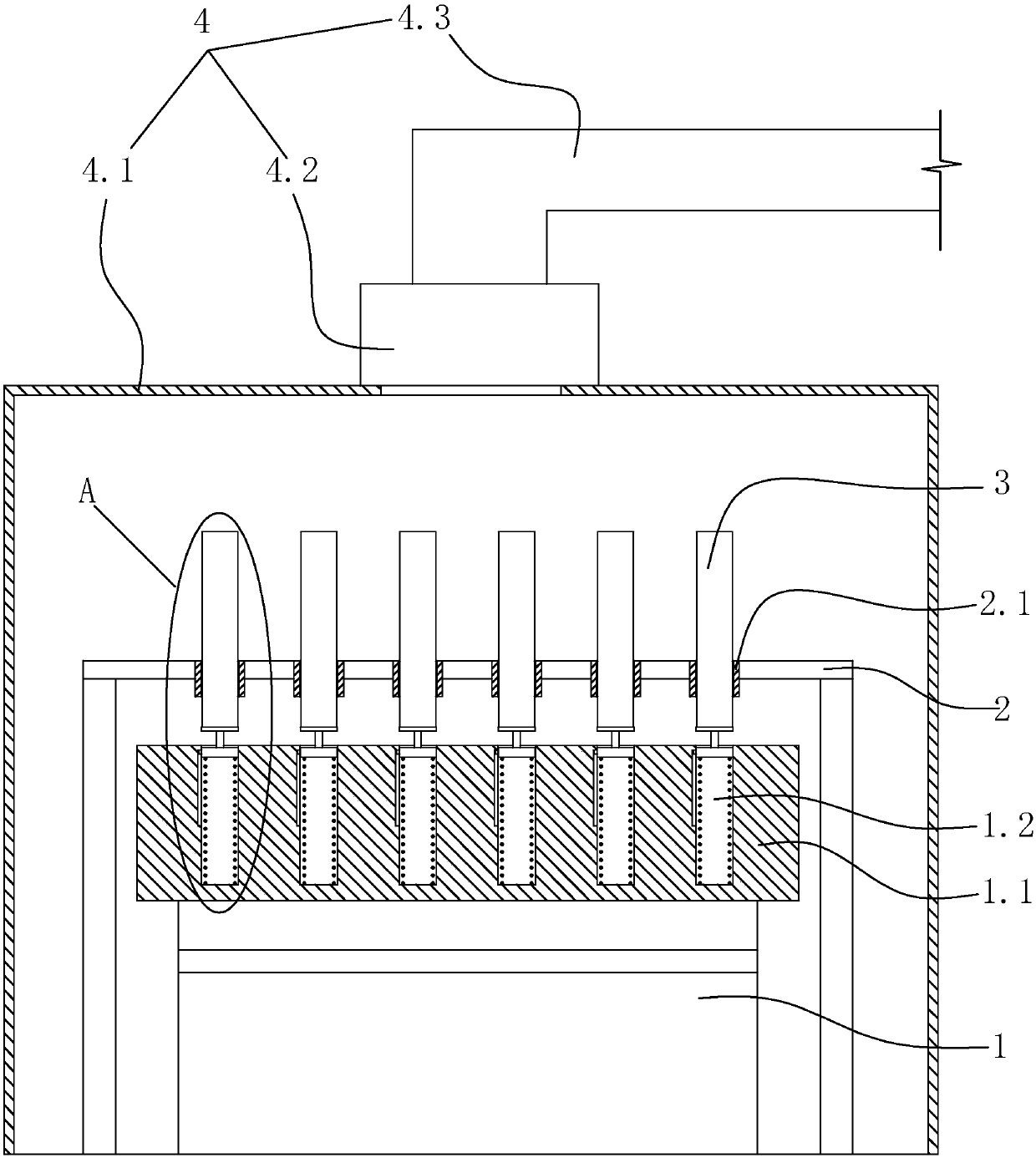

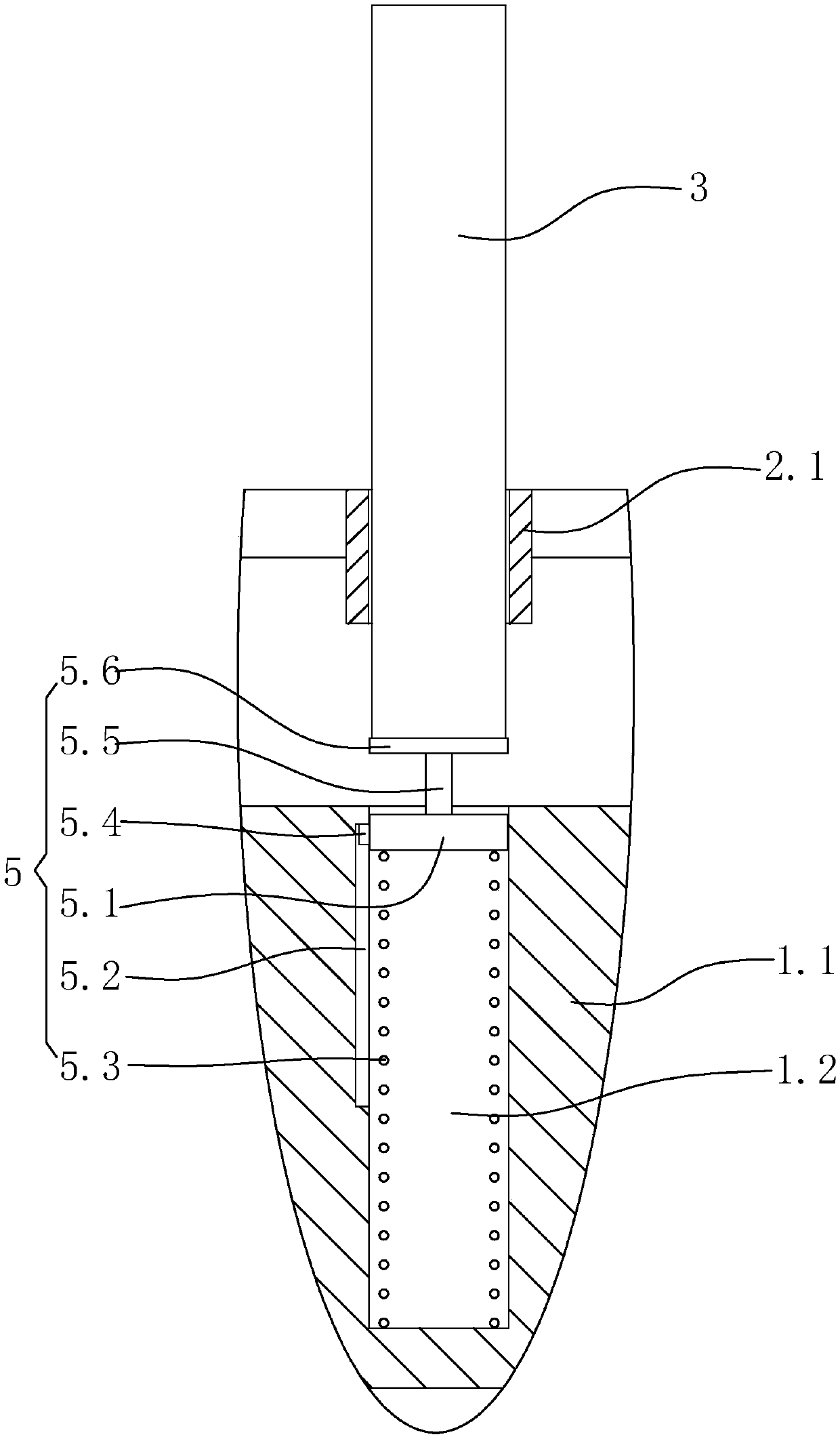

Acid removal device

ActiveCN107727482ATroubleshoot experiment failuresGuarantee the environmentPreparing sample for investigationThermal insulationDigestion

The invention discloses an acid removal device. The acid removal device solves the problem that a solution in a digestion tube is evaporated or coked because of the negligence of an experimenter so that the experiment is failed. The acid removal device comprises multiple digestion tubes, a heater comprising a heating flat plate of which the upper surface is provided with multiple vertical heatingholes, a digestion tube support frame provided with digestion tube vertical guide sleeves corresponding to the multiple vertical heating holes, wherein the digestion tube vertical guide sleeves are located above the corresponding vertical heating holes, and multiple self-adaptive heating isolation devices which are corresponding to the vertical heating holes, wherein the self-adaptive heating isolation device comprises a guide slide block sliding in the vertical heating hole, a reset compression spring between the bottom surface of the vertical heating hole and the guide slide block, a thermalinsulation support plate for supporting the digestion tubes above the guide slide block and a connection rod connecting the guide slide block and the thermal insulation support plate.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

