Formaldehyde removal solution and support carrier thereof, preparation method and formaldehyde removal filter element

A solution and carrier technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as incomplete removal, limited use of aldehyde removers, and insufficient reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A solution for removing aldehydes, the raw material components of the solution for removing aldehydes include amines, co-solvents, compounds containing active α hydrogen atoms, and solvents, and the mass ratio of the amines, co-solvents, and solvents is 1:3 :10-1:7:20, the mass ratio of the amine substance to the compound containing active α-hydrogen atoms is 2:3-4:1.

[0031] The amines include ethylenediamine, propylenediamine, hexamethylenediamine, etc., and hexamethylenediamine is used as an example in this embodiment; the cosolvents include methanol, ethanol, isopropanol, etc. ethanol. In this embodiment, the compound containing active α-hydrogen atoms is chitosan monomer, and the solvent is water, so that chitosan monomer and hexamethylenediamine can be fully dissolved in the aqueous solution of ethanol.

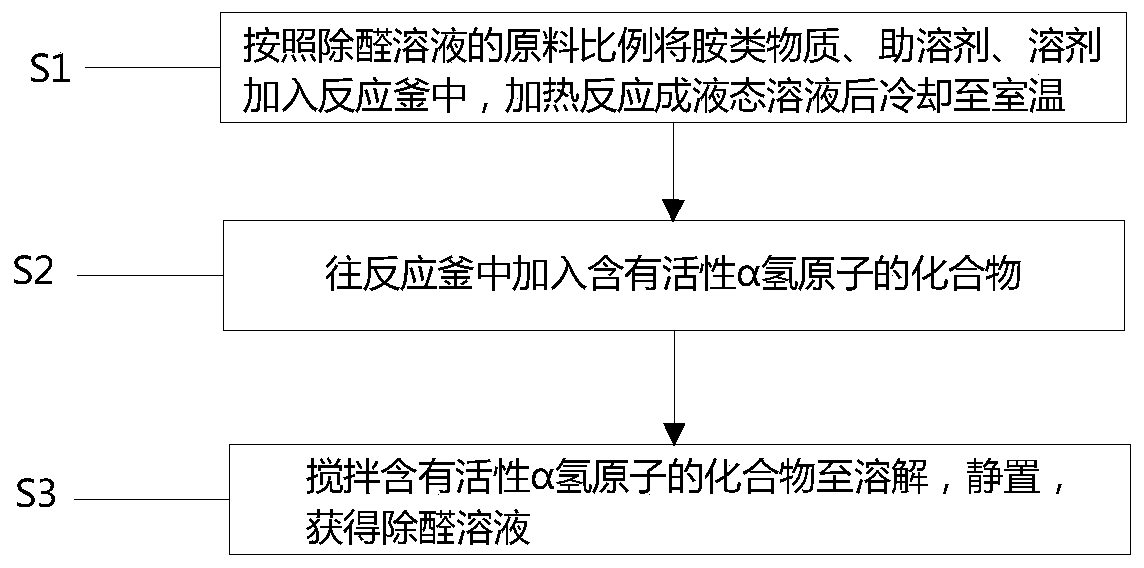

[0032] Such as figure 1 Shown, a kind of preparation method of aldehyde-removing solution,

[0033] S1: Add amines, co-solvents, and solvents into the reacti...

Embodiment 2

[0052] The difference between this example and Example 1 is that the mass ratio of amines, co-solvents, and solvents is 1:5:15, and the mass ratio of the amines to compounds containing active α-hydrogen atoms is 3:2.

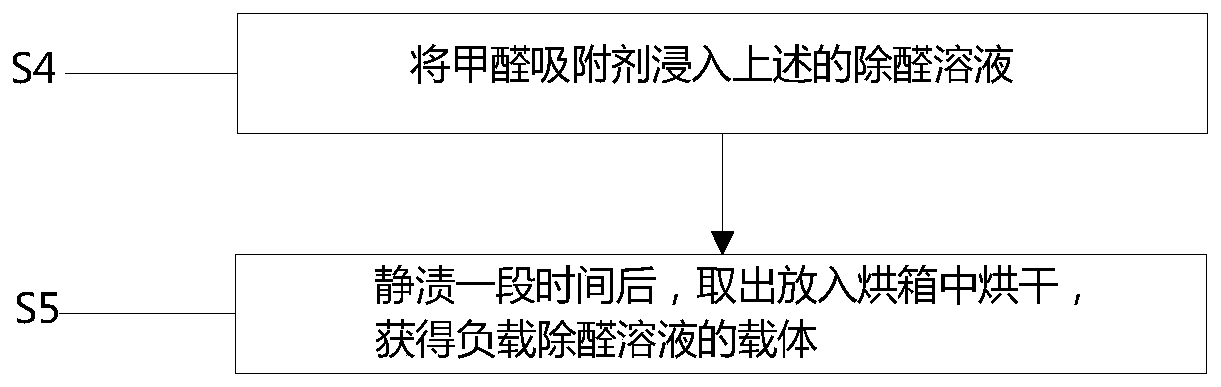

[0053] In this example, the formaldehyde adsorbent is illustrated by taking 2*5mm coal-based activated carbon as an example. Then, the loaded aldehyde-removing solution is made into a filter element and put into a testing machine for testing. The test results are shown in Table 2 below.

[0054] Table 2

[0055] Formaldehyde initial value 1ppm 0 hours 3 hours 6 hours 12 hours Formaldehyde concentration 0ppm 0.16ppm 0.33ppm 0.423ppm Penetration rate 0% 16% 33% 43%

[0056] Through the test, it can be seen that the aldehyde removal filter element has obvious aldehyde removal effect. Compared with the traditional aldehyde removal filter element, the aldehyde removal efficiency and stability of the filter element have incr...

Embodiment 3

[0058] The difference between this embodiment and Example 1 is that the mass ratio of the amines, co-solvents, and solvents is 1:7:20, and the ratio of the amines to the compound containing active α hydrogen atoms is 4: 1.

[0059] In this example, the formaldehyde adsorbent is illustrated by taking 30-60 mesh coconut shell activated carbon as an example. Then, the loaded aldehyde-removing solution is made into a filter element and put into a testing machine for testing. The test results are shown in Table 3 below.

[0060] table 3

[0061] Formaldehyde initial value 1ppm 0 hours 3 hours 6 hours 12 hours Formaldehyde concentration 0ppm 0.175ppm 0.36ppm 0.45ppm Penetration rate 0% 17.5% 36% 45%

[0062] Through the test, it can be seen that the aldehyde removal filter element has obvious aldehyde removal effect. Compared with the traditional aldehyde removal filter element, the aldehyde removal efficiency and stability of the filter el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com