Quickly-removable propping material for melt deposition molding and preparation method thereof

A technology of fused deposition molding and supporting materials, which is applied in the field of 3D printing technology and plastic processing, can solve the problems of damage to the surface smoothness of printed parts, cannot be removed very conveniently and quickly, and reduce the polarity of polyvinyl alcohol materials, etc., to achieve large Large-scale promotion of production, low requirements for process conditions and production equipment, and enhanced mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing a support material for fused deposition modeling, comprising the following steps:

[0035] (1) Drying treatment of raw materials: polyvinyl alcohol, acid agent, alkali agent, plasticizer, filler and additives are dried at a constant temperature of 80°C for more than 5 hours to remove residual moisture and dry the raw materials completely;

[0036] (2) Mixing of raw materials: First mix the acid agent and plasticizer evenly, then put it into a high-speed mixer together with polyvinyl alcohol, fillers and additives and mix it, then add alkali agent and antioxidant, and mix it for 10 Cool to room temperature after minutes;

[0037] (3) Heated extrusion: Add the mixed raw materials into the twin-screw extruder, and keep the feeding speed uniform and smooth to ensure that there is no blockage during the extrusion process, and the filament is stable and smooth. The first stage temperature during the twin-screw extrusion process 160°C, the temperature o...

Embodiment 1~3

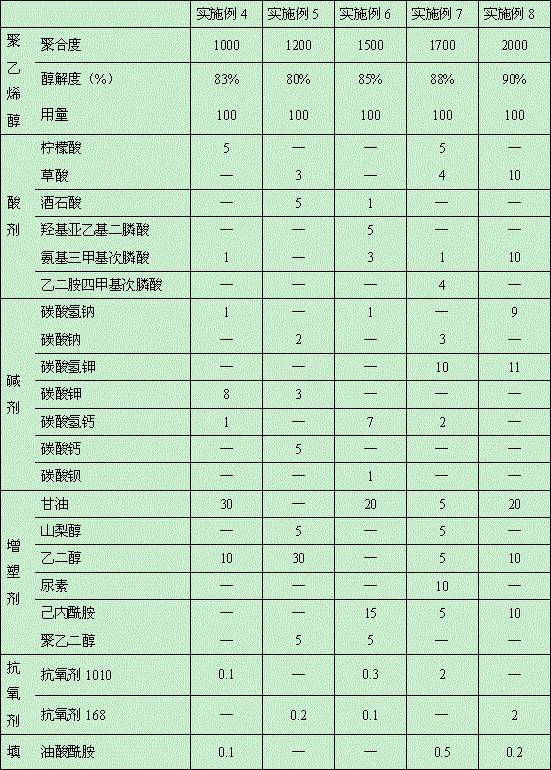

[0040] Table 1 is the specific formulation and performance test results of the support materials prepared in Examples 1-3.

[0041] Table 1 Embodiment 1-3 and comparative example 1 material formula (weight / part)

[0042]

[0043] The support materials prepared in Comparative Example 1 and Examples 1-3 were tested for water solubility, processability, mechanical properties and melt index, and the test results are shown in Table 1. In terms of water solubility, compared with Comparative Example 1, the time for the support material prepared in Examples 1-3 to start to dissolve does not change much, but the time for complete dissolution is significantly reduced, and it can be observed that a large number of bubbles in the solution are produced during dissolution, which shows that This is because when water is wetted on the surface of the support material and begins to dissolve, the acid and alkali agents can dissolve and undergo an acid-base reaction to generate carbon dioxide ...

Embodiment 4~8

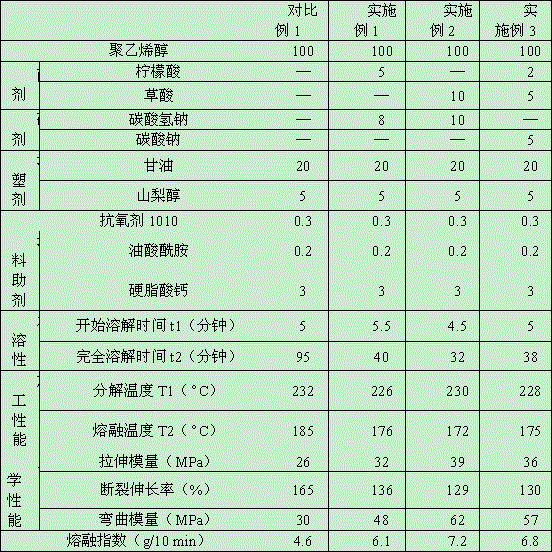

[0053] Table 2 is the specific formulation and performance test results of the support materials prepared in Examples 4-8.

[0054] Table 2 Example 4-8 material formulation (weight / part) and performance test results

[0055]

[0056] It can be seen from Table 2 that the support material prepared within the composition range of the present invention has excellent water solubility and processability, and the material can be quickly dissolved and removed within 40 minutes at room temperature, which is very suitable for use as a support material for FDM .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com