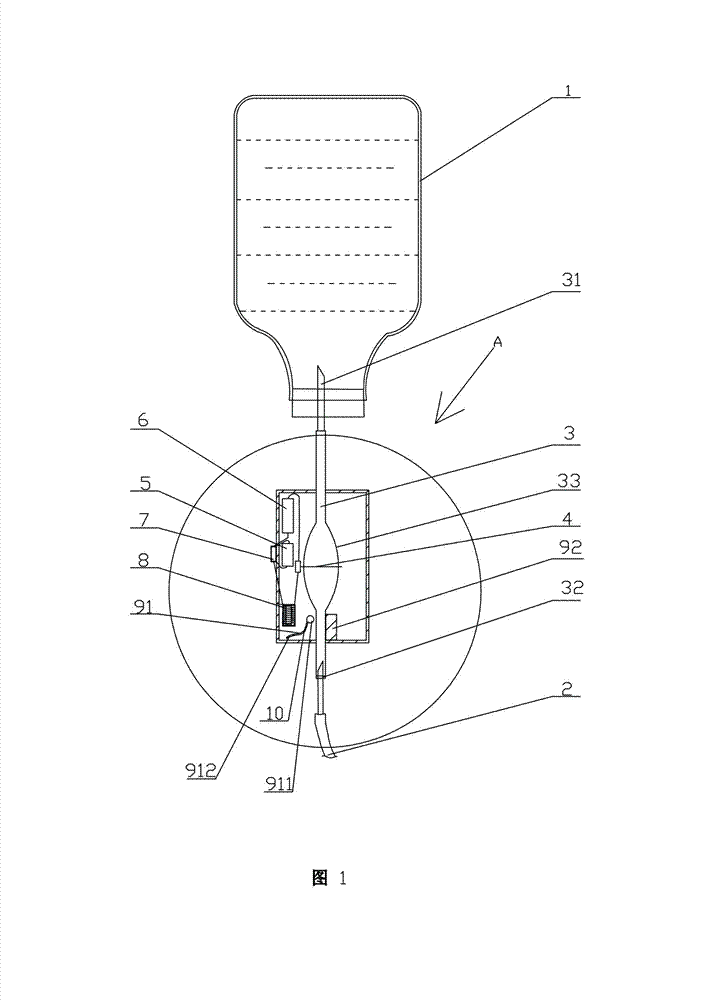

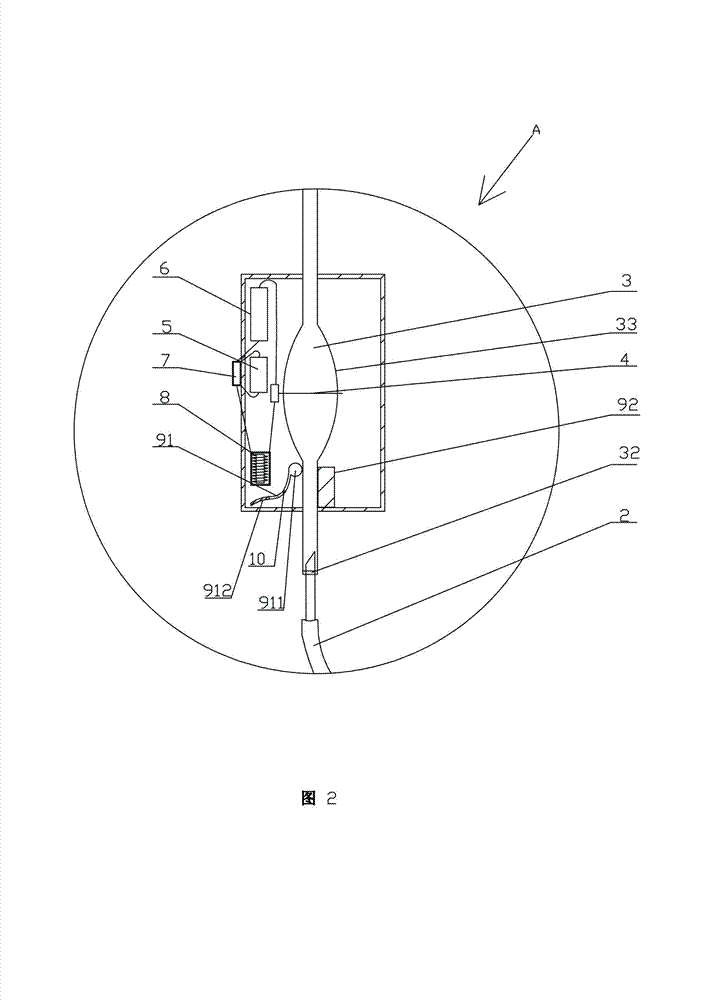

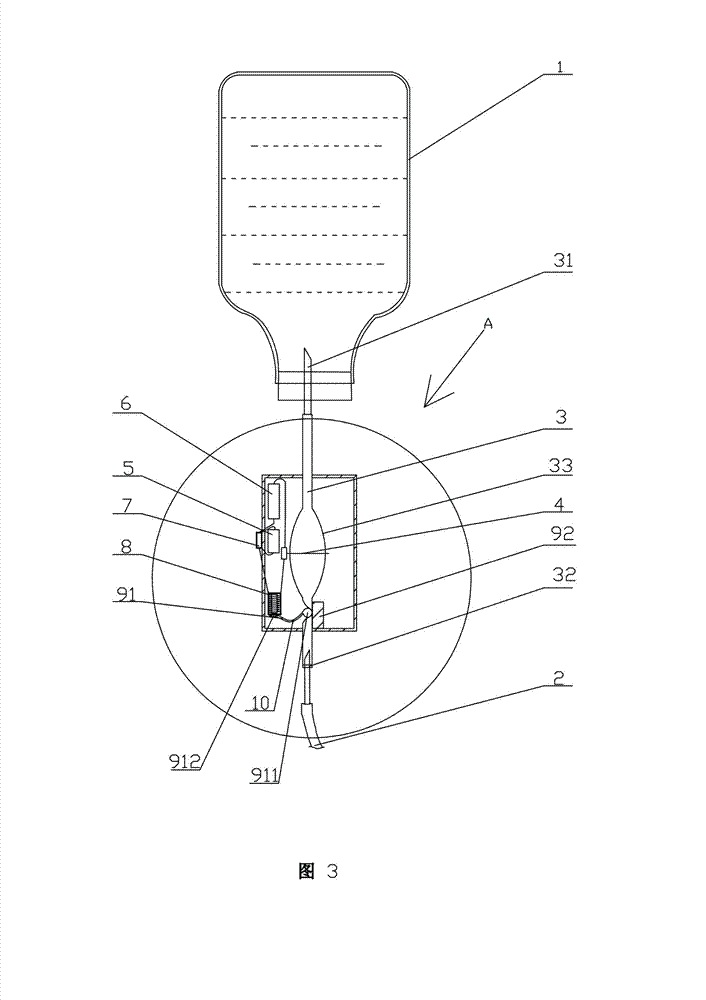

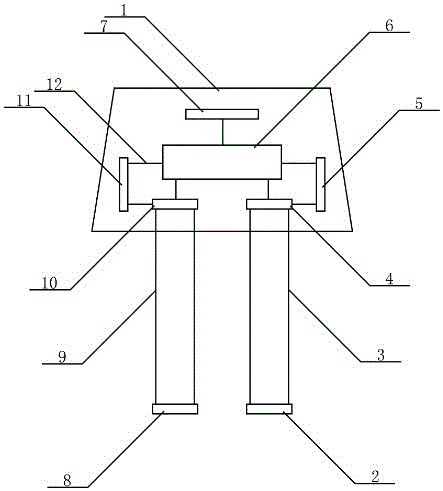

Automatically alarming and interrupting device for fluid infusion device

The invention discloses an automatically alarming and interrupting device for a fluid infusion device. The automatically alarming and interrupting device comprises a connecting tube the two ends of which are in sealed connection with an fluid infusion bottle and an infusion catheter respectively, wherein the middle-part tube wall of the connecting tube is an elastic tube wall, and an elastic clamp is arranged on the elastic tube wall; the elastic clamp is connected with an alarm circuit, and two clamping arms of the elastic clamp are respectively provided with a power contact connected with the alarm circuit; an alarm, a circuit power supply, a circuit switch and an electromagnetic induction device are connected in series with the alarm circuit; and a cutoff device which is matched with an electromagnetic induction device to cut off fluid infusion is arranged on the lower part of the connecting tube. The automatically alarming and interrupting device for the fluid infusion device provided by the invention is simple in structure and convenient to use, and realizes the functions of alarming during fluid infusion and interrupting fluid infusion, can avoid the risk to a patient due to the fact that the infusion bottle is not timely replaced or fluid infusion is not stopped after completion of fluid infusion, and can also greatly reduce the work load of medical care personnel at the same time.

Owner:安徽格太信控科技有限公司

Intelligent leg muscle exercise and movement instrument for old people

InactiveCN106110586AAppropriate amount of exerciseIntelligent management and controlMovement coordination devicesCardiovascular exercising devicesBand countsOlder people

The invention relates to an intelligent exercise device for exercising leg muscles for the elderly, and belongs to the technical field of products for the elderly. Place the hip pad under the buttocks of the elderly lying on their backs, install the information storage processor and lithium-ion battery in the middle of the hip pad, install the right pressure sensor and the right counting display on the right part of the hip pad, and install the right pressure sensor in the right part of the hip pad. Right bungee cord and right pedal board are installed in the bottom of the bottom, left pressure sensor and left counter indicator are installed in the left part in the buttock pad, and left bungee cord and left pedal board are installed below the left pressure sensor. The elderly step on the right pedal with their right foot, and do stretching and flexing of their right leg; step on the left pedal with their left foot, and do stretching and flexing of their left leg. The stretching and flexing movement data of the leg muscles are converted into electrical signal information by the pressure sensor and input to the counting display and the information storage processor respectively, and are stored, calculated, analyzed and processed in the information storage processor, and the leg muscles are exercised through intelligent control a.

