Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Achieve the purpose of combining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

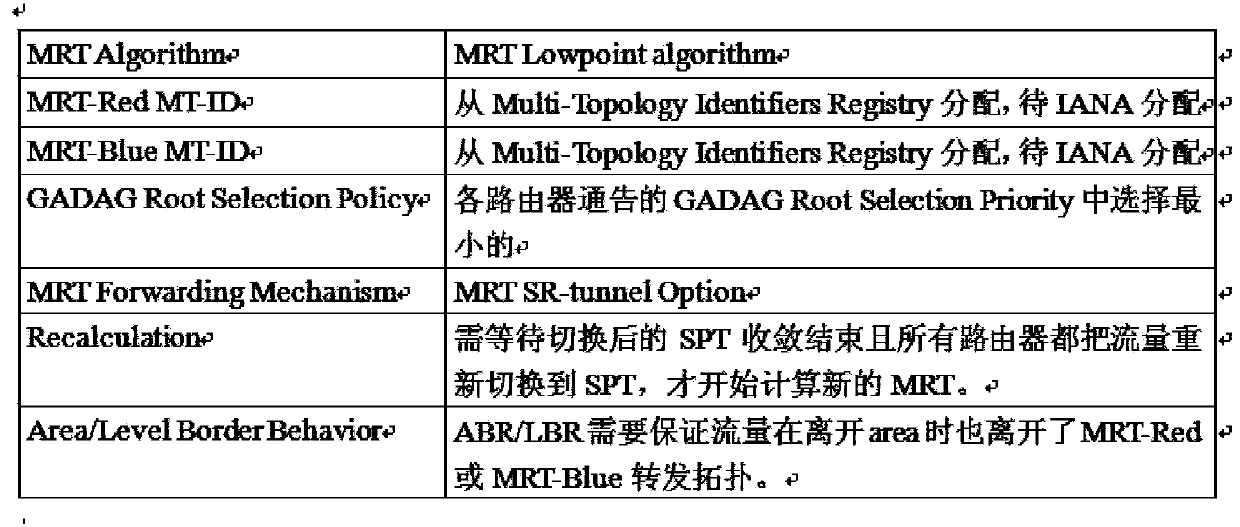

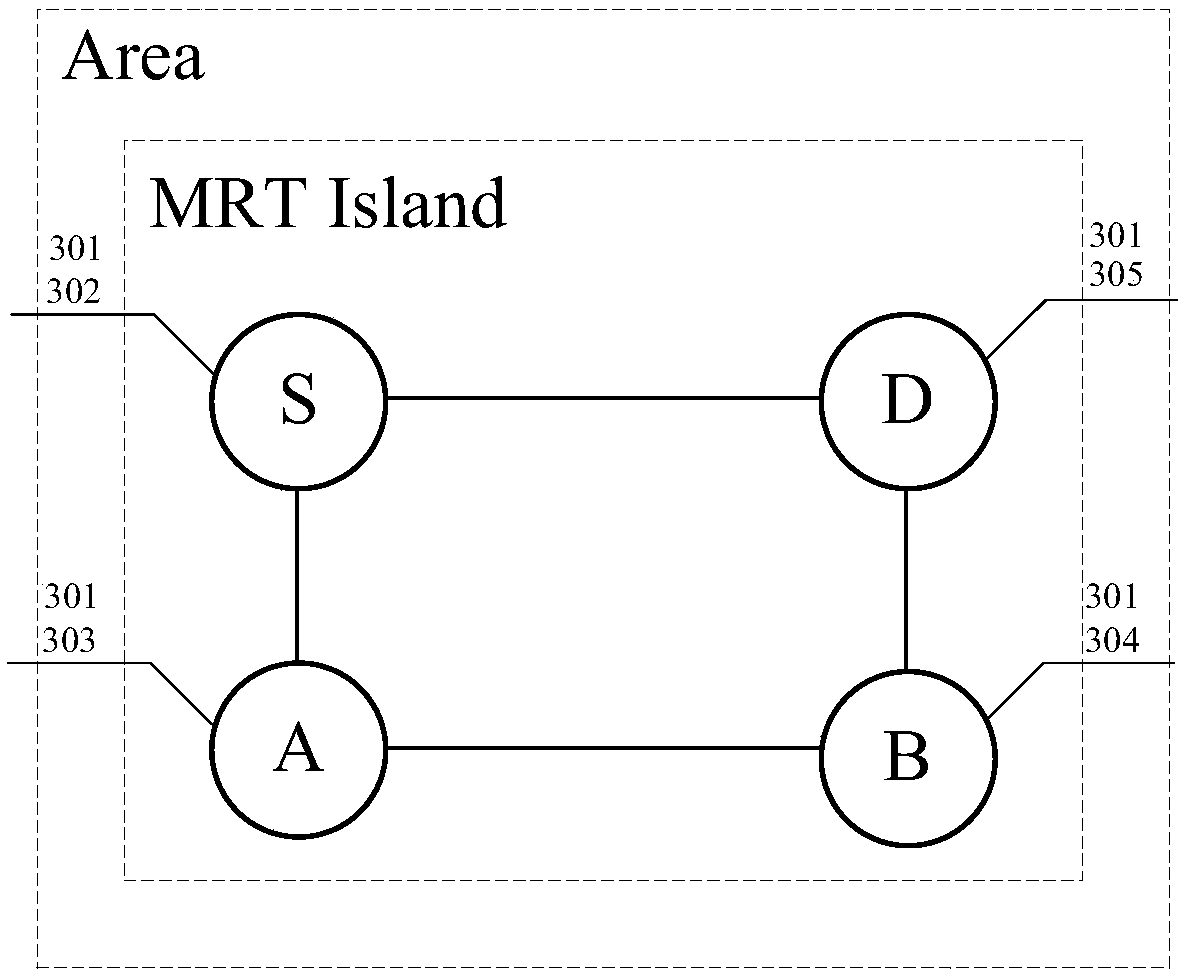

Message forwarding method and device thereof

InactiveCN107770063AAchieve the purpose of combiningNetworks interconnectionDistributed computingMessage forwarding

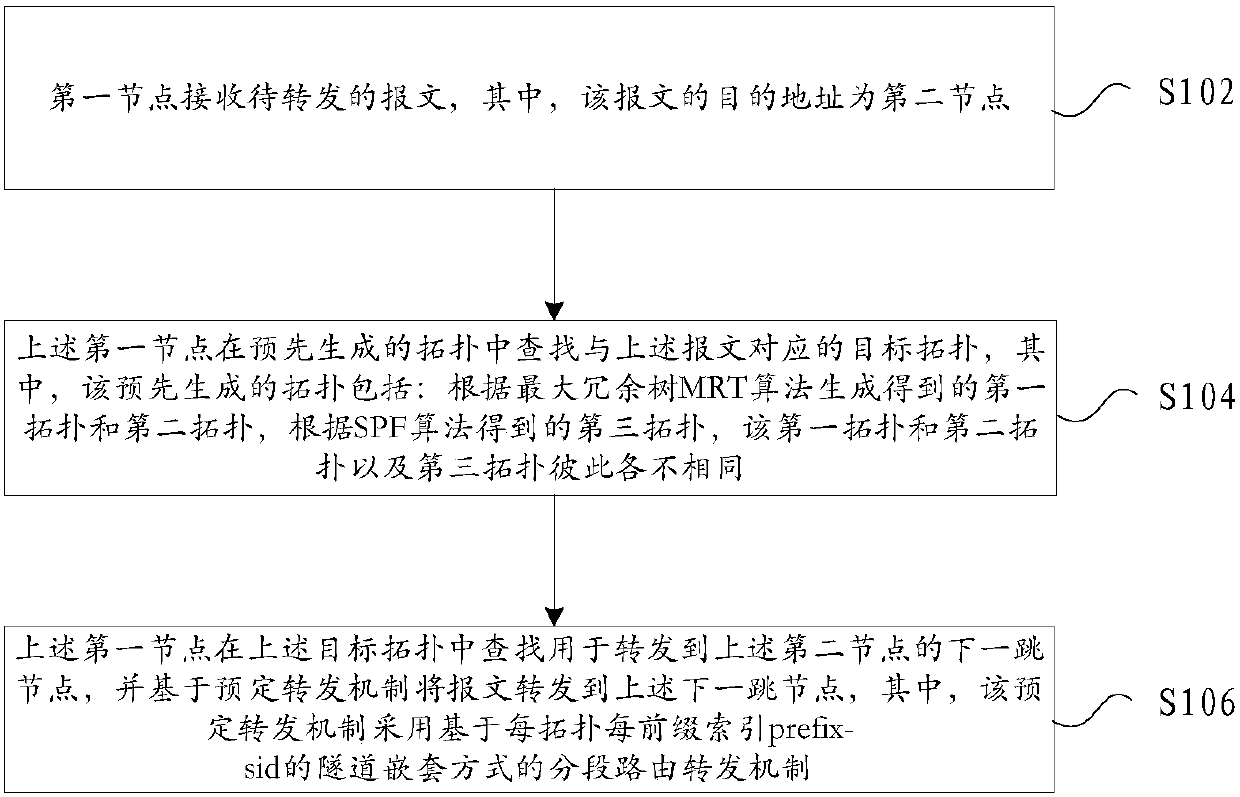

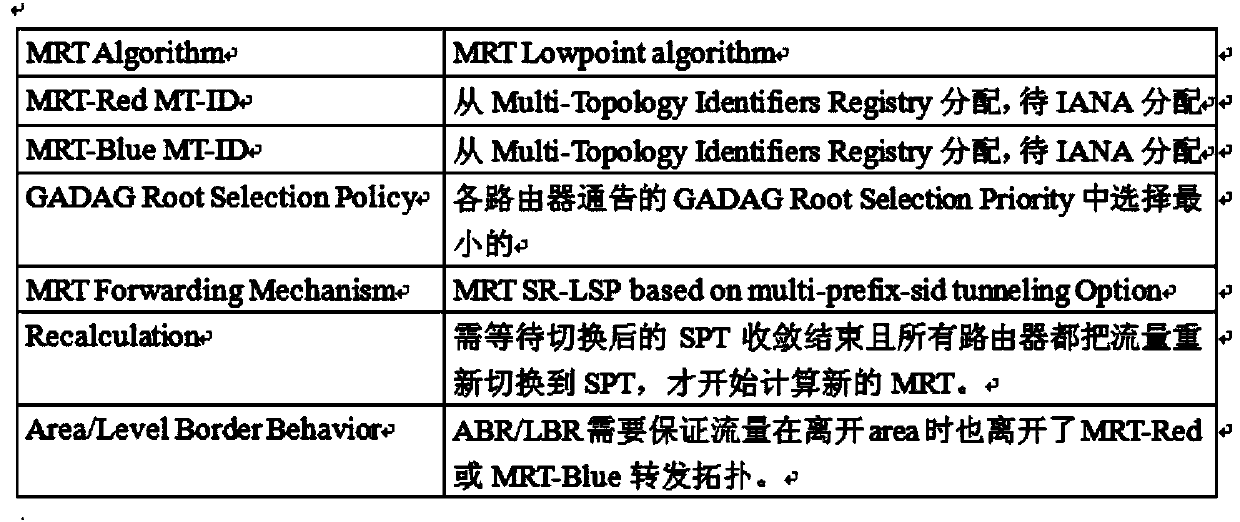

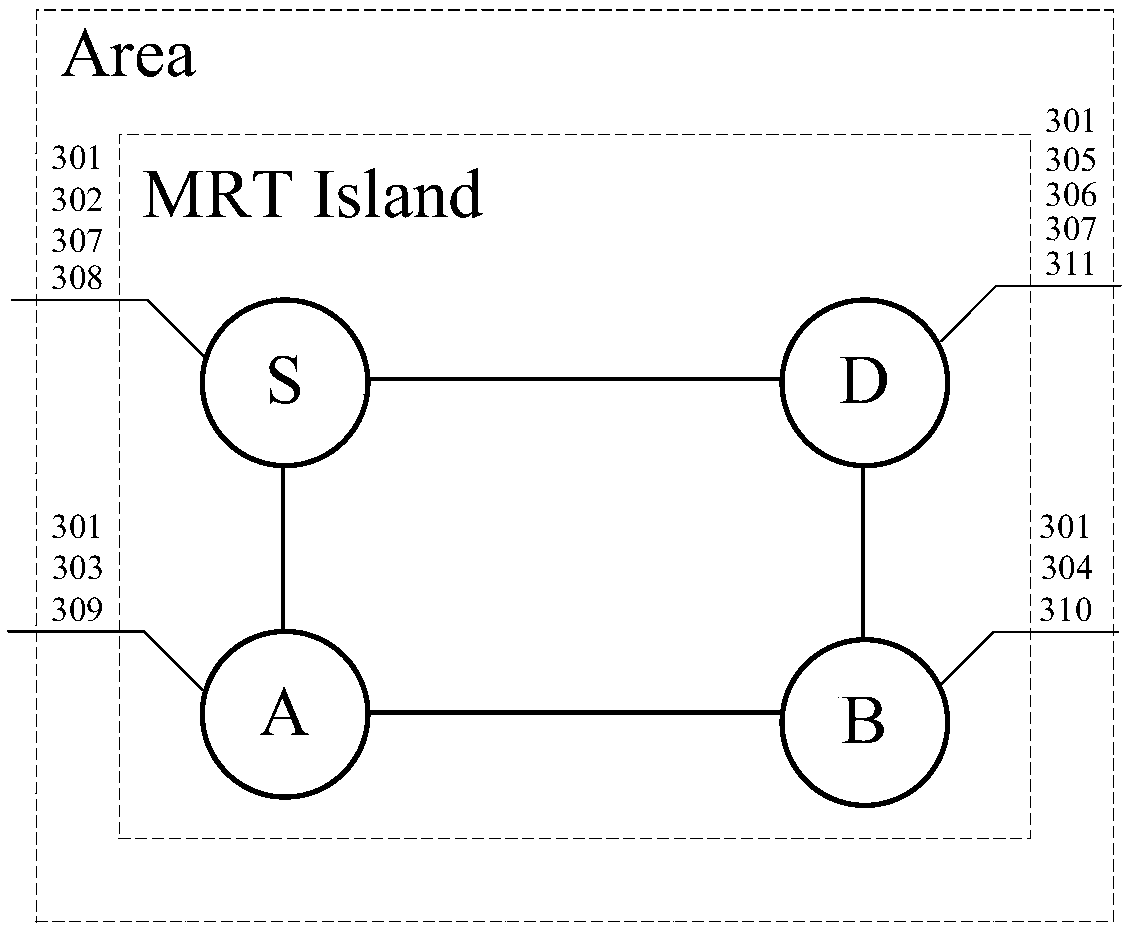

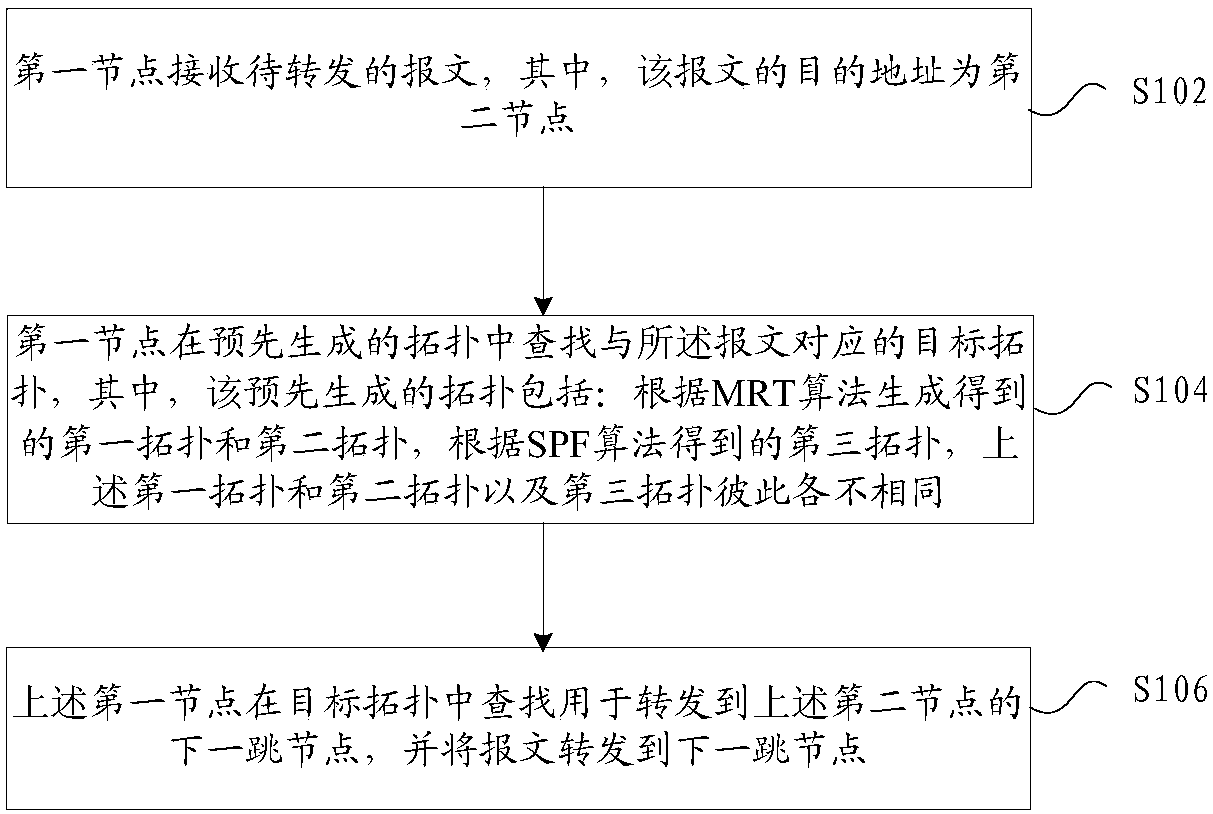

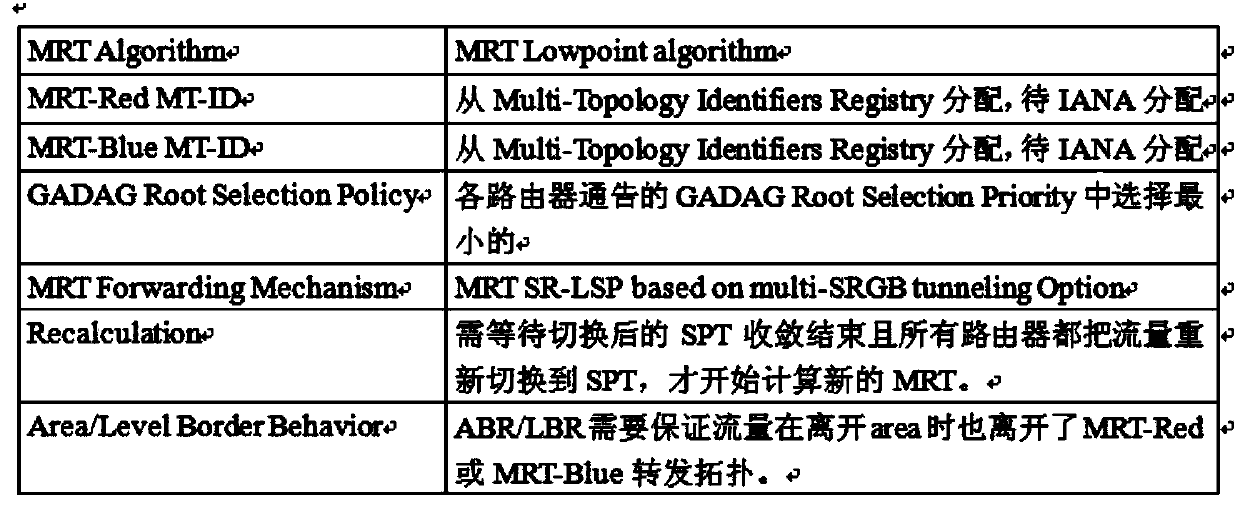

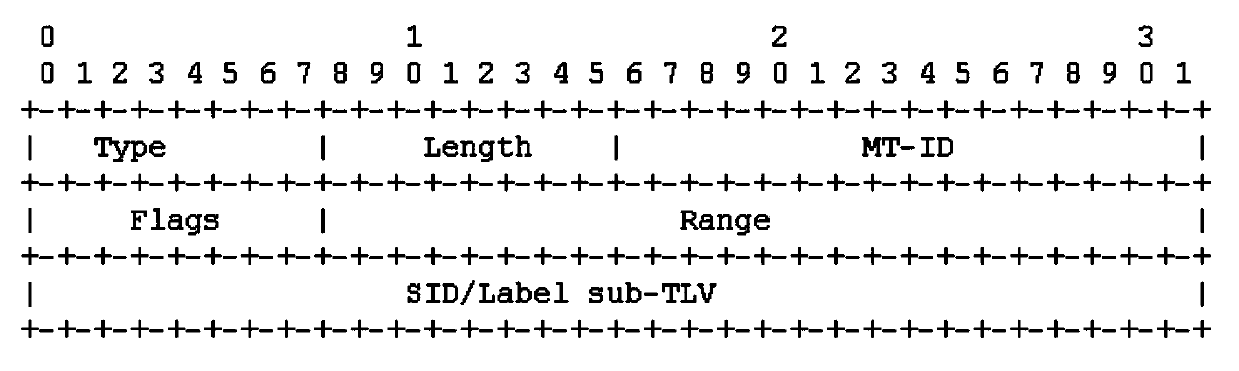

The invention provides a message forwarding method and a device thereof. The message forwarding method comprises the steps of receiving a to-be-forwarded message by a first node, wherein the target address of the message is a second node; searching a target topology which corresponds with the message in a pre-generated topology, wherein the pre-generated topology comprises a first topology and a second topology which are generated according to an MRT algorithm, and a third topology which is obtained according to an SPF algorithm, wherein the first topology, the second topology and the third topology are different from one another; and searching a next hop node for forwarding to the second node in the target topology by the first node, and forwarding the message to the next hop node based on a preset forwarding mechanism, wherein the preset forwarding mechanism utilizes a segmented routing forwarding mechanism based on a tunnel nesting mode of every topology every prefix-sid. The message forwarding method and the device thereof realize a purpose of combining the segmented routing network and the MTR function.

