Preparation method of environment-friendly polymeric isocyanate glue

A polyisocyanate glue, polyisocyanate technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of water and soil and air pollution, working environment hazards, etc., and achieve stable performance, Versatile and strong bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

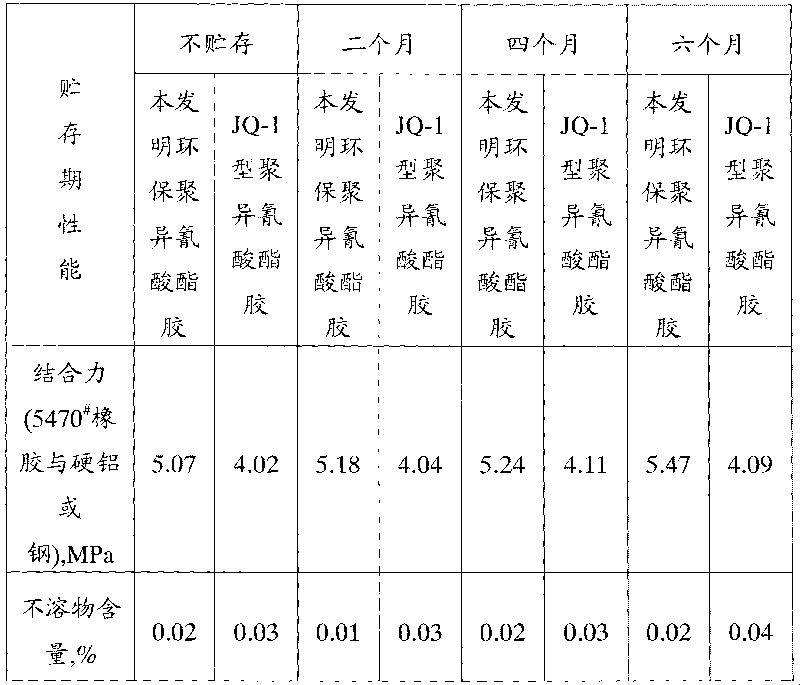

Image

Examples

Embodiment Construction

[0015] 1), photochemical reaction

[0016] In the low-temperature reaction kettle, dissolve triaminotriphenylmethane in chlorobenzene so that the weight percentage of triaminotriphenylmethane in the mixed solution is 21-23%, and wait until the temperature of the mixed solution drops to -5~-10°C When the temperature is high, phosgene is introduced to carry out low-temperature photochemical reaction; when the specific gravity of the low-temperature photochemical mixture reaches 1.2, it is transferred to a high-temperature reactor and the temperature is raised to 120-125°C, and then phosgene is introduced to carry out high-temperature photochemical reaction; Carry out high-temperature degassing when the weight content of polyisocyanate produced is greater than 10%;

[0017] 2), high temperature catch air

[0018] Control the high-temperature reaction liquid at 125-130°C, and use dry compressed air to drive out the excess phosgene and hydrogen chloride gas generated in the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com