Molding method of foamed sole with concolorous, dissimilar properties wearable area

A molding method and area technology, which is applied in the field of foam sole molding with the same color and foreign body wear-resistant area, and can solve problems such as warping, deformation, overflow of embryo material 1, and abnormal movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] For the convenience of description, in the following embodiments, the same components are denoted by the same reference numerals.

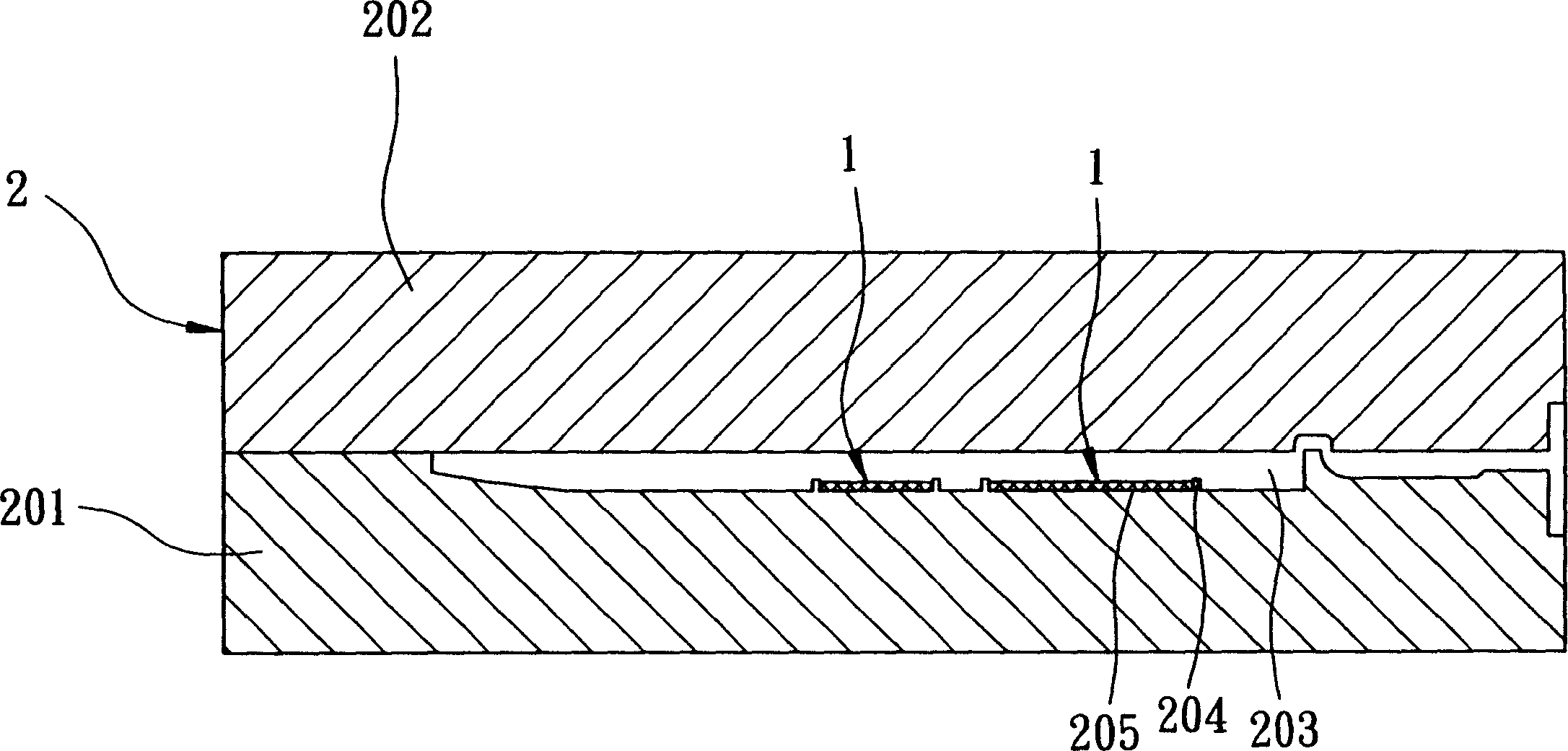

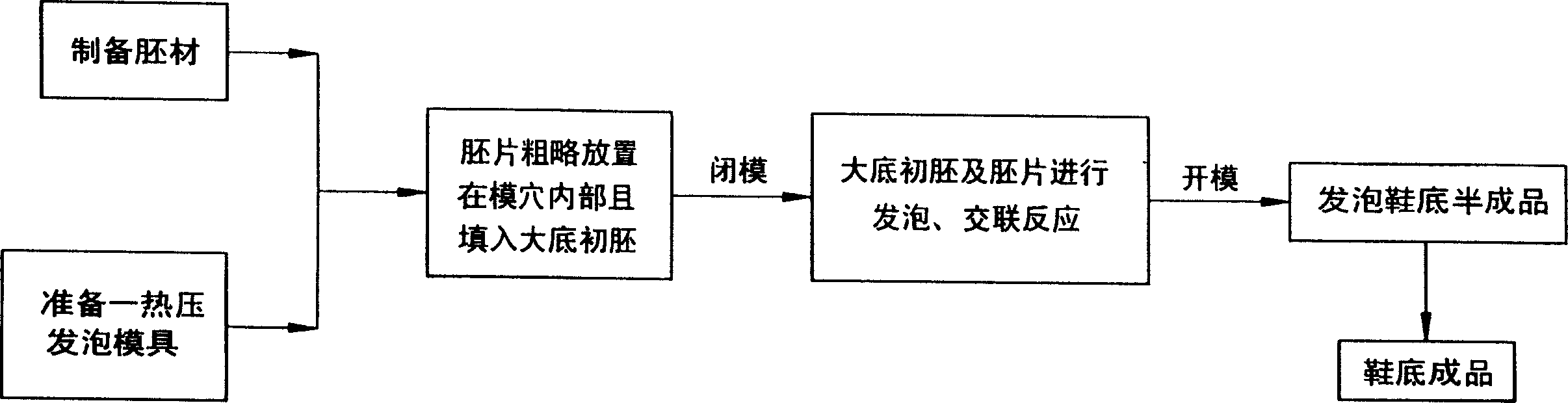

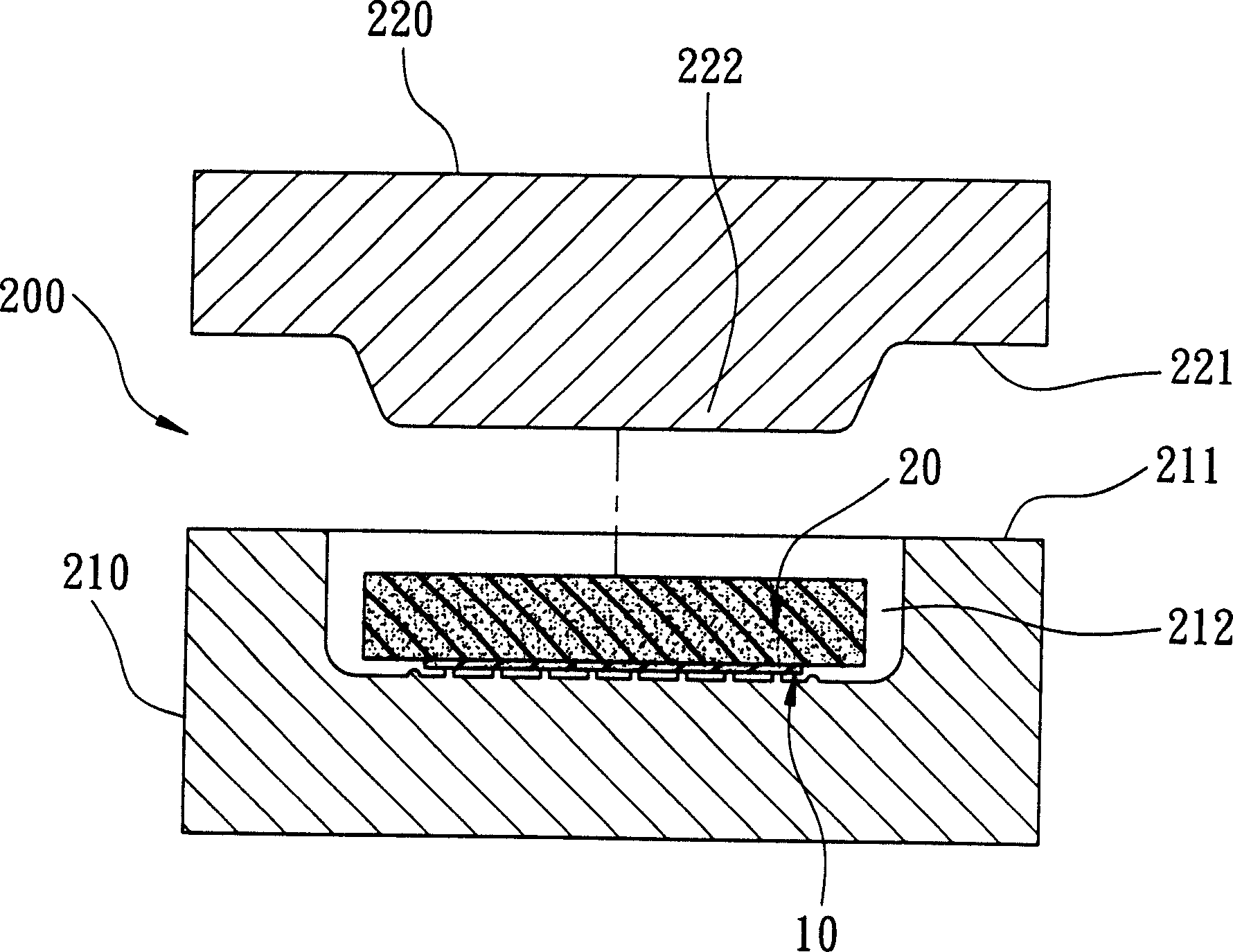

[0019] Such as figure 2 , image 3 Shown, the present invention has the same color, the first preferred embodiment of the foaming shoe sole forming method of foreign body wear-resisting zone comprises the following steps:

[0020] Step 1: Pre-preparing at least one green sheet 10 that has not undergone foaming and cross-linking reactions and has physical properties of hard, wear-resistant and non-slip properties with ethylene-vinyl acetate copolymer material. The green sheet 10 is in the shape of a thin sheet at room temperature , its physical properties can be controlled by the formulation of the compounding ingredients added during kneading.

[0021] Step 2: Prepare a hot-press foaming mold 200 that keeps the reaction temperature at 150° C. to 180° C. The hot-press foaming mold 200 has a lower mold 210 and an upper mold 220 that can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com