Owner:ZTE CORP

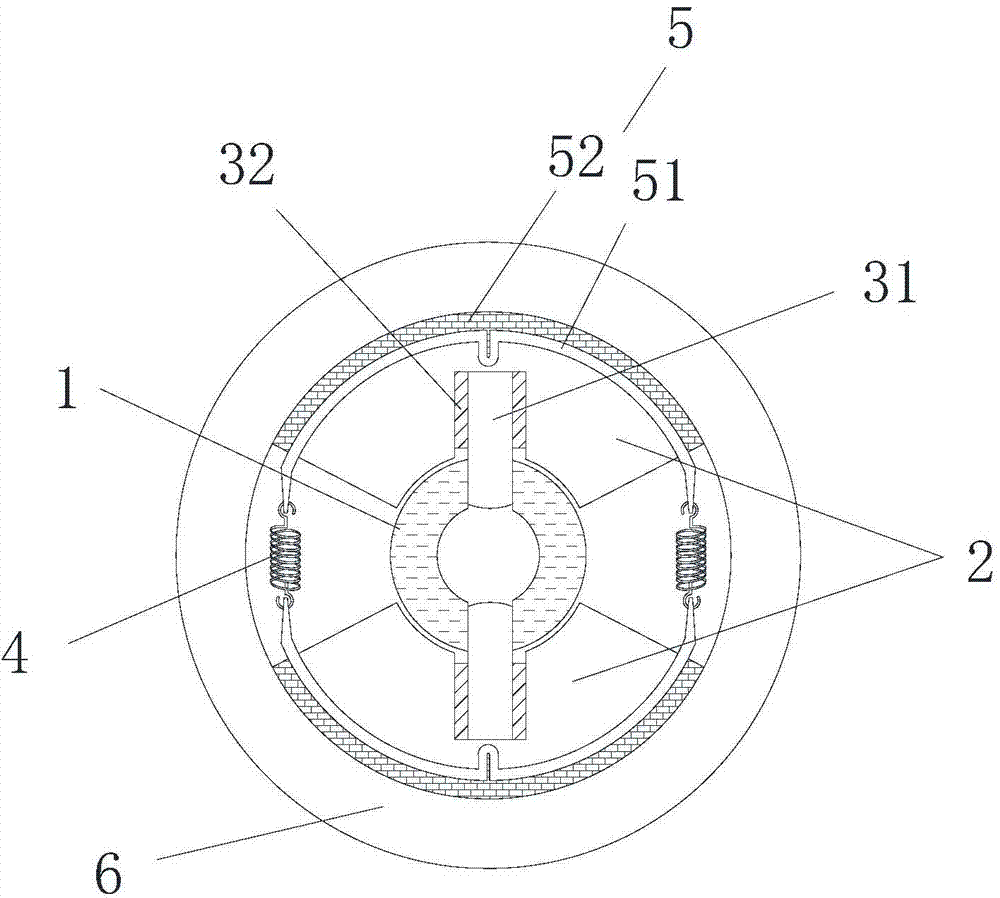

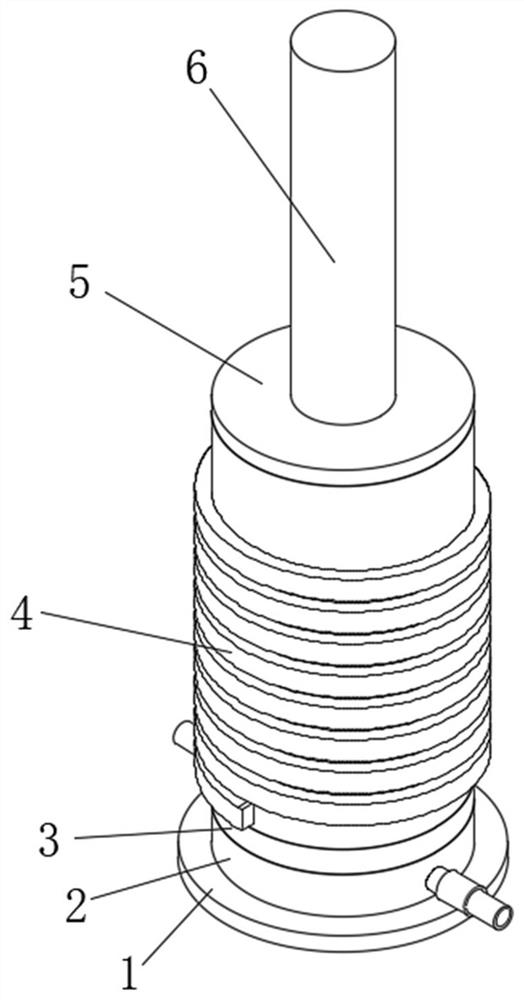

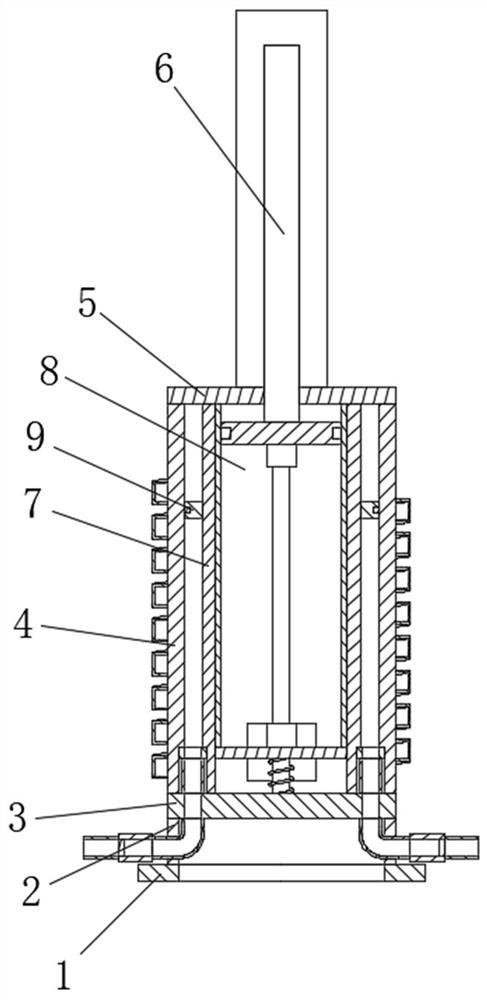

Clutch

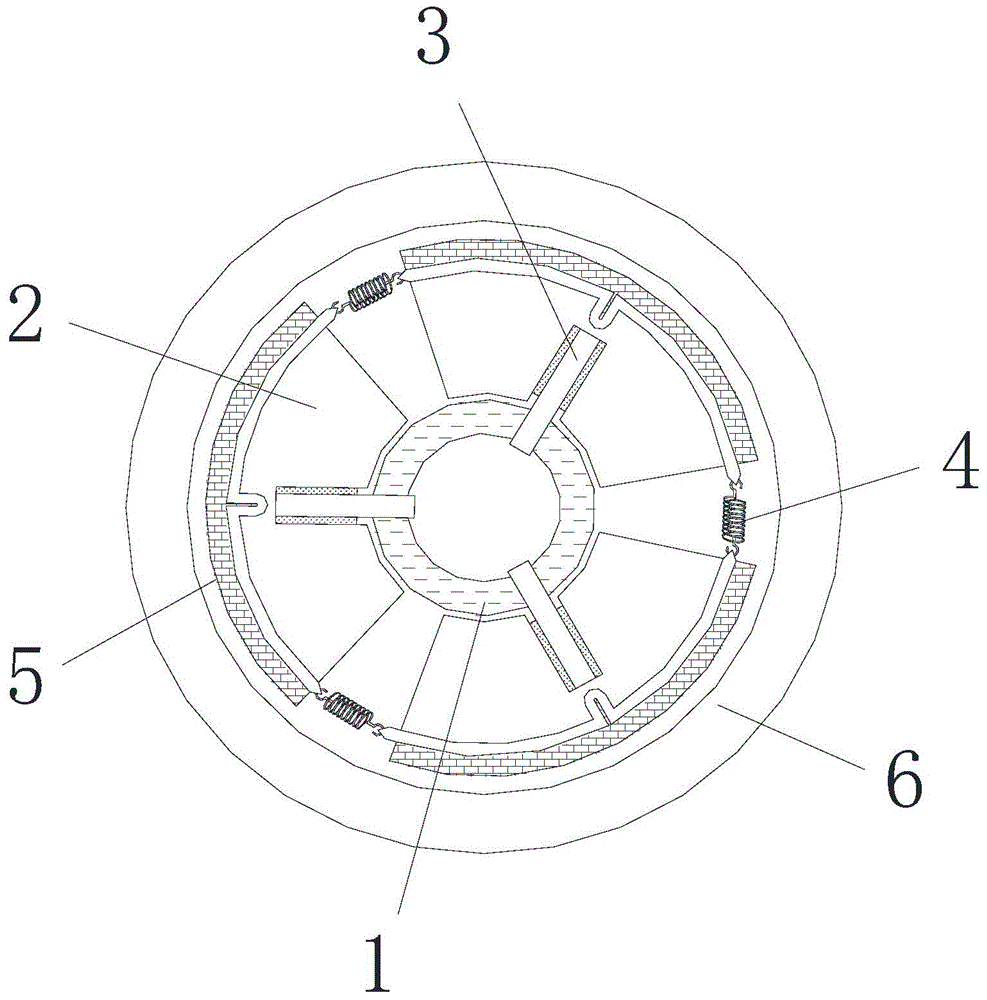

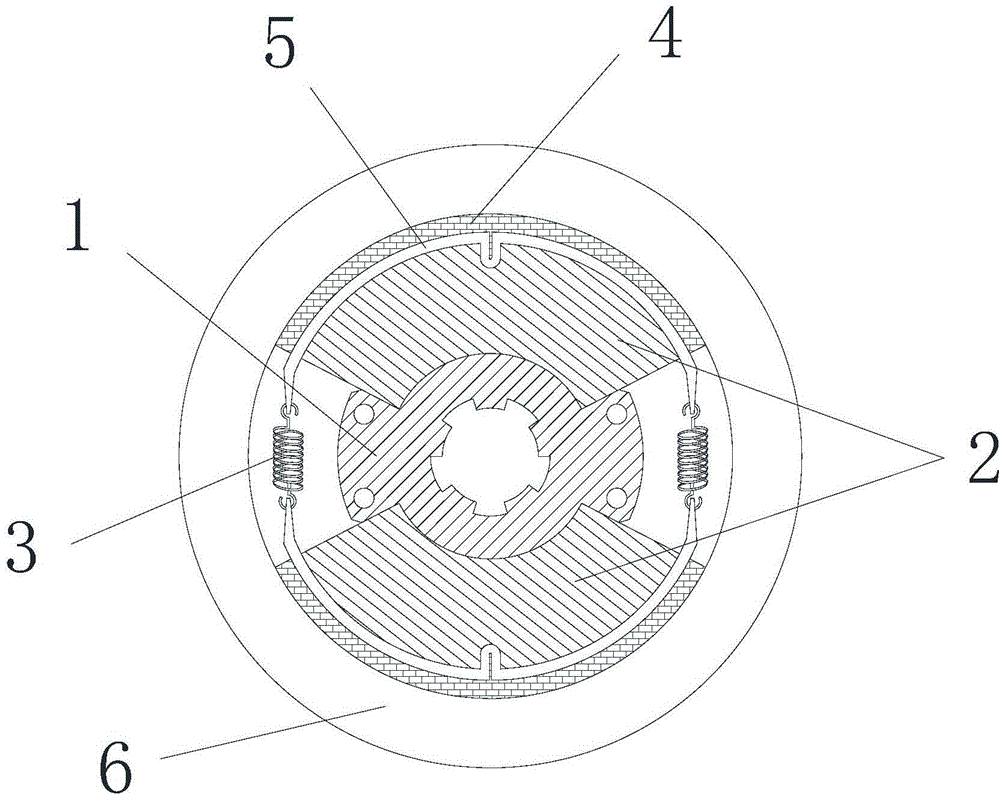

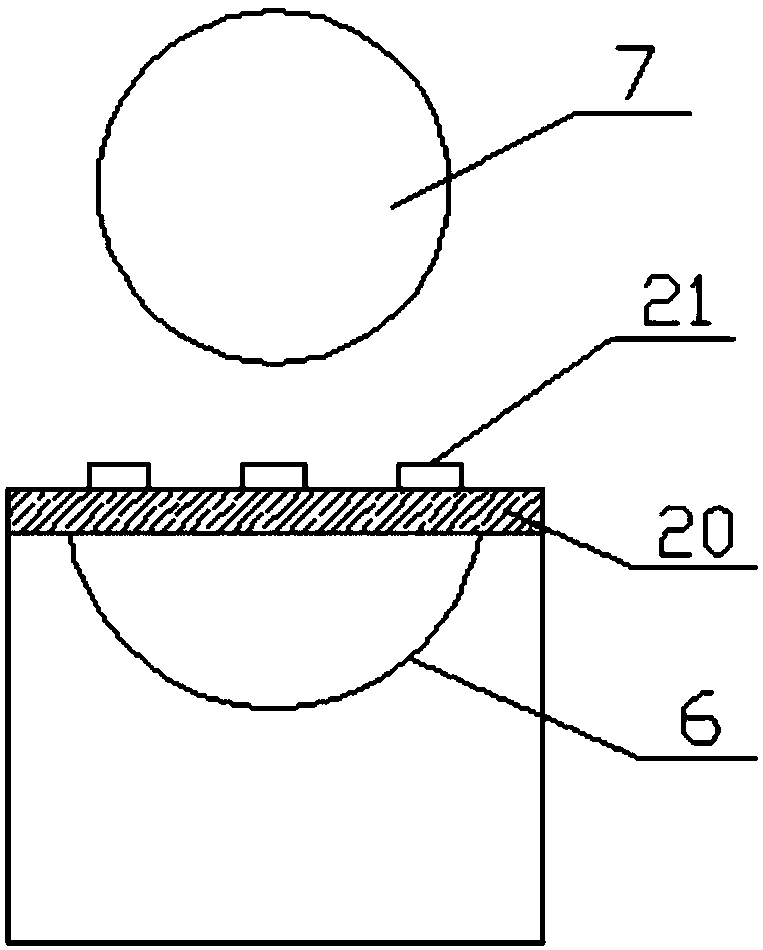

The invention discloses a clutch. The clutch comprises a clutch cover (6), a hub (1) and two fly wheels (2), wherein the hub (1) and the clutch cover (6) are coaxially arranged, the hub (1) is rotationally arranged in the clutch cover (6), and the fly wheels (2) are fitted to the outer circumference surface of the hub (1) at intervals along the circumference direction of the hub (1) and can rotate along with the hub (1). The fly wheels (2) stay still relative to the circumferential position of the hub (1) and can be adjusted relative to the radial position of the hub (1), friction plates (5) are fixedly connected on the outer circumference of the fly wheels (2), and the outer circumferences of the friction plates (5) contact with or are separated from the inner circumference of the clutch cover (6). The clutch is simple in structure and convenient to connect and disconnect.

Owner:芜湖市中亚汽车制动元件有限公司

Message forwarding method and device

InactiveCN107689915AAchieve the purpose of combiningData switching networksDistributed computingMessage forwarding

The invention provides a message forwarding method and device. The method comprises the steps that a first node receives a to-be-forwarded message, wherein a destination address of the message is a second node; the first node searches a target topology corresponding to the message from pre-generated topologies, wherein the pre-generated topologies comprise a first topology and a second topology generated according to a maximum redundant tree MRT algorithm, and a third topology obtained according to a shortest path first SPF algorithm, and the first topology, the second topology and the third topology are different; and the first node searches a next hop node for forwarding the message to the second node from the target topology and forwards the message to the next hop node. Through application of the method and the device, the purpose of combining a segment routing network and an MTR function is achieved.

Owner:ZTE CORP

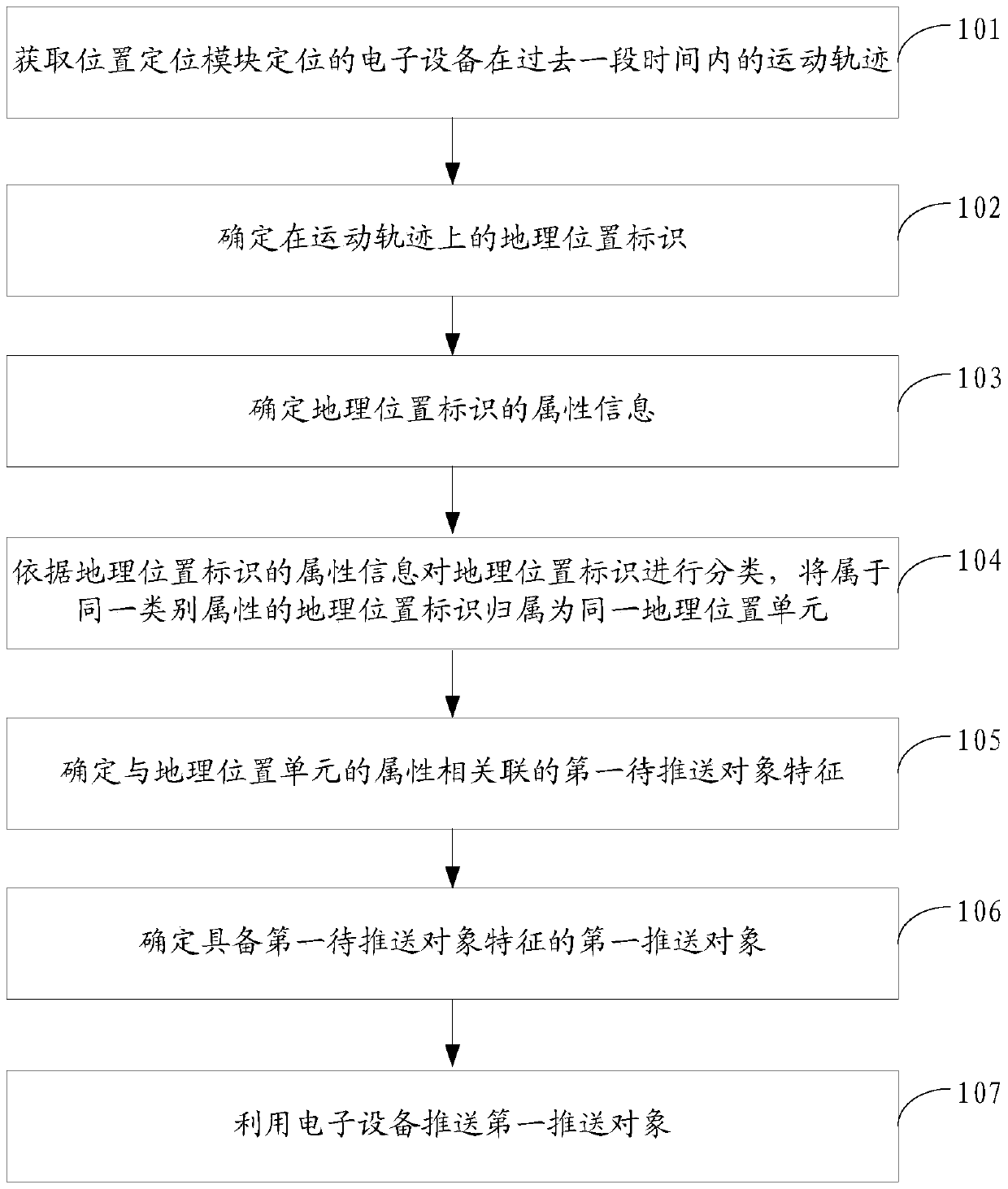

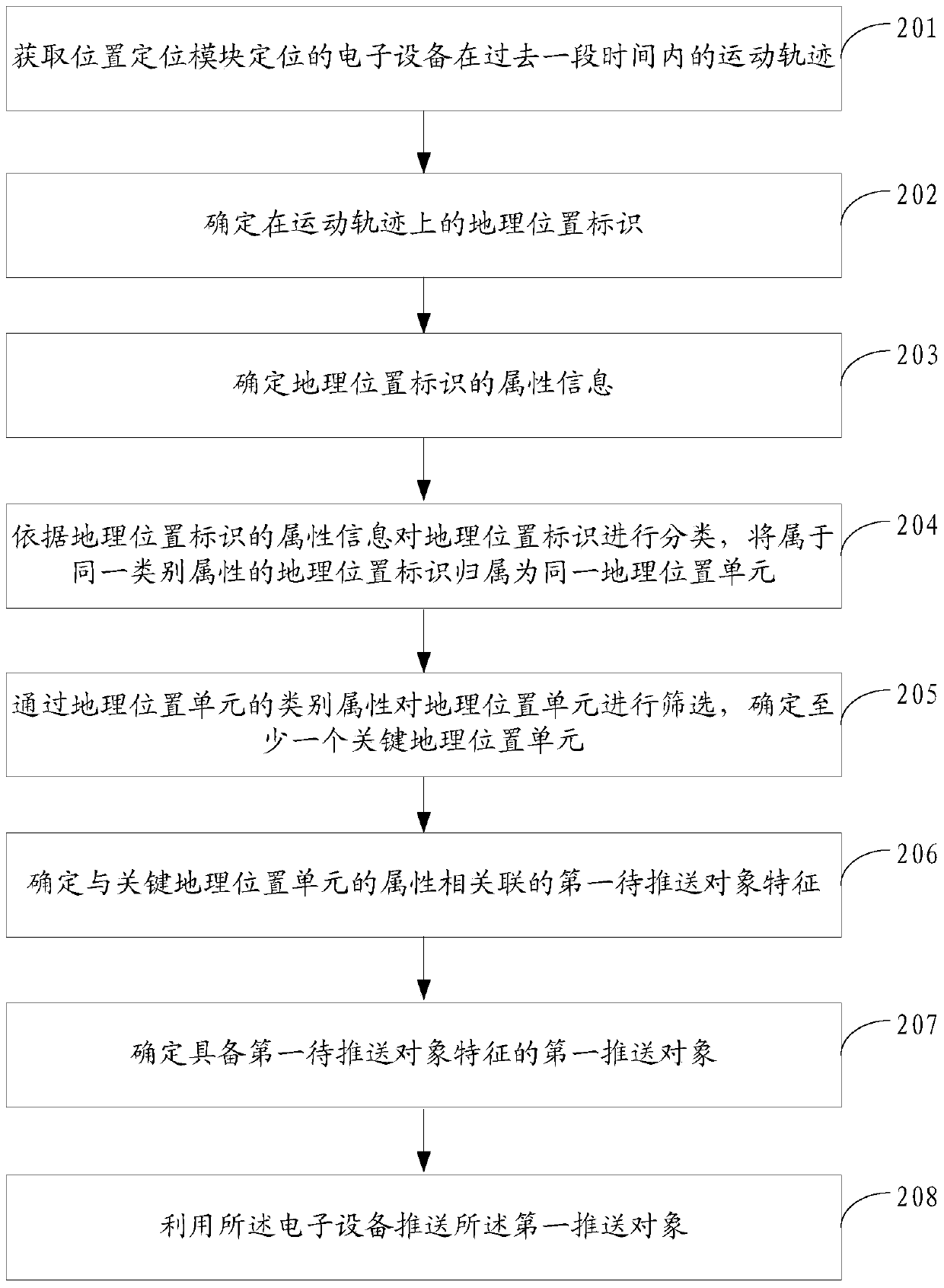

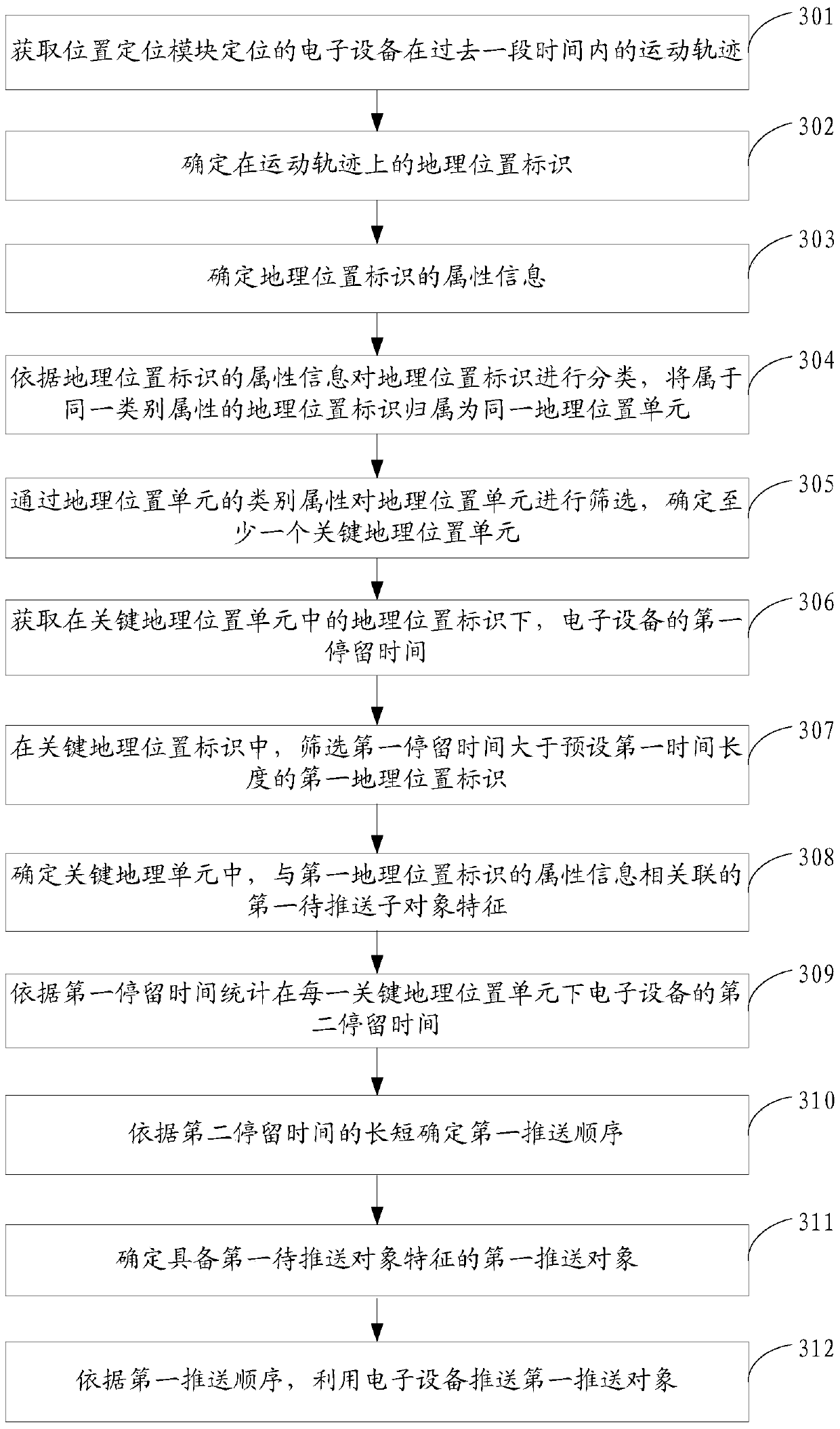

Method and device for processing information

ActiveCN104199936AAchieve the purpose of combiningSpecial data processing applicationsGeolocationComputer vision

