Meat grill

A meat grill, frying and grilling technology, applied in the field of meat grills, can solve problems such as unsatisfactory design of meat grills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The aforementioned and other technical contents, features and effects of the present invention will be clearly understood in the following detailed description with accompanying drawings and three preferred embodiments.

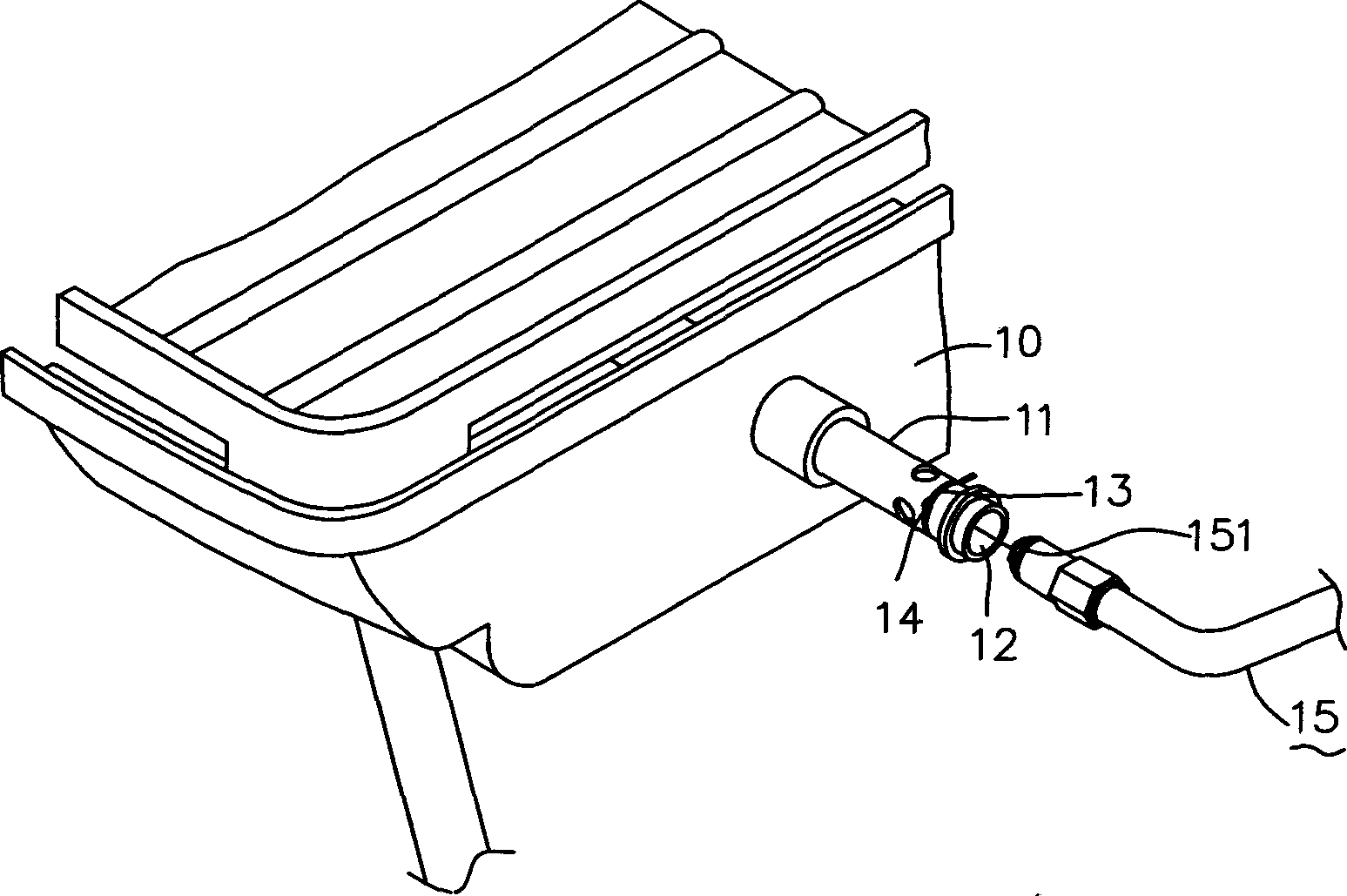

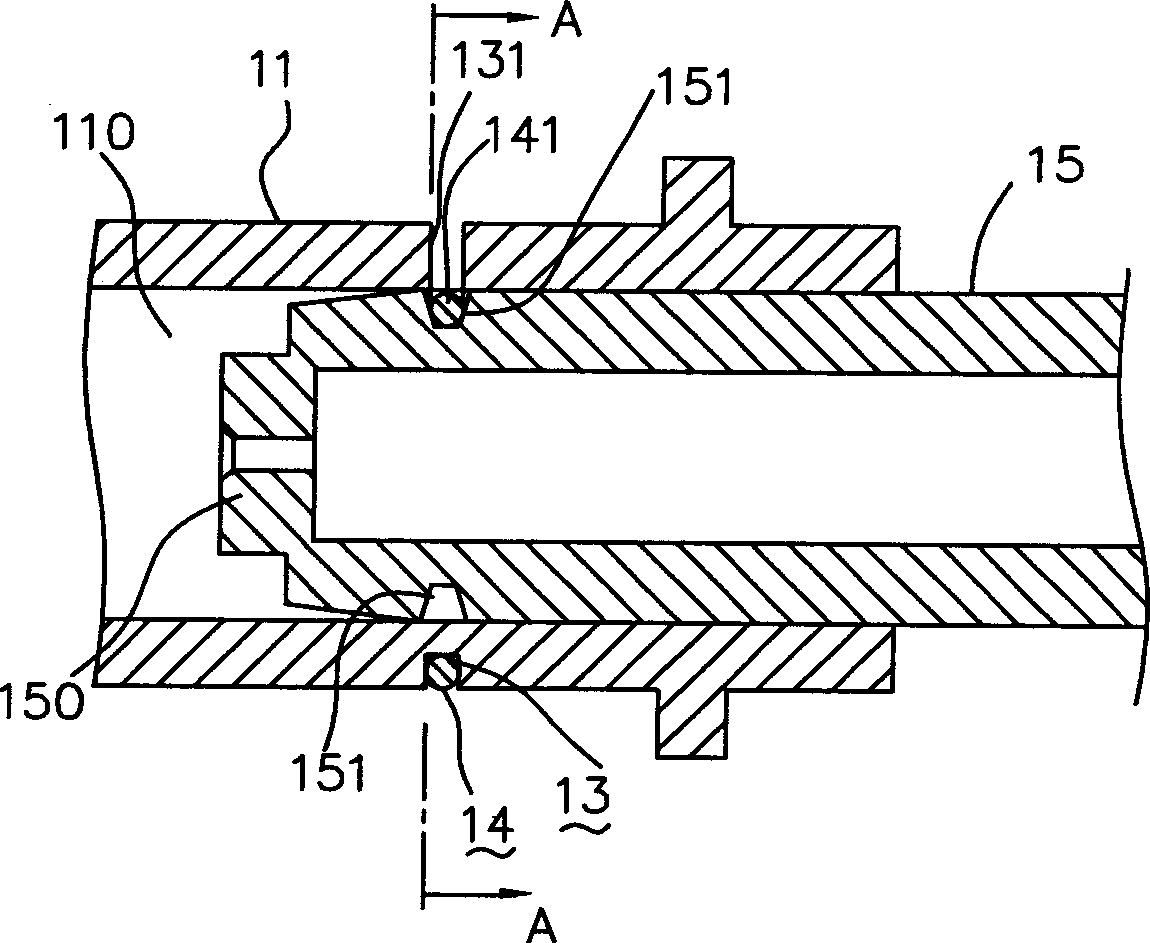

[0044] Such as Figure 5 , 6 , 7, and 8, the first preferred embodiment of the grill of the present invention includes a grilling mechanism 3 provided with an inner fuel pipe 34, a fuel supply mechanism 4 with an outer fuel pipe 6, a coupling part and a Joint 5. The fuel supply mechanism 4 is used to provide fuel; the outer fuel pipe 6 is used to transmit predetermined fuel; the coupling member 5 is used to combine the frying mechanism 3 with the outer fuel pipe 6; Figure 5 as the benchmark. The inner fuel pipe 34 and the outer fuel pipe 6 are coaxial.

[0045] The grilling mechanism 3 has a housing base 31 , a hollow inner fuel pipe 34 extending outward from the housing base 31 , and a heating unit 32 disposed inside the housing base 31 .

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com