Owner:WUXI TONGCHUN NEW ENERGY TECH

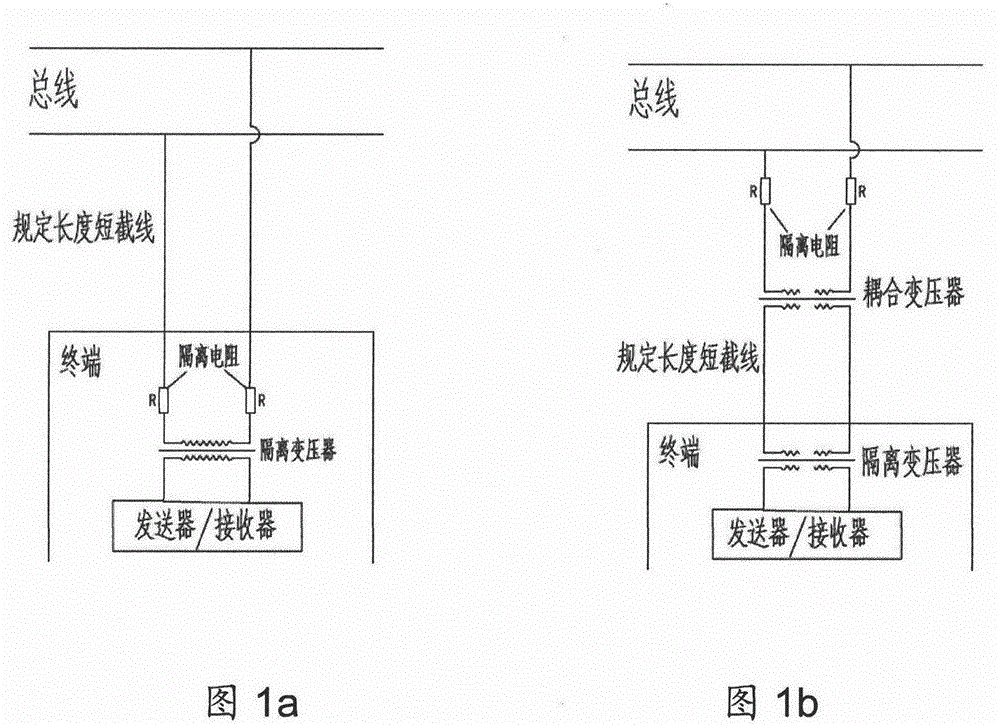

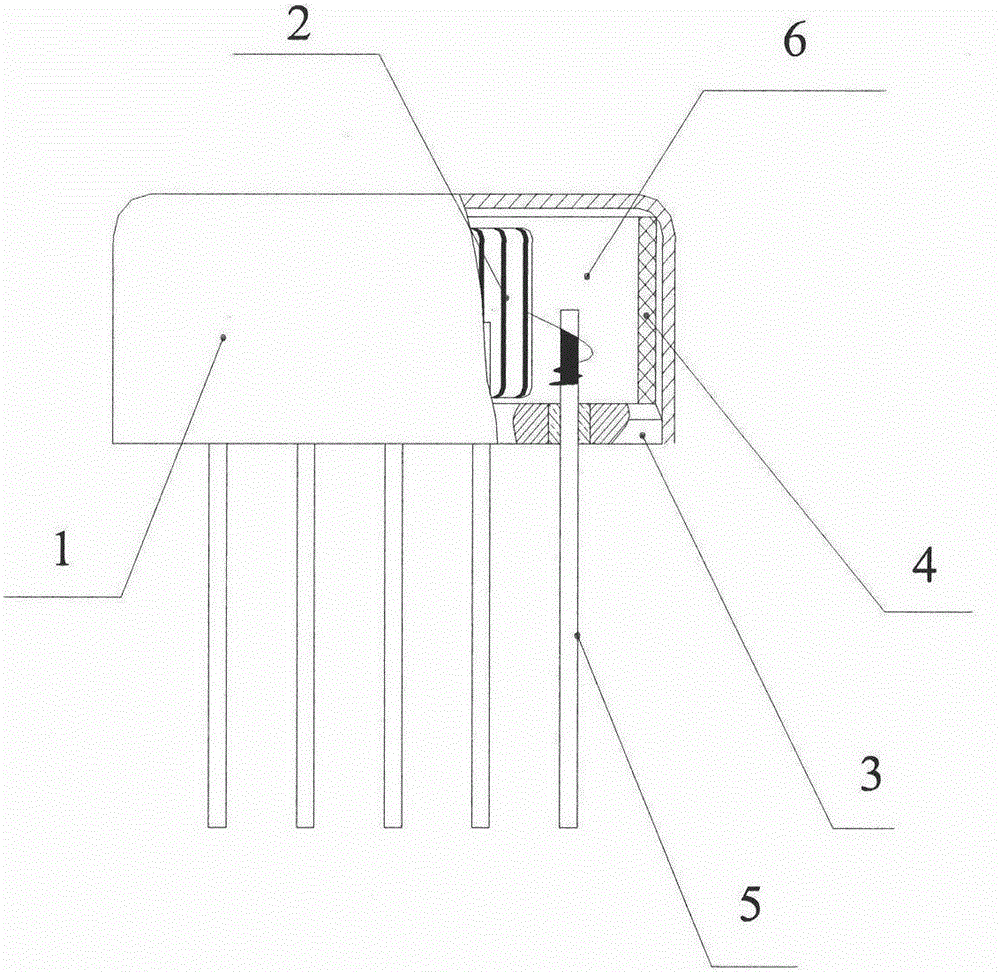

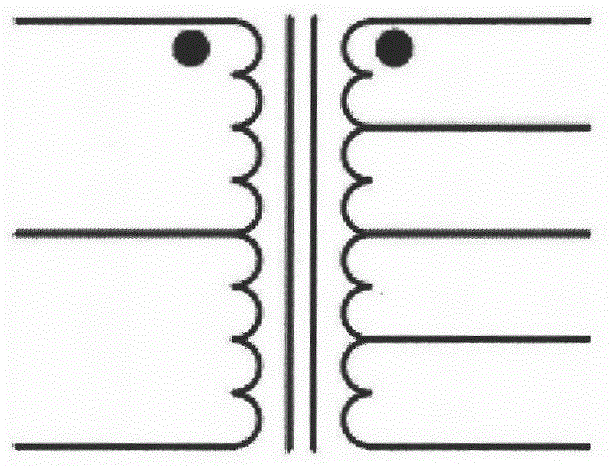

An isolation transformer with environment-resistant metal full potting structure

ActiveCN103050248BImprove mechanical environmental performanceHigh mechanical strengthTransformers/inductances coils/windings/connectionsMetallic enclosureEngineering

The invention relates to a weather-proof isolation transformer with a metal full filling and sealing structure. The isolation transformer comprises a metal shell, a transformer coil, a bottom plate, a glue filling wall and an extraction rod. The extraction rod penetrates through the bottom plate to be fixed onto the bottom plate, one end of the extraction rod is connected with the transformer coil, the other end of the extraction rod is connected with an external device, the glue filling wall is fixedly connected to the edge of the bottom plate to form a filling and sealing space on the bottom plate, the filling and sealing space is filled with filling and sealing glue to fix the transformer coil, an opening at one end of the metal shell is sleeved on the glue filling wall, and an opening end of the metal shell is fixedly connected with the bottom plate to achieve a function of integral sealing. The isolation transformer has the advantages of high mechanical strength, more outstanding weatherproof performance, longer storage and service life, more excellent space adaptability and high electromagnetic compatibility.