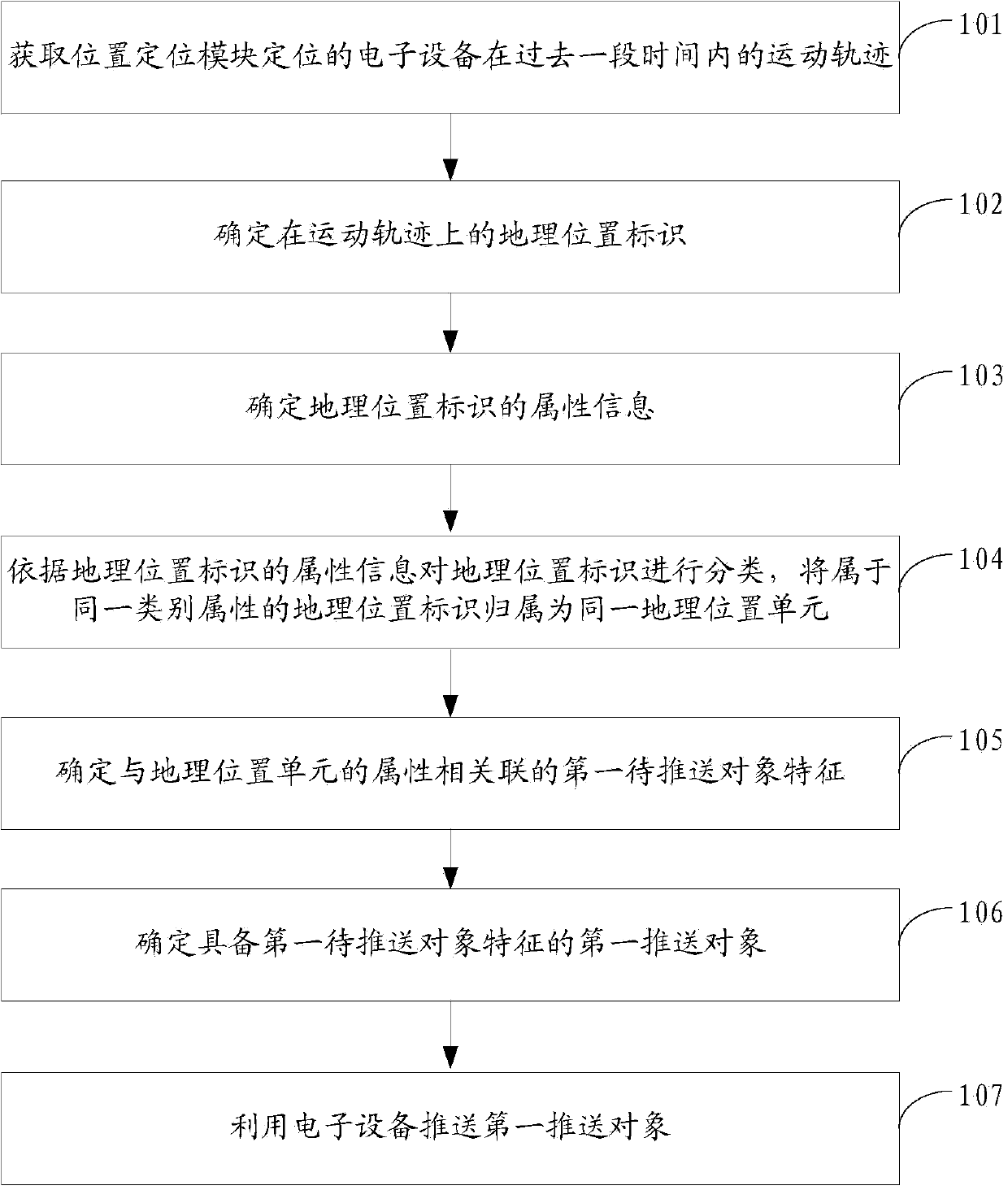

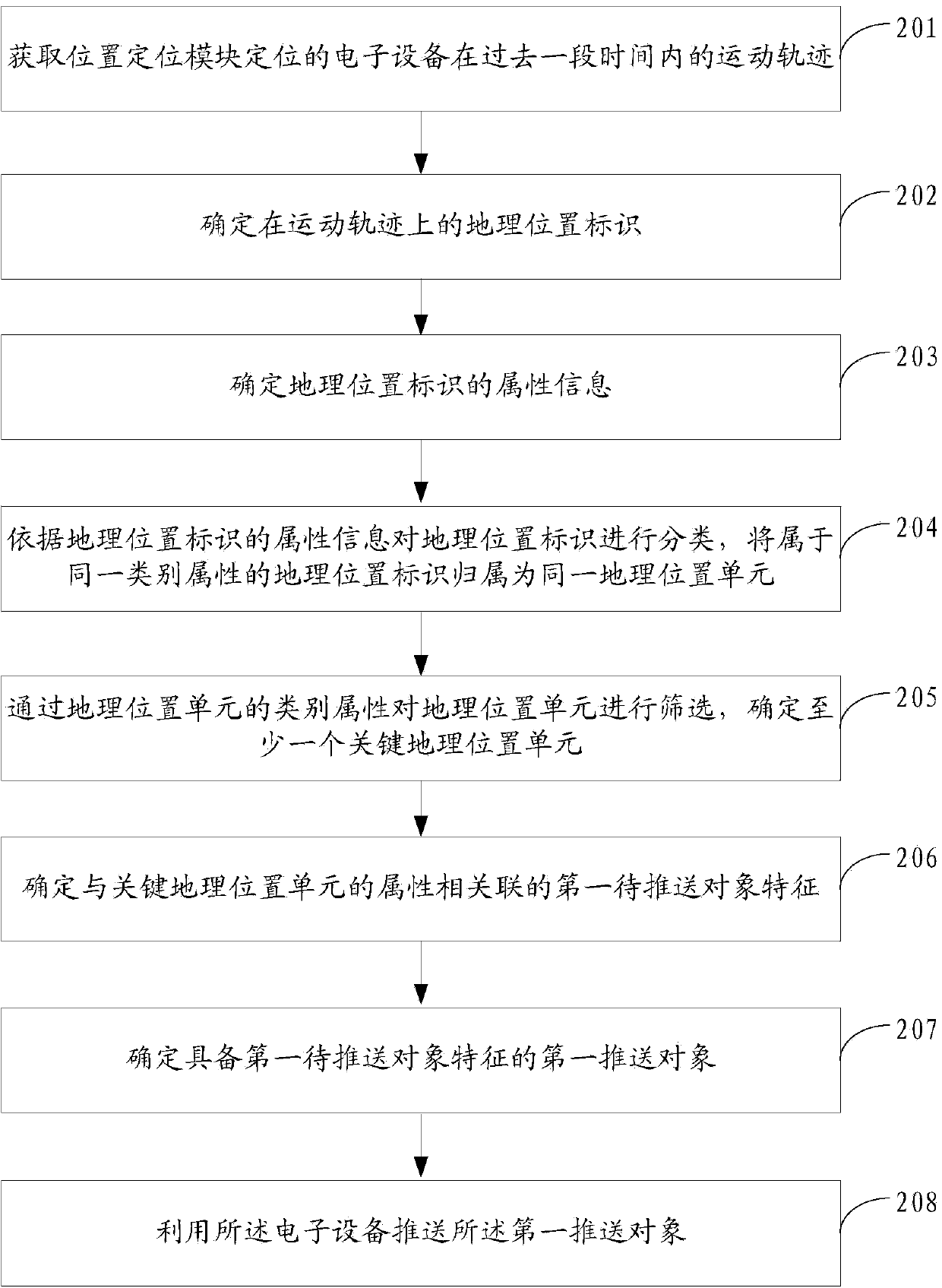

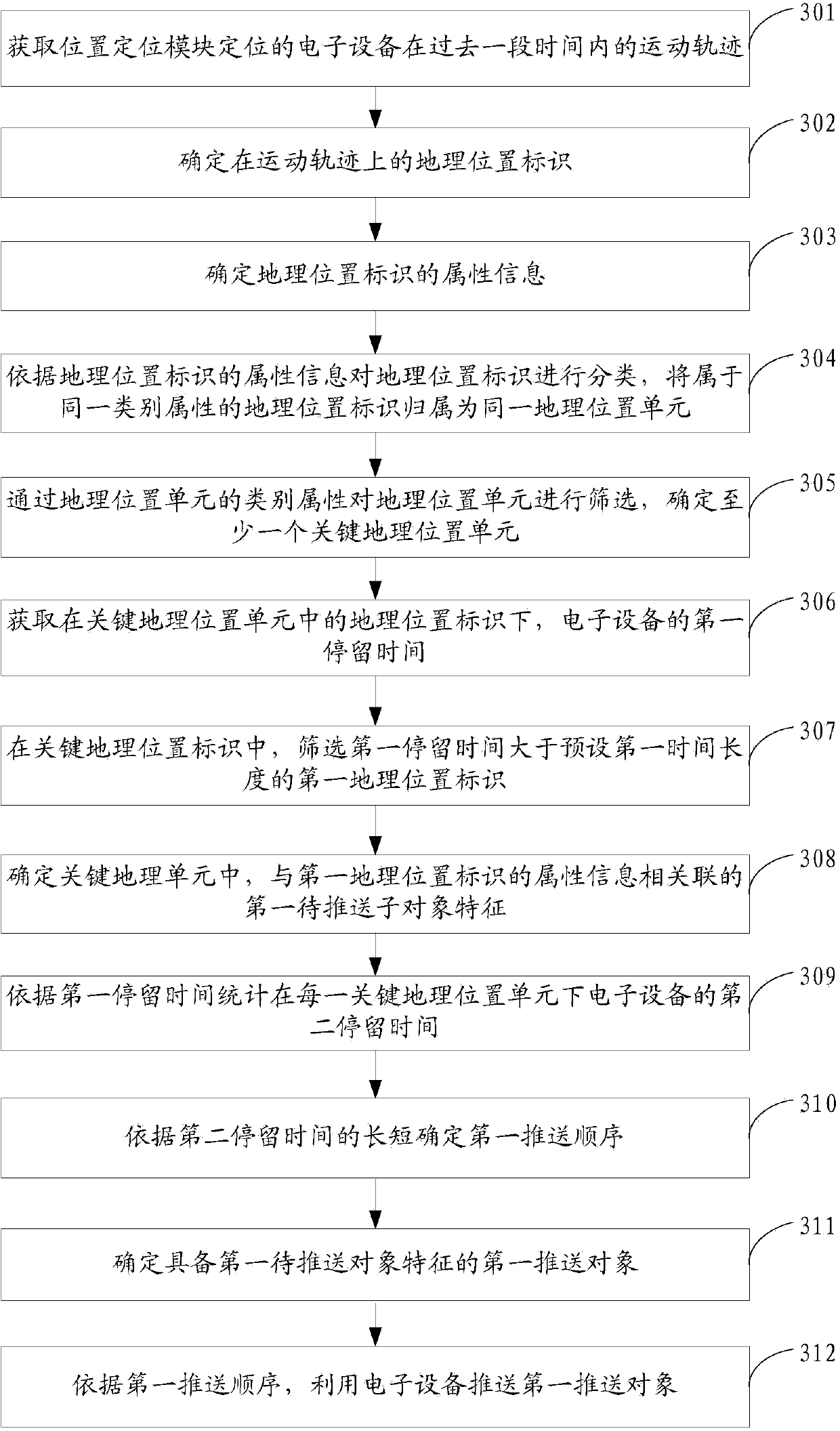

The invention discloses a method and device for processing information. The method and device are applied in an electronic device. The electronic device is provided with a position positioning module used for positioning the movement track of the electronic device. The method comprises the steps that the movement track, positioned through the position positioning module, of the electronic device for some time past is acquired, geographic position marks on the movement track are determined, the attribution information of the geographic position marks is determined, the geographic position marks are classified according to the attribution information of the geographic position marks, the geographic position marks belonging to one type are allocated to the same geographic position unit, first to-be-pushed object features related to the attribution of the geographic position units are determined, a first push object with the first to-be-pushed object features is determined, and the first push object is pushed through the electronic device. By means of the method and device, the purpose of combining the first push object with activity behaviors of a user in reality is achieved.

Owner:LENOVO (BEIJING) LTD

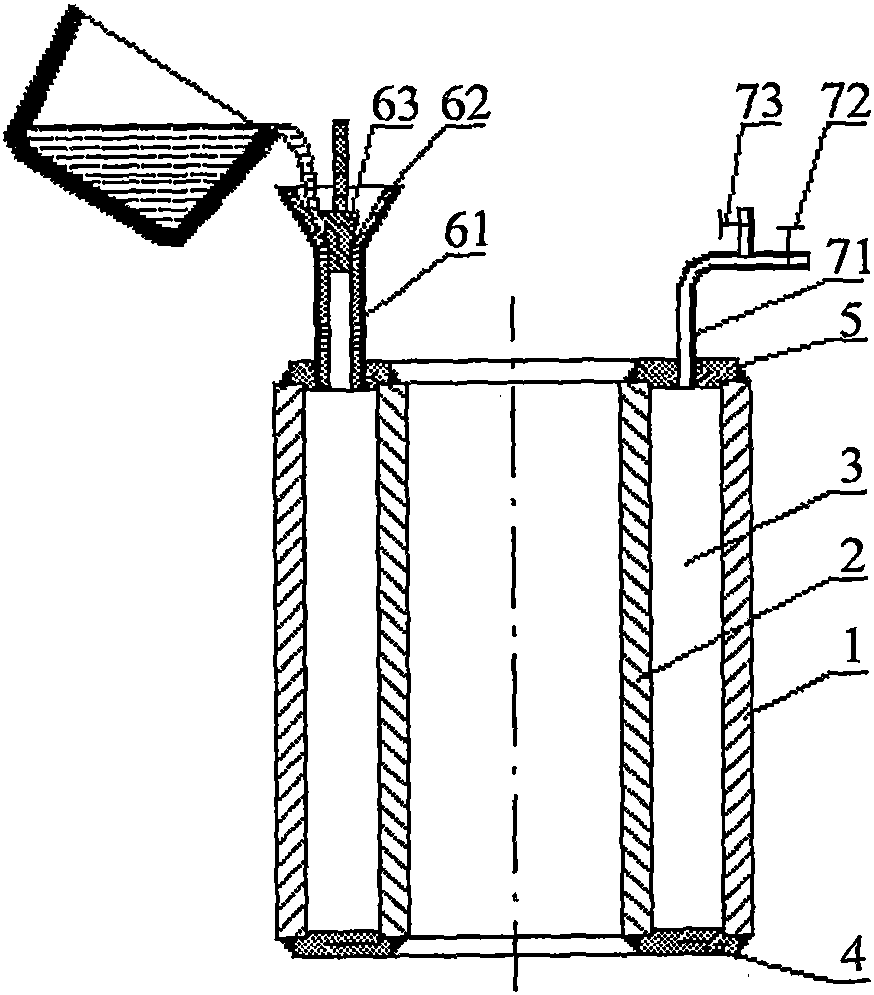

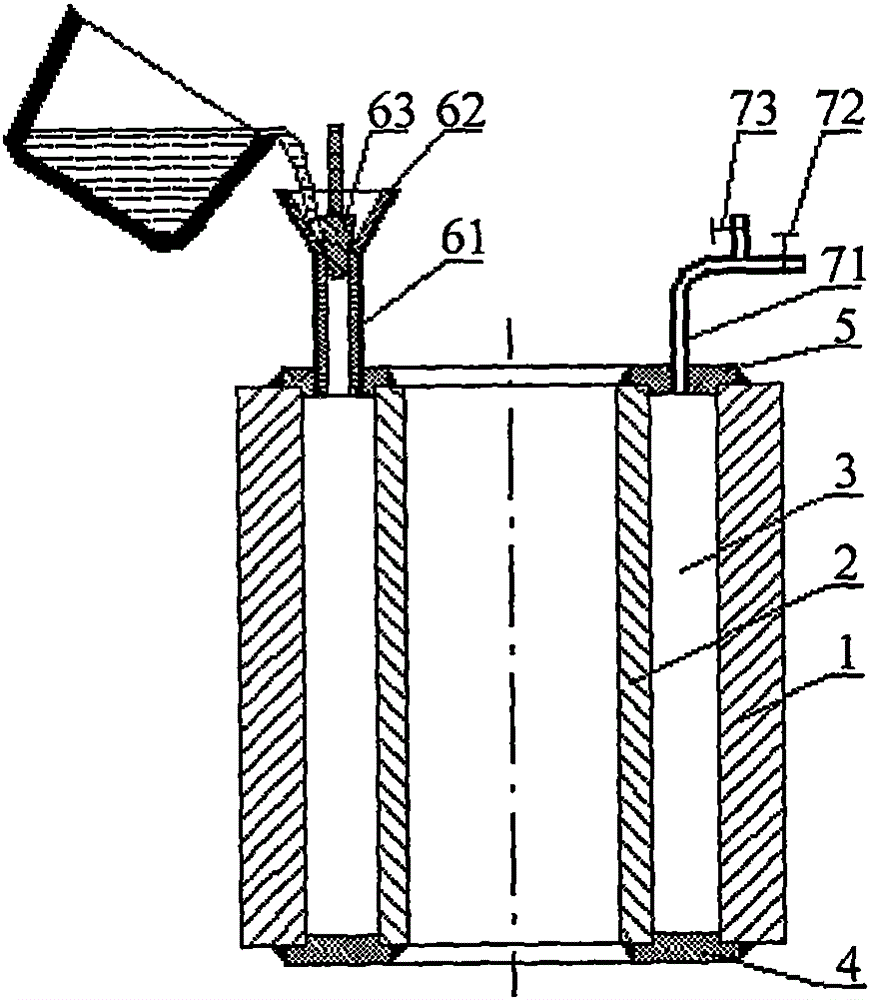

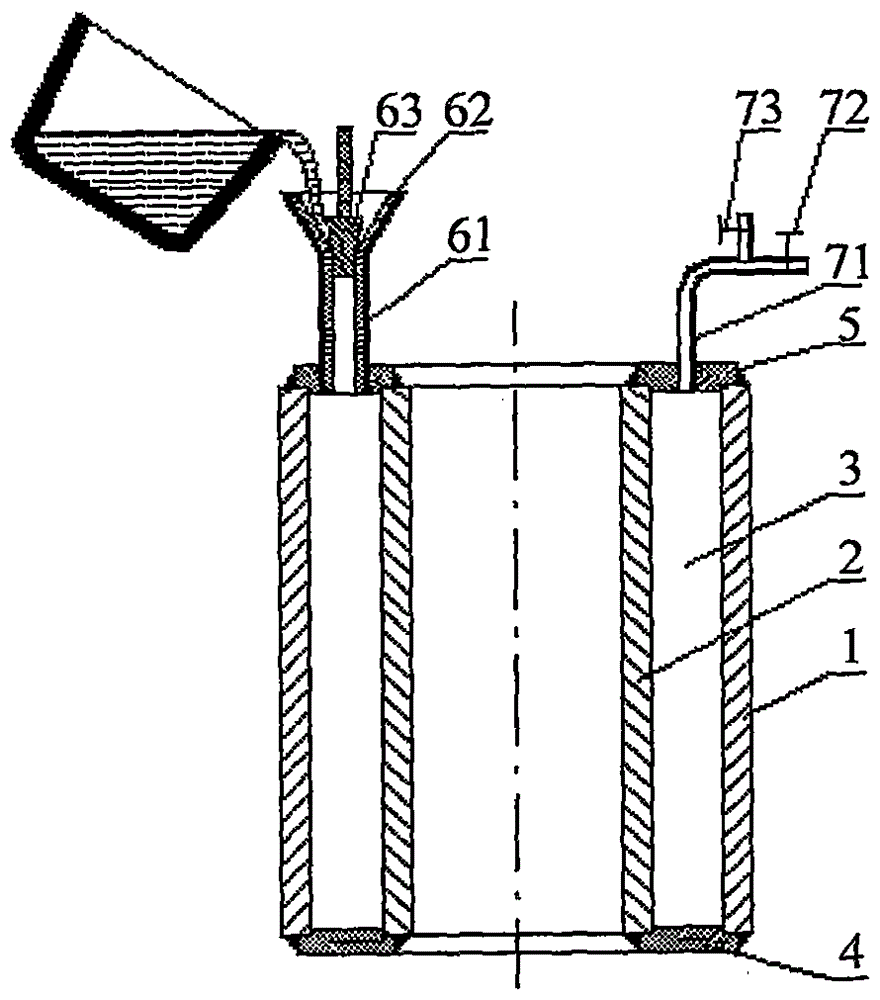

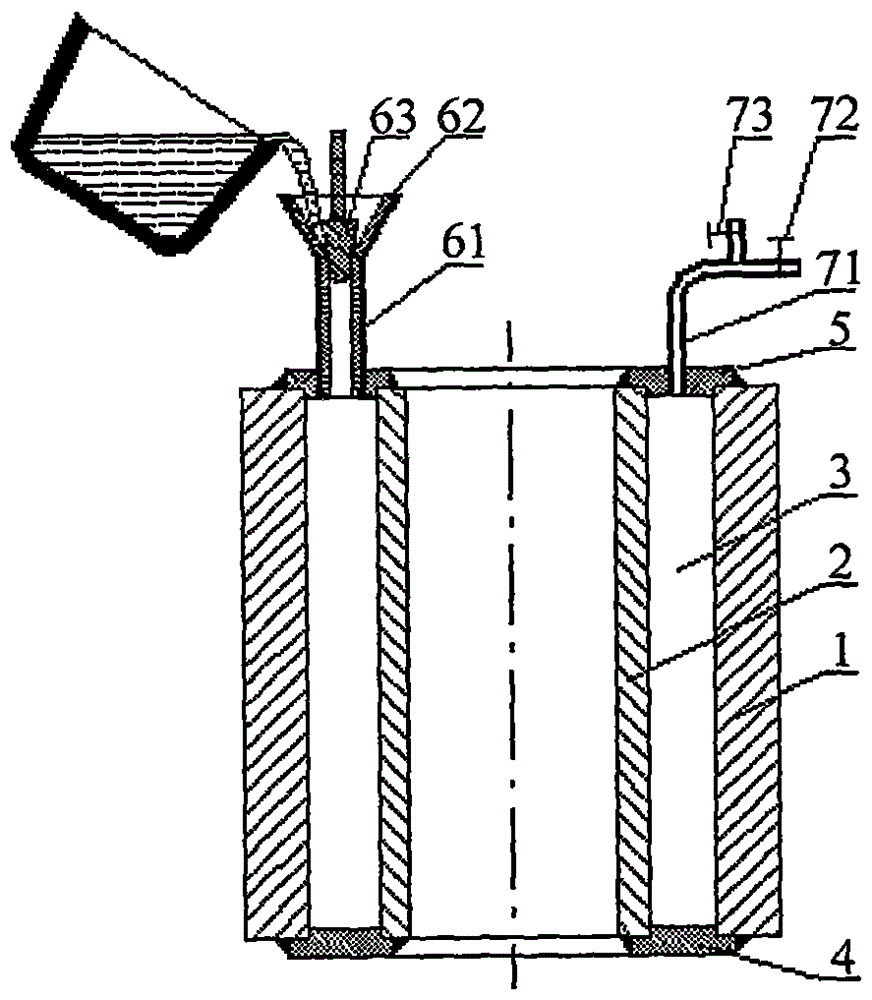

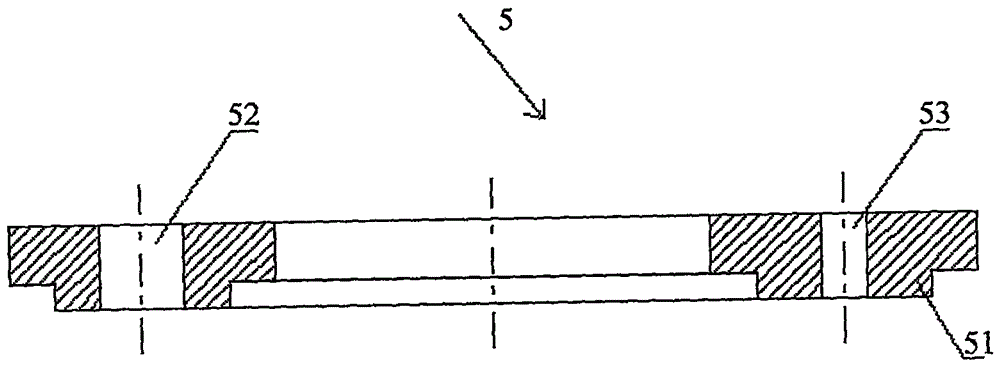

Preparation method of double-layer or multi-layer metal composite pipe blank

ActiveCN105170947AAbundant sources of raw materialsImprove the bonding strength of the interfacePre treatmentLiquid phase

The invention provides a preparation method of a double-layer or multi-layer metal composite pipe blank. The preparation method comprises the steps that the upper ends of a pretreated inner metal pipe and a pretreated outer metal pipe and the lower ends of the pretreated inner metal pipe and the pretreated outer metal pipe are fixed to circular seams of an upper sealing flange and a lower sealing flange respectively, and a casting cavity is formed between the inner metal pipe and the outer metal pipe; a casting device and an air inlet and exhaust device are arranged through the upper sealing flange to carry out exhausting and preheating on the casting cavity; metal melt is poured into the casting cavity to form a composite pipe blank; and the composite pipe blank is cooled and finished, and the excellent composite pipe blank is obtained. According to the method, the double-layer or multi-layer metal composite pipe blank which cannot be produced through existing methods and is provided with a solid-liquid phase metallurgical bonding interface can be prepared, and the technological method has the beneficial effects of being simple in technology, low in manufacturing cost, good in interface bonding quality of the composite pipe blank, high in yield, capable of being used for preparing various double-layer or multi-layer metal composite pipe blanks and the like.

Owner:安徽巨鼎高分子科技股份有限公司

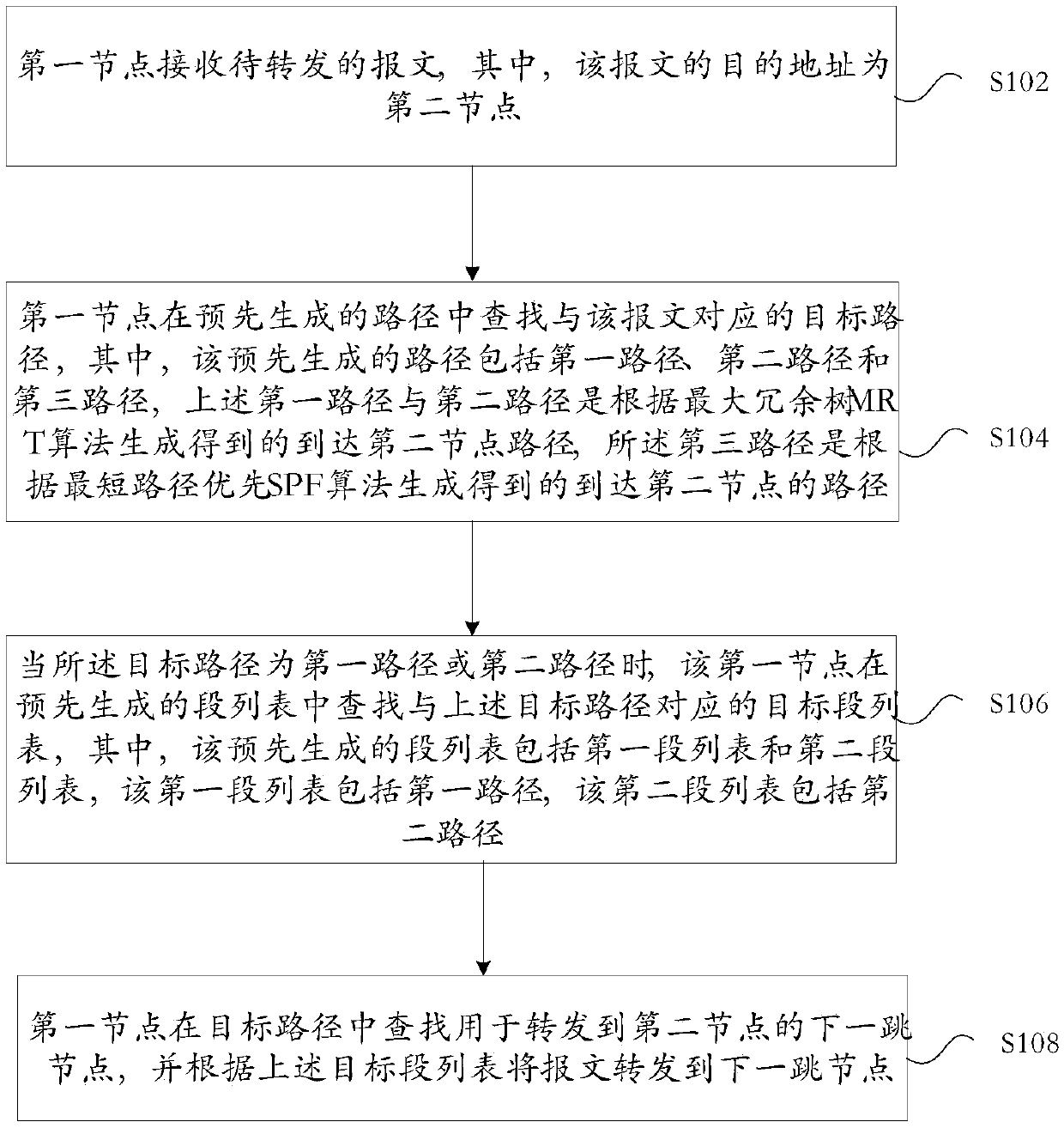

Packet forwarding method and device

InactiveCN107666436AAchieve the purpose of combiningData switching networksDistributed computingPacket forwarding

The present invention provides a package forwarding method and device. The method comprises: receiving, a packet to be forwarded by a first node, wherein a destination address of the packet is a second node; searching a target path corresponding to the packet in a pre-generated path by the first node, wherein the pre-generated path includes a first path, a second path and a third path, the first path and the second path are paths that reach the second node and are generated according to the MRT algorithm, and the third path is a path that reaches the second node that is generated according tothe SPF algorithm; and when the target path is the first path or the second path, searching a target segment list corresponding to the target path in a pre-generated segment list by the first node, wherein the first node searches a next hop node for forwarding to the second node in the target path and forwards the packet to the next hop node according to the target segment list. The purpose of combining a segment routing network and an MTR function is realized.

