Preparation method of spherical nickel-lithium manganate anode material

A technology of lithium nickel manganate and cathode material, applied in the field of cathode material of chemical power supply lithium ion battery, can solve the problems of high equipment condition requirements and complex process, and achieve the effects of good processing performance, simple process and rich source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

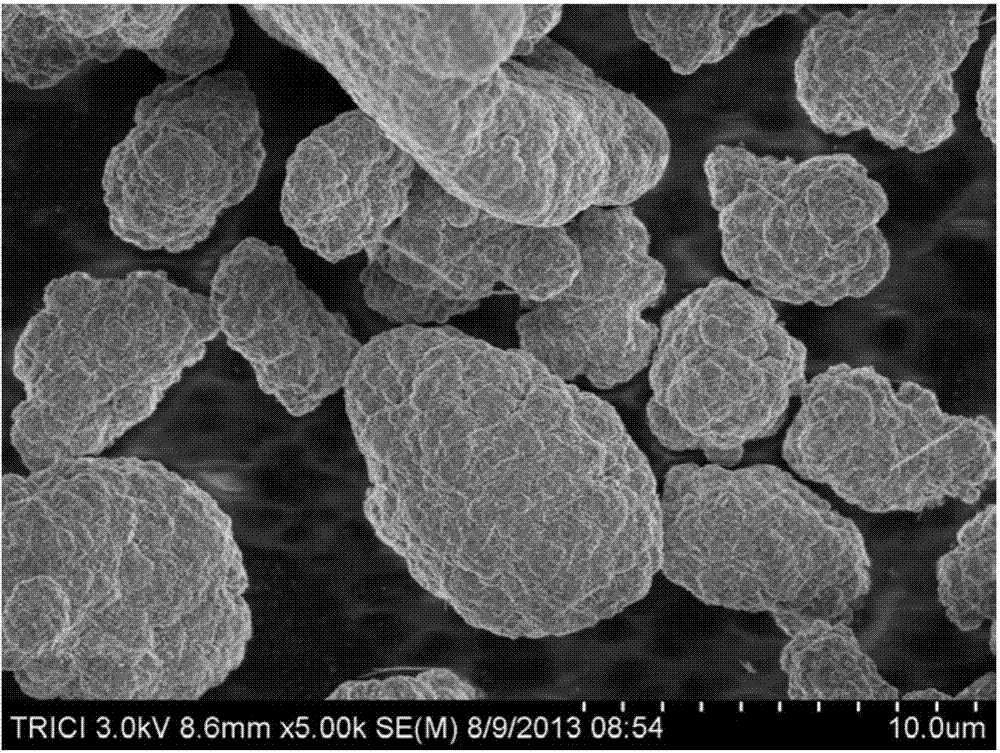

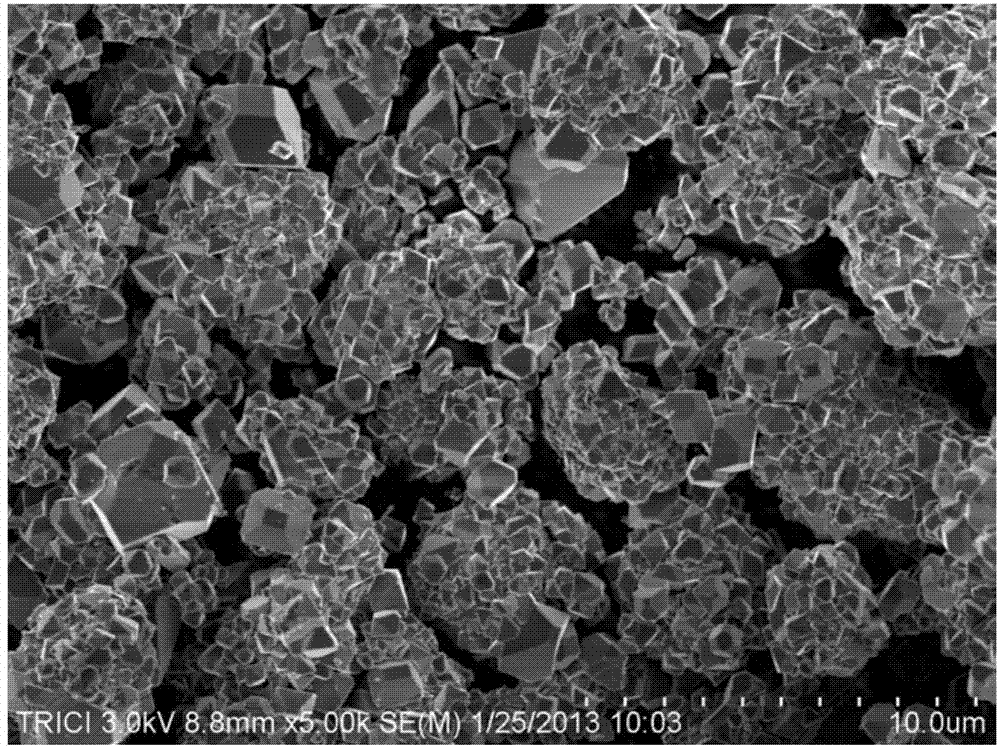

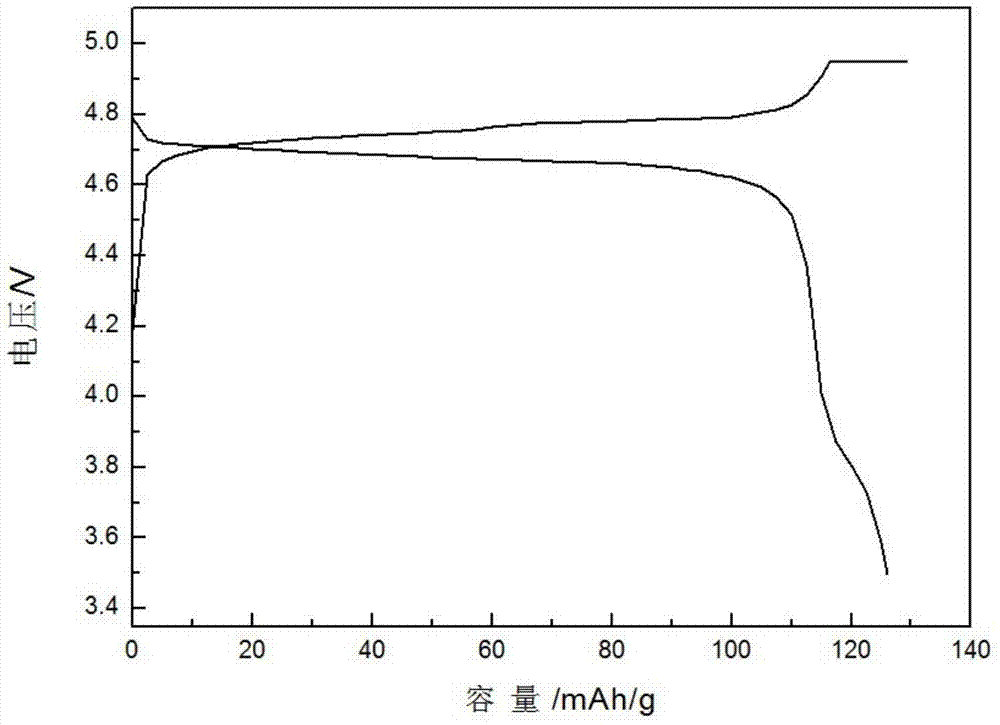

[0017] Weigh out lithium acetate, nickel acetate, and spherical trimanganese tetroxide according to the molar ratio of 2:1:1. figure 1 As shown), dissolve lithium acetate and nickel acetate in ethanol to form a solution with a total metal cation concentration of 0.1 mol / L, add spherical trimanganese tetroxide to the above solution, and heat it in a 50°C water bath while stirring to form a paste The mixture is dried at 90°C to obtain a gray-black powder, which is calcined at 750°C for 6 hours, annealed at 615°C for 2 hours, and directly sieved after cooling to obtain lithium nickel manganate cathode material. The resulting material inherited the spherical morphology of trimanganese tetroxide ( figure 2 ), the first 1C discharge capacity of its button battery is 126.1mAh / g ( image 3 ), the capacity retention rate of 100 cycles is 100.1%.

Embodiment 2