Owner:CHINA AEROSPACE TIMES ELECTRONICS CORP

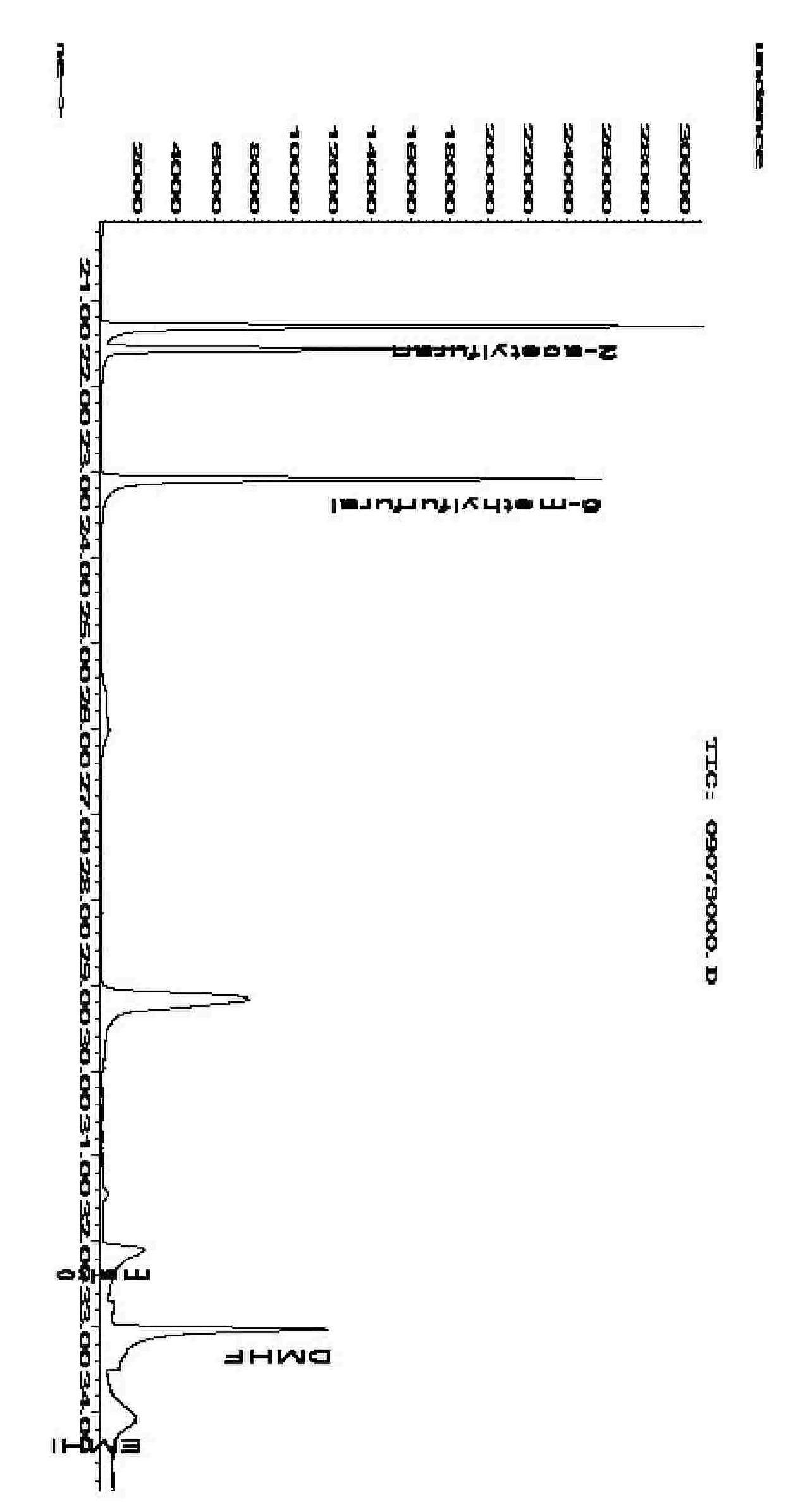

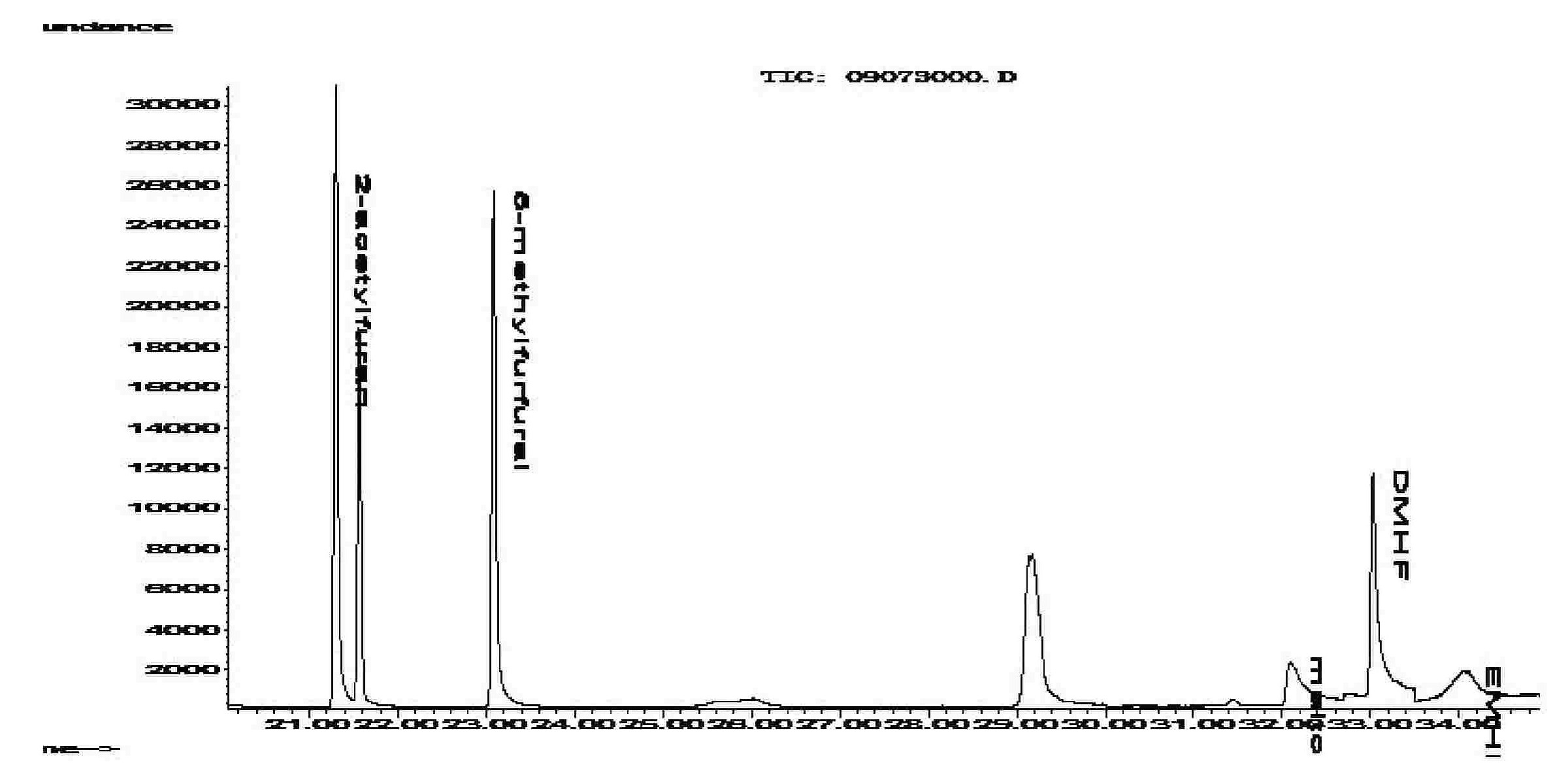

Analysis method for detecting furans compounds and pyrans compounds in beer

ActiveCN102095810ALess sample volumeImprove adsorption capacityComponent separationFuranOrganic solvent

The invention discloses an analysis method for detecting furans compounds and pyrans compounds in beer, which combines a solid-phase extraction analysis method and a gas chromatogram / mass spectrometry analysis method. The analysis method comprises the following steps of preparation, solid-phase extraction, gas chromatogram / mass spectrometry analysis, detection and the like. The analysis method for detecting volatile furans compounds and pyrans compounds in beer is established and has the advantages of rapidness, small sample usage, accuracy, sensitiveness, high efficiency and the like. Small polystyrene / divinyl benzene columns selected in the solid-phase extraction process have the characteristics of strong adsorption capability, small organic solvent usage, convenience, safety, high efficiency and the like.

Owner:TSINGTAO BREWERY

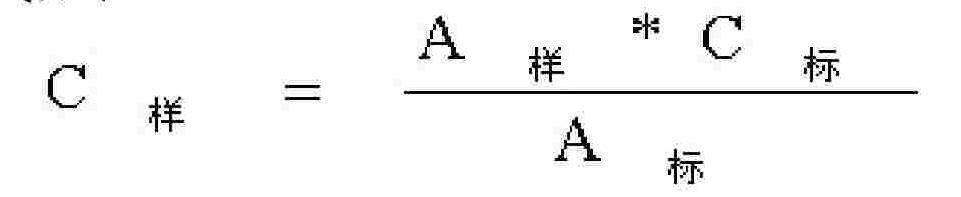

Preparation method for feed-grade copper citrate

ActiveCN107903166ACause bodily harmAvoid problems with impurities such as copper carbonateOrganic compound preparationCarbon compoundsImpurityCarbonic acid

The invention discloses a preparation method for feed-grade copper citrate. The method comprises the following steps: (1) throwing citric acid and water into a reaction kettle to form a 20%-25% citricacid aqueous solution, and performing heating to the temperature of 80 DEG C-100 DEG C; (2) turning on a stirrer, slowly adding basic copper carbonate for a neutralization reaction according to the mass ratio of the citric acid to the basic copper carbonate of 1:(0.8-1) to form copper citrate, and adding a little amount of citric acid to control the pH value of a reaction solution to be 4-6, wherein a generated CO2 gas enters an absorption tank through a gas discharging opening to be absorbed; (3) filtering the generated copper citrate, performing concentration, performing cooling to a room temperature, putting the cooled material into a centrifugation machine, performing dehydration to obtain a copper citrate crystal, and discharging a separated waste liquid into a waste-liquid pond forrecycling; and (4) putting the obtained copper citrate crystal into a dryer, performing drying for 1-2h at the temperature condition of 100 DEG C-120 DEGC to remove some of crystal water to obtain a finished product of the feed-grade copper citrate. The product obtained by the method provided by the invention has a high yield, less impurities, and an environmentally-friendly production process.

Owner:SICHUAN ANIMAL SCI ACAD

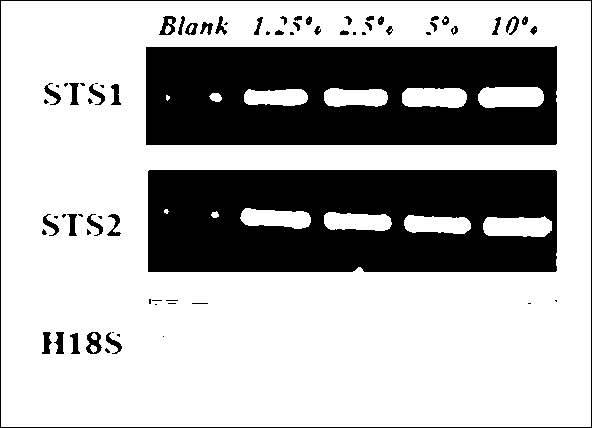

Method for inducing accumulation of stilbenes in grapes

InactiveCN102835263AInduction effect is not goodSolve effective useHorticulture methodsBiotechnologyPathogenic bacteria

The invention relates to a method for inducing the accumulation of stilbenes resveratrol, polydatin and pterostilbene in grape leaves, grape stems and grape fruits. The method comprises related methods for preparation of a hydrogen peroxide inducer, spraying treatment of in-vivo and in-vitro materials of grapes and impregnation treatment of the in-vitro materials of the grapes. According to the technical scheme, increase of stilbene content of the materials can be effectively, specifically and comprehensively induced, and the method has the characteristics of safety and convenience for large-scale application to township enterprises with rich grape resources, and is easy to operate. The quality of the grapes can be improved, grape planting waste can be comprehensively utilized, and grape trees can resist pathogenic bacteria to a certain extent to reduce loss caused by diseases.

Owner:张波 +1

Roadblock with interception function

ActiveCN112030823AImprove interception efficiencySave police forceTraffic restrictionsEmbedded systemCar door

A roadblock with an interception function comprises a fixed road surface, license plate recognizers, a slope blocking mechanism, a vehicle door clamping mechanism, a movable road surface plate, a buffer pull rope, a buffer, a storage battery and a wireless control module. Each license plate recognizer and the wireless control module are connected to the Internet in a wireless mode, remote signalsof a remote command center can be received through the license plate recognizer, and the remote command center sends license plate information of a vehicle driven by a suspect to each license plate recognizer. Each license plate recognizer recognizes license plate information of passing vehicles and then compares the license plate information with license plate information, provided by the remotecommand center, of vehicle driven by the suspect, if the license plate information is different, the vehicles are allowed to pass normally, and if the license plate information is the same, the license plate recognizer sends an interception action signal to the wireless control module. And meanwhile, the license plate information is reported to the remote command center so that intelligent networking interception is realized, interception efficiency is improved, and police strength is saved.