Owner:ZTE CORP

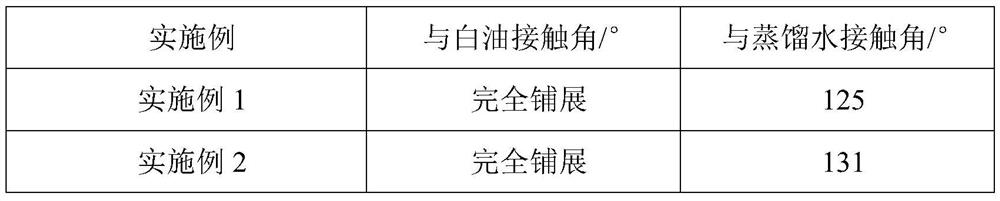

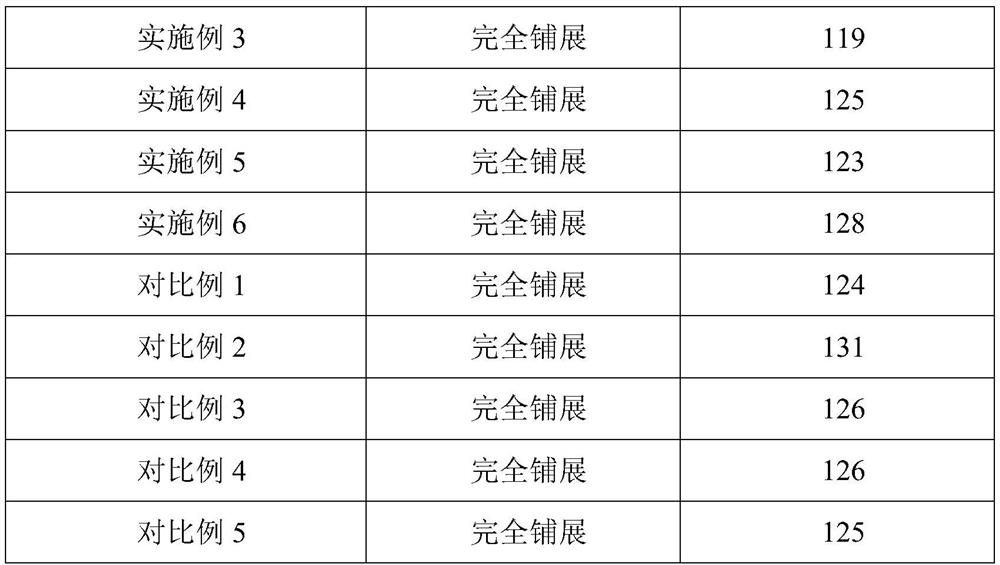

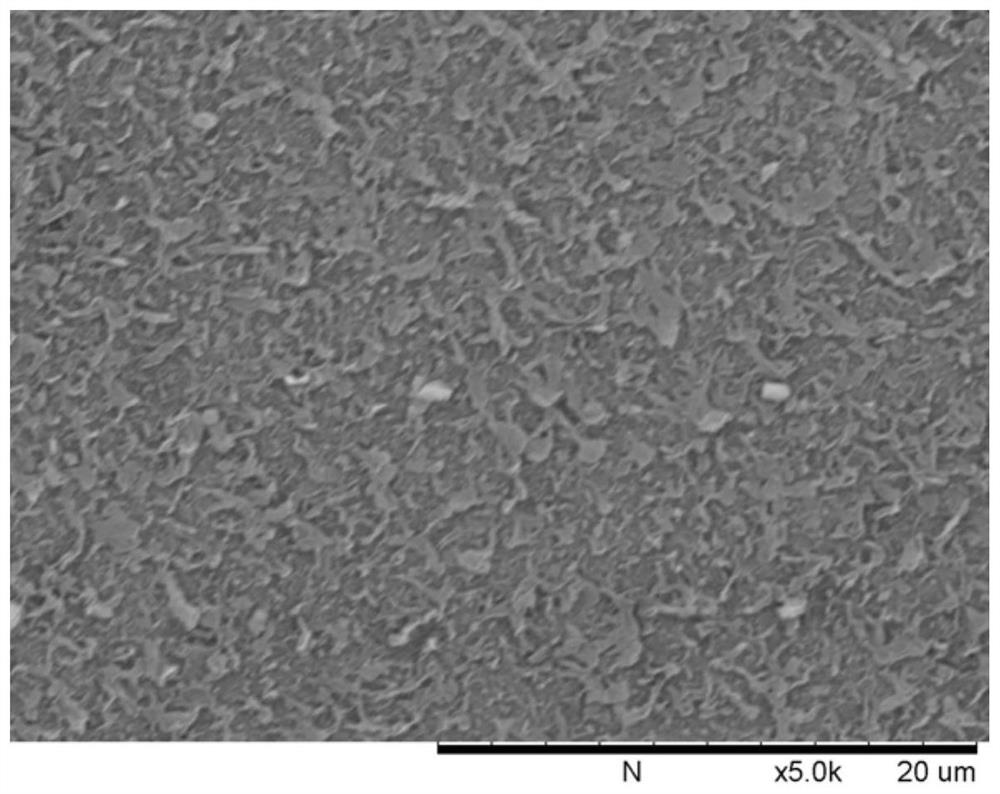

Inorganic/polymer composite plugging agent for ultrahigh-temperature-resistant oil-based drilling fluid, and preparation method and application thereof

ActiveCN112011315AImprove seal strengthAct as a bridgeDrilling compositionAcrylic resinPolymer composites

The invention provides an inorganic / polymer composite plugging agent for an ultrahigh-temperature-resistant oil-based drilling fluid, and a preparation method and application thereof. The plugging agent has a core-shell structure, the core is silane coupling agent modified quartz powder, and the shell is an acrylic resin material; the acrylic resin material is prepared from styrene, a vinyl-containing organic silicon monomer and a high-temperature-resistant monomer; and the high-temperature-resistant monomer comprises an oil-soluble hard monomer and an oil-soluble soft monomer. The invention also provides a preparation method of the plugging agent. The plugging agent disclosed by the invention is high in lipophilicity and has relatively good dispersity in an oil-based system; and the plugging agent has the advantages of good high-temperature resistance, good adaptability, good adsorption performance and excellent plugging capability.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

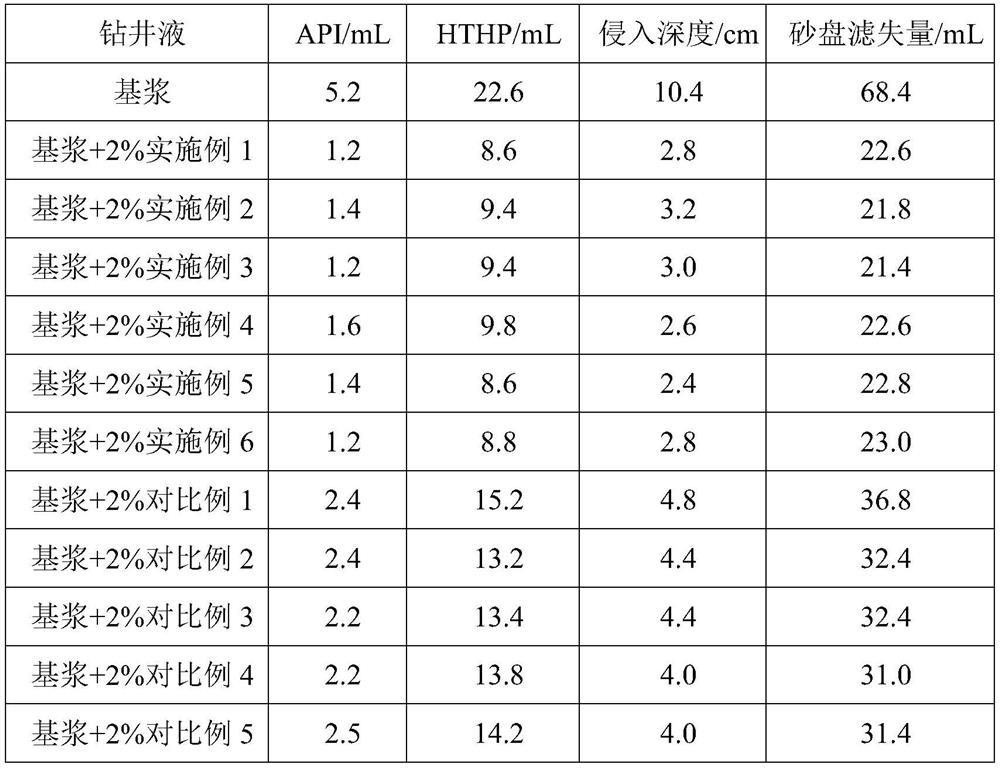

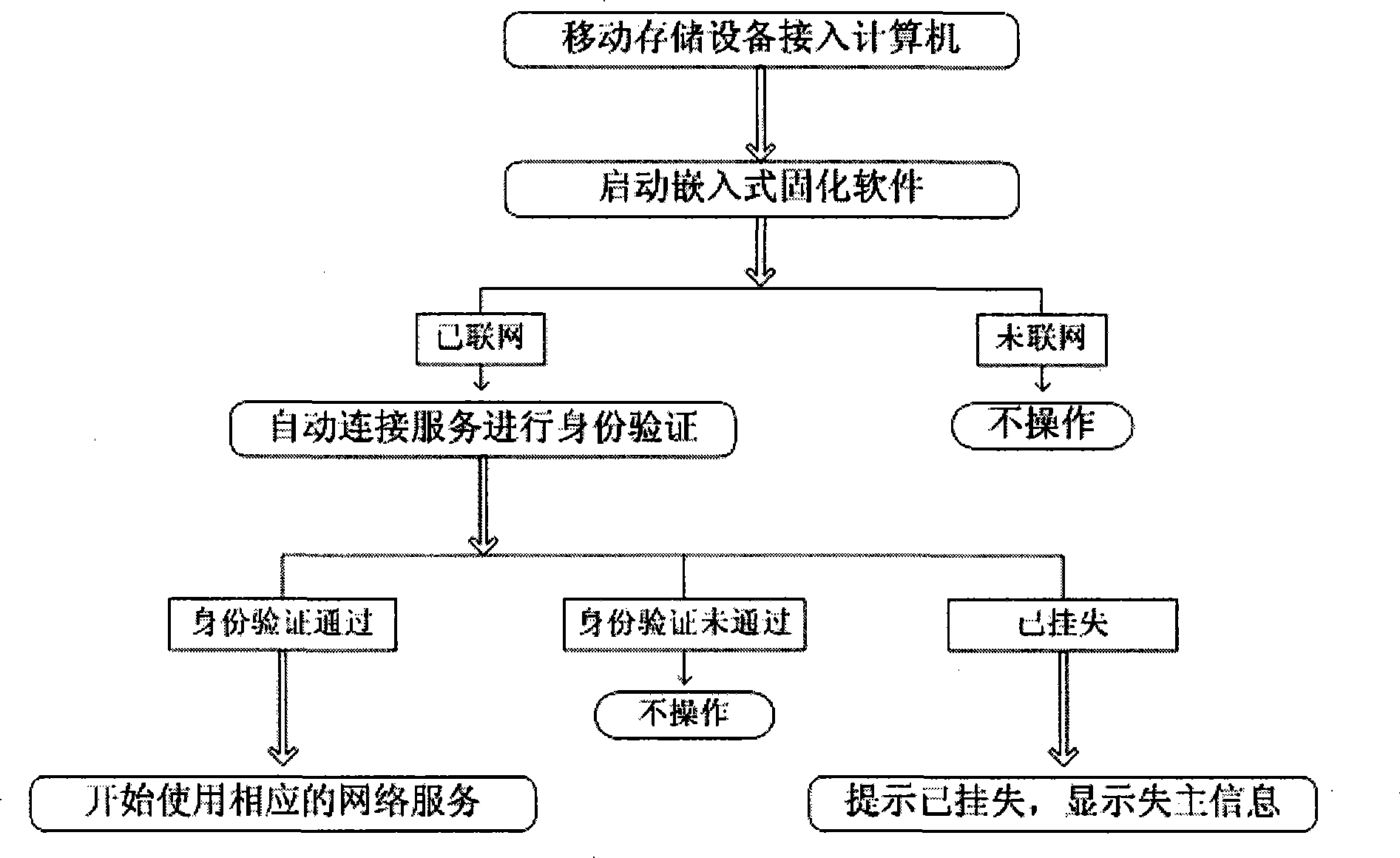

Method for combining mobile memory apparatus with network verification

InactiveCN101252433ARealize soft expansionEnsure safetyUser identity/authority verificationSpecial data processing applicationsInformatizationThe Internet

Disclosed is a method for combing a mobile storage device with network verification, relating to the mobile storage device network verification technique. The method is based on a mobile storage device, a computer and a network application server. The mobile storage device comprises a U disc, a mobile hard disk, as well as a mobile-phone, an MP3 and an MP4 which are provided with U-disc functions; the mobile storage device is connected with the computer; the computer is connected with the network application server through internet. In the method, an embedded fixed program is arranged in the mobile storage device; when the mobile storage device is connected with the computer, the fixed program sends the fixed massage to the network application server; the safety verification of the mobile storage device is done by the computer network; when the verification of the mobile storage device is passed, the various functions of a website can be operated. The method of the invention can realize corresponding network functions and reach the functions of soft expansion, internet site application, enterprise informatization application and multiple identification verification.

Owner:张晶

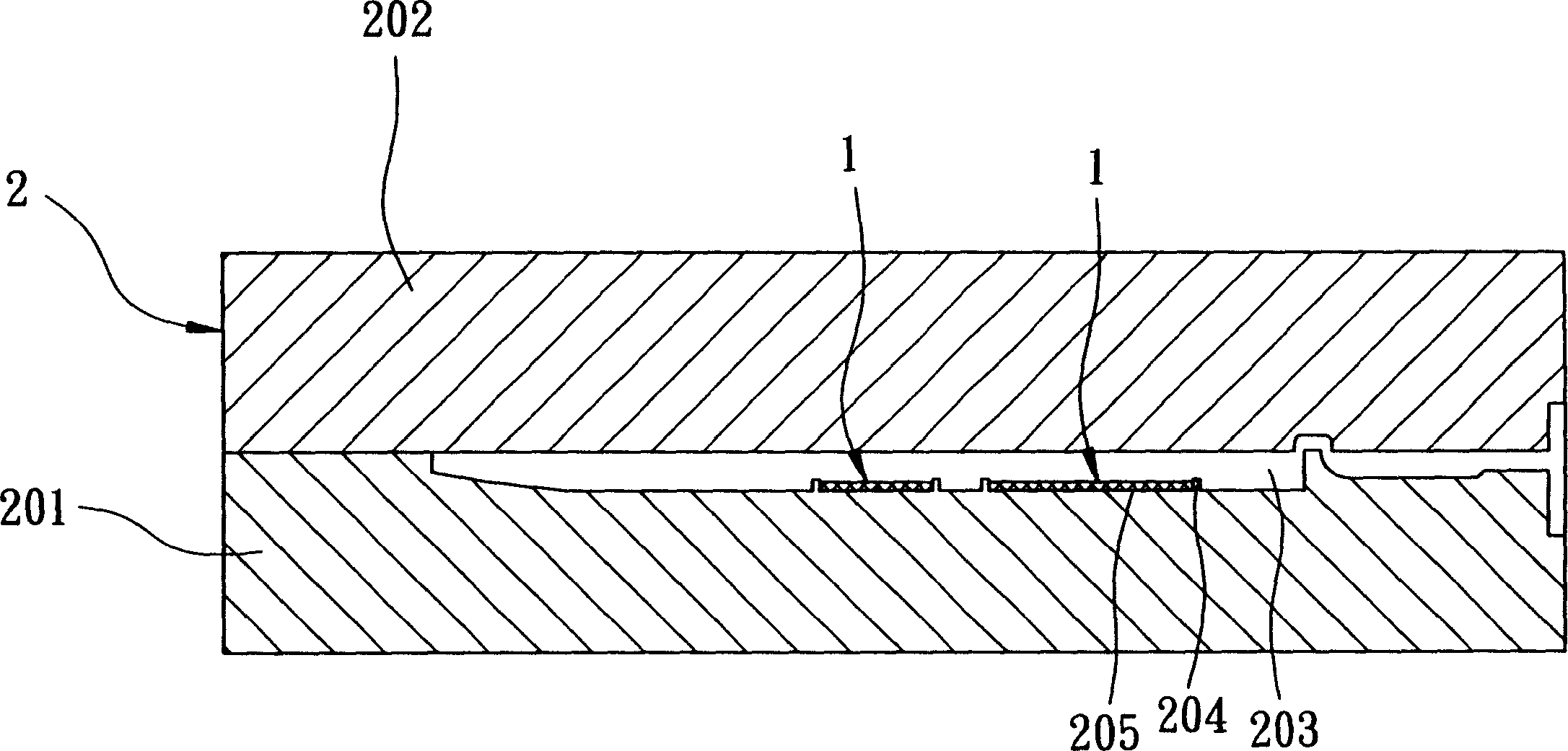

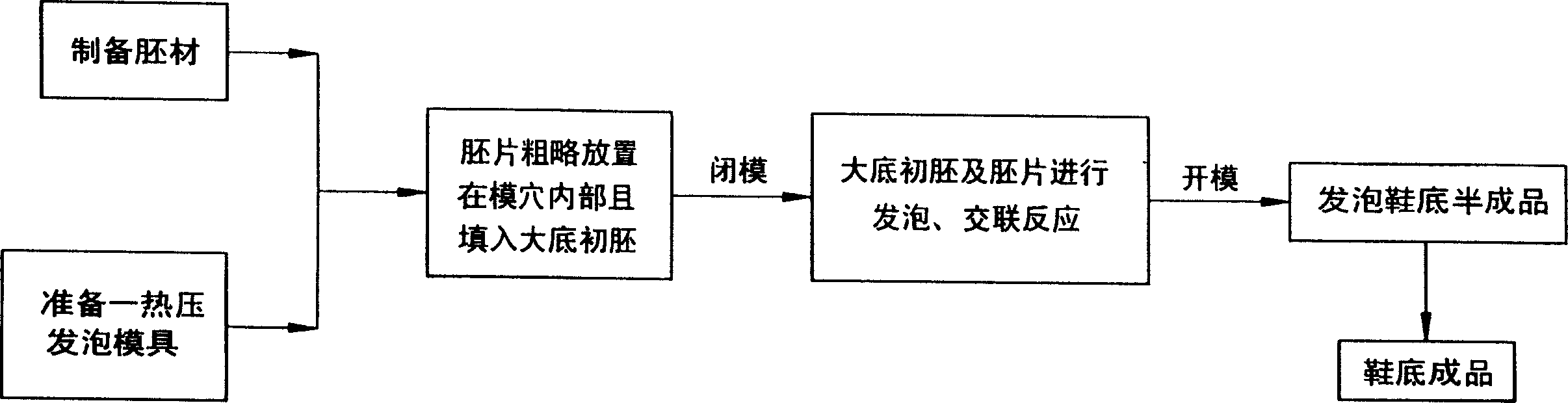

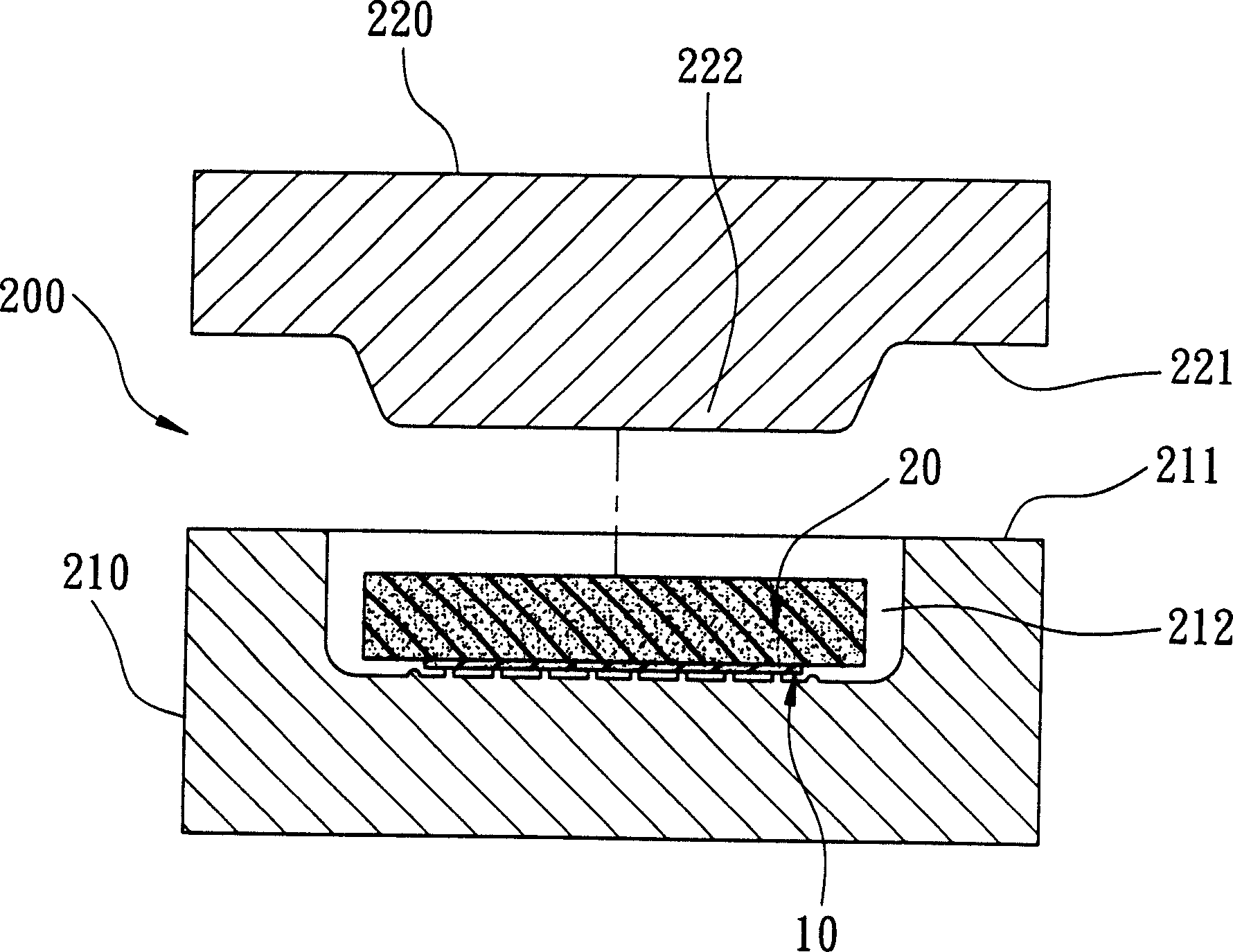

Molding method of foamed sole with concolorous, dissimilar properties wearable area

InactiveCN1628959AAchieve the purpose of combiningDomestic footwearForeign matterReaction temperature

This invention relates to a foam shoe sole shaping method with same color and foreign matter wearing area, which comprises the following steps: processing beforehand a hard and wearing embryo and preparing heat pressure foam module; putting the embryo roughly into one module cave and filling the large base initial embryo with same color and different matter into the module cave; the large base embryo and embryo pad trigger the foam and crossing reactions under the foam sustaining temperature; getting the product through module opening, cooling after the reactions.

Owner:刘坤钟

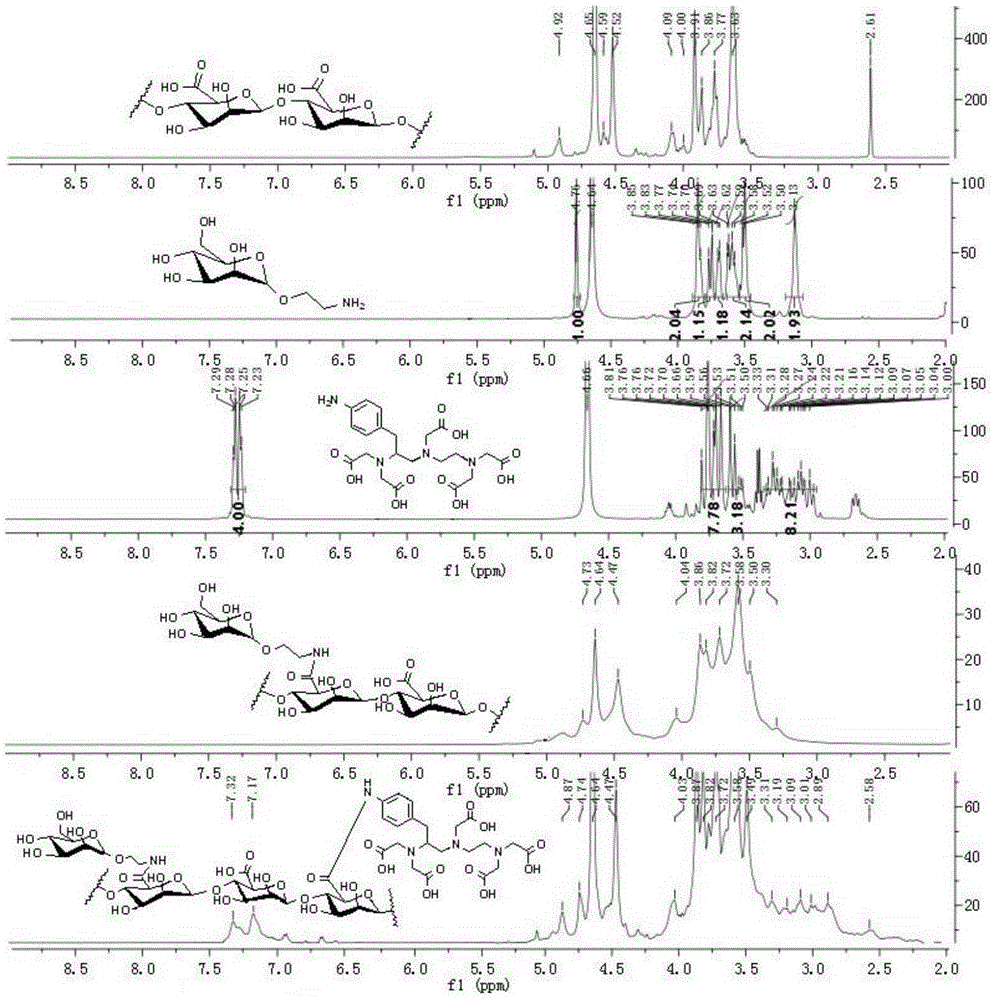

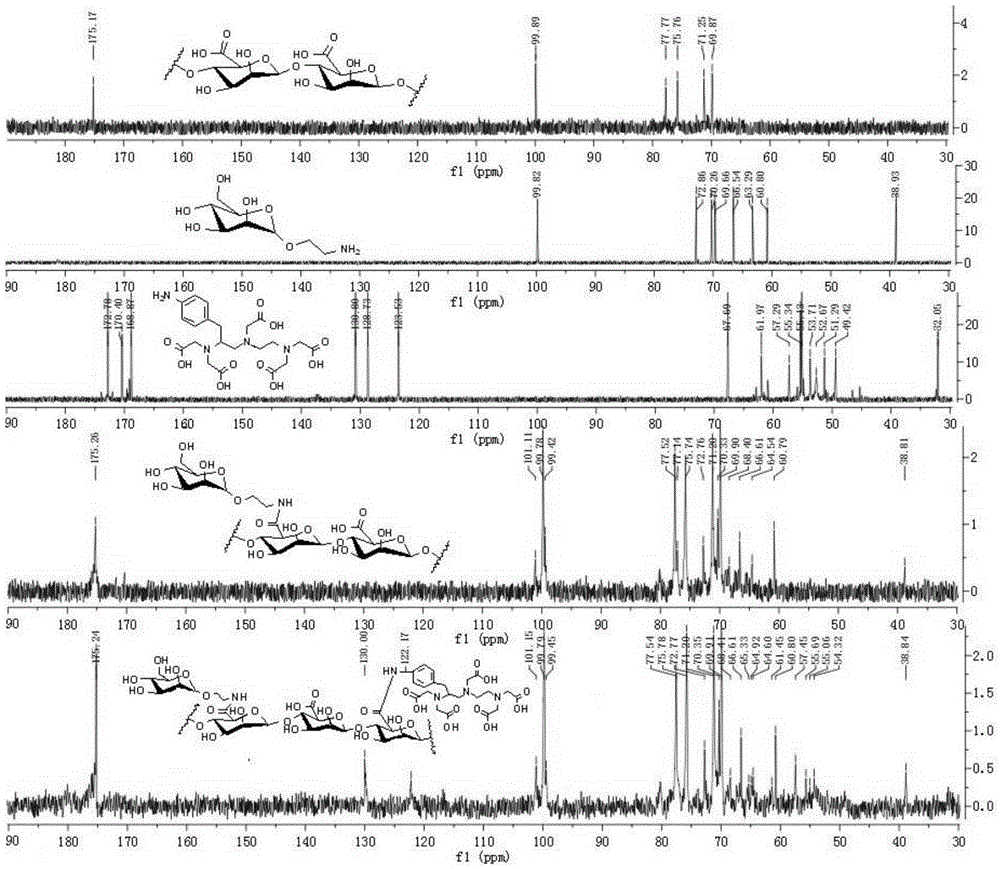

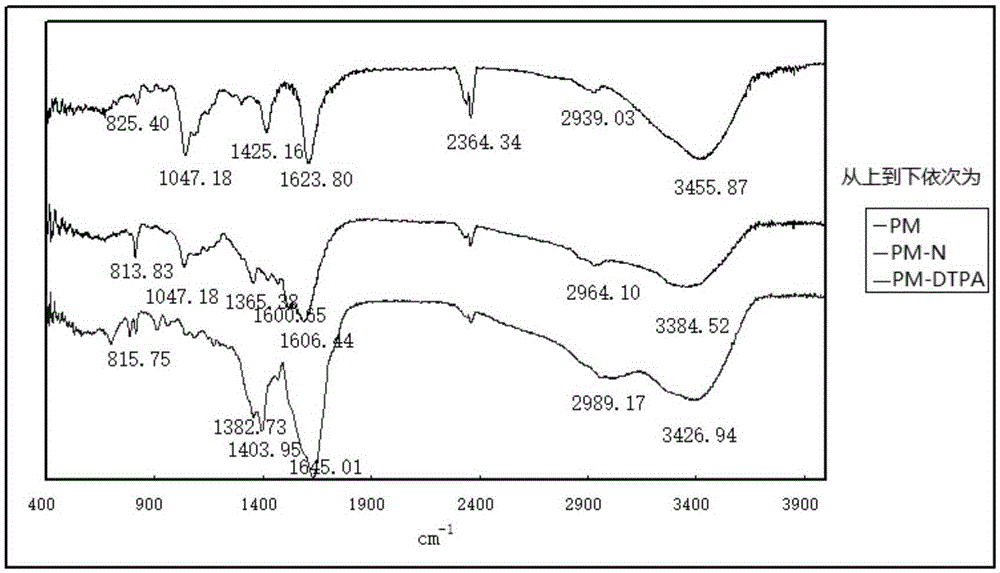

Lymph targeted nuclear magnetic resonance imaging contrast agent with brown algal polysaccharide serving as carrier and preparation method and application of lymph targeted nuclear magnetic resonance imaging contrast agent with brown algal polysaccharide serving as carrier

ActiveCN105343900AAchieve the purpose of combiningImprove bindingEmulsion deliveryIn-vivo testing preparationsLymphatic vesselLymphatic/immune

The invention relates to contrast agents for medical science, in particular to a lymph targeted nuclear magnetic resonance imaging contrast agent with brown algal polysaccharide serving as a carrier and a preparation method and application of the lymph targeted nuclear magnetic resonance imaging contrast agent with the brown algal polysaccharide serving as the carrier. The macromolecular contrast agent high in water solubility is prepared by taking the brown algal polysaccharide as the carrier, taking mannose or mannose derivatives as a mannose receptor MBP (mannose binding protein) recognition group and taking paramagnetic metal ion chelates as a nuclear magnetic resonance imaging group. Lymph tissue binding force is increased, and combination of the mannose or mannose derivative group introduced into the synthetic contrast agent with mannose receptors enriched in lymph tissues is realized. In addition, after hypodermic injection of the contrast agent, lymph vessels and lymph glands are clearly developed under scanning of a nuclear magnetic resonance equipment, lymph gland signal enhancement rate of one side, with the contrast agent injected, of an animal body is remarkably increased while enhancement time is remarkably prolonged, distinct drawing and precise positioning of the lymph glands and the lymph vessels are realized, and a great significance to examination and diagnosis of lymphatic diseases is achieved.

