Preparation method of double-layer or multi-layer metal composite pipe blank

A multi-layer metal and composite pipe technology is applied in the field of preparing double-layer or multi-layer metal composite pipe blanks and metal pipe blanks, which can solve the problem of increasing the cost of lost foam and sand mold production, worsening the toughness of the interface zone, and increasing the production cost. and other problems, to achieve the effect of clear composite interface, improved interface bonding strength, and improved composite quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a method for preparing a double-layer or multi-layer metal composite tube blank, including raw material preparation; pipe fitting assembly; installing accessories; anti-oxidation ventilation; preheating the metal tube; pouring metal melt; cooling the composite tube blank; There are eight steps for finishing the composite tube blank, the specific steps are:

[0036] S1. Raw material preparation

[0037] Select two metal outer tubes 1 and metal inner tubes 2 to be combined, clean and remove oil and mud stains on the inner and outer surfaces, dry them and then use conventional mechanical methods such as sandblasting, grinding, wire brushing, etc., or conventional chemical Methods such as alkali washing or pickling, remove the scale on the inner surface of the metal outer tube 1 and the outer surface of the metal inner tube 2, and dry them for later use.

[0038] S2. Fitting assembly

[0039] Insert the metal inner tube 2 into the metal outer tube 1...

Embodiment 1

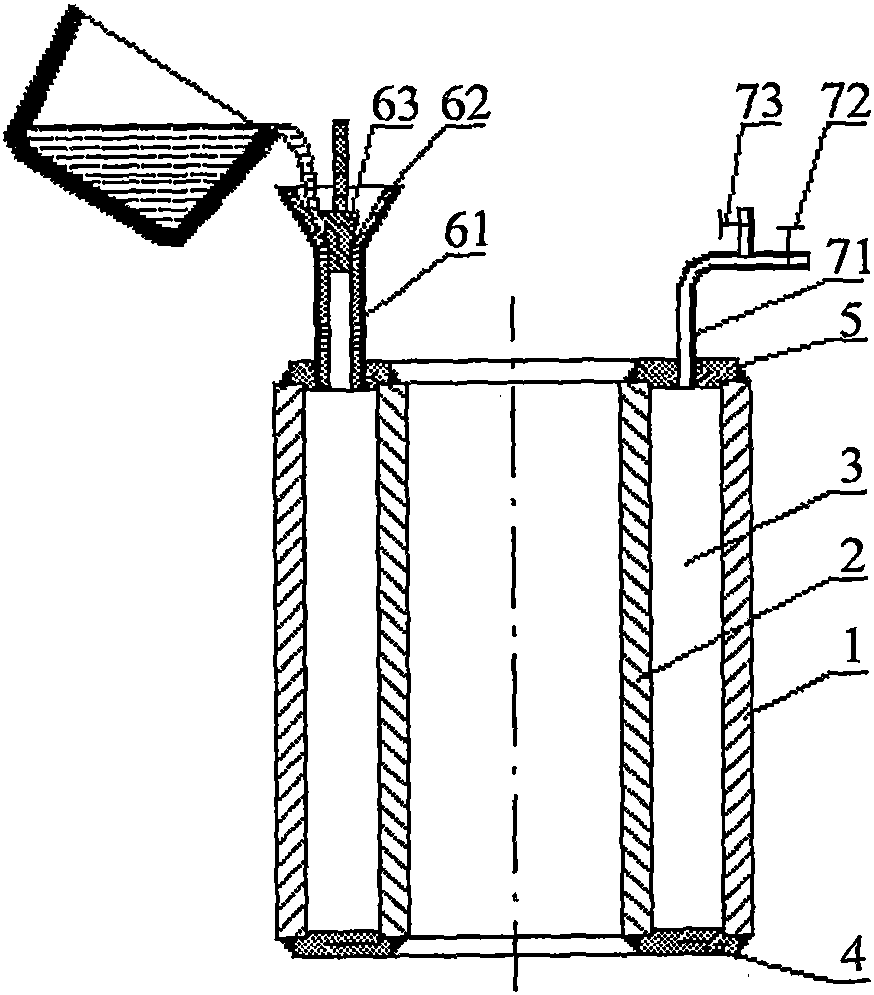

[0056] Taking the preparation of 304 stainless steel / Q235 plain carbon steel / 304 stainless steel composite steel pipe as an example, the specific preparation method is shown in the schematic diagram figure 1 As shown, two 304 stainless steel pipes are selected as the metal outer pipe 1 and the metal inner pipe 2 respectively. Specifically, the outer diameter of the metal outer pipe 1 is φ219mm, the inner diameter is φ210mm, the wall thickness is 4.5mm, and the length is 2m. The outer diameter of the tube 2 is φ108mm, the inner diameter is φ100mm, the wall thickness is 4.0mm, and the length is 2m. The chemical composition of the metal outer tube 1 and the metal inner tube 2 is the same, both are 304 stainless steel; the metal melt of Q235 ordinary carbon steel is selected as Metal melt to be cast; use 8% mass fraction of sodium carbonate solution to clean the oil and mud stains on the inner and outer surfaces of the metal outer pipe 1 and metal inner pipe 2 to be compounded, and...