[0019] Weigh out lithium nitrate, nickel acetate and spherical trimanganese tetroxide according to the molar ratio of 2:1:1, dissolve lithium nitrate and nickel acetate in ethanol to form a solution with a total concentration of metal cations of 0.2mol / L. Add spherical trimanganese tetroxide to the solution, heat it in a water bath at 60℃ while stirring to form a paste-like mixture, and dry it at 100℃ to obtain a gray-black powder. The obtained powder is calcined at 850℃ for 12h, annealed at 650℃ for 4h, and directly after cooling Sieve to obtain lithium nickel manganate cathode material. The obtained material button battery has a 1C first discharge capacity of 128.2 mAh / g, and a capacity retention rate of 100.2% after 100 cycles.

Embodiment 3

[0021] Weigh out lithium nitrate, nickel nitrate and spherical manganese tetroxide in a molar ratio of 2:1:1, dissolve lithium nitrate and lithium nitrate in ethanol to form a solution with a total concentration of metal cations of 0.3 mol / L. Add spherical manganese tetroxide to the solution, heat it in a water bath at 70°C while stirring to form a paste-like mixture, and dry at 110°C to obtain a gray-black powder. The resulting powder is calcined at 950°C for 24h and annealed at 675°C for 6h. Sieve to obtain lithium nickel manganate cathode material. The obtained material button battery has a 1C first discharge capacity of 123.2mAh / g, and a capacity retention rate of 100.3% after 100 cycles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com