Owner:OCEAN UNIV OF CHINA

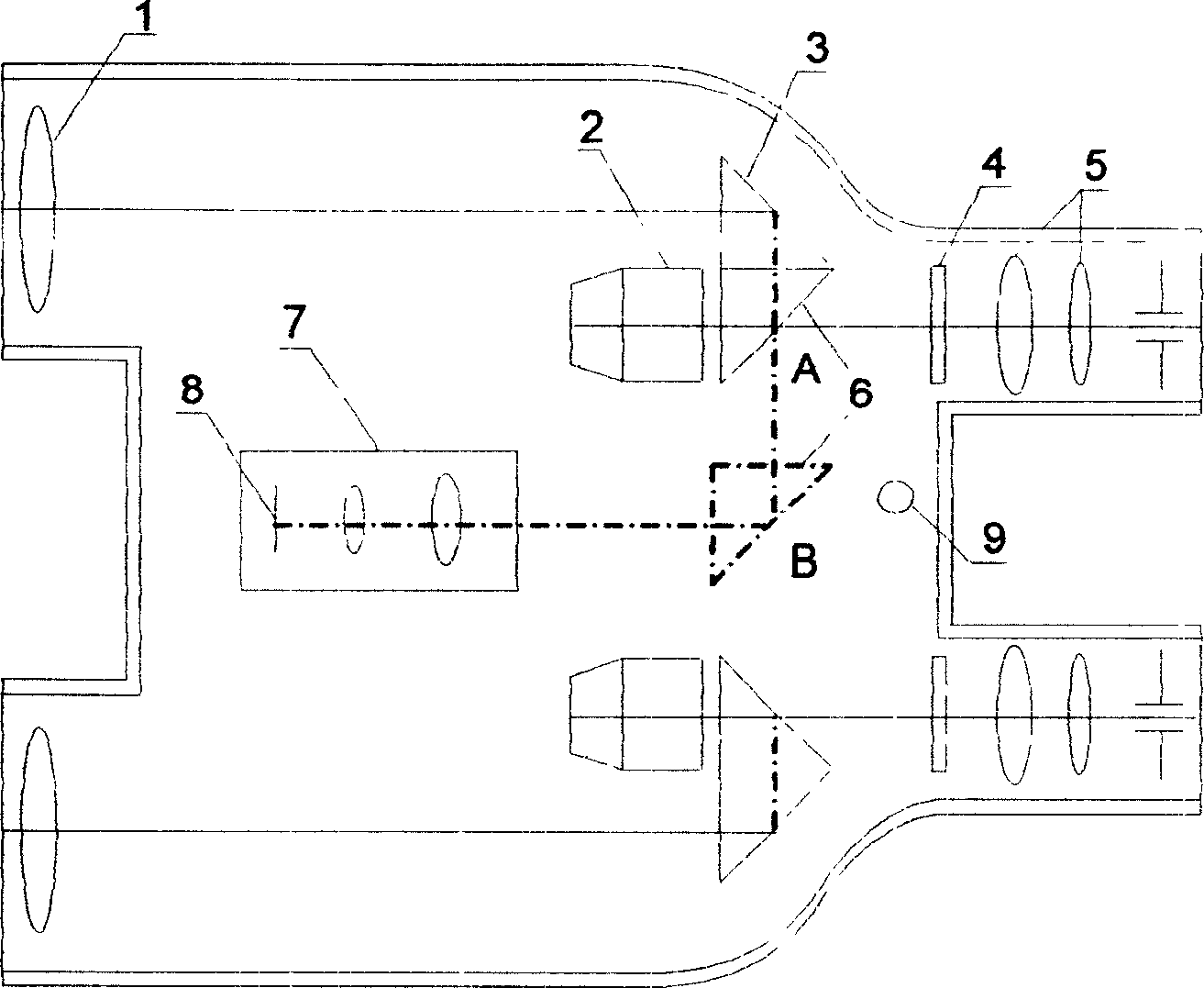

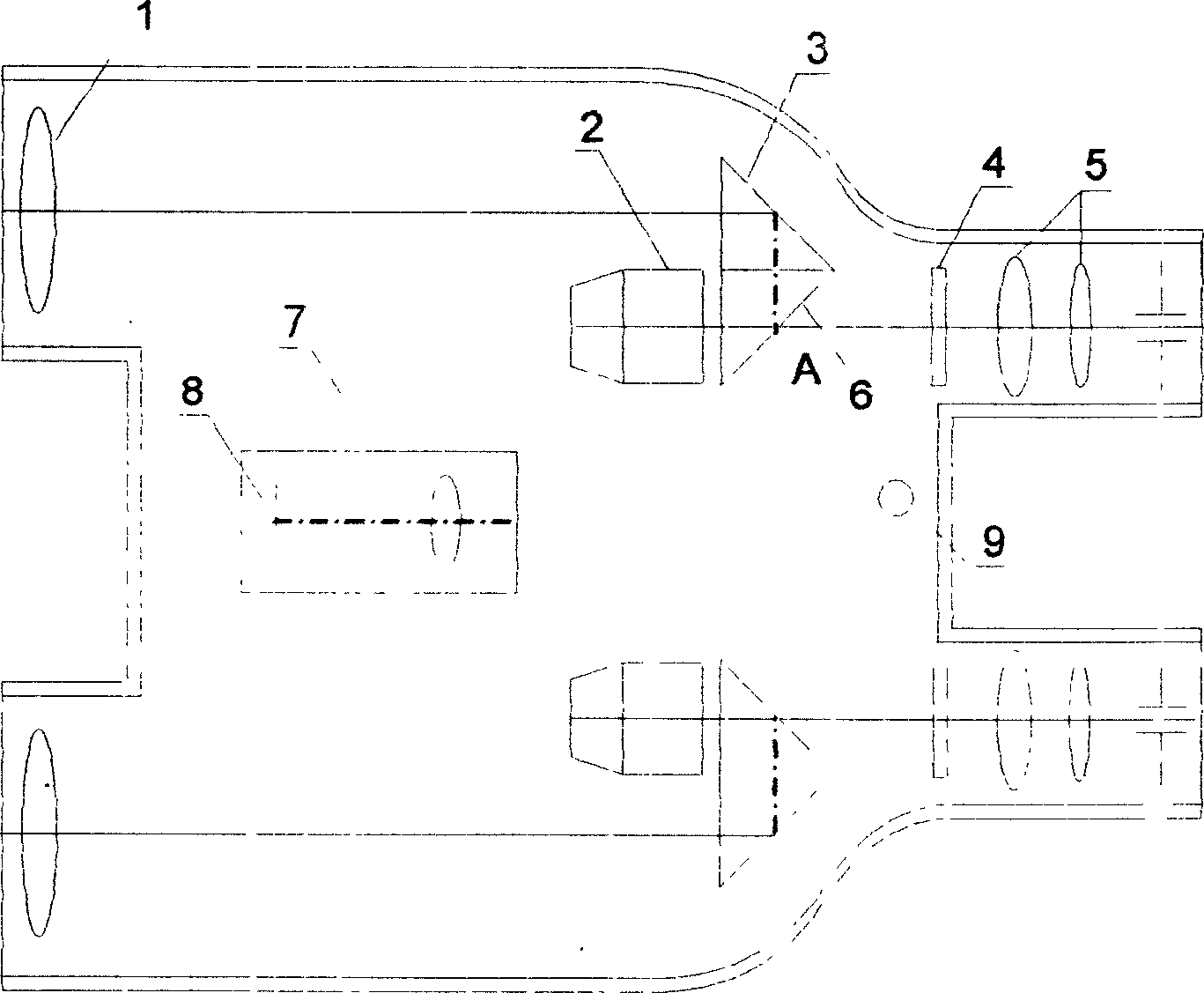

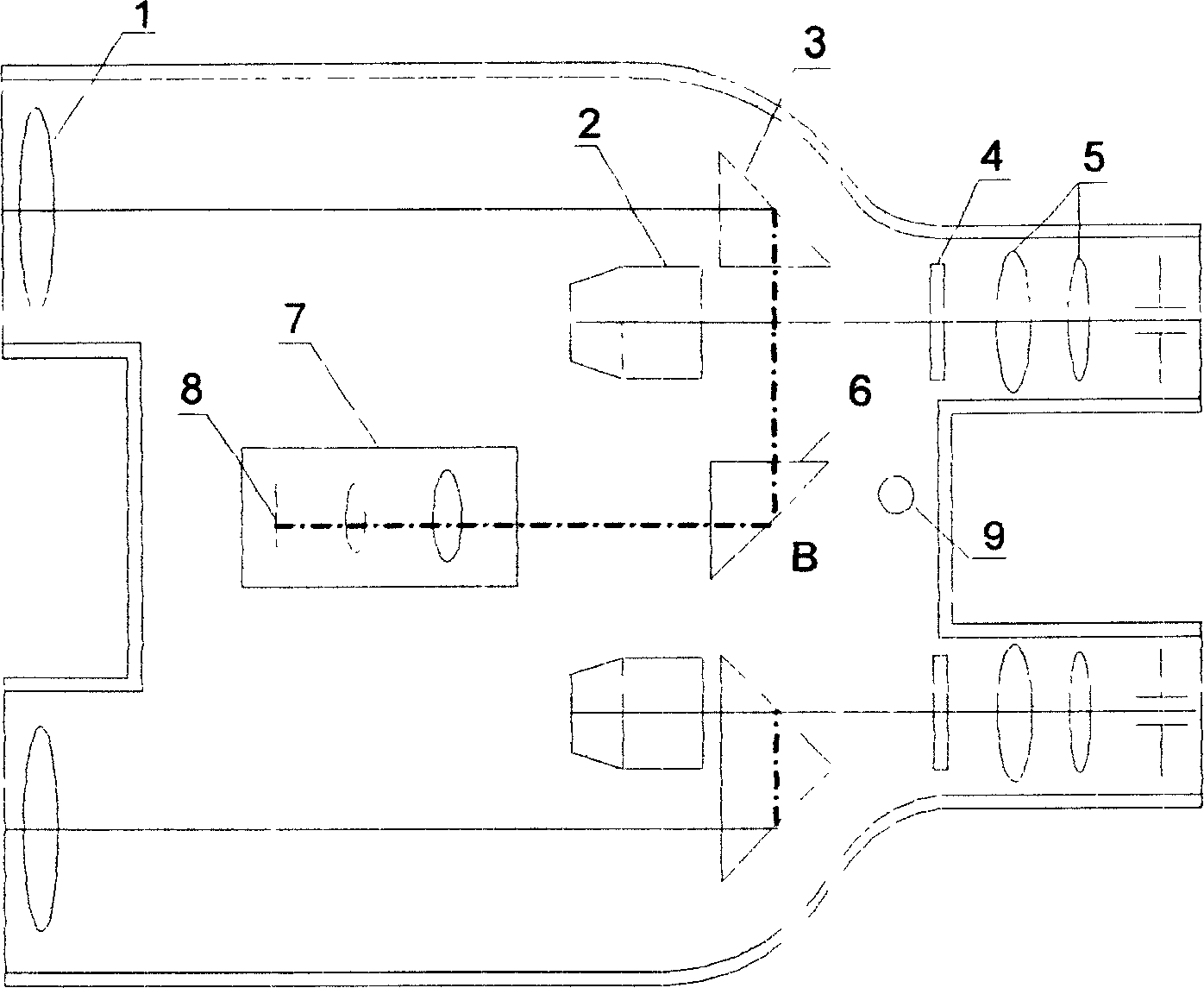

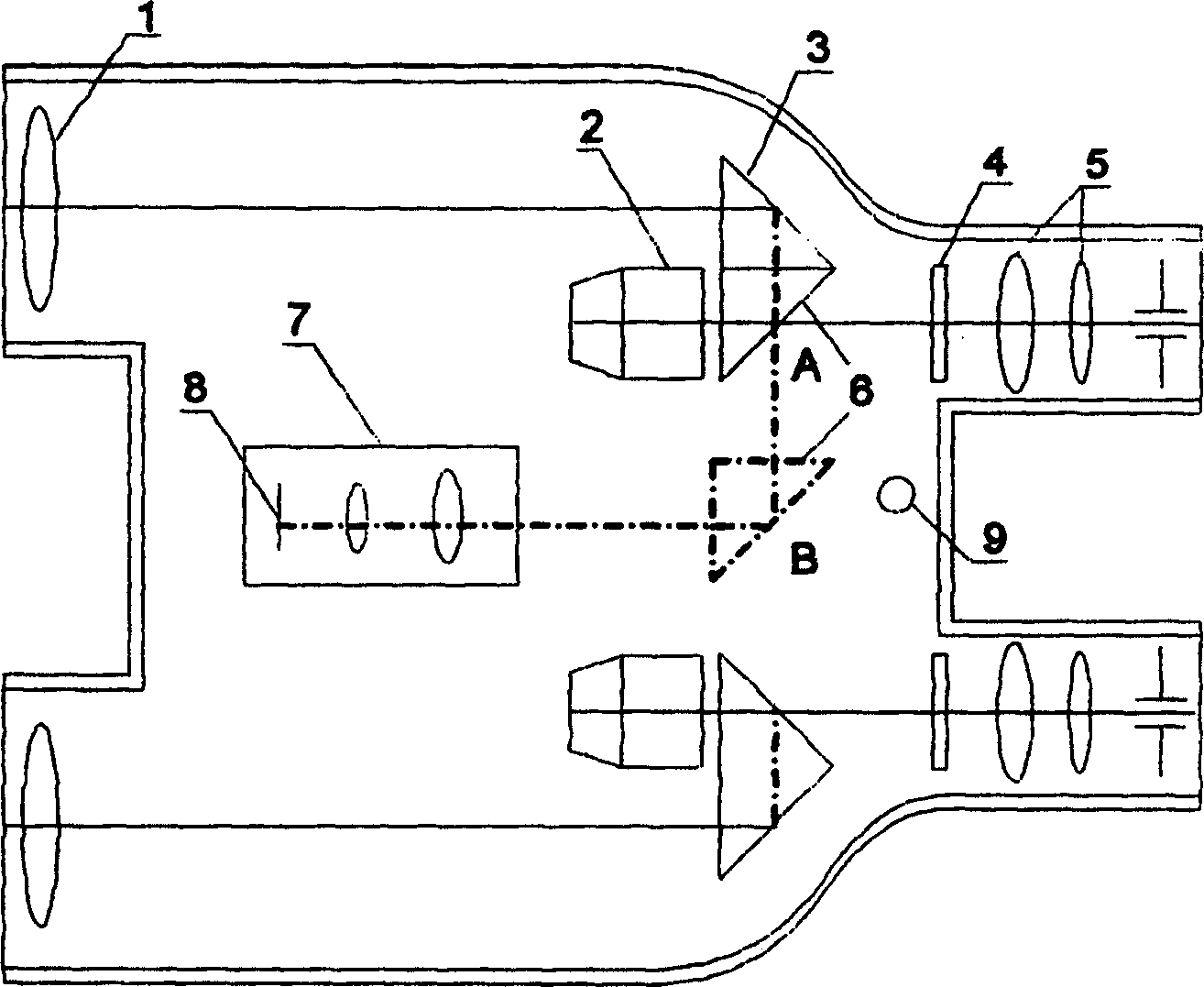

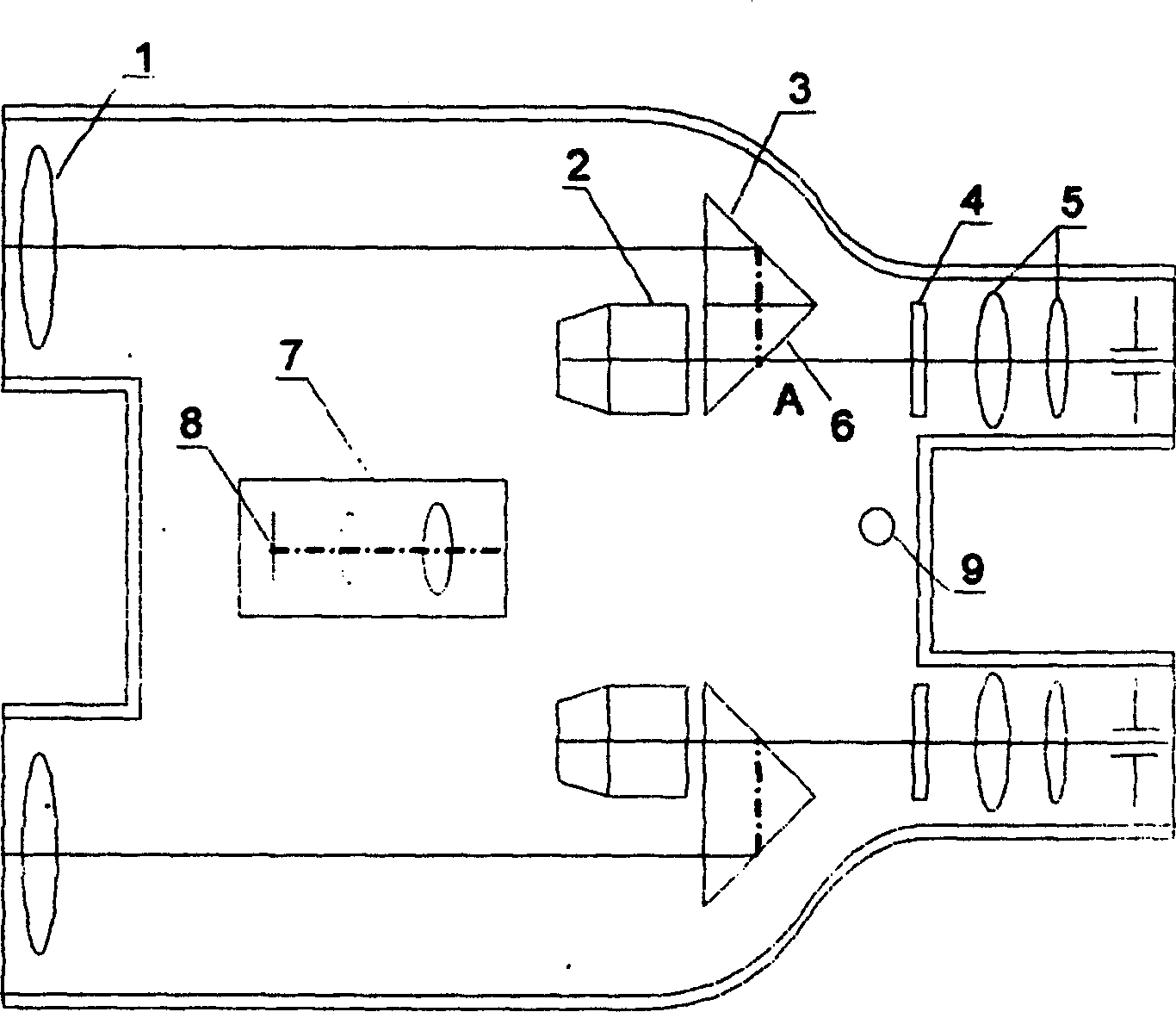

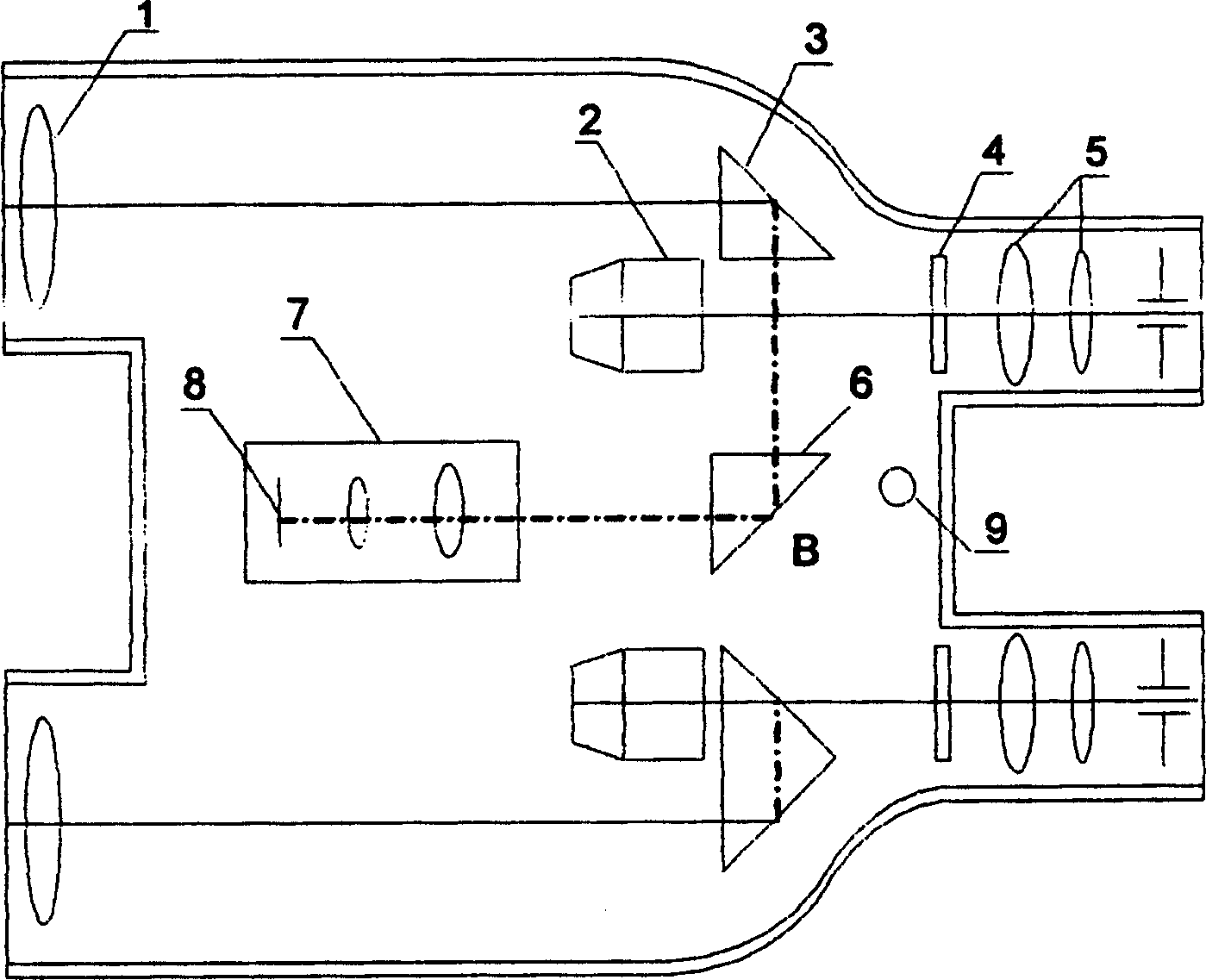

Integrated light path switching type telescope with photographic function

InactiveCN1580857AAchieve the purpose of combiningRealize natural linkageTelevision system detailsColor television detailsEyepiecePrism

The prsent invention relates to an integrated optical circuit switched telescope with photographic function. The electronic photographic device is placed in the middle of binocular telescope, the telescope adopts Paul prism erecting device, and is formed from fixed right angle prism, mobile right angle prism and another fixed right angle prism. The mobile right angle prism is connected with position change-over mechanism and is driven by it, moved to near vacant position and separated from telescopic optical circuit. A reflecting device is placed in the front of electronic photographic device, and is opposite to the right angle face of the fixed right angle prism, so that the light of the telescopic optical circuit can be switched to the optical circuit of lectronic photographic device, and the light-receiving face of the sensor ofthe electronic photographic device is parafocal with telescopic eyepiece.