Owner:泉州台商投资区双霞机械设计服务中心

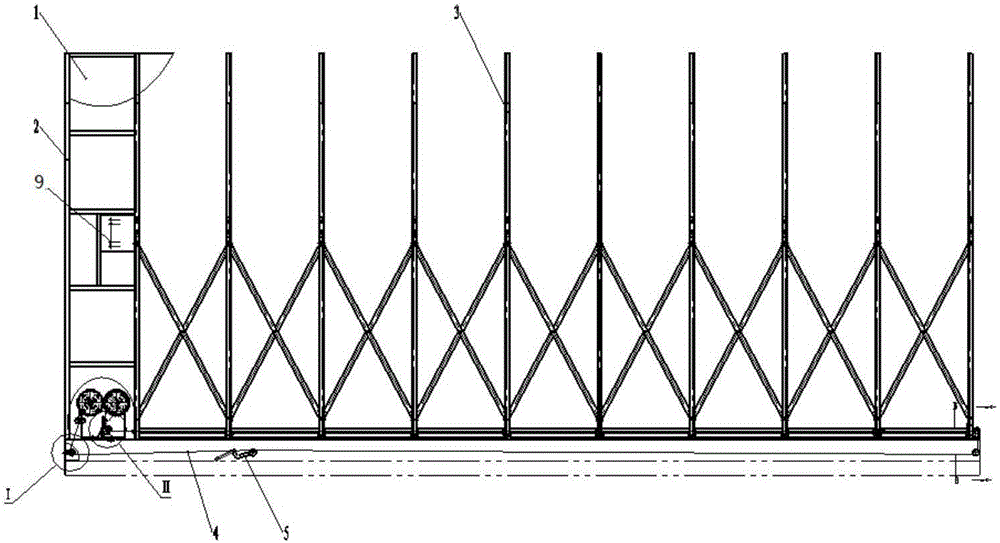

Electric telescopic tent for vehicle

The invention provides an electric telescopic tent for a vehicle. The electric telescopic tent comprises rainproof canvas, a shears-fork type movable support, an installing platform, a fixed support, a transmission steel wire rope, a tensioning mechanism, an electric device of the telescopic tent, a first guiding pulley, a second guiding pulley, a guide rail and a travel switch; one end of the transmission steel wire rope is fixed to a driving steel wire reel of a winding wheel, and the other end of the transmission steel wire rope sequentially bypasses the guiding pulleys and then is wound on a driven steel wire reel. By adopting the electric device, the transmission torque is large, the load is high, and the tent unfolding and folding time is greatly shortened.

Owner:SHAANXI SIDA AVIATION SCI & TECH

Anti-toppling and automatic shaking device for cradle

The invention relates to the technical field of bamboo and wood products, and discloses an anti-toppling and automatic shaking device for a cradle. The device includes a housing and a toothed bar, a positive plate is fixedly connected to the interior of the housing, a negative plate is fixedly connected to the interior of the housing, a movable block is movably connected to the interior of the housing, a spring I is movably connected to the interior of the housing, a sliding rail I is movably connected to the left side of the spring I, an electromagnet is movably connected to the interior of the sliding rail I, a clamping ball is movably connected to the exterior of the sliding rail I, and a spring II is movably connected to the interior of the sliding rail I; under the interaction of thehousing, the positive plate, the negative plate and the movable block, if the shaking angle of the cradle is too large, capacitive sensing can be triggered, and then a subsequent structure is driven to operate to enable the cradle to return to a normally set shaking angle, so that the cradle is prevented from toppling over, and no body damage caused by a too large shaking angle of the cradle is guaranteed to a baby.

Owner:杭州纺瑰谛家具有限公司

Automatic planer capable of processing one-face, two-face or short wood slide with angle

ActiveCN101508122BContinuous processingStable processingWood feeding arangementsBark-zones/chip/dust/waste removalRatchetElectric machinery

The invention discloses an automatic planer capable of simultaneously processing one-sided, two-sided or angular short and small piece wood, which mainly comprises a worktable, a drive motor and an upper planning tool and a lower planning tool arranged on the worktable. A control door mechanism consisting of a left control panel, a right control panel and an upper control panel is arranged at a feeding opening of the worktable; a delivery tug is arranged below the worktable; the left side and the right side of the worktable are provided with a left occulting bar and a right occulting bar respectively so as to form a closed delivery passage, wherein the a transverse compress roller wheel on the left occulting bar is provided with a spring, a directional traveler and a nut for adjusting thecompress distance; and a delivery ratchet wheel capable of adjusting angle, compress force and up-down distance is arranged above the delivery passage. The automatic planer solves the problem that the prior equipment cannot process short and small piece wood, and can continuously and efficiently manufacture products with stable size, angle and quality; and the equipment has low fault rate and high safety, does not damage the bodies of operators, and has quite convenient use, debugging and maintenance.

Owner:重庆谭木匠工艺品有限公司

Anti-collision height limiting rod

An anti-collision height limiting rod comprises a table top, a height limiting rod, an ultrahigh detection device and a speed reduction brake device. The ultrahigh detection device, an LED display screen and an alarm are arranged at the top end of the height limiting rod, when the ultrahigh detection device detects that a vehicle is ultrahigh, the LED display screen displays ultrahigh reminding subtitles, and the alarm gives out an ultrahigh warning sound to remind a driver to decelerate and brake in time so that collision accidents are avoided; when the ultrahigh vehicle is detected not to brake in time and is about to impact the height limiting rod, a deceleration braking signal is immediately sent to a control device of the deceleration braking device, the control device automatically uses a hook of a braking hook to hook a front axle crossbeam of an automobile chassis, and the automobile drives the hook to move forwards under the action of an inertia force; and a buffer brake performs buffer braking on the hook through the brake pull rope so that the automobile decelerates, buffers and brakes, and physical injury to an automobile driver due to sudden braking is avoided.

