Dry type strong magnetic screening device used for steel and iron manufacture

A screening device and dry technology, applied in the field of iron and steel manufacturing, can solve the problems of inability to uniformly heat ore and low work efficiency of ore, and achieve the effects of high work efficiency, avoiding pollution, and ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

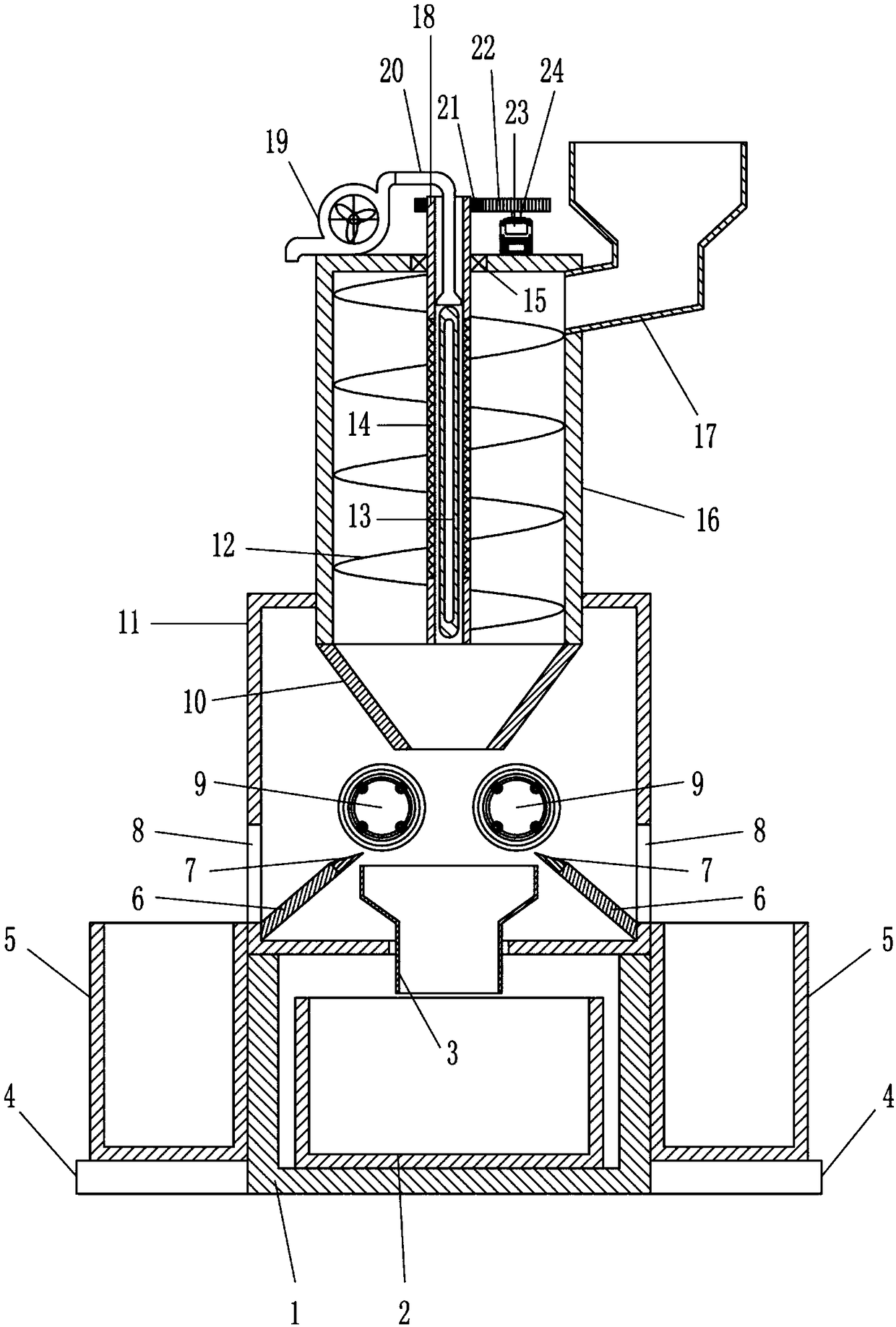

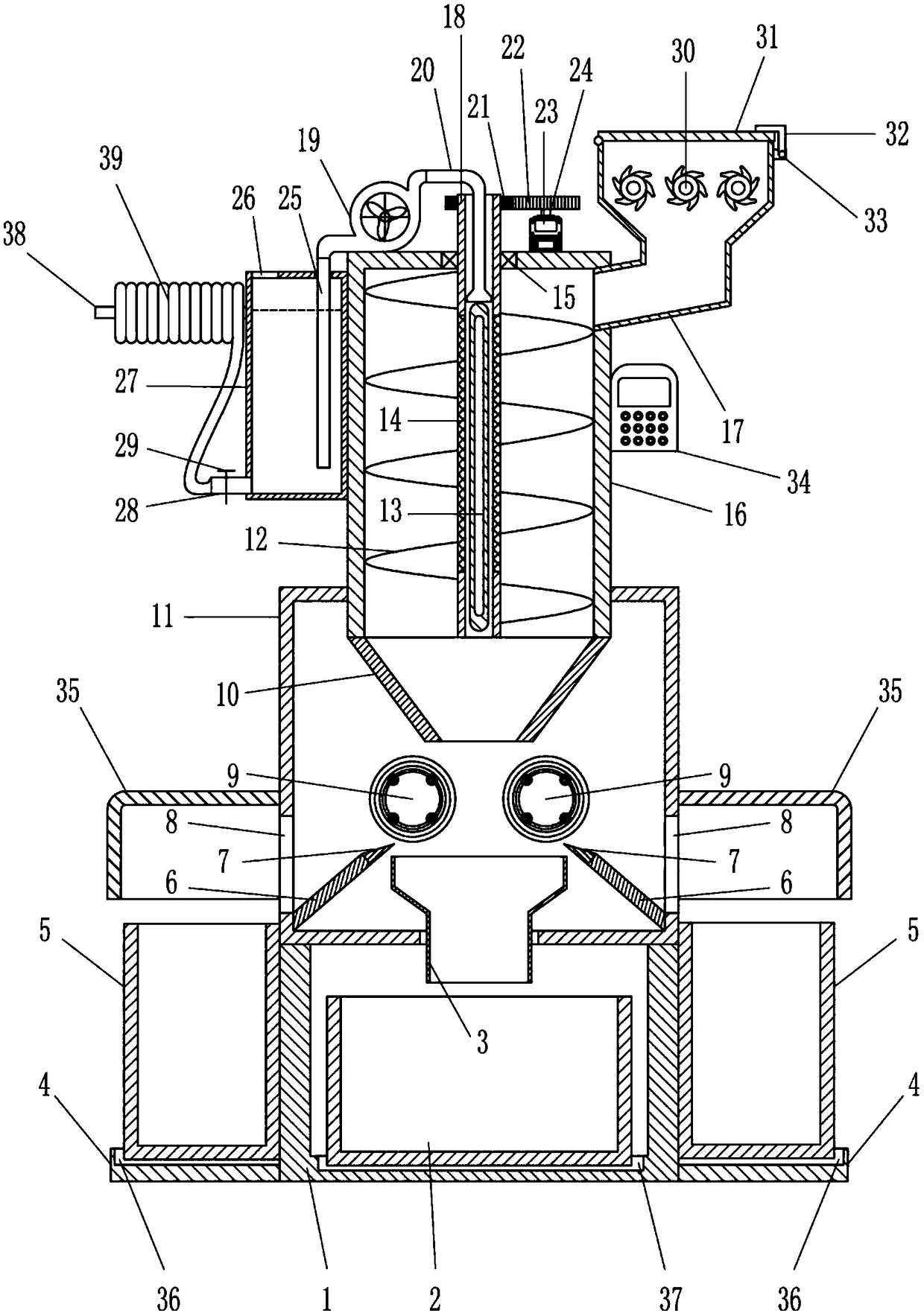

[0027] A dry-type strong magnetic screening device for iron and steel manufacturing, such as Figure 1-2 As shown, it includes a fixed frame 1, a first collection frame 2, a first discharge hopper 3, a second collection frame 5, a slant guide plate 6, a scraper 7, an electromagnetic roller 9, a second discharge hopper 10, an installation box 11, a screw Blade 12, heating lamp 13, screen 14, bearing seat 15, processing cylinder 16, feed hopper 17, hollow rotating rod 18, exhaust fan 19, hard pipe 20, first gear 21, second gear 22, motor 23 and the rotating shaft 24; the installation box 11 is fixedly connected to the top of the fixed frame 1, the processing cylinder 16 is embedded in the top of the installation box 11, the bearing seat 15 is embedded in the top of the processing cylinder 16, and the hollow rotating rod 18 is pivotally connected with the bearing seat 15; the screw blade 12 is fixed Connected to the outer surface of the hollow rotating rod 18, and the spiral blad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com