Owner:CHONGQING UNIV +1

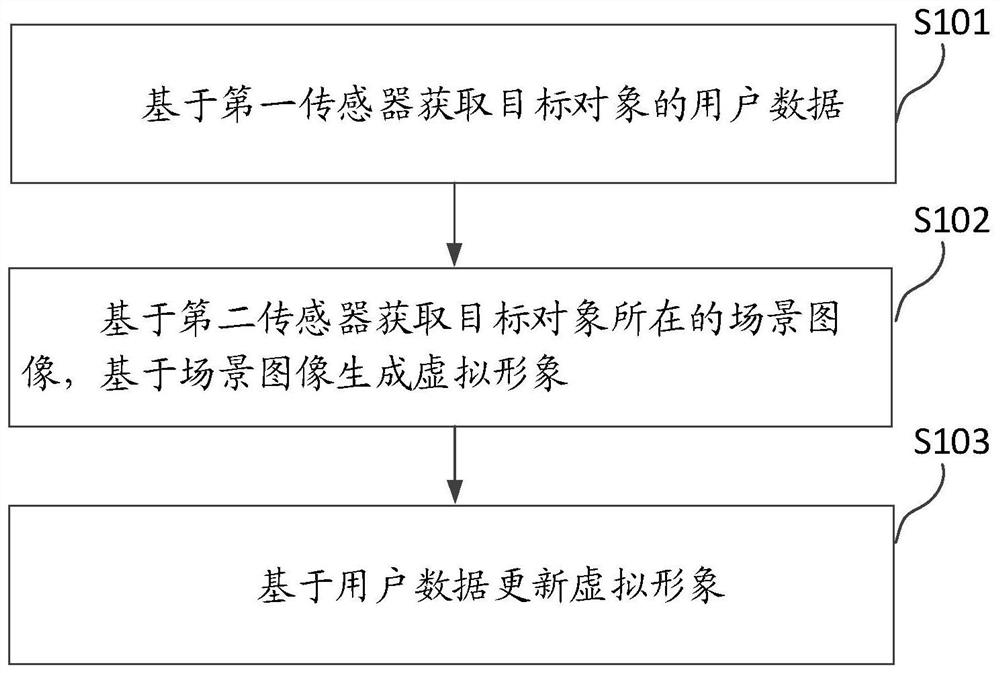

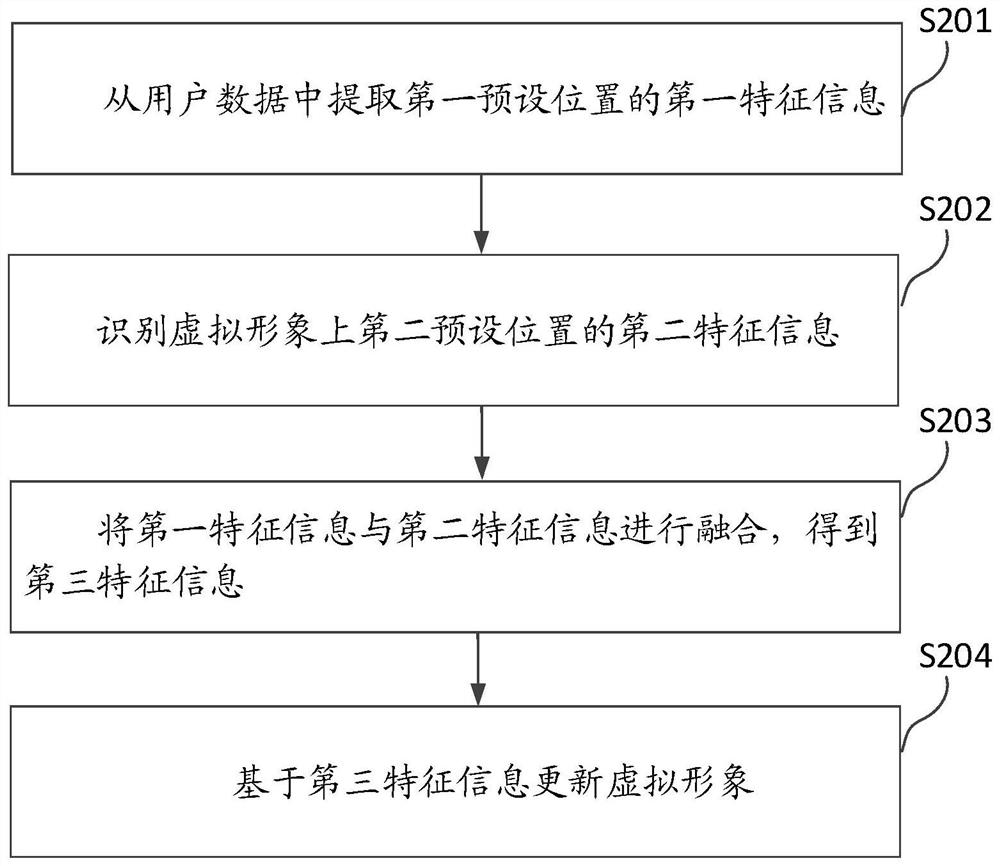

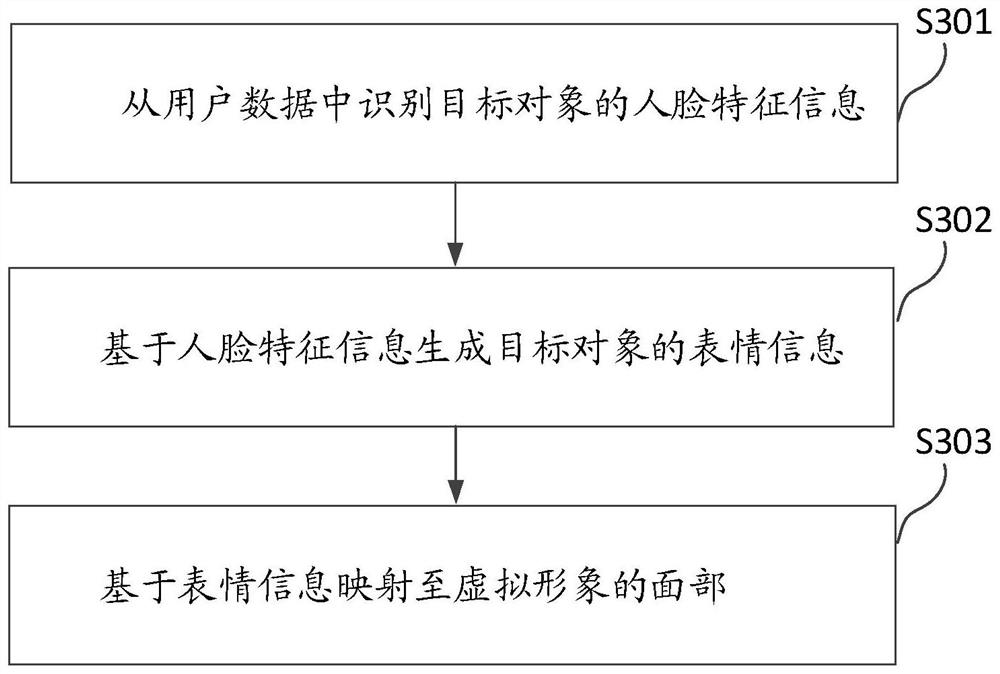

Virtual display method and device and storage medium

PendingCN114332374AAchieve the purpose of combiningRich interactivityCharacter and pattern recognition3D modellingVirtual spaceRadiology

The invention discloses a virtual display method and device and a storage medium. The virtual display method comprises the steps that a scene image where a target object is located is acquired based on a second sensor, and a virtual image is generated based on the scene image; and updating the virtual image in the virtual space based on the user data. Therefore, through the above mode, the user data acquired by the first sensor can be utilized to update the virtual image generated based on the scene image acquired by the second sensor, so that the purpose of combining the spatial data acquired by the two sensors can be achieved, the interaction effect of the scene image and the target object is enriched, and the user experience is improved. And the use interestingness is improved.

Owner:SHENZHEN TETRAS AI TECH CO LTD

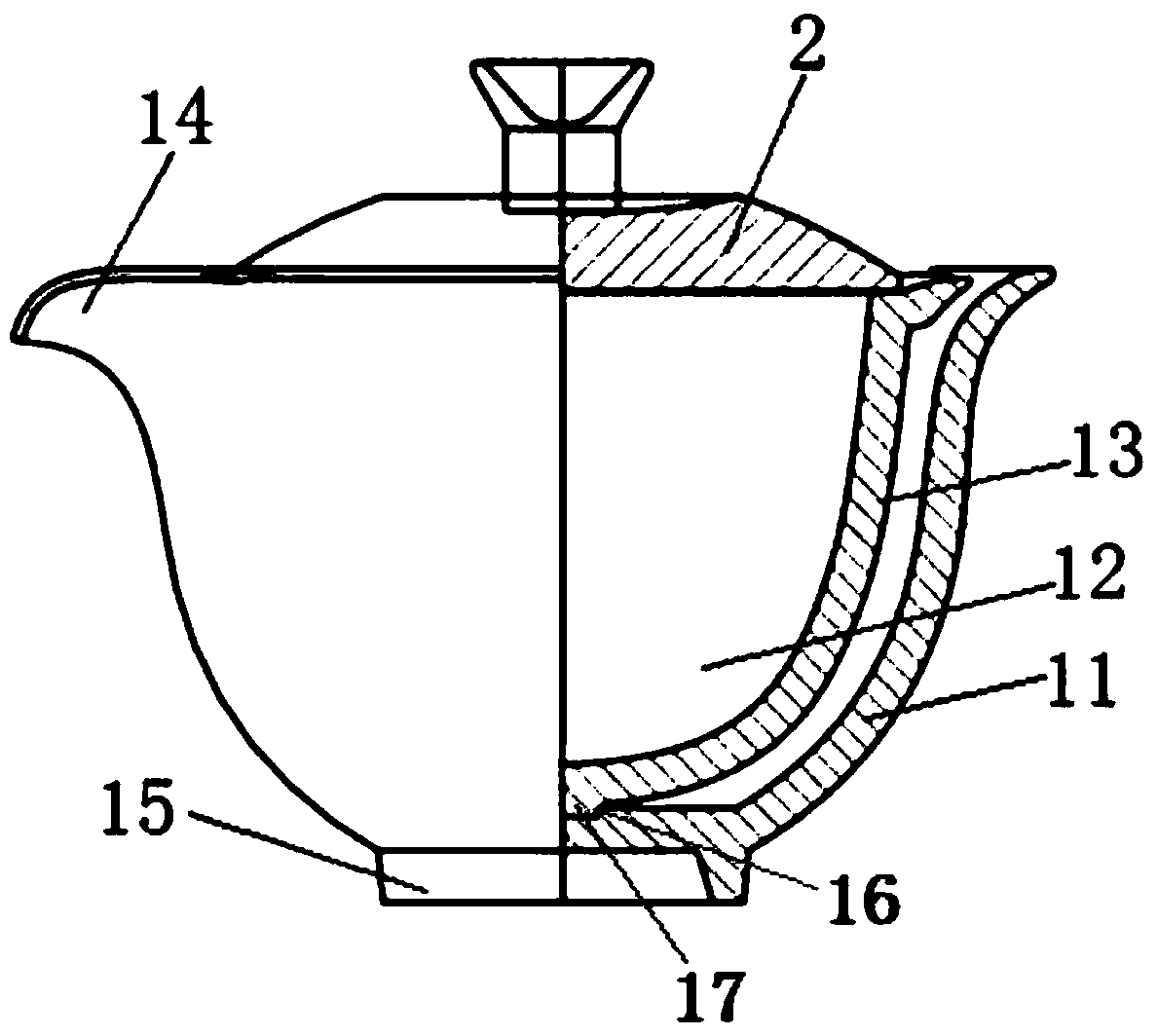

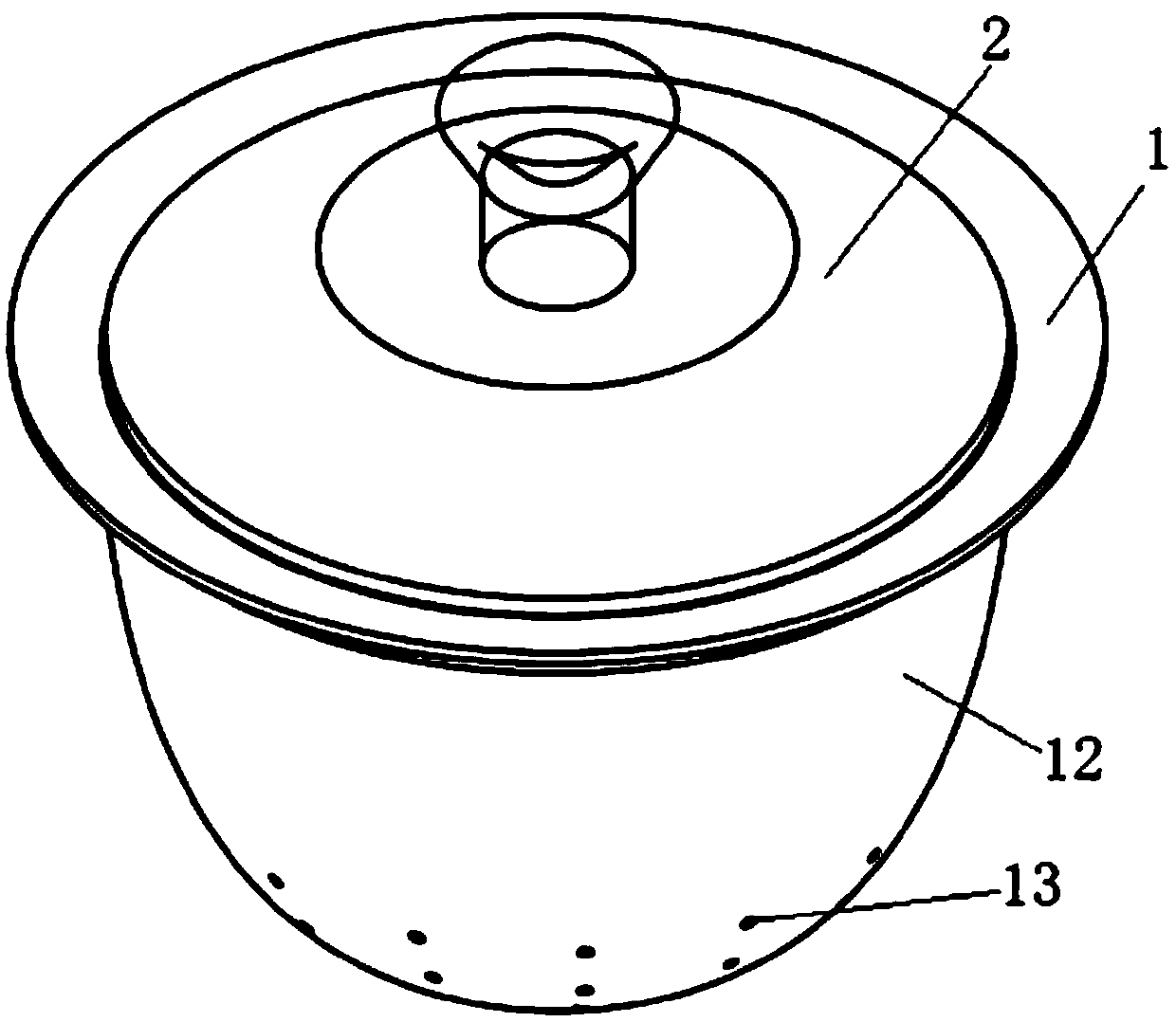

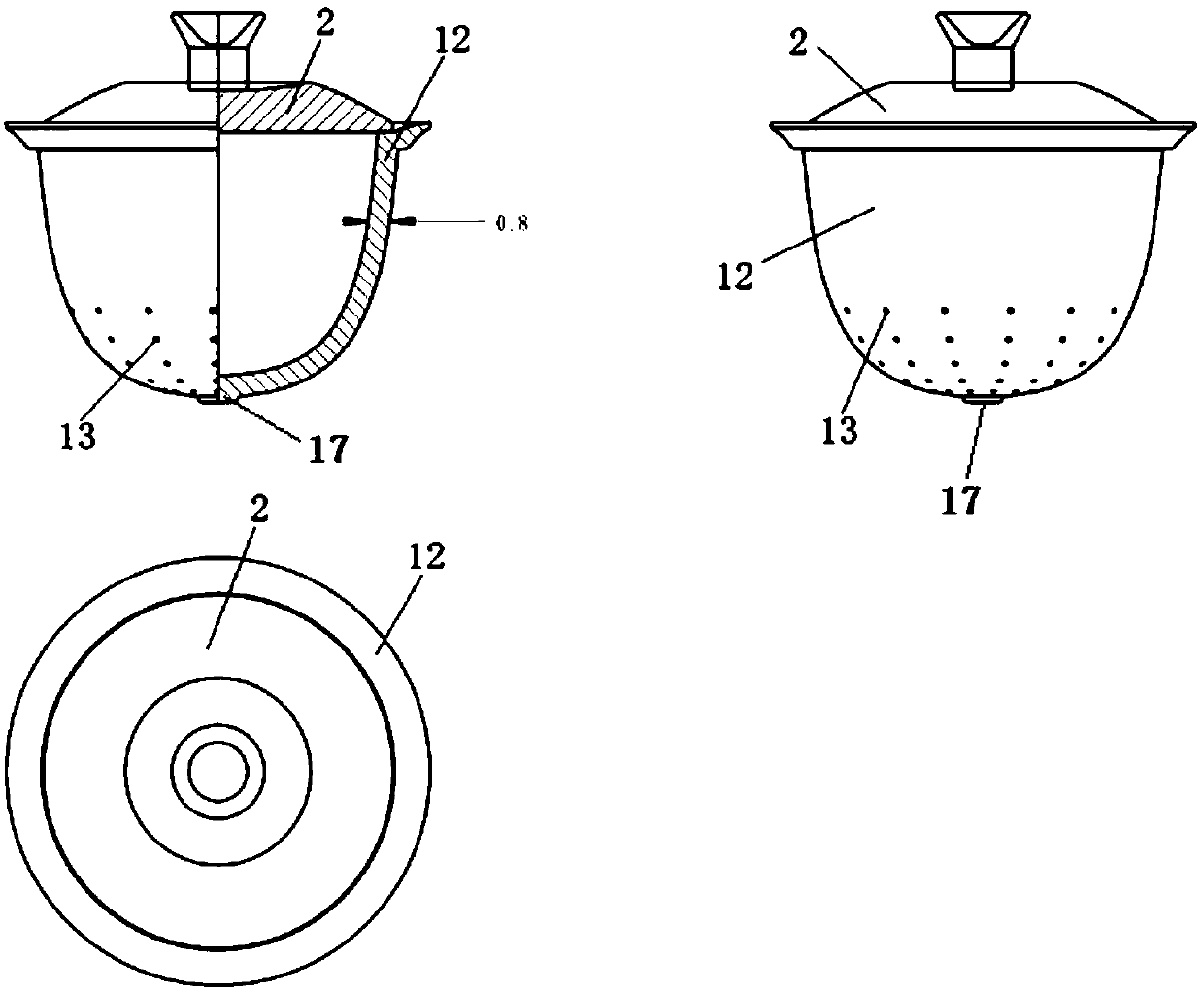

Integrated functional tea ware containing cover bowl, serving cup and filter screen and preparation method thereof

PendingCN109619939AAchieve the purpose of combiningNot hotBeverage vesselsDomestic vesselsWater dischargeEngineering

The invention provides an integrated functional tea ware containing a cover bowl, a serving cup and a filter screen and a preparation method thereof. The integrated functional tea ware comprises a cover bowl body and a cover, wherein the cover bowl body comprises an outer cover bowl layer and an inner cover bowl layer; the outer cover bowl layer sleeves the inner cover bowl layer; a gap is formedbetween the outer cover bowl layer and the inner cover bowl layer so as to form an integrated double-layer structure and achieve the purpose of heat preservation; the middle part of the bottom of theouter cover bowl layer is concavely provided with a clamping groove, and the middle part of the bottom of the inner cover bowl layer is convexly provided with a bulge matched with the clamping groove,so that the inner cover bowl layer is stably placed in the outer cover bowl layer; the height of an opening end of the outer cover bowl layer is higher than that of the opening end of the inner coverbowl layer, and one side of the opening end of the outer cover bowl layer is provided with a water outlet so as to control the tea water discharging direction; the bowl wall of the lower half part ofthe inner cover bowl layer is provided with a plurality of hyperfine drainage holes so that the inner cover bowl layer is used as a filter screen; the cover covers the opening end of the inner coverbowl layer. The tea ware has the advantages of health, energy saving, heat preservation, no hand scalding, space saving, tea making integration and convenient use.

Owner:福建省德化县陶缘茗陶瓷文化有限公司

Metallurgical compound technology for copper aluminum bimetal compound electronic framework strip

InactiveCN103599936AReduce bond strengthAchieve the purpose of combiningWork treatment devicesRollsWater vaporIngot

The invention discloses a metallurgical compound technology for a copper aluminum bimetal compound electronic framework strip. After an aluminum ingot is completely melted into molten aluminum, the molten aluminum flows into a compound region after standing by a standing furnace, online degassing and filtering, the electronic framework strip and the roller are continuously dehumidified by hot air in the compound region, the temperature of the roller and the electronic framework strip is kept at 150-200 DEG C in compounding, and the electronic framework strip and the molten aluminum are rolled by a cast-rolling mill to form the metallurgical compounded copper aluminum bimetal compound strip. During compounding, water vapor and oxidation of copper aluminum metal surfaces are avoided, water molecules are prevented from condensing on a copper aluminum compound interface and forming bubbles, and the post processing quality of the copper aluminum bimetal compound electronic framework strip is ensured. By adding 0.2-0.5% of aluminum titanium boron wires into the molten aluminum, copper aluminum metal molecules are metallurgically bonded. The problems of cracking, breaking, layering, falling-off and the like in post deep processing are thoroughly solved, the rate of finished products can reach more than 85-97%, and production cost is reduced. The metallurgical compound technology is widely applied to an electronic lead framework with the mark of TPO / H65 / c19210 / c19400 / Lc7025.

Owner:洛阳市伟创复合材料科技有限公司 +1

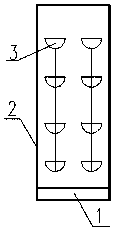

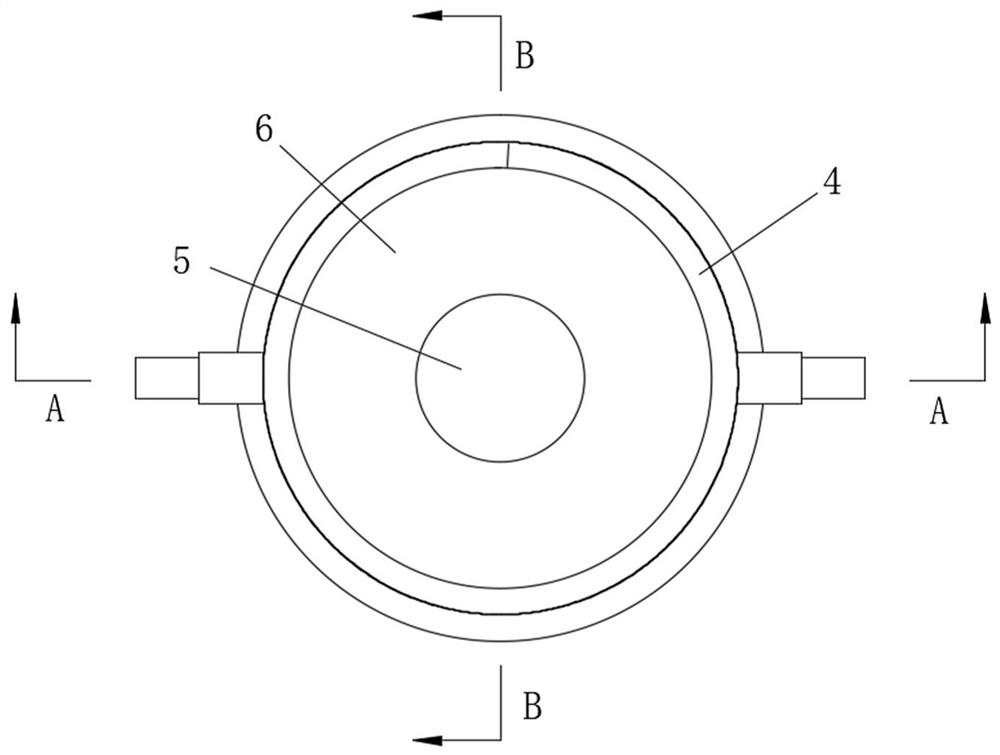

Spring clutch

The invention discloses a spring clutch. The spring clutch comprises a hub (1), a clutch hood (6), three fan-shaped flywheels (2), three guide columns (3), three elastic connecting pieces (4) and three fan-shaped friction sheets (5), wherein the hub is coaxially arranged in the clutch hood; the guide columns are connected to the peripheral part of the hub at intervals along the circumferential direction and extend outwards along the radial direction; the fan-shaped flywheels correspond to the guide columns; a radial guide groove matched with each guide column is formed inside the corresponding fan-shaped flywheel; each fan-shaped flywheel is mounted on the corresponding guide column through the corresponding radial guide groove in a sleeving manner and can radially move; the fan-shaped friction sheets correspond to the fan-shaped flywheels and are arranged between the fan-shaped flywheels and the clutch hood; each fan-shaped friction sheet is combined with the corresponding fan-shaped flywheel into a whole; any two adjacent fan-shaped friction sheets are elastically connected through the corresponding elastic connecting piece. The spring clutch is simple in structure and convenient to disengage and engage.

Owner:芜湖市中亚汽车制动元件有限公司

Metallurgical compound technology for titanium aluminum bimetal compound strip

InactiveCN103599933ANot reach the purpose of dryingAvoid condensationRoll mill control devicesMetal rolling arrangementsWater vaporIngot

The invention discloses a metallurgical compound technology for a titanium aluminum bimetal compound strip. After an aluminum ingot is completely melted into molten aluminum, the molten aluminum flows into a compound region after standing by a standing furnace, online degassing and filtering, a roller and a titanium strip are continuously blown and baked by hot air in the compound region, the temperature of the roller and the titanium strip is kept at 150-300 DEG C in compounding, and the titanium strip and the molten aluminum are rolled by a rolling mill to form the metallurgical compounded titanium aluminum bimetal compound strip. The roller and the titanium strip are continuously blown and baked by the high-pressure hot air in the compound region of the titanium strip and the molten aluminum, and the temperature of the roller and the titanium strip is kept at 150-300 DEG C, so that water vapor and oxidation are avoided in compounding, water molecules are prevented from condensing on a titanium aluminum compound interface and forming bubbles, and the post processing quality of the titanium aluminum bimetal compound strip is ensured. By adding 0.2-0.5% of aluminum titanium boron wires into the molten aluminum, titanium aluminum metal molecules are metallurgically bonded. The problems of cracking, breaking, layering, falling-off and the like in post deep processing are thoroughly solved, the rate of finished products can reach more than 80%, and production cost is reduced.

Owner:洛阳市伟创复合材料科技有限公司 +1

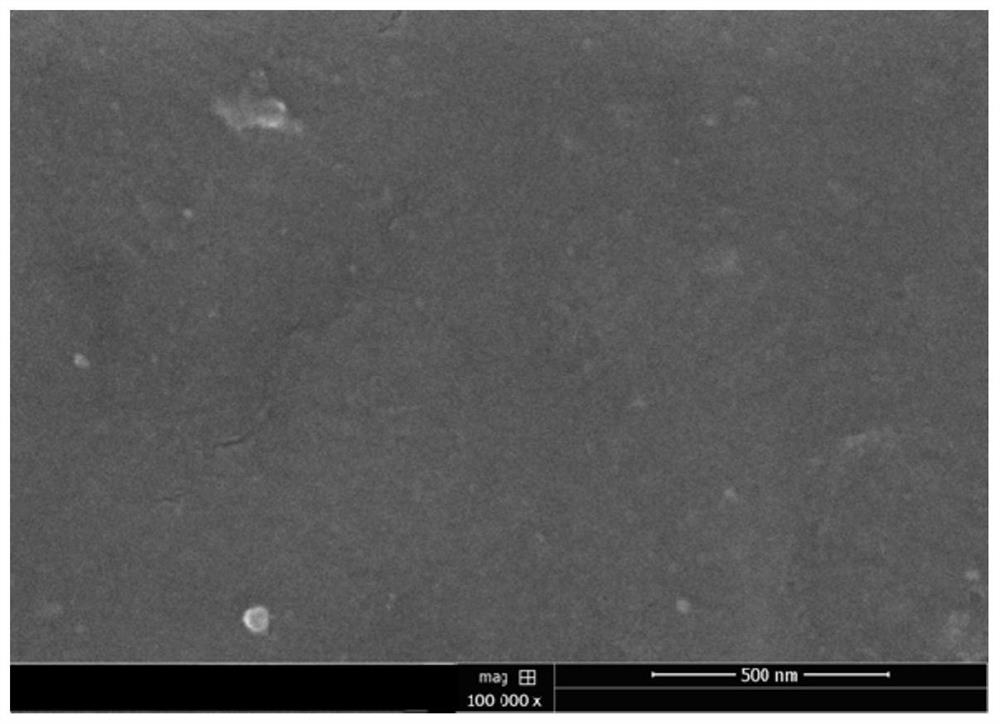

A nanofiltration membrane for water purification and its preparation method and application

ActiveCN111013411BImprove cold resistanceExcellent resistance to UV radiationSemi-permeable membranesMembranesSurface reactionDesalination

The invention discloses a nanofiltration membrane used for water purification, a preparation method and application thereof. The nanofiltration membrane comprises a modified PVB porous base membrane and a polyamide ultra-thin desalination layer formed by reaction on one side surface of the modified PVB porous base membrane. The polyamide ultra-thin desalination layer and the PVB porous base membrane are combined by chemical bonds, so that the base membrane and the polyamide separation layer are firmly bonded and the separation layer is complete and free of defects, which solves the problem of the current nanofiltration membrane. The problem of weak binding force caused by simple adhesion combination avoids the degradation of membrane performance such as separation layer defects, shedding, and delamination of the nanofiltration membrane due to operating pressure fluctuations, flow rate changes, and cleaning during long-term operation. or failure issues. The nanofiltration membrane of the present invention has good hydrophilicity, high water flux, double-effect heavy metal removal ability and antibacterial property, excellent swelling resistance and pollution resistance, stable long-term use performance, and is suitable for water purification equipment requiring high filtration accuracy. Especially household water purification equipment.

Owner:美蓝飘尔(上海)过滤设备有限公司

Friction clutch, transmission structure of friction clutch and vehicle

InactiveCN104315012AImprove stabilityEasy to moveFriction clutchesVibration suppression adjustmentsFreewheelFlywheel

The invention discloses a friction clutch, which comprises a clutch cover (6) and a wheel hub (1), wherein the wheel hub (1) is arranged in the clutch cover (6) and is connected with a plurality of spaced flywheels (2), the flywheels (2) can move between the wheel hub (1) and the clutch cover (6) along the radial direction of the wheel hub (1), the peripheral surface of each flywheel (2) is provided with a friction sheet (4), and the two adjacent flywheels (2) are connected by an elastic reset part (3). The invention also provides a transmission structure of the friction clutch and a vehicle. The friction clutch has the advantages that the structure is simple, and the disengagement and engagement operation is simple.