Owner:泉州台商投资区双霞机械设计服务中心

A Commodity Shelf Life Reminder System

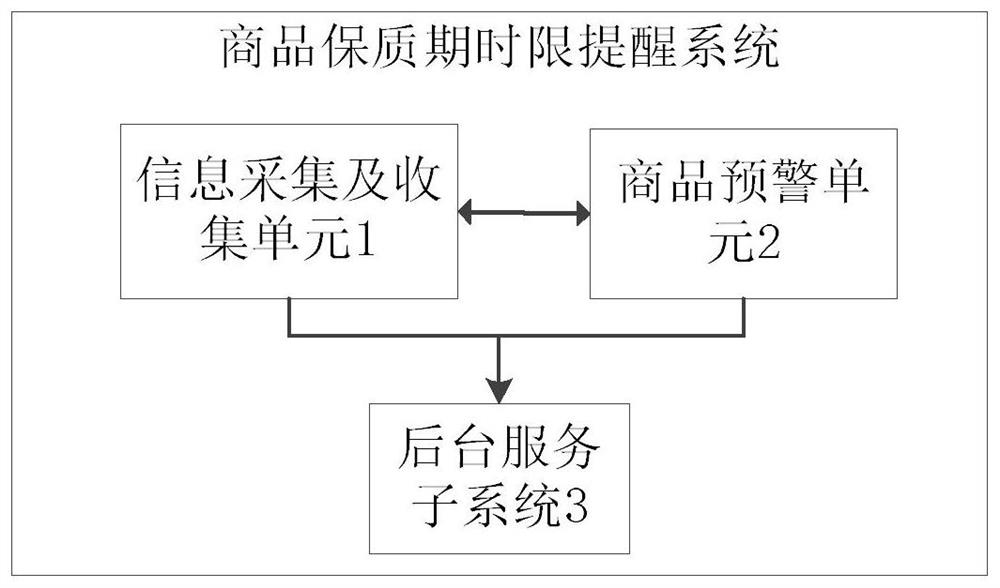

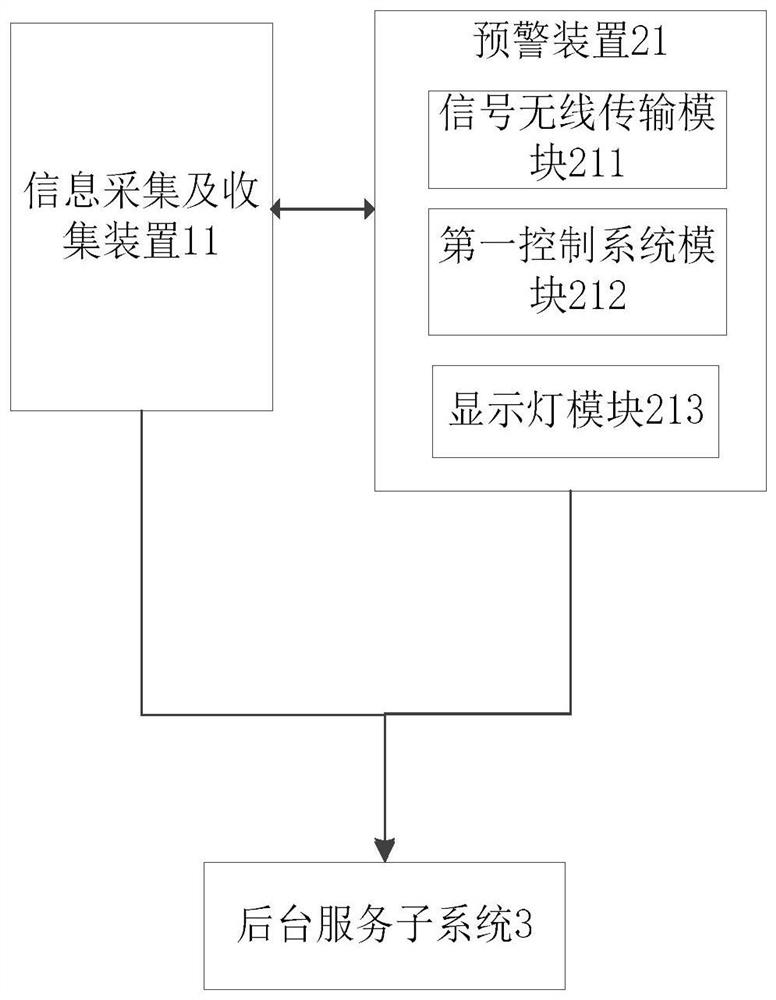

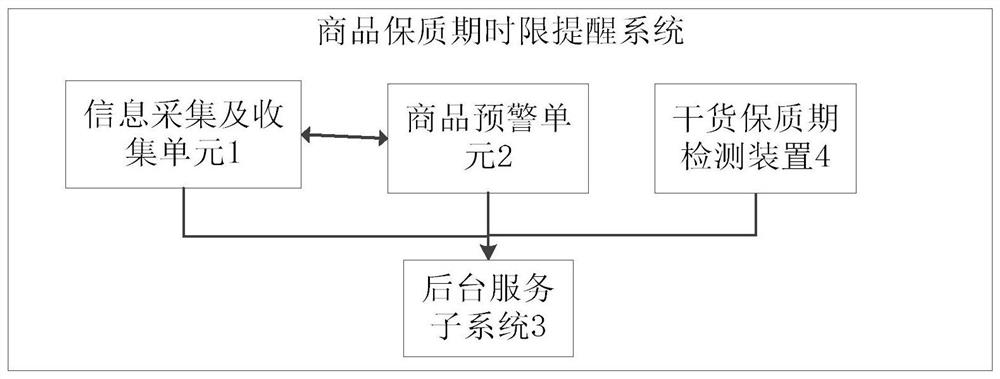

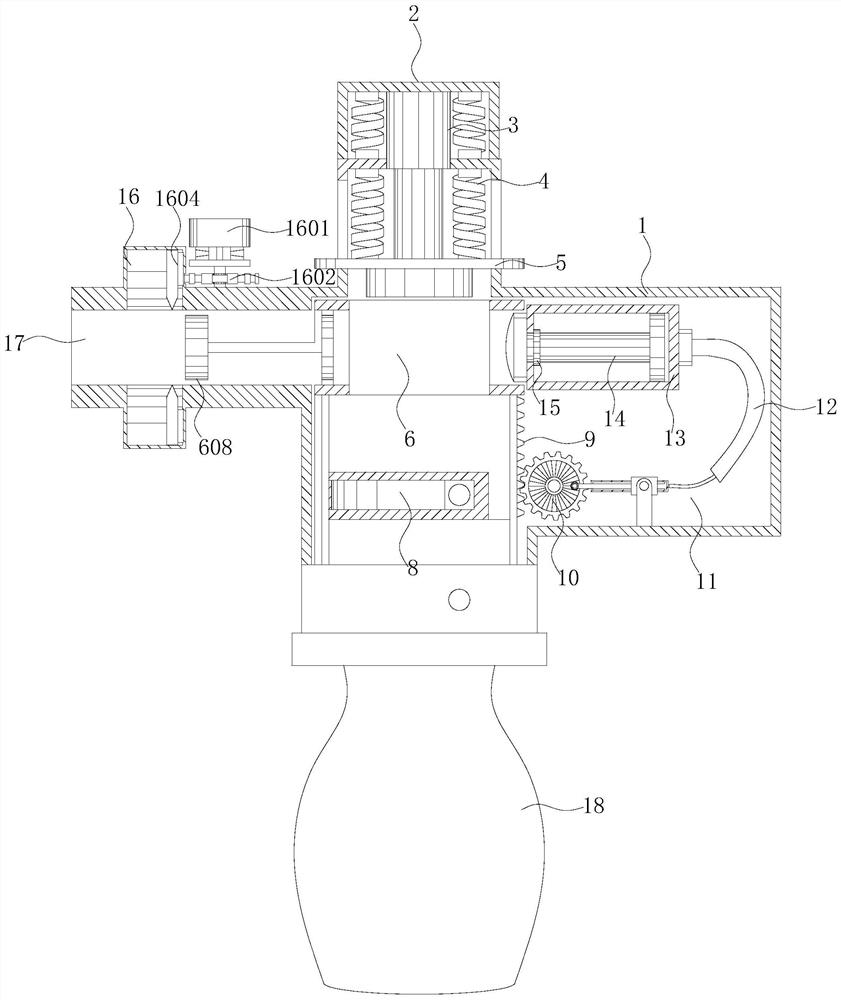

ActiveCN109741080BImprove qualityReduce economic lossTransmission systemsAlarmsBarcodeEarly warning signs

The invention provides a reminding system for the shelf life of commodities, which includes an information collection and collection unit, a commodity early warning unit, and a background service subsystem; the information collection and collection unit includes an information collection and collection device, which is used for scanning commodity barcodes and manually Entering the commodity barcode corresponding to the commodity production date, the expiration time is automatically displayed; it is also used to receive the commodity early warning signal sent by the expired commodity early warning unit, and obtain the information of the early warning commodity; the commodity early warning unit includes an early warning device for monitoring the commodity The shelf life time limit is used for early warning; the background service subsystem is used to receive all commodity information, commodity shelf life early warning signals, and send commodity sales information to information collection and collection devices and early warning devices. The invention can not only improve the guarantee of commodity quality for customers, but also can reduce the economic losses caused to merchants and customers due to the problem of commodity shelf life.

Owner:宋昱锋

Inorganic reinforcement water-plugging agent

InactiveCN104263336AGood infiltration affinityHigh strengthDrilling compositionPlasticizerFatty amine

The invention discloses a reinforcement water-plugging agent, particularly relates to an inorganic reinforcement water-plugging agent and belongs to the technical field of production and manufacturing of water-plugging agents. The inorganic reinforcement water-plugging agent comprises a component A and a component B in a weight part ratio of 1:1, wherein the component A is isocyanate and the component B comprises the following components in parts by weight: 36-48 parts of water glass, 0.5-4 parts of fatty amine, 0- 5.5 parts of alum salt, 0-0.8 part of a foaming agent, 0-8 parts of water, 0-3 parts of potassium dichromate and 0-5 parts of a plasticizer, wherein the plasticizer is conventional DOP (Dioctyl Phthalate)or DBP (Dibutyl Phthalate). In application, the inorganic reinforcement water-plugging agent is pumped into a mixer and a mixing pipe by virtue of a double-liquid pump for automatic mixing and grouting. The inorganic reinforcement water-plugging agent has the advantages of high coagulation speed, high early strength, no pollution and convenient construction, and the compressive strength which is equal to or greater than 40MPa can be achieved in 30 minutes.

Owner:JIANGSU BAODING MINE IND TECH CO LTD

Cable breakpoint wiring device for electric power

ActiveCN111969504AEasy to fixEasy to separateLine/current collector detailsApparatus for removing/armouring cablesStructural engineeringInsulation layer

The invention discloses a cable breakpoint wiring device for electric power. The device comprises a body, a feeding mechanism is arranged in the middle of the upper surface of the body; a telescopic rod is mounted in the middle of the interior of the feeding mechanism; a material receiving opening is formed in the surface of the left side of the clamping mechanism; a second rack is arranged underthe right side surface of the clamping mechanism; a feeding hole is formed in the center of the left side surface of the body; a collecting box is mounted under the body; and the clamping mechanism and the cutting mechanism are arranged in the body. The body is arranged, so that the clamping mechanism and the cutting mechanism can be fixed conveniently, through arrangement of the cutting mechanism, body injuries caused by manual misoperation of a technician can be avoided conveniently through mechanical operation, meanwhile, through arrangement of the clamping mechanism, a cable insulation layer can be fixed conveniently, and therefore separation between the insulation layer and an electric wire is facilitated.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO PINGYUAN POWER SUPPLY CO

Synthesis process for TBHQ (Tertiary Butyl Hydroquinone) crude product

InactiveCN103864579AIncrease profitCause bodily harmOrganic chemistryOrganic compound preparationPhosphoric acidHydroquinone Compound

The invention discloses a synthesis process for a TBHQ (Tertiary Butyl Hydroquinone) crude product. The synthetic process comprises the following steps: 1) pouring 2-4 parts by weight of phosphoric acid and 0.1-0.4 parts by weight of water into a stirring cylinder, then adding 5-7 parts by weight of hydroquinone, and stirring; 2) putting the stirred mixture solution into a reaction kettle, heating to 55-65DEG C, and then feeding 7-9 parts by weight of tert-butyl alcohol into the reaction kettle; 3) after heating to 75-85DEG C, and insulating for two to three hours for reaction; 4) performing centrifugal separation, washing and dehydration on a reaction product, to obtain the TBHQ crude product. According to the preparation process for the TBHQ crude product, water instead of methylbenzene is adopted as a solvent, so that the pollution is less, the raw material utilization ratio is high, and the purity of the obtained TBHQ crude product is higher.

Owner:GUANGZHOU TAIBANG FOOD TECH

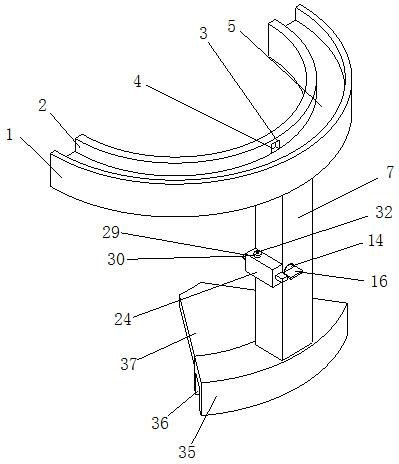

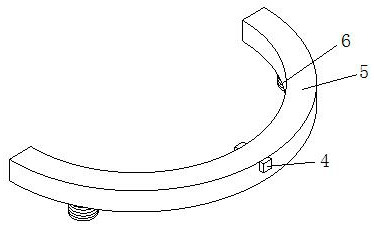

See-through protective appliance for oral cavity detector

The invention relates to the technical field of oral cavity detection, and discloses a see-through protective appliance for an oral cavity detector. The see-through protective appliance comprises an upper arc-shaped fixing block; the lower end of the upper arc-shaped fixing block is fixedly provided with a connecting plate; the lower end of the connecting plate is fixedly provided with a rectangular fixing block; the upper end of the rectangular fixing block and the lower end of the upper arc-shaped fixing block are fixedly installed; the lower end of the arc-shaped fixing block is provided with a connecting block; and the rectangular fixing block moves vertically in the connecting block. According to the see-through protective appliance for the oral cavity detector disclosed by the invention, a rotating gear is engaged with a rack to drive the rack to move upwards; the rack drives the rectangular fixing block to move upwards; the rectangular fixing block drives the connecting plate tomove upwards; the connecting plate props up the upper arc-shaped fixing block to move upwards, and the mouth is distracted by a lower arc-shaped fixing block and the upper arc-shaped fixing block, thus avoiding that a child often violently bites the hand of a doctor in the detection process due to incompliance of the child to cause physical injury to the doctor.