Embodiment 2

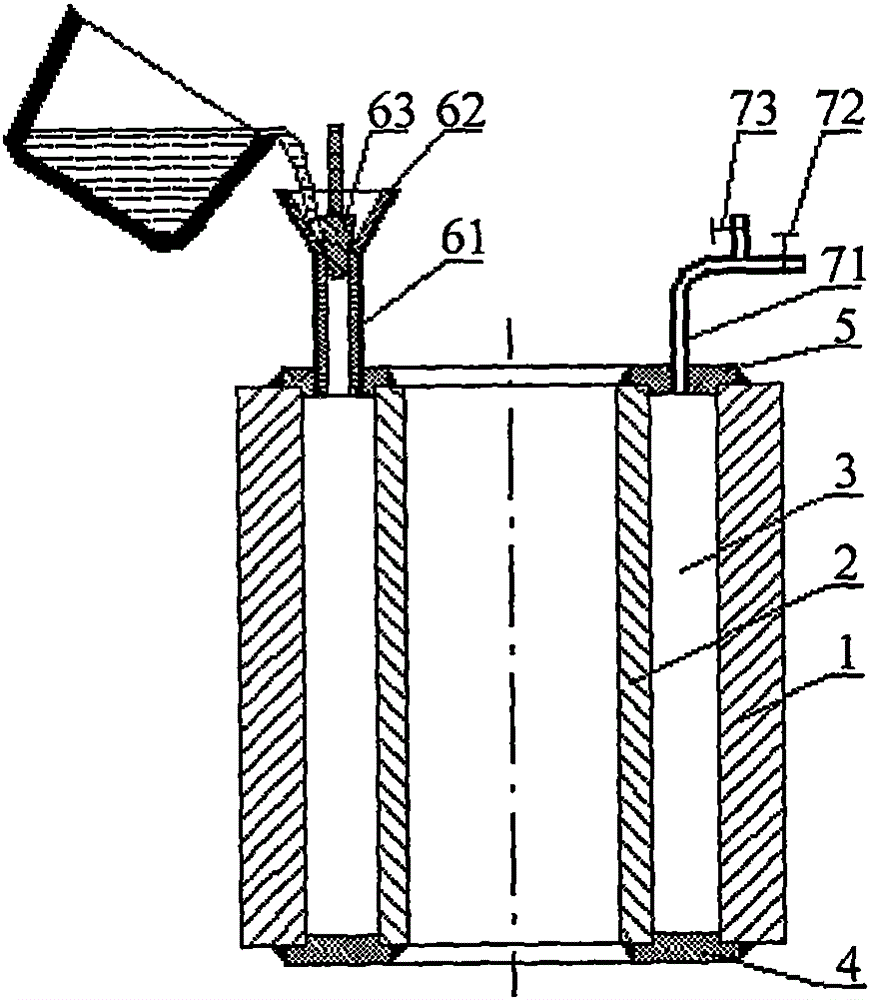

[0061] Taking the preparation of 16Mn low-alloy steel / 316 stainless steel composite square pipe as an example, the specific preparation method schematic diagram is as follows figure 2 As shown, two steel pipes are selected, one of which is a 16Mn low-alloy square pipe as the metal outer pipe 1. The side length of the square pipe is 200×200mm, the wall thickness is 5mm, and the length is 2m. The other is a 316 stainless steel square pipe , as the metal inner tube 2, the side length of the square tube is 80×80mm, the wall thickness is 4.0mm, and the length is 2m; the metal melt of 16Mn low alloy steel is selected as the metal melt to be cast; the sodium carbonate solution of 10% mass fraction is adopted Clean the oil stains and mud stains on the inner and outer surfaces of the metal outer tube 1 and the metal inner tube 2 to be combined, and then use 10% by mass fraction of hydrochloric acid aqueous solution to pickle to remove the oxide scale on the inner surface of the metal o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com