Owner:芜湖市中亚汽车制动元件有限公司

Double-metal bonding method and structure

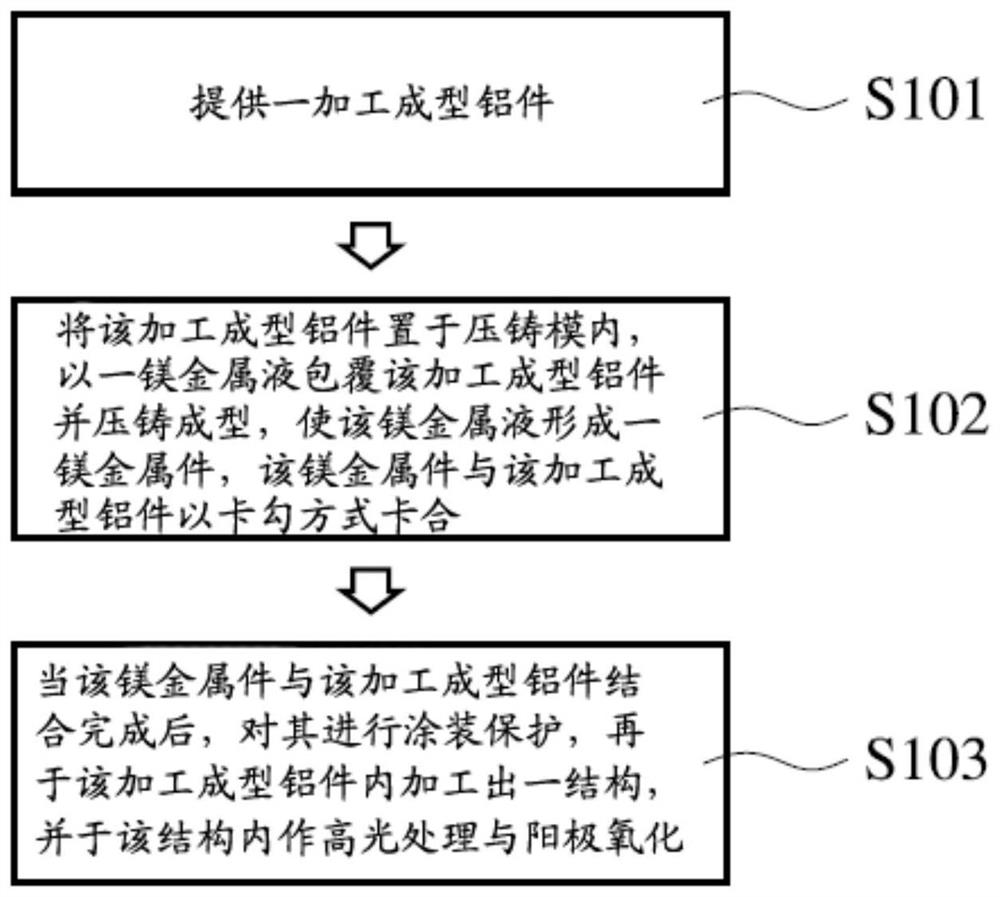

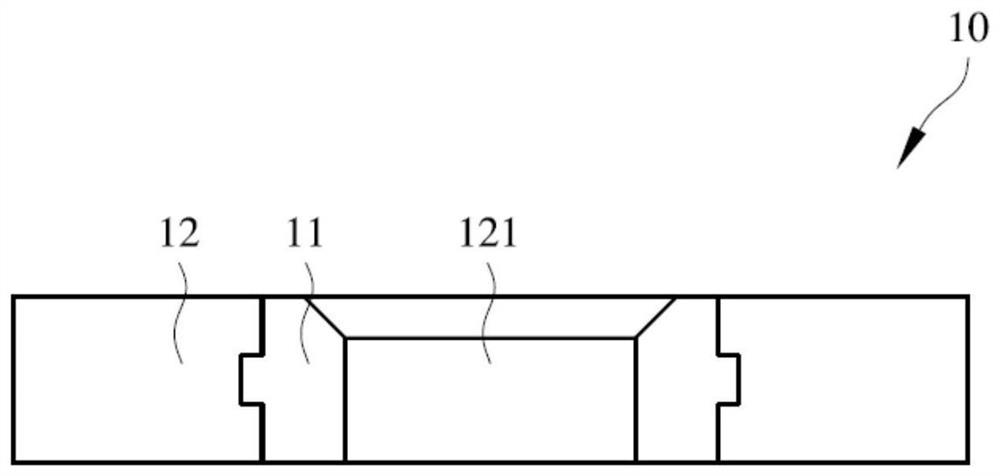

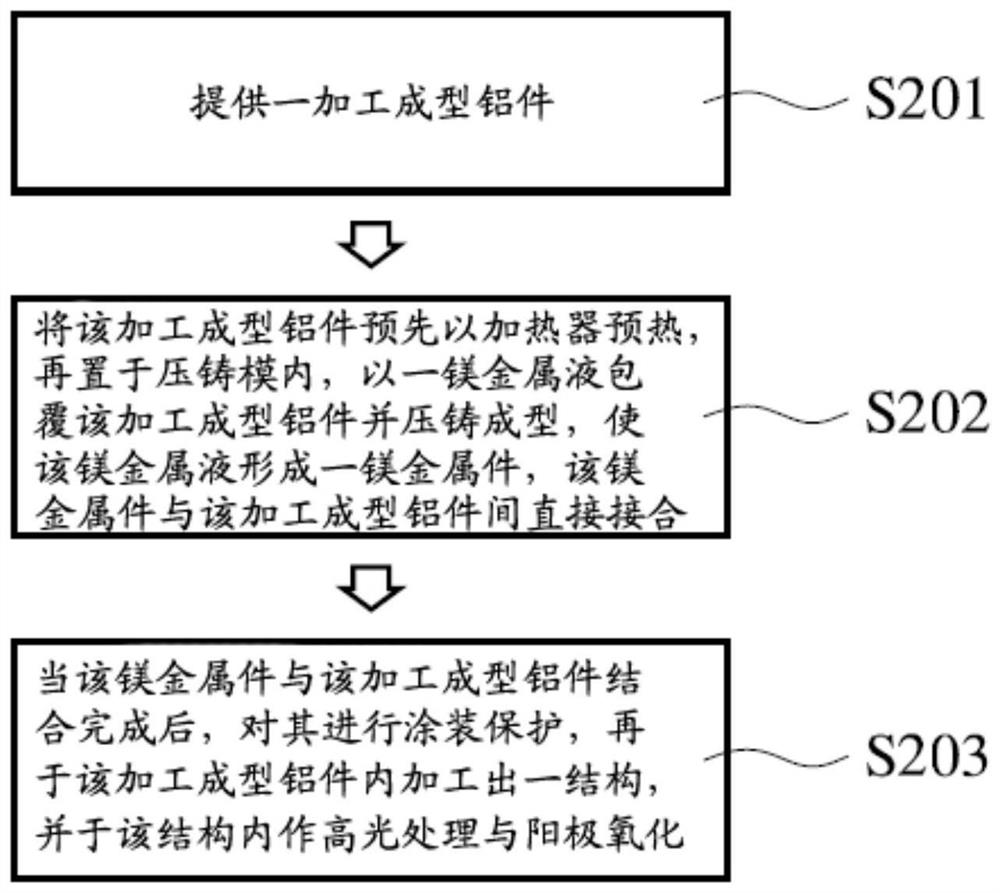

PendingCN113369454AAchieve the purpose of combiningReduce time-consuming grindingLiquid surface applicatorsCoatingsNano structuringAluminum metal

The invention discloses a double-metal bonding method and structure. The method comprises the following steps that one machined and formed aluminum piece is provided; the machined and formed aluminum piece is placed in a die-casting die, the machined and formed aluminum piece is coated with one magnesium metal liquid, die-casting forming is carried put, the magnesium metal liquid forms one magnesium metal piece, and the magnesium metal piece and the machined and formed aluminum piece are clamped in a clamping and hooking mode; and after the magnesium metal piece and the machined and formed aluminum piece are combined, coating protection is carried out on the magnesium metal piece and the machined and formed aluminum piece, one structure is machined in the machined and formed aluminum piece, and highlight treatment and anodic oxidation are carried out in the structure. According to the double-metal bonding method and structure, the structural inner wall of the aluminum piece or an aluminum metal piece is machined and formed through highlight treatment, and a smooth surface can be obtained after double-metal combination, so that time-consuming grinding is reduced, and surface shrinkage limit and air holes are reduced; and according to the double-metal bonding method and structure, the purpose of double-metal combination can be achieved in a mode of direct connection of plastic or a surface nano structure or double metal.

Owner:JU TENG INT HLDG

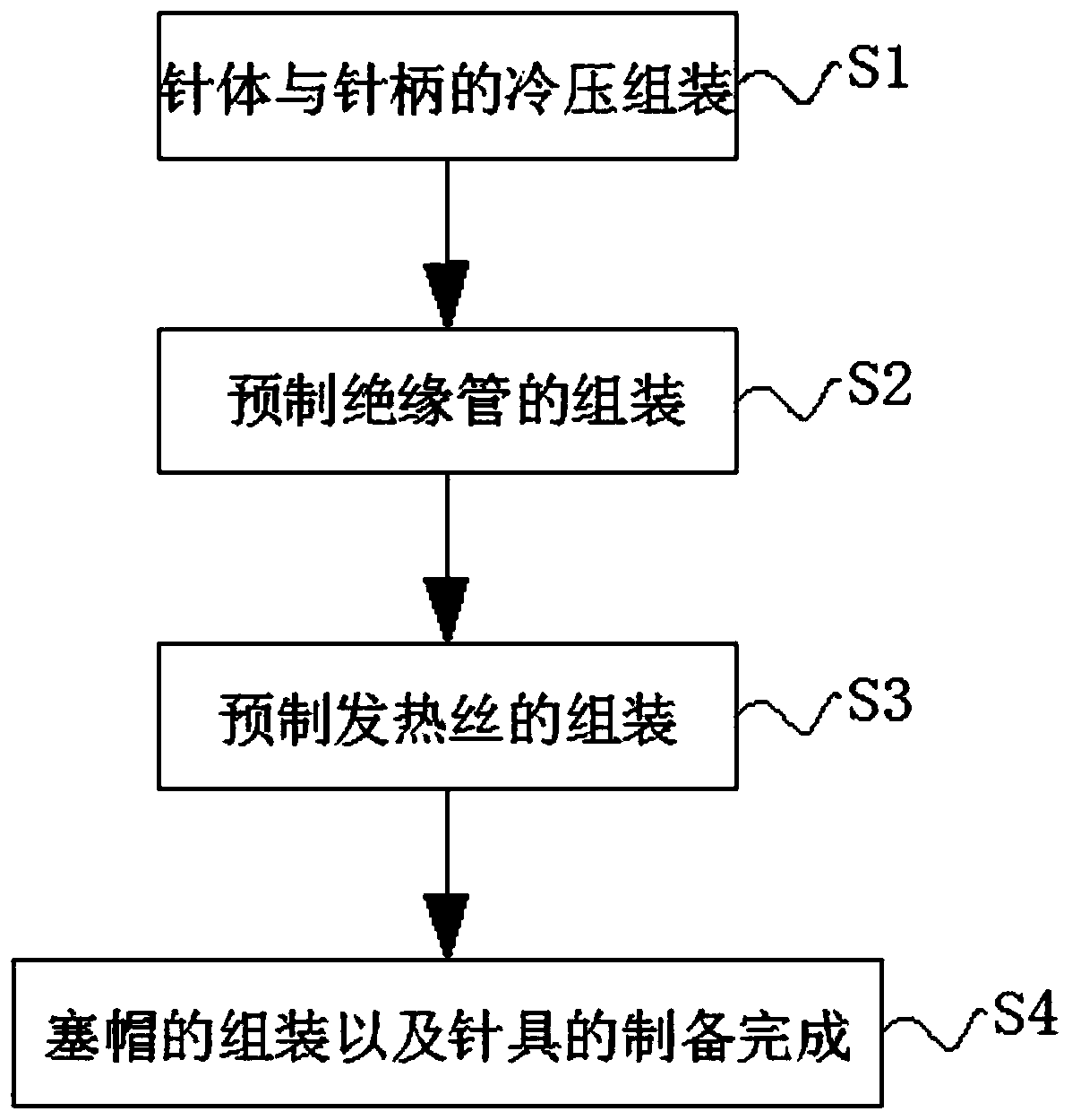

Production process of internal heating needle tool

The invention discloses a production process of an internal heating needle tool. The process specifically comprises the following steps: S1, selecting a corresponding needle body and a needle handle,cleaning the surface of the needle body in advance, limiting the length of the needle body by using a limiting mechanism, and exposing an opening end of the needle body to a certain length by using the limiting mechanism. The invention relates to the technical field of medical needles. The production process of the internal heating needle tool adopts a combination mode of the needle handle and theneedle body, after the needle body is inserted into the metal tubular handle, the friction between the handle and the needle body is increased through external force physical deformation, so that theneedle handle and the needle body are combined and the needle body is firmly combined in the needle handle, namely the opening end of the needle body is inserted into the tubular metal handle for a certain length, and the connecting part is physically deformed by means of a pressure tool, so that the needle body cannot be pulled out of the needle handle, and the purpose of combination is achieved. The process not only can rapidly complete the combination of the needle handle and the needle body, but also does not bring impurities such as oxides, soldering flux and the like, and reduces a plurality of production procedures brought by the impurities.

Owner:济宁市佳科医疗科技有限公司

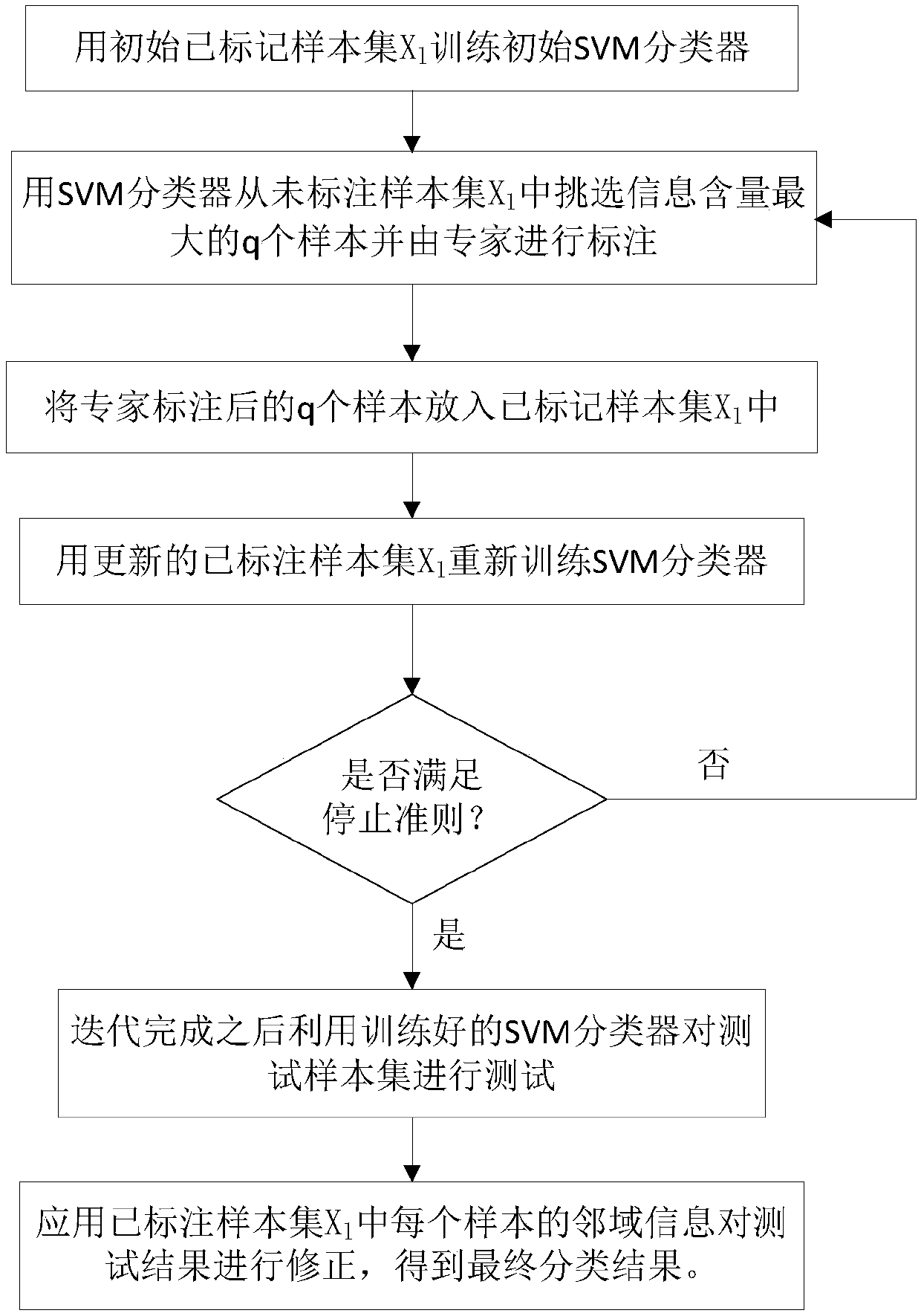

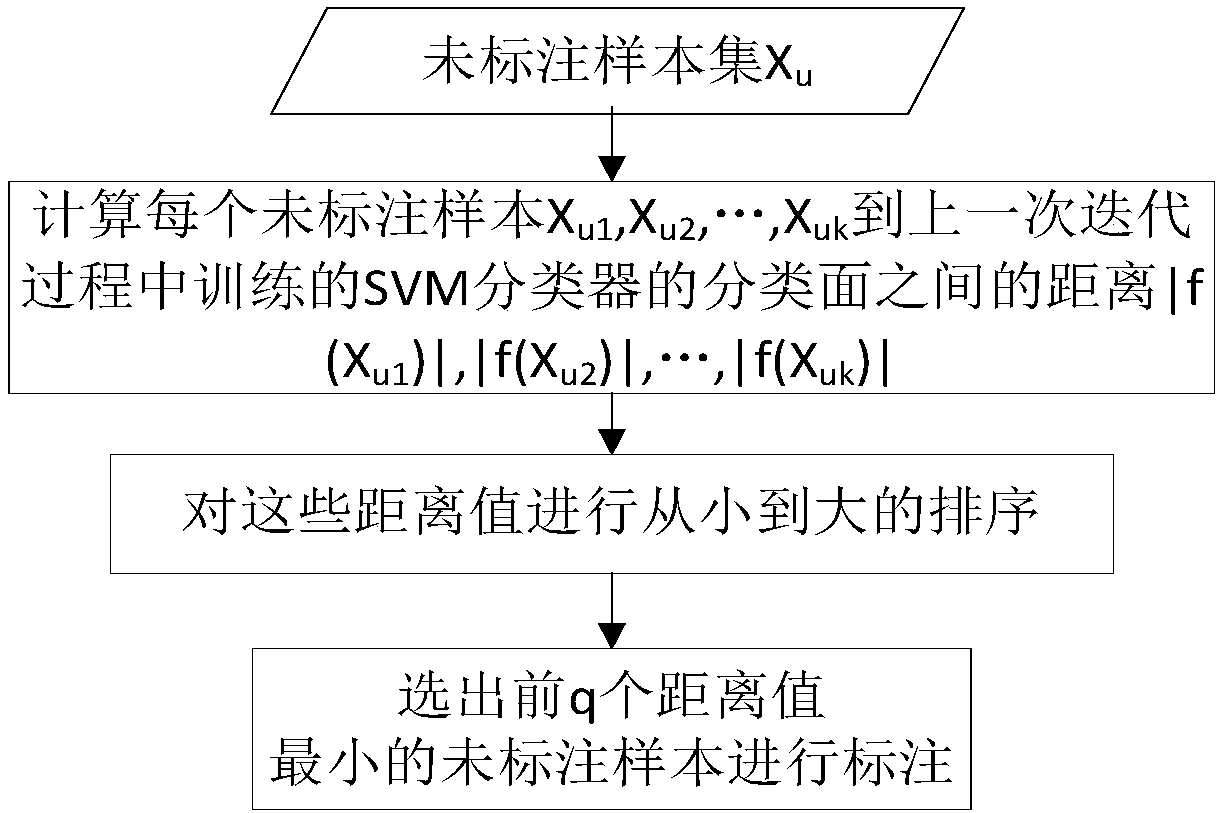

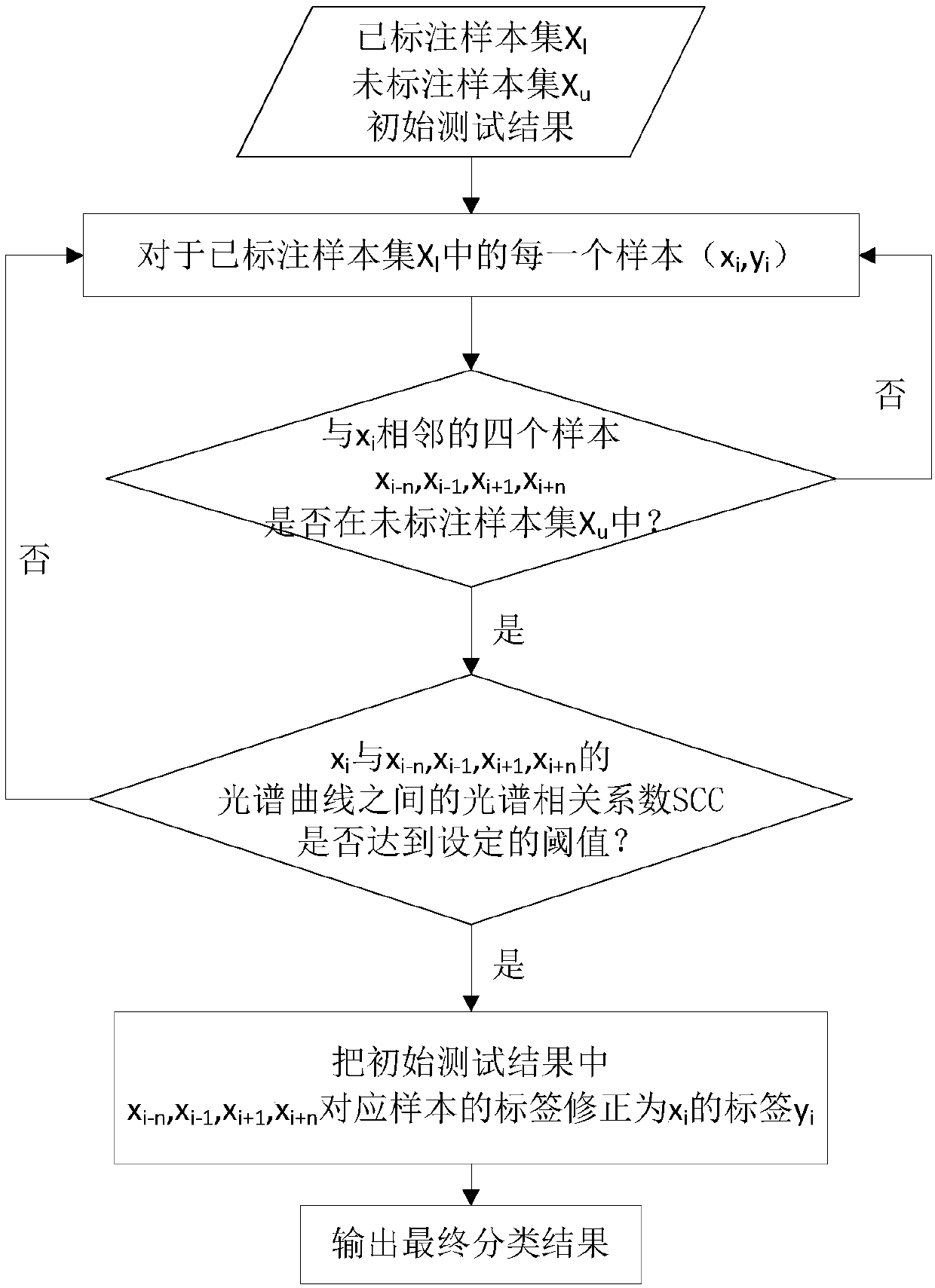

Hyperspectral Image Classification Method Combining Active Learning and Neighborhood Information

ActiveCN104182767BImprove performanceReduce workloadCharacter and pattern recognitionPattern recognitionSite Visit

The invention discloses a hyperspectral image classification method combining active learning and neighborhood information. The establishment of label samples in hyperspectral images requires field inspections and traditional methods only consider a single spectral information problem. The implementation steps are: (1) use the initial labeled sample set Xl to train the SVM classifier; (2) use the SVM classifier to select the q samples with the largest amount of information from the unlabeled sample set Xu and label them by experts; Put the q samples marked by experts into Xl; (4) retrain the SVM classifier with the updated Xl; (5) judge whether to exit the loop according to the stopping criterion; (6) use the trained SVM classifier to The test sample set is tested; (7) Use the neighborhood information of each sample in X1 to correct the test result to obtain the final classification result. The invention realizes the space-spectrum combination of hyperspectral images, and can obtain better classification results compared with other similar methods.

Owner:XIDIAN UNIV

Integrated light path switching type telescope with photographic function

InactiveCN1287187CAchieve the purpose of combiningRealize natural linkageTelevision system detailsColor television detailsEyepiecePrism

The prsent invention relates to an integrated optical circuit switched telescope with photographic function. The electronic photographic device is placed in the middle of binocular telescope, the telescope adopts Paul prism erecting device, and is formed from fixed right angle prism, mobile right angle prism and another fixed right angle prism. The mobile right angle prism is connected with position change-over mechanism and is driven by it, moved to near vacant position and separated from telescopic optical circuit. A reflecting device is placed in the front of electronic photographic device, and is opposite to the right angle face of the fixed right angle prism, so that the light of the telescopic optical circuit can be switched to the optical circuit of lectronic photographic device, and the light-receiving face of the sensor ofthe electronic photographic device is parafocal with telescopic eyepiece.

Owner:CHONGQING UNIV +1

A kind of preparation method of metal composite pipe blank with more than two layers

The invention provides a method for preparing metal composite tube blanks with more than two layers. The upper and lower ends of the pretreated metal inner tube and outer tube are respectively fixed on the ring seams of the upper and lower sealing flanges, forming a In the casting cavity, the casting device and the intake and exhaust device are installed through the upper sealing flange to exhaust and preheat the casting inner cavity, and pour metal melt into the casting cavity to form a composite tube blank, and cool the composite tube blank And finishing, to obtain high-quality composite tube. The method provided by the invention can prepare more than two layers of metal composite tube blanks with a solid-liquid phase metallurgical bonding interface that cannot be produced by existing methods. The process method of the invention has the advantages of simple process, low manufacturing cost, and excellent composite tube blank interface bonding quality Good quality, high yield, can prepare a variety of more than two-layer metal composite tube blanks and other characteristics.