Owner:山东艾博康生物科技有限公司

Dry type strong magnetic screening device used for steel and iron manufacture

ActiveCN108855606AHeating evenlyAvoid affecting selection difficultyDirt cleaningMagnetic separationSpiral bladeMaterials science

The invention belongs to the field of steel and iron manufacture, and particularly relates to a dry type strong magnetic screening device used for steel and iron manufacture. The technical problem tobe solved is to provide the dry type strong magnetic screening device used for steel and iron manufacture, wherein the dry type strong magnetic screening device is uniform in heat born by ore and highin ore screening work efficiency. The dry type strong magnetic screening device used for steel and iron manufacture comprises a fixed frame, a first collection frame, a first discharge hopper, secondcollection frames, guide inclined plates, scrapers, electromagnetic rollers, a second discharge hopper, an installation box, a spiral blade and the like. A treatment barrel is embedded in the top ofthe installation box. A bearing pedestal is embedded in the top of the treatment barrel. A hollow rotating rod is connected with the bearing pedestal in a pivoted manner. The spiral blade is fixedly connected to the outer surface of the hollow rotating rod and is located in the treatment barrel. A first gear is fixedly connected to the outer surface of the hollow rotating rod. By means of the drytype strong magnetic screening device, the effects that the ore is uniformly heated and the ore screening work efficiency is high are achieved.

Owner:山东鲁钢再生资源有限公司

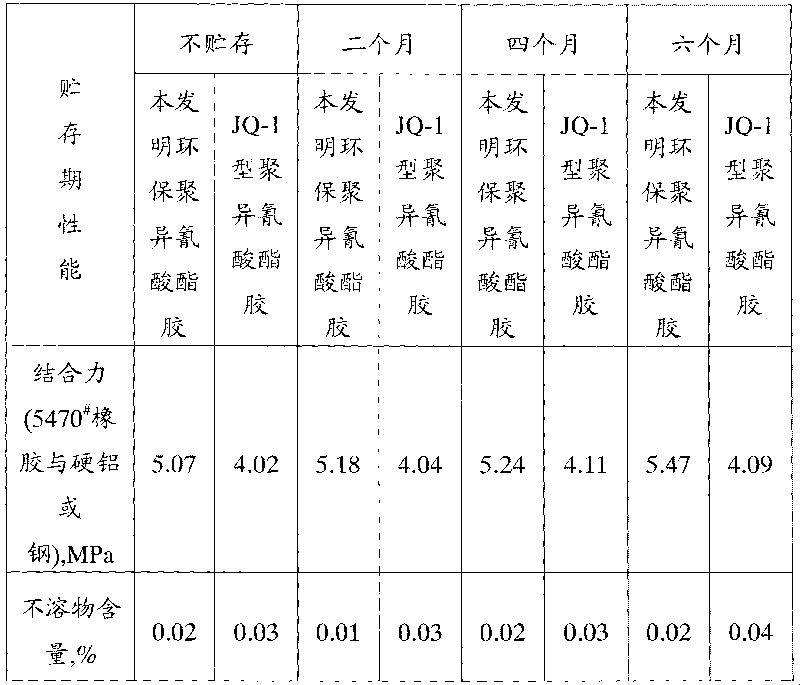

Preparation method of environment-friendly polymeric isocyanate glue

ActiveCN101709209AGood solubilityWide range of usesPolyureas/polyurethane adhesivesIsocyanateEthyl ester

The invention discloses a preparation method of environment-friendly polymeric isocyanate glue, which comprises the steps of photochemical reaction, high temperature scavenging and reduced pressure distillation. On the premise of not influencing product quality, ethyl acetate is selected as an organic solvent component, and the produced environment-friendly polymeric isocyanate glue can not only enhance the environmental protection performance of products, but also greatly improve the bond strength of the products.

Owner:LIAONING HONGSHAN CHEM

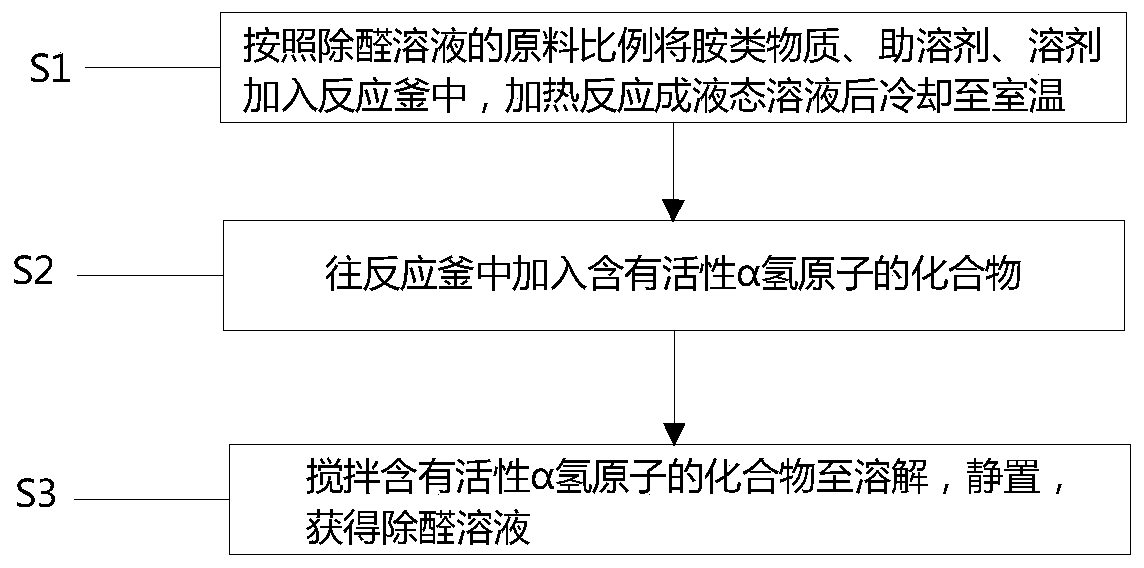

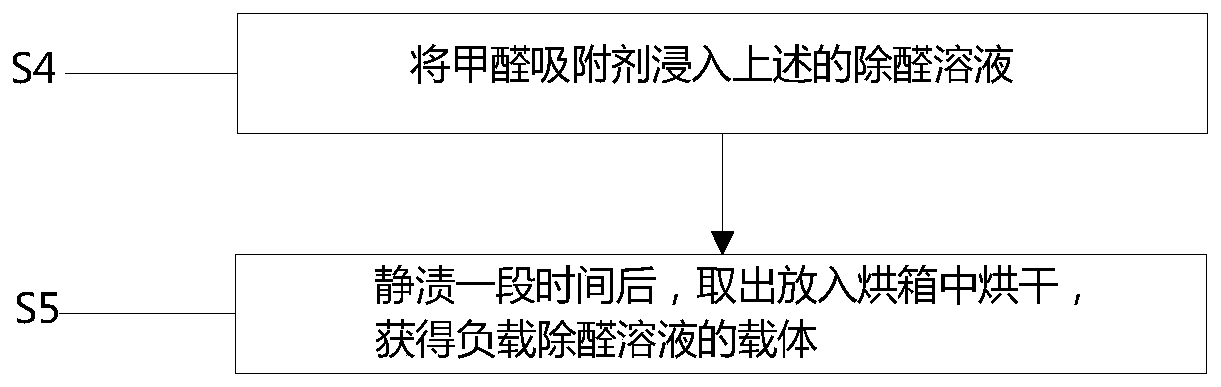

Formaldehyde removal solution and support carrier thereof, preparation method and formaldehyde removal filter element

InactiveCN110141954ACause bodily harmNon-toxic and harmless production processDispersed particle separationHydrogen atomSolvent

The invention belongs to the technical field of formaldehyde removal, in particular to a formaldehyde removal solution and a support carrier thereof, a preparation method and a formaldehyde removal filter element. The formaldehyde removal solution and the support carrier thereof, As that amine substance, a cosolvent, a compound containing the active alpha hydrogen atom and a solvent are added intoa reaction kettle in a certain proportion to obtain the formaldehyde removal solution, and then the formaldehyde adsorbent is immersed into the formaldehyde removal solution to obtain a carrier loaded with the formaldehyde removal solution, wherein the formaldehyde removal solution adopts the principle of aldehyde-amine carboxylation reaction and realizes non-toxic and harmless treatment of formaldehyde by changing amine substance groups, and does not cause secondary environmental pollution; as compared with that traditional preparation method, the preparation process of the formaldehyde removal solution is non-toxic and harmless, does not cause physical damage to the user, and the formaldehyde removal efficiency and the stability are improved by about 30 percent.

Owner:GREE ELECTRIC APPLIANCES INC

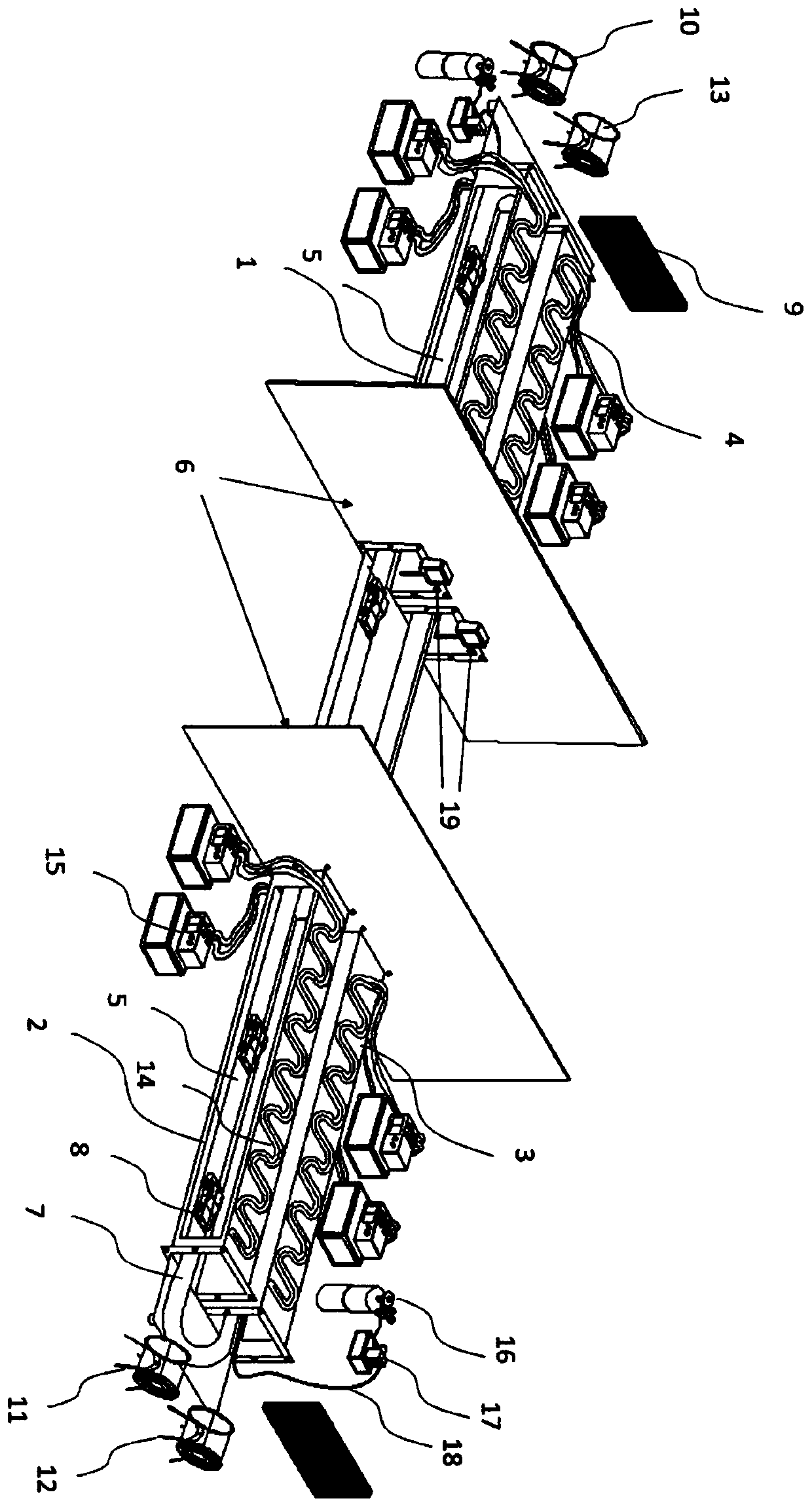

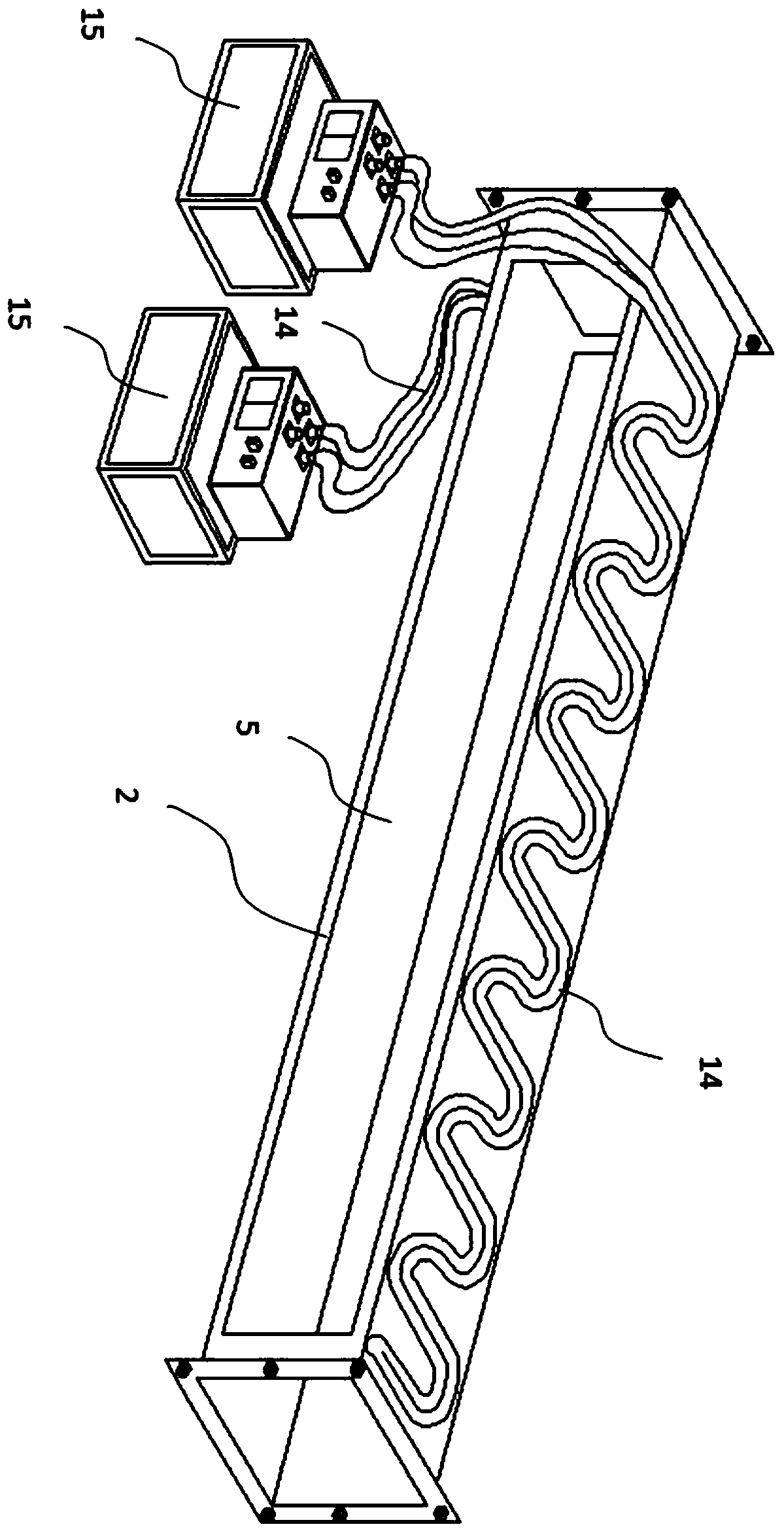

Adjacent continuous tunnel group ventilation experiment device and manufacture method

ActiveCN111456795ALow production costShort production cycleTunnel/mines ventillationStructural engineeringTunnel ventilation

The invention discloses an adjacent continuous tunnel group ventilation experiment device and a manufacture method. The experiment device comprises a left line upstream main tunnel, a left line downstream main tunnel, a right line upper stream main tunnel and a right line downstream main tunnel, wherein the four sections of main tunnels are bidirectional two-hole adjacent continuous tunnels whichare divided into left lines and right lines, and the middle parts of the four main tunnels are adjacent opening sections. According to the experiment device, four sections of main tunnels are combined, a longitudinal distance between each upstream tunnel and each downstream tunnel as well as a lateral distance between each left line tunnel and each right line tunnel can be regulated at will, so that an influence on tunnel group ventilation and pollution discharge by an adjacent tunnel interval, a tunnel group lateral distance, a tunnel temperature as well as a traffic flow and a speed in the tunnel is evaluated in the same tunnel ventilation experiment device, so that the manufacture cost of a model is saved, a manufacture period is shortened, in addition, an evaluation error is greatly lowered, and the accuracy of an evaluation result is guaranteed.

Owner:CHINA JILIANG UNIV +1

A method for pyro-reduction smelting bismuth to enrich platinum group metals in waste automobile exhaust catalysts

ActiveCN110735045BReduce the difficulty of separation and recoveryHigh recovery rateProcess efficiency improvementPtru catalystMaterials science

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A double-type closed space external gas barrier device

ActiveCN105571041BReasonable structureSoft linesLighting and heating apparatusAir-flow control membersGas barrierExhaust gas

The invention discloses dual closed space external gas barrier equipment. The dual closed space external gas barrier equipment comprises a closed space shell provided with a window; a guide runner surrounding the edge of the window, and enclosed by an annular inner wall and an annular outer wall to form a gas flow channel; a first air guide port and a second air guide port formed in gaps in the connecting places of the annular inner wall and the annular outer wall, receiving gas flows from the gas flow channel in the guide runner, and leading the gas flows to flow out of the closed space shell; a wall surface near the annular inner wall of the first air guide port serving as a first Keenda surface; a wall surface near the annular outer wall of the second air guide port serving as a second Keenda surface; and an air supply device conveying the gas flows to the guide runner through a ventilation way. The equipment can be installed in a window of an expressway ticket kiosk for discharging tail gas, peculiar smell and the like of vehicles out of a closed space to prevent workers from harm of various harmful gases.

Owner:NEWLAND DIGITAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com