Owner:安徽巨鼎高分子科技股份有限公司

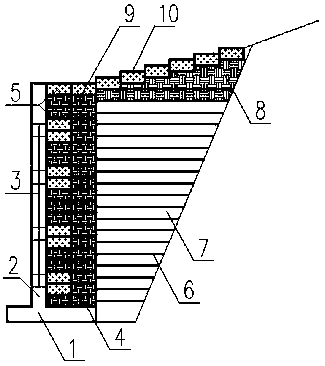

Ecological cantilever retaining system

PendingCN108547314AGuaranteed structural strengthReduce thicknessArtificial islandsUnderwater structuresGeocellsEngineering

The invention discloses an ecological cantilever retaining system. The ecological cantilever retaining system comprises a bottom plate; a panel is arranged on the bottom plate; through holes are formed in the panel; vertical earthwork standard rooms are formed in the inner side of the panel; back filled regions are formed in the inner sides of the vertical earthwork standard rooms; reinforcing ribs are arranged in the back filled regions; a clay layer is arranged at the top of the back filled regions; oblique plane earthwork standard rooms are formed above the vertical earthwork standard roomsand the clay layer; greening backfill materials are arranged in the oblique plane earthwork standard rooms, and the vertical earthwork standard rooms adjacent to the through holes; and soil-rock backfill materials are arranged in the rest vertical earthwork standard rooms. The ecological cantilever retaining system has the characteristics that the mechanical property is good, the materials are used less, resources are saved, the cost is low, and landscape is organically combined with rock-soil support.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

An information processing method and device

ActiveCN104199936BAchieve the purpose of combiningSpecial data processing applicationsInformation processingGeolocation

The invention discloses a method and device for processing information. The method and device are applied in an electronic device. The electronic device is provided with a position positioning module used for positioning the movement track of the electronic device. The method comprises the steps that the movement track, positioned through the position positioning module, of the electronic device for some time past is acquired, geographic position marks on the movement track are determined, the attribution information of the geographic position marks is determined, the geographic position marks are classified according to the attribution information of the geographic position marks, the geographic position marks belonging to one type are allocated to the same geographic position unit, first to-be-pushed object features related to the attribution of the geographic position units are determined, a first push object with the first to-be-pushed object features is determined, and the first push object is pushed through the electronic device. By means of the method and device, the purpose of combining the first push object with activity behaviors of a user in reality is achieved.

Owner:LENOVO (BEIJING) LTD

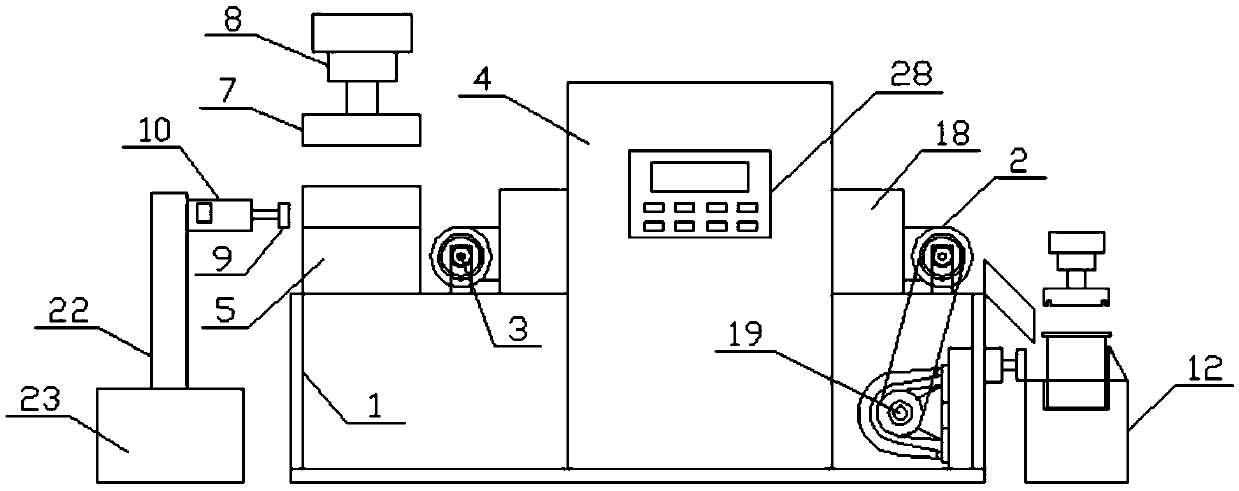

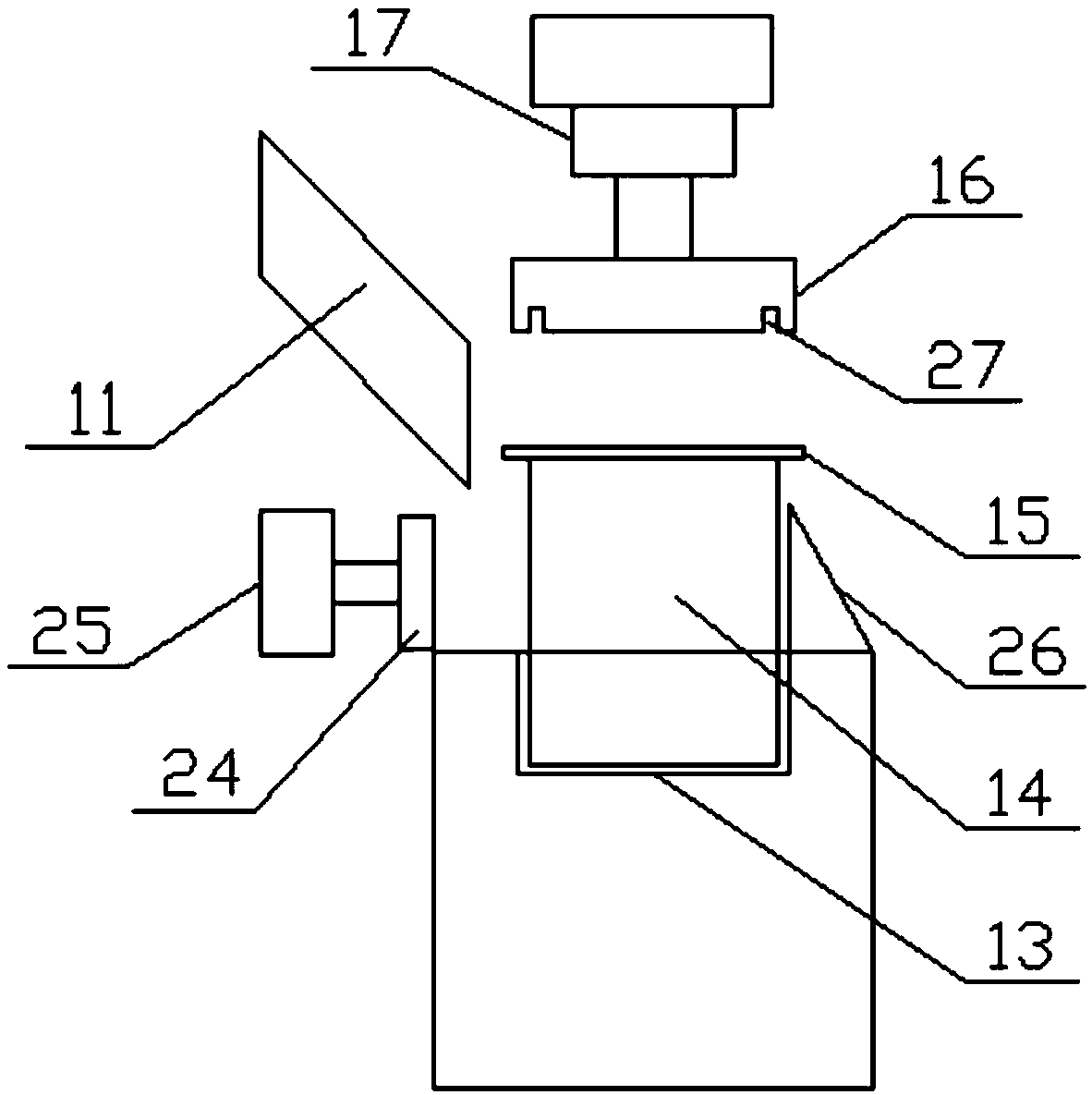

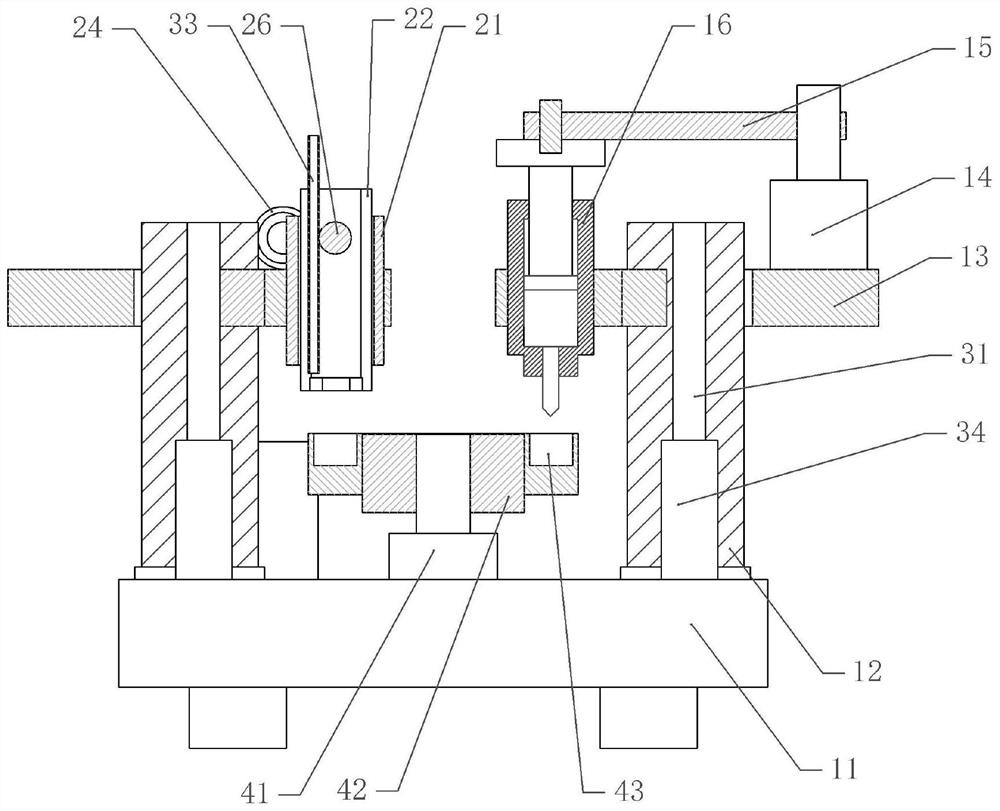

Flanging, rib rolling and can sealing integrated machine

InactiveCN111346986AAchieve the purpose of combiningIncrease productivityHollow articlesPackaging TankIntegrated technology

The invention discloses a flanging, rib rolling and can sealing integrated machine and relates to the field of the flanging, rib rolling and can sealing integrated technology. The flanging, rib rolling and can sealing integrated machine comprises a supporting platform. A guide conveyor belt is arranged on the right side of the upper surface of the supporting platform. A welding device is erected in the middle position of the outer side of the supporting platform. A flanging die is fixedly connected to the left end of the upper surface of the supporting platform. The middle position of the flanging die is provided with an arc-shaped groove. A flanging pressing block is arranged at the upper end of the flanging die. A first push plate is arranged in the position, close to the arc-shaped groove, of the left side of the flanging die. A bottom sealing device is arranged at the lower end of the right side of the supporting platform. The middle position of the bottom sealing device is provided with a limiting groove. A semi-finished packaging can is arranged in the limiting groove. A bottom cover is placed on the upper surface of the semi-finished packaging can. A bottom sealing pressingblock is arranged at the upper end of the bottom cover. The flanging, rib rolling and can sealing integrated machine achieves the purpose of integrating the flanging, rib rolling and can sealing functions and improves the production efficiency of packaging cans.

Owner:连云港富鑫包装有限公司

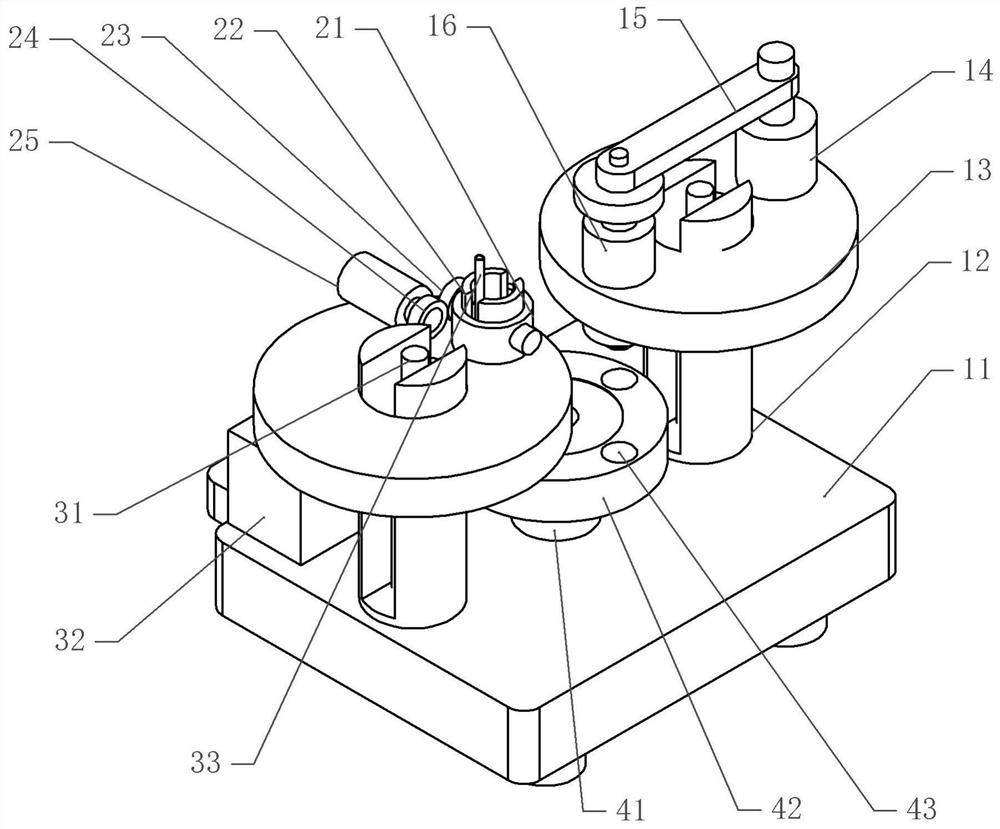

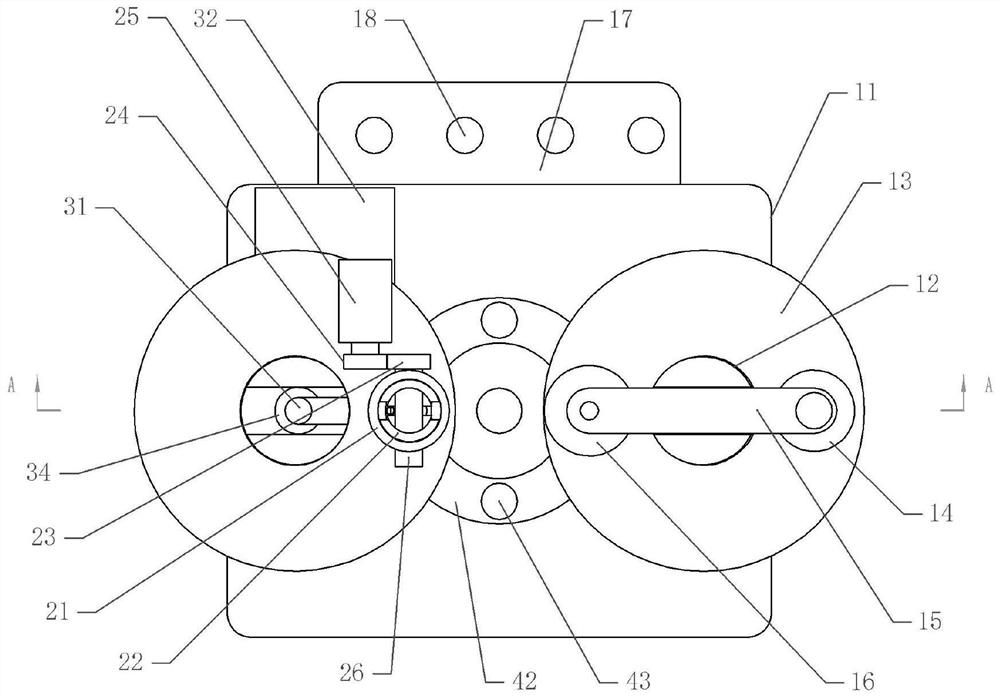

Tumor chemotherapy medicine preparation combiner

PendingCN114011550AReduce the chance of exposureAchieve the purpose of combiningOpening closed containersBottle/container closureMedical equipmentDrugs preparations

The invention belongs to the technical field of medical equipment, and provides a tumor chemotherapy medicine preparation combiner. The combiner comprises a supporting seat, an intermittent working driving part is installed on the supporting seat, a station plate is fixed to the output shaft of the driving part, and a plurality of station grooves are formed in the station plate; conveying parts are fixed to the two sides of the station plate, a needle cylinder is detachably connected to the conveying part on one side and driven by a power part, and a crushing structure is arranged on the conveying part on the other side; and the crushing structure comprises a crushing barrel and a rotating shaft rotationally connected to the crushing barrel, the rotating shaft is connected with a driving assembly, the two sides of the rotating shaft are in threaded connection with crushing plates located in the crushing barrel, and the movement directions of the crushing plates are opposite. The combiner is simple in structure; and an ampoule bottle is crushed through the crushing structure, and then the power part is used for driving the needle cylinder to suck a liquid medicine in the ampoule bottle, so contact between operators and the liquid medicine is reduced.

Owner:SHAOYANG UNIV

Internet of things intelligent cloud terminal

The invention discloses an internet of things intelligent cloud terminal. The internet of things intelligent cloud terminal comprises a master control CPU, a pyroelectric infrared sensor, a smoke sensor, a temperature sensor, a microwave detection circuit, a gas sensor, a door control switch, an audible and visual alarm, an internet of things gateway, a camera, a timer, and a power supply module,wherein the master control CPU is connected with the pyroelectric infrared sensor, the smoke sensor, the temperature sensor, the microwave detection circuit, the gas sensor, the door control switch, an audio processing module, the audible and visual alarm module, the internet of things gateway, a video processing module, the timer and the power supply module. Multiple sensors cooperate with each other, so that the internet of things intelligent cloud terminal realizes harmful gas alarm, fire alarm and invasion alarm, and has functions of long-distance alarm, sound monitor and image monitor, thereby having advantages of high intelligence degree, integrated control and multiple functions.

Owner:湖南智祥智能科技服务有限公司

Wet separation process and equipment for lead-zinc-vanadium concentrate

ActiveCN113171978AImprove binding efficiencyAchieve the purpose of combiningGas current separationWater vaporEngineering

The invention relates to the technical field of ore separation, and discloses a wet separation process and equipment for lead-zinc-vanadium concentrate. The wet separation process for the lead-zinc-vanadium concentrate is characterized in that a compressed gas can enter a spiral gas guide pipe through a gas guide hole, spirally ascends along the gas guide hole, enters an inner cavity of an attachment bin again and is located in an accommodating cavity above a compression ring, the compression ring is pushed to move in the vertical downward direction in the figure 3, water vapor with fine dust in the accommodating cavity between the compression ring and a partition plate is compressed, the water vapor is atomized under the compression effect to generate small liquid drops, and the small liquid drops are combined with the fine dust, so that the purpose of combining the small liquid drops with the fine dust is achieved; and in addition, participation of airflow is not needed in the combination process, so that the situation that fluttering of the small liquid drops along with the airflow in traditional equipment disturbs surrounding airflow and some tiny powder cannot be in contact with the airflow under the effect of turbulent flow is avoided, and the combination efficiency of the small liquid drops and fine particles is improved.

Owner:江西林力高新材料有限公司

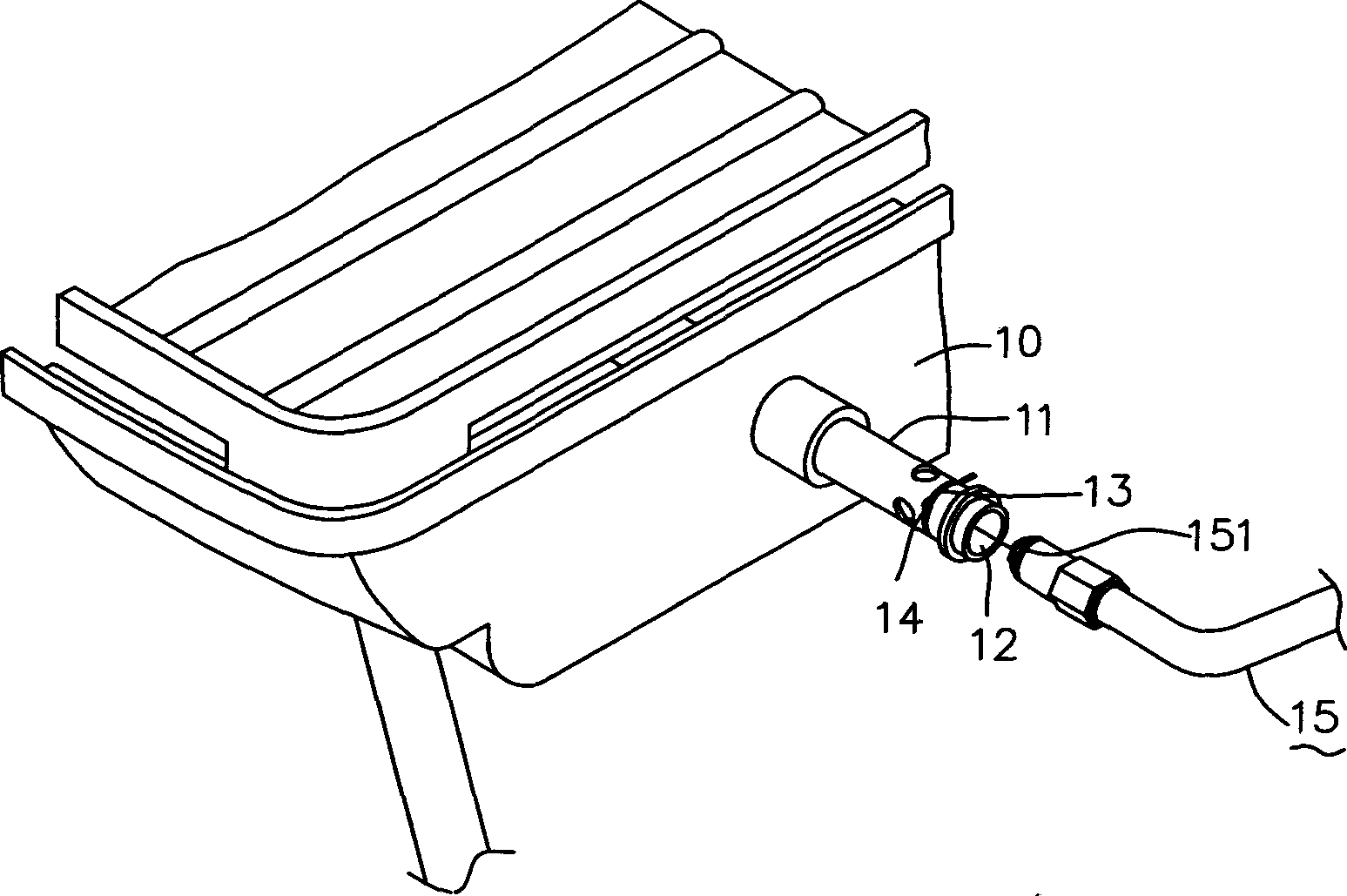

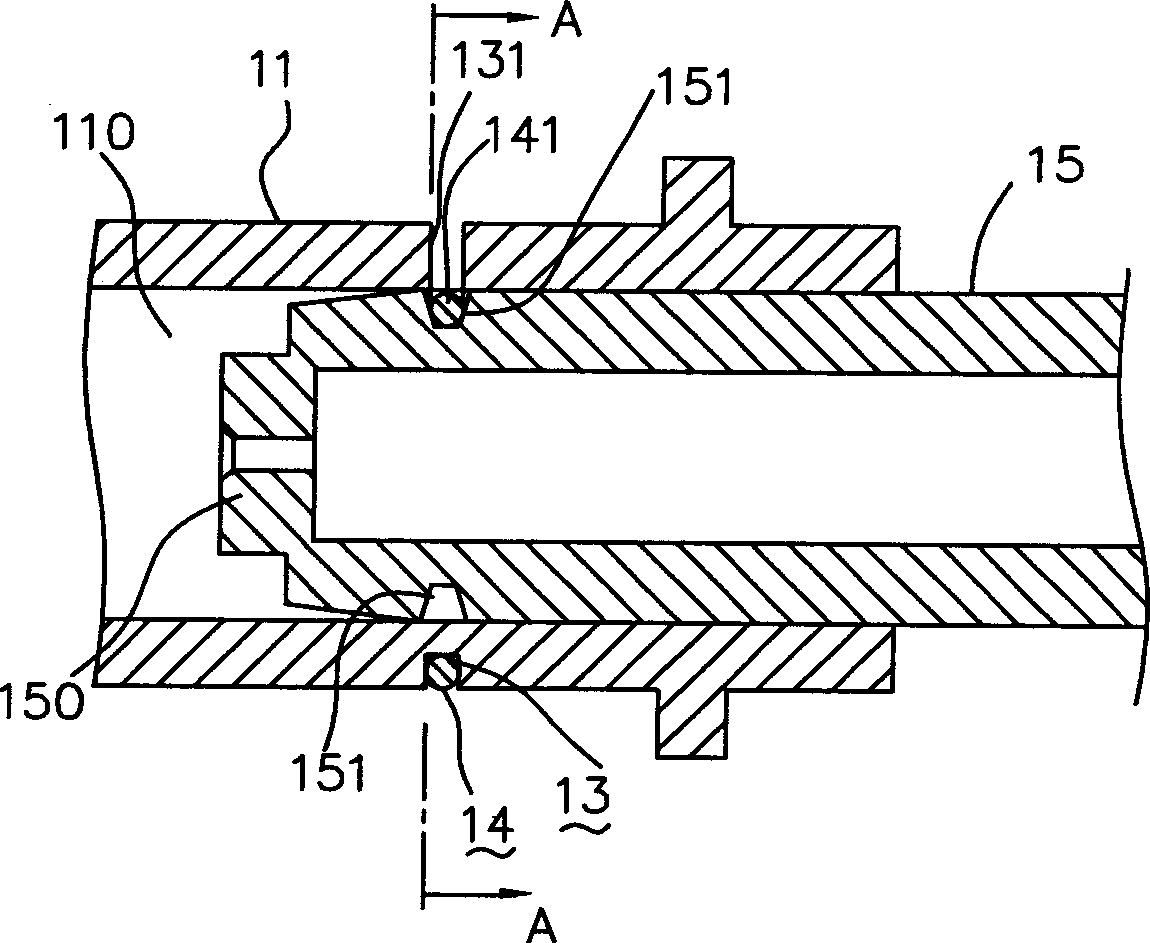

Meat grill

InactiveCN1704009AWon't leave easilyPrevent insertionRoasters/grillsEngineeringMechanical engineering

The invention discloses a frying roaster which comprises a frying-roasting mechanism with an internal fuel conductor, a fuel feeding mechanism with an external fuel conductor, a connecting part which comprises two connecting ends separately posited on internal fuel conductor and external fuel conductor, wherein one connecting end has two gas-mixing holes, while the other connecting end has associative ring groove; internal fuel conductor and external fuel conductor have common axis; associative ring groove is aligned with gas-mixing holes. It also comprises a joint which has course extensibility and comprises a U-shaped curved section posited on one side of internal fuel conductor, two straight sections which are formed by threading the two ends of U-shaped curved section into the gas-mixing hole of connecting end and compounding the other connecting end with associative ring groove; releasable applying associative ring groove of two straight sections, two force sections posited on the other end of internal fuel conductor which is formed by overlapping and extending the end of two straight sections.

Owner:TSANN KUEN CHINA ENTERPRISE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com